Professional Documents

Culture Documents

Nepcoat 2022

Nepcoat 2022

Uploaded by

jennifergiannouCopyright:

Available Formats

You might also like

- Petronas/Ucc JV Malaysia Project: Painting and Coatings Epoxy-Phenolic Paint System (Inhibitive Primer) Ep-Pr/Ep/EpDocument6 pagesPetronas/Ucc JV Malaysia Project: Painting and Coatings Epoxy-Phenolic Paint System (Inhibitive Primer) Ep-Pr/Ep/EpkhairurNo ratings yet

- Handbook of Paper and Pulp Chemicals (PDFDrive)Document1,032 pagesHandbook of Paper and Pulp Chemicals (PDFDrive)Langtu Dung100% (2)

- Build Up RateDocument4 pagesBuild Up RateLai Chungyi100% (2)

- Painting and FRP System For CP4E Link Bridge RevA - HPTDocument81 pagesPainting and FRP System For CP4E Link Bridge RevA - HPTChan Kin CheungNo ratings yet

- Painting Cycle: Document TitleDocument8 pagesPainting Cycle: Document TitleMaffone NumerounoNo ratings yet

- KI XL 03HS SC 10 HS LT XLPE Ambient CureableDocument4 pagesKI XL 03HS SC 10 HS LT XLPE Ambient CureableAshish bhattNo ratings yet

- XL 09 XL 10Document3 pagesXL 09 XL 10Engr. Mehadi Hassan NahidNo ratings yet

- DP B58W00610Document4 pagesDP B58W00610tangouzeNo ratings yet

- Department of Public Works and HighwaysDocument5 pagesDepartment of Public Works and HighwaysFaustino AbadNo ratings yet

- Zap-Lok System For Pipeline Installation January 2019 PDFDocument35 pagesZap-Lok System For Pipeline Installation January 2019 PDFmutadiNo ratings yet

- Napca Bulletins 1-65-94 Thru 17-98Document72 pagesNapca Bulletins 1-65-94 Thru 17-98lemuel bacsaNo ratings yet

- Vendor PerformanceDocument38 pagesVendor PerformanceManojNo ratings yet

- Metco®601NS 10-141Document11 pagesMetco®601NS 10-141張政雄No ratings yet

- Solder Paste SC Blf03: Lead-FreeDocument2 pagesSolder Paste SC Blf03: Lead-FreeluismcmcNo ratings yet

- Chembloc Series 239Sc: Product ProfileDocument2 pagesChembloc Series 239Sc: Product ProfileSky MoonNo ratings yet

- Pipe Kote Coal TarDocument4 pagesPipe Kote Coal TarAnonymous YcAZv5qF67No ratings yet

- Carbon Black MoistureDocument14 pagesCarbon Black MoistureSanjay SurpuriyaNo ratings yet

- 3K PRO ME CNS P02 001 010 033 240 Rev A PDFDocument19 pages3K PRO ME CNS P02 001 010 033 240 Rev A PDFErol DAĞNo ratings yet

- Energex Estimation GuideDocument88 pagesEnergex Estimation GuideCarl James GranadaNo ratings yet

- Sur Tec 650Document17 pagesSur Tec 650donhan91No ratings yet

- Fluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetDocument4 pagesFluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetFrancisco RodríguezNo ratings yet

- Durability of Coating Repair Systems For Offshore Services - Eurocorr 2014Document17 pagesDurability of Coating Repair Systems For Offshore Services - Eurocorr 2014ANIBALLOPEZVEGA100% (1)

- 500 TPD KilnDocument19 pages500 TPD KilnPratik TyagiNo ratings yet

- Fast Clad Urethane Spec SheetDocument4 pagesFast Clad Urethane Spec SheetScott Van PeltNo ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Coating ProcedureDocument11 pagesCoating Procedureyoussef gaafarNo ratings yet

- Paint Systems For MRTS88Document72 pagesPaint Systems For MRTS88asankaNo ratings yet

- Chemical Mechanical Polishing Slurry For Amorphous Ge 2015 Procedia EngineerDocument8 pagesChemical Mechanical Polishing Slurry For Amorphous Ge 2015 Procedia EngineerTân HoàngNo ratings yet

- Specifications For Manufactured Materials: 1. Product Description 1.1. DescriptionDocument9 pagesSpecifications For Manufactured Materials: 1. Product Description 1.1. Descriptionعبدالحميد علبNo ratings yet

- HPCL Cement Lined Spec PDFDocument167 pagesHPCL Cement Lined Spec PDFvenkateshwaranNo ratings yet

- 12 Procedure For Coating Wrapping Rev 01Document6 pages12 Procedure For Coating Wrapping Rev 01dnbinh100% (2)

- 3 LPE CoatingDocument58 pages3 LPE Coatingkailash100% (2)

- Application of Supported Perovskite-Type Catalysts For Vehicular Emission ControlDocument10 pagesApplication of Supported Perovskite-Type Catalysts For Vehicular Emission ControlKirti GadeNo ratings yet

- Coatings Deposited Using A Valve-Less Detonation SystemDocument5 pagesCoatings Deposited Using A Valve-Less Detonation SystemycwbycwbNo ratings yet

- X-Roc Epoxybond: Epoxy Resin Bonding AgentDocument2 pagesX-Roc Epoxybond: Epoxy Resin Bonding AgentAmr RagabNo ratings yet

- Sigma 1DDocument8 pagesSigma 1Dyogeshkumar121998No ratings yet

- Simacover EP Tar Epoxy 3404-00Document4 pagesSimacover EP Tar Epoxy 3404-00Perseroan MustikaNo ratings yet

- Arc Insulations BrochureDocument5 pagesArc Insulations BrochureacompositesNo ratings yet

- Pipeline Coatings PDFDocument29 pagesPipeline Coatings PDFAsimNo ratings yet

- Carbozinc 859Document2 pagesCarbozinc 859Khemaraj PathNo ratings yet

- Dye Penetration TestDocument66 pagesDye Penetration Testezarul fitri100% (1)

- O2 Analyzer - Document - REV-B - 24-03-2018 PDFDocument10 pagesO2 Analyzer - Document - REV-B - 24-03-2018 PDFambeshNo ratings yet

- Quality Plan 1325-27 Rev 02 - Blasting PaintingDocument10 pagesQuality Plan 1325-27 Rev 02 - Blasting Paintingsuriya100% (1)

- Procedure FOR Quality Assurance System Fusion Bonded Epoxy Coating On RebarsDocument12 pagesProcedure FOR Quality Assurance System Fusion Bonded Epoxy Coating On RebarsPramod SingareNo ratings yet

- 7) PPG Amercoat 385 - Pds - AiDocument4 pages7) PPG Amercoat 385 - Pds - AididbeauNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Cortec ProductDocument20 pagesCortec ProductLiu YangtzeNo ratings yet

- BillDocument2 pagesBillvectra engineeringNo ratings yet

- WO 33-4 Shastri Bridge Panel Cost R0 25.09.2021 - FINALDocument27 pagesWO 33-4 Shastri Bridge Panel Cost R0 25.09.2021 - FINALJayashree GopalakrishnanNo ratings yet

- Pipeline CoatingsDocument29 pagesPipeline Coatingstrpac100% (3)

- DM SSSDocument5 pagesDM SSSiitmpdNo ratings yet

- Cat Konik 1Document29 pagesCat Konik 1Soma GhoshNo ratings yet

- Procedure - 3lpe - Msl-Rev.00Document15 pagesProcedure - 3lpe - Msl-Rev.00Suresh KrishnanNo ratings yet

- DacrometDocument6 pagesDacrometdavideNo ratings yet

- Novalux PaintDocument22 pagesNovalux PaintLionparcel Qonitah Talang JambeNo ratings yet

- Recent Advances in Cast SX Superalloys: Jacqueline Wahl and Ken HarrisDocument34 pagesRecent Advances in Cast SX Superalloys: Jacqueline Wahl and Ken Harrisjohn davidsNo ratings yet

- Concrete BlanketDocument19 pagesConcrete BlanketIan lawrenz LeeNo ratings yet

- Toe LoadDocument4 pagesToe Loadcheikh ahmedNo ratings yet

- 253 PDS AiDocument4 pages253 PDS AiAchraf BoudayaNo ratings yet

- Micro Surfacing: Cost Effective Solution For Pavement Preservation and RenewalDocument16 pagesMicro Surfacing: Cost Effective Solution For Pavement Preservation and RenewalCristhian Riveros RojasNo ratings yet

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Covalence HTLP80: Product Data SheetDocument2 pagesCovalence HTLP80: Product Data SheetbasukiNo ratings yet

- 01 - CEMS Field Equipment Installation ManualDocument15 pages01 - CEMS Field Equipment Installation ManualheikelNo ratings yet

- Conductivity Sorted by Resistivity Eddy Current TechnologyDocument14 pagesConductivity Sorted by Resistivity Eddy Current TechnologyKalai VananNo ratings yet

- Selecting Tips, Speeds, and Pressures For Oxyfuel Gas CuttingDocument2 pagesSelecting Tips, Speeds, and Pressures For Oxyfuel Gas CuttingRonny De La CruzNo ratings yet

- Materials For Direct RestorationsDocument9 pagesMaterials For Direct RestorationsBerty SusantoNo ratings yet

- LF880 TAB RexnordDocument1 pageLF880 TAB RexnordAkhmadiNo ratings yet

- Hess LawDocument4 pagesHess LawDarlene Jane Taladro Caga-ananNo ratings yet

- Testing Abrasion Resistance of High-Strength ConcreteDocument11 pagesTesting Abrasion Resistance of High-Strength ConcreteKeerti BonguNo ratings yet

- India's Legendary 'Wootz' SteelDocument90 pagesIndia's Legendary 'Wootz' SteelRonak Shah100% (1)

- CP 653 BA Technical-information-ASSET-DOC-LOC-1540979Document1 pageCP 653 BA Technical-information-ASSET-DOC-LOC-1540979AdityaNo ratings yet

- Nylon Plastics by M. I. Kohan P. 14-15Document1 pageNylon Plastics by M. I. Kohan P. 14-15Guery SaenzNo ratings yet

- Tsu-Wei Chou - Microstructural Design of Fiber Composites (Cambridge Solid State Science Series) (2005)Document589 pagesTsu-Wei Chou - Microstructural Design of Fiber Composites (Cambridge Solid State Science Series) (2005)Genby Ardinugraha100% (1)

- Past Paper - Microscopic WorldDocument7 pagesPast Paper - Microscopic Worldapi-3739994100% (1)

- Properties of Particleboard From Wood Wastes FinalCopy 06 May 2016Document8 pagesProperties of Particleboard From Wood Wastes FinalCopy 06 May 2016sojorj22No ratings yet

- Elemental Group Properties: Unit 3 Pharm 114Document39 pagesElemental Group Properties: Unit 3 Pharm 114Kim JunkyuNo ratings yet

- CH 05Document30 pagesCH 05Ariq Rama NurvirgianNo ratings yet

- Materials System SpecificationDocument11 pagesMaterials System SpecificationJeck MaquitedNo ratings yet

- GGBSDocument20 pagesGGBSratnakarNo ratings yet

- 10th OBJECTIVE 2022 CHEMISTRYDocument20 pages10th OBJECTIVE 2022 CHEMISTRYVarenayam editzNo ratings yet

- DUPA PoW MASBATEDocument122 pagesDUPA PoW MASBATEIrene Ionie Rarangol - TengcoNo ratings yet

- Assembling The Puzzle of Superconducting Elements: A ReviewDocument10 pagesAssembling The Puzzle of Superconducting Elements: A Reviewalesol2No ratings yet

- CATpg 6 ADocument1 pageCATpg 6 AcbrittaivNo ratings yet

- Quality Control Flow Chart (10.12.22)Document2 pagesQuality Control Flow Chart (10.12.22)mido_20067581No ratings yet

- Approved List of Manufacturers: CategoryDocument4 pagesApproved List of Manufacturers: CategoryFahadAl100% (1)

- Suma PharmaDocument14 pagesSuma PharmaRamboNo ratings yet

- Safety Data Sheet Ammonia, AnhydrousDocument3 pagesSafety Data Sheet Ammonia, AnhydrousEleonoraNo ratings yet

- 70-3695-HMS Material Composition Declaration ABS-PDP-4Document4 pages70-3695-HMS Material Composition Declaration ABS-PDP-4Bob YahyaNo ratings yet

- Astm ManualsDocument8 pagesAstm ManualsTrushar ParmarNo ratings yet

Nepcoat 2022

Nepcoat 2022

Uploaded by

jennifergiannouOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nepcoat 2022

Nepcoat 2022

Uploaded by

jennifergiannouCopyright:

Available Formats

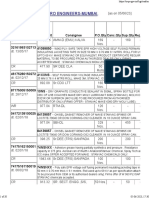

Mtg/Date: 6/5/96, 9/4/96, 1/8/97, 7/22/97, 5/20/98, 3/3/99, 9/22/99, 3/30/00, 11/8/00, 3/28/01, 5/14/01, 11/20/01, 11/29/01, 4/24/02,

2/24/03, 4/17/03, 3/16/04, 2/15/05,

4/19/05 R1, 11/17/05 R1, 10/5/06 R1, 06/21/07, 10/16/08, 4/7/09 R1, 10/7/09 R1, 11/09/10, 01/25/11, 4/5/11 R2, 12/14/11, 4/3/12, 4/3/12 R1, 10/02/12, 10/02/12 R1,

4/16/13, 11/15/13 R1, 04/14/14 R1, 10/07/14, 4/7/15, 10/6/15 R2, 04/05/16, 10/04/16 R1, 04/04/17, 10/3/17 R1, 4/3/18, 10/2/18, 4/2/19, 10/1/19, 12/10/20, 4/6/21, 10/5/21

4/5/22

NEPCOAT Qualified Products List A

for Protective Coatings for

NEW and 100% BARE EXISTING Steel for Bridges

NTPEP Slip Manuf’r Coating VOC QPL

System 3-COAT SYSTEM Coef DFT (min/max) Tested Accepted

No. Coats TESTED AND ACCEPTED Class mil micron g/L Dates

NEPCOAT LIST A - INORGANIC Zinc Rich Primer / Epoxy or Urethane Intermediate / Aliphatic Urethane Finish

SSC(17)-03 * INTERNATIONAL PAINT INC from

SSC(10)-02 Primer Interzinc® 22HS Inorganic Zinc Rich B1 2.5-3 62-75 311 04/02/19

Interm Intergard 475HS Epoxy 4-8 100-200 188 until mtg.

Topcoat Interthane® 870 UHS Polyurethane 3-5 75-125 257 es spring 2023

1

Footnote 5 mils max DFT, 24 hours min cure, zero thinner

SSC(19)-03 * CARBOLINE COMPANY from

1

Primer Carbozinc® 11 HS Inorganic Zinc Primer B 2-6 50-150 289 12/10/20

Interm Carboguard® 893 Epoxy Intermediate 3-6 75-150 225 until mtg.

Topcoat Carbothane® 133 LV Aliphatic Polyurethane 3-5 75-125 252 fall 2024

1

Footnote 6 mils max DFT, 18 hrs min cure, 12% max thinner

1

Footnote Information from the Slip-Coefficient and Creep Resistance Test Certificate is given for use w/ primed bolted connections.

NOTE 1 NEPCOAT- NORTHEAST PROTECTIVE COATINGS COMMITTEE of CT, DE, ME, MA, NH, NJ, NY, PA, RI, VT

2 NTPEP (Nat’l Transport’n Product Evaluat’n Program). See Structural Steel Coating test data at http://data.ntpep.org.

3 Accelerated lab and field testing of coating systems is performed according to AASHTO NTPEP R-31 criteria.

4 Systems are accepted for use on NEW and 100% BARE EXISTING steel for bridges cleaned by abrasive blasting.

5 SSC(yr)-xx systems comply with AASHTO R-31 Evaluation Practice & NEPCOAT Acceptance Criteria.

6 VOC values are lab test results using unthinned samples. NEPCOAT max VOC limit is 420 g/L (3.5 lb/gal). Individual

state requirements for VOC limits may differ.

7 Recommended DFT values are listed by manufacturer (see Product Data Sheets.)

8 Any change in coating formulation from that tested will result in removal of the system from the QPL.

9 The full QPL term is seven years starting from the date of acceptance until the next biannual NEPCOAT meeting.

* Acceptance is CONDITIONAL pending submission within four years of successful 2-year field history. A startup list of

five bridges painted with the paint system must be submitted within two years. See Acceptance Criteria.

Note that R-31-09 Section 12.1, Requalification Testing, has been discontinued.

es VOC value adjusted for exempt solvents

NEPCOAT QPL page 1 of 7

Mtg/Date: 6/5/96, 9/4/96, 1/8/97, 7/22/97, 5/20/98, 3/3/99, 9/22/99, 3/30/00, 11/8/00, 3/28/01, 5/14/01, 11/20/01, 11/29/01, 4/24/02, 2/24/03, 4/17/03, 3/16/04, 2/15/05,

4/19/05 R1, 11/17/05 R1, 10/5/06 R1, 06/21/07, 10/16/08, 4/7/09 R1, 10/7/09 R1, 11/09/10, 01/25/11, 4/5/11 R2, 12/14/11, 4/3/12, 4/3/12 R1, 10/02/12, 10/02/12 R1,

4/16/13, 11/15/13 R1, 04/14/14 R1, 10/07/14, 4/7/15, 10/6/15 R2, 04/05/16, 10/04/16 R1, 04/04/17, 10/3/17 R1, 4/3/18, 10/2/18, 4/2/19, 10/1/19, 12/10/20, 4/6/21, 10/5/21

4/5/22

NEPCOAT Qualified Products List B

for Protective Coatings for

NEW and 100% BARE EXISTING Steel for Bridges

NTPEP Slip Manuf’r Coating VOC QPL

System 3-COAT SYSTEM Coef DFT (min/max) Tested Accepted

No. Coats TESTED AND ACCEPTED Class mil micron g/L Dates

NEPCOAT LIST B - ORGANIC Zinc Rich Primer / Epoxy or Urethane Intermediate / Aliphatic Urethane Finish

SSC(15)-07 SHERWIN WILLIAMS COMPANY from

1

Primer Zinc Clad® 4100 Organic Zinc Rich Epoxy Primer B 3-5 75-125 319 10/3/17

Interm Macropoxy® 646 Fast Cure Epoxy 3-10 75-250 265 until mtg.

Topcoat Hi-Solids Polyurethane 250 3-4 75-100 234 es spring 2025

1

Footnote 5 mils max DFT, 72 hours min cure, 5% max thinner

SSC(18)-08 * WASSER COATINGS from

SSC(10)-05 Primer MC-Zinc 100 B1 3-5 75-125 140 es 10/01/19

Interm MC-Miomastic 100 3-5 75-125 106 es until mtg.

Topcoat MC-Ferrox A 100 2-4 50-100 149 es fall 2023

1

Footnote 5.5 mils max DFT, 72 hrs min cure, 10% max thinner

SSC(18)-09 * SHERWIN WILLIAMS COMPANY from

1

Primer Zinc Clad® 4100 Organic Zinc Rich Epoxy Primer B 3-5 75-125 336 10/01/19

Interm Macropoxy® 646 Fast Cure Epoxy 3-10 75-250 229 until mtg.

Topcoat Acrolon™ 218 HS Acrylic Polyurethane 3-6 75-150 276 fall 2023

1

Footnote 5 mils max DFT, 72 hours min cure, 5% max thinner

SSC(18)-11 * SHERWIN WILLIAMS COMPANY from

® 1

Primer Zinc Clad 4100 Organic Zinc Rich Epoxy Primer B 3-5 75-125 333 10/01/19

Interm Steel Spec Epoxy 3-8 75-200 290 until mtg.

Topcoat Acrolon™ 218 HS Acrylic Polyurethane 3-6 75-150 254 fall 2023

1

Footnote 5 mils max DFT, 72 hours min cure, 5% max thinner

(continues) (List B continues)

1

Footnote Information from the Slip-Coefficient and Creep Resistance Test Certificate is given for use w/ primed bolted connections.

NOTE 1 NEPCOAT- NORTHEAST PROTECTIVE COATINGS COMMITTEE of CT, DE, ME, MA, NH, NJ, NY, PA, RI, VT

2 NTPEP (Nat’l Transport’n Product Evaluat’n Program). See Structural Steel Coating test data at http://data.ntpep.org.

3 Accelerated lab and field testing of coating systems is performed according to AASHTO NTPEP R-31 criteria.

4 Systems are accepted for use on NEW and 100% BARE EXISTING steel for bridges cleaned by abrasive blasting.

5 SSC(yr)-xx systems comply with AASHTO R-31 Evaluation Practice & NEPCOAT Acceptance Criteria.

6 VOC values are lab test results using unthinned samples. NEPCOAT max VOC limit is 420 g/L (3.5 lb/gal). Individual

state requirements for VOC limits may differ.

7 Recommended DFT values are listed by manufacturer (see Product Data Sheets.)

8 Any change in coating formulation from that tested will result in removal of the system from the QPL.

9 The full QPL term is seven years starting from the date of acceptance until the next biannual NEPCOAT meeting.

* Acceptance is CONDITIONAL pending submission within four years of successful 2-year field history. A startup list of

five bridges painted with the paint system must be submitted within two years. See Acceptance Criteria.

Note that R-31-09 Section 12.1, Requalification Testing, has been discontinued.

es VOC value adjusted for exempt solvents

NEPCOAT QPL page 2 of 7

Mtg/Date: 6/5/96, 9/4/96, 1/8/97, 7/22/97, 5/20/98, 3/3/99, 9/22/99, 3/30/00, 11/8/00, 3/28/01, 5/14/01, 11/20/01, 11/29/01, 4/24/02, 2/24/03, 4/17/03, 3/16/04, 2/15/05,

4/19/05 R1, 11/17/05 R1, 10/5/06 R1, 06/21/07, 10/16/08, 4/7/09 R1, 10/7/09 R1, 11/09/10, 01/25/11, 4/5/11 R2, 12/14/11, 4/3/12, 4/3/12 R1, 10/02/12, 10/02/12 R1,

4/16/13, 11/15/13 R1, 04/14/14 R1, 10/07/14, 4/7/15, 10/6/15 R2, 04/05/16, 10/04/16 R1, 04/04/17, 10/3/17 R1, 4/3/18, 10/2/18, 4/2/19, 10/1/19, 12/10/20, 4/6/21, 10/5/21

4/5/22

NEPCOAT Qualified Products List B

for Protective Coatings for

NEW and 100% BARE EXISTING Steel for Bridges

NTPEP Slip Manuf’r Coating VOC QPL

System 3-COAT SYSTEM Coef DFT (min/max) Tested Accepted

No. Coats TESTED AND ACCEPTED Class mil micron g/L Dates

NEPCOAT LIST B - ORGANIC Zinc Rich Primer / Epoxy or Urethane Intermediate / Aliphatic Urethane Finish

SSC(19)-02 * CARBOLINE COMPANY from

Primer Carbozinc® 859 Organic Zinc Rich Epoxy Primer B1 3-10 75-250 342 12/10/20

Interm Carboguard® 893 Epoxy Intermediate 3-6 75-150 218 until mtg.

Topcoat Carbothane® 133 LV Aliphatic Polyurethane 3-5 76-127 254 fall 2024

1

Footnote 6 mils max DFT, 6 days min cure, 10% vol max thin

1

Footnote Information from the Slip-Coefficient and Creep Resistance Test Certificate is given for use w/ primed bolted connections.

NOTE 1 NEPCOAT- NORTHEAST PROTECTIVE COATINGS COMMITTEE of CT, DE, ME, MA, NH, NJ, NY, PA, RI, VT

2 NTPEP (Nat’l Transport’n Product Evaluat’n Program). See Structural Steel Coating test data at http://data.ntpep.org.

3 Accelerated lab and field testing of coating systems is performed according to AASHTO NTPEP R-31 criteria.

4 Systems are accepted for use on NEW and 100% BARE EXISTING steel for bridges cleaned by abrasive blasting.

5 SSC(yr)-xx systems comply with AASHTO R-31 Evaluation Practice & NEPCOAT Acceptance Criteria.

6 VOC values are lab test results using unthinned samples. NEPCOAT max VOC limit is 420 g/L (3.5 lb/gal). Individual

state requirements for VOC limits may differ.

7 Recommended DFT values are listed by manufacturer (see Product Data Sheets.)

8 Any change in coating formulation from that tested will result in removal of the system from the QPL.

9 The full QPL term is seven years starting from the date of acceptance until the next biannual NEPCOAT meeting.

* Acceptance is CONDITIONAL pending submission within four years of successful 2-year field history. A startup list of

five bridges painted with the paint system must be submitted within two years. See Acceptance Criteria.

Note that R-31-09 Section 12.1, Requalification Testing, has been discontinued.

es VOC value adjusted for exempt solvents

NEPCOAT QPL page 3 of 7

Mtg/Date: 6/5/96, 9/4/96, 1/8/97, 7/22/97, 5/20/98, 3/3/99, 9/22/99, 3/30/00, 11/8/00, 3/28/01, 5/14/01, 11/20/01, 11/29/01, 4/24/02, 2/24/03, 4/17/03, 3/16/04, 2/15/05,

4/19/05 R1, 11/17/05 R1, 10/5/06 R1, 06/21/07, 10/16/08, 4/7/09 R1, 10/7/09 R1, 11/09/10, 01/25/11, 4/5/11 R2, 12/14/11, 4/3/12, 4/3/12 R1, 10/02/12, 10/02/12 R1,

4/16/13, 11/15/13 R1, 04/14/14 R1, 10/07/14, 4/7/15, 10/6/15 R2, 04/05/16, 10/04/16 R1, 04/04/17, 10/3/17 R1, 4/3/18, 10/2/18, 4/2/19, 10/1/19, 12/10/20, 4/6/21, 10/5/21

4/5/22

NEPCOAT Qualified Products List C

for Protective Coatings for

NEW and 100% BARE EXISTING Steel for Bridges

NTPEP Slip Manuf’r Coating VOC QPL

System 2-COAT SYSTEM Coef DFT (min/max) Tested Accepted

No. Coats TESTED AND ACCEPTED Class mil micron g/L Dates

NEPCOAT LIST C - ORGANIC Zinc Rich Primer / ----- / Topcoat

SSC(18)-03 * SHERWIN WILLIAMS COMPANY from

Primer Zinc Clad® 4100 Organic Zinc Rich Epoxy Primer B 1

3-5 75-125 318 04/02/19

Interm --- --- --- --- until mtg.

Topcoat Sher-Loxane 800 Polysiloxane 4-6 100-150 122 spring 2023

1

Footnote 5 mils max DFT, 72 hours min cure, 5% thinner

SSC(19)-05 * SHERWIN WILLIAMS COMPANY from

Primer Zinc Clad® 4100 Organic Zinc Rich Epoxy Primer B1 3-5 75-125 329 04/06/21

Interm --- --- --- --- until mtg.

Topcoat Envirolastic 940 LV Polyaspartic 6-9 150-225 217 spring 2025

1

Footnote 5 mils max DFT, 72 hours min cure, 5% thinner

1

Footnote Information from the Slip-Coefficient and Creep Resistance Test Certificate is given for use w/ primed bolted connections.

NOTE 1 NEPCOAT- NORTHEAST PROTECTIVE COATINGS COMMITTEE of CT, DE, ME, MA, NH, NJ, NY, PA, RI, VT

2 NTPEP (Nat’l Transport’n Product Evaluat’n Program). See Structural Steel Coating test data at http://data.ntpep.org.

3 Accelerated lab and field testing of coating systems is performed according to AASHTO NTPEP R-31 criteria.

4 Systems are accepted for use on NEW and 100% BARE EXISTING steel for bridges cleaned by abrasive blasting.

5 SSC(yr)-xx systems comply with AASHTO R-31 Evaluation Practice & NEPCOAT Acceptance Criteria.

6 VOC values are lab test results using unthinned samples. NEPCOAT max VOC limit is 420 g/L (3.5 lb/gal). Individual

state requirements for VOC limits may differ.

7 Recommended DFT values are listed by manufacturer (see Product Data Sheets.)

8 Any change in coating formulation from that tested will result in removal of the system from the QPL.

9 The full QPL term is seven years starting from the date of acceptance until the next biannual NEPCOAT meeting.

* Acceptance is CONDITIONAL pending submission within four years of successful 2-year field history. A startup list of

five bridges painted with the paint system must be submitted within two years. See Acceptance Criteria.

Note that R-31-09 Section 12.1, Requalification Testing, has been discontinued.

es VOC value adjusted for exempt solvents

NEPCOAT QPL page 4 of 7

Mtg/Date: 6/5/96, 9/4/96, 1/8/97, 7/22/97, 5/20/98, 3/3/99, 9/22/99, 3/30/00, 11/8/00, 3/28/01, 5/14/01, 11/20/01, 11/29/01, 4/24/02, 2/24/03, 4/17/03, 3/16/04, 2/15/05,

4/19/05 R1, 11/17/05 R1, 10/5/06 R1, 06/21/07, 10/16/08, 4/7/09 R1, 10/7/09 R1, 11/09/10, 01/25/11, 4/5/11 R2, 12/14/11, 4/3/12, 4/3/12 R1, 10/02/12, 10/02/12 R1,

4/16/13, 11/15/13 R1, 04/14/14 R1, 10/07/14, 4/7/15, 10/6/15 R2, 04/05/16, 10/04/16 R1, 04/04/17, 10/3/17 R1, 4/3/18, 10/2/18, 4/2/19, 10/1/19, 12/10/20, 4/6/21, 10/5/21

4/5/22

NEPCOAT Qualified Products List D

for Protective Coatings for

NEW and 100% BARE EXISTING Steel for Bridges

NTPEP Slip Manuf’r Coating VOC QPL

System 2-COAT SYSTEM Coef DFT (min/max) Tested Accepted

No. Coats TESTED AND ACCEPTED Class mil micron g/L Dates

NEPCOAT LIST D - INORGANIC Zinc Rich Primer / ----- / Topcoat

SSC(18)-02 * SHERWIN WILLIAMS COMPANY from

Primer Zinc Clad® II Plus Inorganic Zinc Rich Coating B 1

2-4 50-100 325 04/02/19

Interm --- --- --- --- until mtg.

Topcoat Sher-Loxane 800 Polysiloxane 4-6 100-150 119 spring 2023

1

Footnote 5 mils max DFT, 72 hours min cure, 5% thinner

1

Footnote Information from the Slip-Coefficient and Creep Resistance Test Certificate is given for use w/ primed bolted connections.

NOTE 1 NEPCOAT- NORTHEAST PROTECTIVE COATINGS COMMITTEE of CT, DE, ME, MA, NH, NJ, NY, PA, RI, VT

2 NTPEP (Nat’l Transport’n Product Evaluat’n Program). See Structural Steel Coating test data at http://data.ntpep.org.

3 Accelerated lab and field testing of coating systems is performed according to AASHTO NTPEP R-31 criteria.

4 Systems are accepted for use on NEW and 100% BARE EXISTING steel for bridges cleaned by abrasive blasting.

5 SSC(yr)-xx systems comply with AASHTO R-31 Evaluation Practice & NEPCOAT Acceptance Criteria.

6 VOC values are lab test results using unthinned samples. NEPCOAT max VOC limit is 420 g/L (3.5 lb/gal). Individual

state requirements for VOC limits may differ.

7 Recommended DFT values are listed by manufacturer (see Product Data Sheets.)

8 Any change in coating formulation from that tested will result in removal of the system from the QPL.

9 The full QPL term is seven years starting from the date of acceptance until the next biannual NEPCOAT meeting.

* Acceptance is CONDITIONAL pending submission within four years of successful 2-year field history. A startup list of

five bridges painted with the paint system must be submitted within two years. See Acceptance Criteria.

Note that R-31-09 Section 12.1, Requalification Testing, has been discontinued.

es VOC value adjusted for exempt solvents

NEPCOAT QPL page 5 of 7

Mtg/Date: 6/5/96, 9/4/96, 1/8/97, 7/22/97, 5/20/98, 3/3/99, 9/22/99, 3/30/00, 11/8/00, 3/28/01, 5/14/01, 11/20/01, 11/29/01, 4/24/02, 2/24/03, 4/17/03, 3/16/04, 2/15/05,

4/19/05 R1, 11/17/05 R1, 10/5/06 R1, 06/21/07, 10/16/08, 4/7/09 R1, 10/7/09 R1, 11/09/10, 01/25/11, 4/5/11 R2, 12/14/11, 4/3/12, 4/3/12 R1, 10/02/12, 10/02/12 R1,

4/16/13, 11/15/13 R1, 04/14/14 R1, 10/07/14, 4/7/15, 10/6/15 R2, 04/05/16, 10/04/16 R1, 04/04/17, 10/3/17 R1, 4/3/18, 10/2/18, 4/2/19, 10/1/19, 12/10/20, 4/6/21, 10/5/21

4/5/22

NEPCOAT Acceptance Criteria List A, B, C, D

for Protective Coatings for

NEW and 100% BARE EXISTING Steel for Bridges

AASHTO R31-Testing Standard & NEPCOAT Acceptance Criteria (3/16/04, 2/15/05, 10/16/08, 4/7/09, 10/12/11)

* * * PERFORM ALL REQUIRED TESTS FOR EACH COATING SYSTEM. * * *

TEST NO. 1 - SLIP COEFFICIENT - Perform Slip Co test on the same primer batch used for the other tests.

- The Slip Co test results may be applied to more than one system provided all

Primer samples come from the same container.

Primer (min.)

IOZ Acceptance criteria: Required to have Class B Slip coefficient min. 0.5

OZ Acceptance criteria: None. Report results only. Class B Slip Co. recommended but not required.

TEST NO. 2 - SALT FOG RESISTANCE (ASTM B117)

Delamination Acceptance criteria: no delamination allowed

Rust / Blistering Acceptance criteria (max.):

//-------------------- RUST CRITERIA -----------------// -- BLISTER CRITERIA--

Primer System @ Hrs max creep ave creep % length in scribe @ Hrs Convers’n #

IOZ P-I-T 5000 4 mm 2 mm not req’d not req’d 4000 8

OZ P-I-T 5000 8 mm 4 mm not req’d not req’d 4000 7

TEST NO. 3 - CYCLIC WEATHERING RESISTANCE (ASTM D5894)

Delamination Acceptance criteria: no delamination allowed

Rust / Blistering Acceptance criteria (max.):

//-------------------- RUST CRITERIA -----------------// -- BLISTER CRITERIA--

Primer System @ Hrs max creep ave creep % length in scribe @ Hrs Convers’n #

IOZ P-I-T 5040 4 mm 2 mm not req’d not req’d 4032 9

OZ P-I-T 5040 8 mm 4 mm not req’d not req’d 4032 8

GLOSS value Acceptance criteria: Report results only

GLOSS % Retent’n Acceptance criteria: Report results only

COLOR Change, Δe Acceptance criteria: Report results only

TEST NO. 4 - ABRASION RESISTANCE (ASTM D4060) – NOT REQUIRED

Weight Loss Acceptance criteria: Test discontinued

Wear Index Acceptance criteria: Test discontinued

TEST NO. 5 - ADHESION (ASTM D4541)

Pull-Off Strength Acceptance criteria (min.) for both primer and PIT panels:

IOZ 2.4 MPa (350 psi)

OZ 4.1 MPa (600 psi)

TEST NO. 6 - FREEZE THAW STABILITY

Pull-Off Strength Acceptance criteria: achieve min. Test 5 req’d PIT adhesion results and fall within 60% of Test 5 values

(continued)

NEPCOAT QPL page 6 of 7

Mtg/Date: 6/5/96, 9/4/96, 1/8/97, 7/22/97, 5/20/98, 3/3/99, 9/22/99, 3/30/00, 11/8/00, 3/28/01, 5/14/01, 11/20/01, 11/29/01, 4/24/02, 2/24/03, 4/17/03, 3/16/04, 2/15/05,

4/19/05 R1, 11/17/05 R1, 10/5/06 R1, 06/21/07, 10/16/08, 4/7/09 R1, 10/7/09 R1, 11/09/10, 01/25/11, 4/5/11 R2, 12/14/11, 4/3/12, 4/3/12 R1, 10/02/12, 10/02/12 R1,

4/16/13, 11/15/13 R1, 04/14/14 R1, 10/07/14, 4/7/15, 10/6/15 R2, 04/05/16, 10/04/16 R1, 04/04/17, 10/3/17 R1, 4/3/18, 10/2/18, 4/2/19, 10/1/19, 12/10/20, 4/6/21, 10/5/21

4/5/22

NEPCOAT Acceptance Criteria List A, B, C, D

for Protective Coatings for

NEW and 100% BARE EXISTING Steel for Bridges

AASHTO R31-09 Testing Standard & NEPCOAT Acceptance Criteria (3/16/04, 2/15/05, 10/16/08, 4/7/09, 10/12/11)

TEST NO. 7 - COATING IDENTIFICATION TESTS

VOC Acceptance criteria: Max. 420 g/L (3.5 lb/gal). Individual state requirements may differ.

Coating properties Acceptance criteria: Report only

Coating thickness Acceptance criteria: A 2-coat system shall be tested and applied at min. total 9 mils DFT.

TEST NO. 8 - ATMOSPHERIC EXPOSURE (TWO YEAR) at outdoor site: – NOT REQUIRED

Acceptance criteria: Test discontinued

ITEM NO. 9 - FIELD HISTORY (TWO YEAR)

Acceptance criteria: (All systems after SSC 06-05) The coating manufacturer shall submit two notifications;

(1) a startup list within two years of product acceptance identifying five bridges (in a cold/wet climatic region)

which have been coated with a minimum of 400 liters (100 gallons) of the coating system (i.e. total volume of primer,

intermediate and topcoat); and

(2) the same list of bridges within four years of product acceptance after the system has two years (min.) of successful field

performance. "Successful performance" is simply defined as whether the Owner is satisfied with its application and

performance to date, and whether the Owner would recommend the use of the coating again.

PRODUCT VERIFICATION TESTING

AASHTO R-31-09 Appendix X1 recommends that the Owner perform product verification testing for determining if the

coatings supplied to a project are the same quality as the manufacturer's materials originally tested and certified for acceptance.

The R-31-09 Test 7- Coating Identification Tests are described in Sect. 9.7 and Appendix X1, and the lab test results are

given in NTPEP DataMine (http://data.ntpep.org) along with the manufacturer's listed values.

When the Owner performs verification testing, the following tolerances apply:

Verification Test R-31-09 Section R-31-09 App X1 ASTM Test DataMine Test 7 Tolerance *

Total solids (% by mass) 9.7.9.1 X1.1.1.6 D 2369 Line 2 ±5%

Pigment (% by mass) 9.7.9.5 X1.1.1.8 D 2371 " 3 ±5%

Mass per volume (g/L) 9.7.9.8 X1.1.1.5 D 1475 " 6 ±2%

Viscosity (Stormer) 9.7.9.9 X1.1.1.4 D 562 " 7 ±8%

* The tolerance is applied to the DATAMINE "test result" value (not the manufacturer's "listed value").

These tolerances apply to the primer and intermediate coats each in their mixed condition (not Part A, Part B components).

For topcoats, if the color is different from the original color in NTPEP testing, then these tolerances apply to the Owner's

verification test values the first time a particular color is used.

------------------------------------------------------------------------------------------------------------------------------------------------

Note 1. Test Criteria: Two of three panels must pass for each test to pass. (e.g. Tests 2, 3, 5, 6)

Note 2. Materials: NEPCOAT does not accept waterborne coatings for the QPL for use in the Northeast States.

Note 3. Field History: If available, include an existing bridge(s) with field-applied coatings.

NEPCOAT QPL page 7 of 7

You might also like

- Petronas/Ucc JV Malaysia Project: Painting and Coatings Epoxy-Phenolic Paint System (Inhibitive Primer) Ep-Pr/Ep/EpDocument6 pagesPetronas/Ucc JV Malaysia Project: Painting and Coatings Epoxy-Phenolic Paint System (Inhibitive Primer) Ep-Pr/Ep/EpkhairurNo ratings yet

- Handbook of Paper and Pulp Chemicals (PDFDrive)Document1,032 pagesHandbook of Paper and Pulp Chemicals (PDFDrive)Langtu Dung100% (2)

- Build Up RateDocument4 pagesBuild Up RateLai Chungyi100% (2)

- Painting and FRP System For CP4E Link Bridge RevA - HPTDocument81 pagesPainting and FRP System For CP4E Link Bridge RevA - HPTChan Kin CheungNo ratings yet

- Painting Cycle: Document TitleDocument8 pagesPainting Cycle: Document TitleMaffone NumerounoNo ratings yet

- KI XL 03HS SC 10 HS LT XLPE Ambient CureableDocument4 pagesKI XL 03HS SC 10 HS LT XLPE Ambient CureableAshish bhattNo ratings yet

- XL 09 XL 10Document3 pagesXL 09 XL 10Engr. Mehadi Hassan NahidNo ratings yet

- DP B58W00610Document4 pagesDP B58W00610tangouzeNo ratings yet

- Department of Public Works and HighwaysDocument5 pagesDepartment of Public Works and HighwaysFaustino AbadNo ratings yet

- Zap-Lok System For Pipeline Installation January 2019 PDFDocument35 pagesZap-Lok System For Pipeline Installation January 2019 PDFmutadiNo ratings yet

- Napca Bulletins 1-65-94 Thru 17-98Document72 pagesNapca Bulletins 1-65-94 Thru 17-98lemuel bacsaNo ratings yet

- Vendor PerformanceDocument38 pagesVendor PerformanceManojNo ratings yet

- Metco®601NS 10-141Document11 pagesMetco®601NS 10-141張政雄No ratings yet

- Solder Paste SC Blf03: Lead-FreeDocument2 pagesSolder Paste SC Blf03: Lead-FreeluismcmcNo ratings yet

- Chembloc Series 239Sc: Product ProfileDocument2 pagesChembloc Series 239Sc: Product ProfileSky MoonNo ratings yet

- Pipe Kote Coal TarDocument4 pagesPipe Kote Coal TarAnonymous YcAZv5qF67No ratings yet

- Carbon Black MoistureDocument14 pagesCarbon Black MoistureSanjay SurpuriyaNo ratings yet

- 3K PRO ME CNS P02 001 010 033 240 Rev A PDFDocument19 pages3K PRO ME CNS P02 001 010 033 240 Rev A PDFErol DAĞNo ratings yet

- Energex Estimation GuideDocument88 pagesEnergex Estimation GuideCarl James GranadaNo ratings yet

- Sur Tec 650Document17 pagesSur Tec 650donhan91No ratings yet

- Fluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetDocument4 pagesFluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetFrancisco RodríguezNo ratings yet

- Durability of Coating Repair Systems For Offshore Services - Eurocorr 2014Document17 pagesDurability of Coating Repair Systems For Offshore Services - Eurocorr 2014ANIBALLOPEZVEGA100% (1)

- 500 TPD KilnDocument19 pages500 TPD KilnPratik TyagiNo ratings yet

- Fast Clad Urethane Spec SheetDocument4 pagesFast Clad Urethane Spec SheetScott Van PeltNo ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Coating ProcedureDocument11 pagesCoating Procedureyoussef gaafarNo ratings yet

- Paint Systems For MRTS88Document72 pagesPaint Systems For MRTS88asankaNo ratings yet

- Chemical Mechanical Polishing Slurry For Amorphous Ge 2015 Procedia EngineerDocument8 pagesChemical Mechanical Polishing Slurry For Amorphous Ge 2015 Procedia EngineerTân HoàngNo ratings yet

- Specifications For Manufactured Materials: 1. Product Description 1.1. DescriptionDocument9 pagesSpecifications For Manufactured Materials: 1. Product Description 1.1. Descriptionعبدالحميد علبNo ratings yet

- HPCL Cement Lined Spec PDFDocument167 pagesHPCL Cement Lined Spec PDFvenkateshwaranNo ratings yet

- 12 Procedure For Coating Wrapping Rev 01Document6 pages12 Procedure For Coating Wrapping Rev 01dnbinh100% (2)

- 3 LPE CoatingDocument58 pages3 LPE Coatingkailash100% (2)

- Application of Supported Perovskite-Type Catalysts For Vehicular Emission ControlDocument10 pagesApplication of Supported Perovskite-Type Catalysts For Vehicular Emission ControlKirti GadeNo ratings yet

- Coatings Deposited Using A Valve-Less Detonation SystemDocument5 pagesCoatings Deposited Using A Valve-Less Detonation SystemycwbycwbNo ratings yet

- X-Roc Epoxybond: Epoxy Resin Bonding AgentDocument2 pagesX-Roc Epoxybond: Epoxy Resin Bonding AgentAmr RagabNo ratings yet

- Sigma 1DDocument8 pagesSigma 1Dyogeshkumar121998No ratings yet

- Simacover EP Tar Epoxy 3404-00Document4 pagesSimacover EP Tar Epoxy 3404-00Perseroan MustikaNo ratings yet

- Arc Insulations BrochureDocument5 pagesArc Insulations BrochureacompositesNo ratings yet

- Pipeline Coatings PDFDocument29 pagesPipeline Coatings PDFAsimNo ratings yet

- Carbozinc 859Document2 pagesCarbozinc 859Khemaraj PathNo ratings yet

- Dye Penetration TestDocument66 pagesDye Penetration Testezarul fitri100% (1)

- O2 Analyzer - Document - REV-B - 24-03-2018 PDFDocument10 pagesO2 Analyzer - Document - REV-B - 24-03-2018 PDFambeshNo ratings yet

- Quality Plan 1325-27 Rev 02 - Blasting PaintingDocument10 pagesQuality Plan 1325-27 Rev 02 - Blasting Paintingsuriya100% (1)

- Procedure FOR Quality Assurance System Fusion Bonded Epoxy Coating On RebarsDocument12 pagesProcedure FOR Quality Assurance System Fusion Bonded Epoxy Coating On RebarsPramod SingareNo ratings yet

- 7) PPG Amercoat 385 - Pds - AiDocument4 pages7) PPG Amercoat 385 - Pds - AididbeauNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Cortec ProductDocument20 pagesCortec ProductLiu YangtzeNo ratings yet

- BillDocument2 pagesBillvectra engineeringNo ratings yet

- WO 33-4 Shastri Bridge Panel Cost R0 25.09.2021 - FINALDocument27 pagesWO 33-4 Shastri Bridge Panel Cost R0 25.09.2021 - FINALJayashree GopalakrishnanNo ratings yet

- Pipeline CoatingsDocument29 pagesPipeline Coatingstrpac100% (3)

- DM SSSDocument5 pagesDM SSSiitmpdNo ratings yet

- Cat Konik 1Document29 pagesCat Konik 1Soma GhoshNo ratings yet

- Procedure - 3lpe - Msl-Rev.00Document15 pagesProcedure - 3lpe - Msl-Rev.00Suresh KrishnanNo ratings yet

- DacrometDocument6 pagesDacrometdavideNo ratings yet

- Novalux PaintDocument22 pagesNovalux PaintLionparcel Qonitah Talang JambeNo ratings yet

- Recent Advances in Cast SX Superalloys: Jacqueline Wahl and Ken HarrisDocument34 pagesRecent Advances in Cast SX Superalloys: Jacqueline Wahl and Ken Harrisjohn davidsNo ratings yet

- Concrete BlanketDocument19 pagesConcrete BlanketIan lawrenz LeeNo ratings yet

- Toe LoadDocument4 pagesToe Loadcheikh ahmedNo ratings yet

- 253 PDS AiDocument4 pages253 PDS AiAchraf BoudayaNo ratings yet

- Micro Surfacing: Cost Effective Solution For Pavement Preservation and RenewalDocument16 pagesMicro Surfacing: Cost Effective Solution For Pavement Preservation and RenewalCristhian Riveros RojasNo ratings yet

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Covalence HTLP80: Product Data SheetDocument2 pagesCovalence HTLP80: Product Data SheetbasukiNo ratings yet

- 01 - CEMS Field Equipment Installation ManualDocument15 pages01 - CEMS Field Equipment Installation ManualheikelNo ratings yet

- Conductivity Sorted by Resistivity Eddy Current TechnologyDocument14 pagesConductivity Sorted by Resistivity Eddy Current TechnologyKalai VananNo ratings yet

- Selecting Tips, Speeds, and Pressures For Oxyfuel Gas CuttingDocument2 pagesSelecting Tips, Speeds, and Pressures For Oxyfuel Gas CuttingRonny De La CruzNo ratings yet

- Materials For Direct RestorationsDocument9 pagesMaterials For Direct RestorationsBerty SusantoNo ratings yet

- LF880 TAB RexnordDocument1 pageLF880 TAB RexnordAkhmadiNo ratings yet

- Hess LawDocument4 pagesHess LawDarlene Jane Taladro Caga-ananNo ratings yet

- Testing Abrasion Resistance of High-Strength ConcreteDocument11 pagesTesting Abrasion Resistance of High-Strength ConcreteKeerti BonguNo ratings yet

- India's Legendary 'Wootz' SteelDocument90 pagesIndia's Legendary 'Wootz' SteelRonak Shah100% (1)

- CP 653 BA Technical-information-ASSET-DOC-LOC-1540979Document1 pageCP 653 BA Technical-information-ASSET-DOC-LOC-1540979AdityaNo ratings yet

- Nylon Plastics by M. I. Kohan P. 14-15Document1 pageNylon Plastics by M. I. Kohan P. 14-15Guery SaenzNo ratings yet

- Tsu-Wei Chou - Microstructural Design of Fiber Composites (Cambridge Solid State Science Series) (2005)Document589 pagesTsu-Wei Chou - Microstructural Design of Fiber Composites (Cambridge Solid State Science Series) (2005)Genby Ardinugraha100% (1)

- Past Paper - Microscopic WorldDocument7 pagesPast Paper - Microscopic Worldapi-3739994100% (1)

- Properties of Particleboard From Wood Wastes FinalCopy 06 May 2016Document8 pagesProperties of Particleboard From Wood Wastes FinalCopy 06 May 2016sojorj22No ratings yet

- Elemental Group Properties: Unit 3 Pharm 114Document39 pagesElemental Group Properties: Unit 3 Pharm 114Kim JunkyuNo ratings yet

- CH 05Document30 pagesCH 05Ariq Rama NurvirgianNo ratings yet

- Materials System SpecificationDocument11 pagesMaterials System SpecificationJeck MaquitedNo ratings yet

- GGBSDocument20 pagesGGBSratnakarNo ratings yet

- 10th OBJECTIVE 2022 CHEMISTRYDocument20 pages10th OBJECTIVE 2022 CHEMISTRYVarenayam editzNo ratings yet

- DUPA PoW MASBATEDocument122 pagesDUPA PoW MASBATEIrene Ionie Rarangol - TengcoNo ratings yet

- Assembling The Puzzle of Superconducting Elements: A ReviewDocument10 pagesAssembling The Puzzle of Superconducting Elements: A Reviewalesol2No ratings yet

- CATpg 6 ADocument1 pageCATpg 6 AcbrittaivNo ratings yet

- Quality Control Flow Chart (10.12.22)Document2 pagesQuality Control Flow Chart (10.12.22)mido_20067581No ratings yet

- Approved List of Manufacturers: CategoryDocument4 pagesApproved List of Manufacturers: CategoryFahadAl100% (1)

- Suma PharmaDocument14 pagesSuma PharmaRamboNo ratings yet

- Safety Data Sheet Ammonia, AnhydrousDocument3 pagesSafety Data Sheet Ammonia, AnhydrousEleonoraNo ratings yet

- 70-3695-HMS Material Composition Declaration ABS-PDP-4Document4 pages70-3695-HMS Material Composition Declaration ABS-PDP-4Bob YahyaNo ratings yet

- Astm ManualsDocument8 pagesAstm ManualsTrushar ParmarNo ratings yet