Professional Documents

Culture Documents

Challenges of Renewall Baterry Cell

Challenges of Renewall Baterry Cell

Uploaded by

broneissalaso-3573Copyright:

Available Formats

You might also like

- Magnet Pole Shape Design of Permanent Magnet MachiDocument5 pagesMagnet Pole Shape Design of Permanent Magnet MachiAymen KammounNo ratings yet

- 2022 06 Poster Lmps NajjarDocument1 page2022 06 Poster Lmps Najjarعمر نجارNo ratings yet

- Lithium IonDocument16 pagesLithium Ionmaruthi prasad nNo ratings yet

- Cambridge 2019 Tugce IslerDocument1 pageCambridge 2019 Tugce IslerdmarandiNo ratings yet

- 2 Zero Gap CLOROSURRev1Document28 pages2 Zero Gap CLOROSURRev1Jesús Javier Antuña CouceiroNo ratings yet

- Machine Learning For Optimal Electrode Wettability in Lithium Ion BatteriesDocument12 pagesMachine Learning For Optimal Electrode Wettability in Lithium Ion BatteriesdaaanuNo ratings yet

- Digimat: The Material Modeling PlatformDocument24 pagesDigimat: The Material Modeling PlatformsuganthNo ratings yet

- Yao, Fujikubo, Nie - 1997 - Development of A Simple Dynamical Model To Simulate Collapse Behaviour of Plates With Welding Residual Stres-AnnotatedDocument12 pagesYao, Fujikubo, Nie - 1997 - Development of A Simple Dynamical Model To Simulate Collapse Behaviour of Plates With Welding Residual Stres-AnnotatedHugo AceNo ratings yet

- Candidato:: Corso Di Laurea Magistrale in Ingenieria ElettronicaDocument27 pagesCandidato:: Corso Di Laurea Magistrale in Ingenieria ElettronicacespalaciosariasNo ratings yet

- Thesis Mid-TermDocument16 pagesThesis Mid-TermPardhu NiharNo ratings yet

- J Jpowsour 2021 229884Document12 pagesJ Jpowsour 2021 229884Firman Adi RifansyahNo ratings yet

- Iwpsd Poster v1Document1 pageIwpsd Poster v1Laura Browning100% (1)

- Model Comparison and Selection For Battery DT Development Using PyBaMMDocument3 pagesModel Comparison and Selection For Battery DT Development Using PyBaMMREX MATTHEWNo ratings yet

- 13.30 Begum BozkayaDocument17 pages13.30 Begum BozkayaMaintenance PTGSNo ratings yet

- Using Abaqus To Model Delamination in Fiber-Reinforced Composite MaterialsDocument18 pagesUsing Abaqus To Model Delamination in Fiber-Reinforced Composite MaterialsdashatanliNo ratings yet

- Research of The Loss of Power Transformer StructurDocument8 pagesResearch of The Loss of Power Transformer StructurbenlahnecheNo ratings yet

- Characterizing Aging Effects of Lithium Ion Batteries by Impedance SpectrosDocument9 pagesCharacterizing Aging Effects of Lithium Ion Batteries by Impedance SpectrosGiova RossiNo ratings yet

- Compact Verilog-A Model of Phase-Change RAM Transient Behaviors For Mult...Document11 pagesCompact Verilog-A Model of Phase-Change RAM Transient Behaviors For Mult...이은지100% (1)

- Lightning Performance of 500-kV Double-Circuit Line Schemes For The Three-Gorge ProjectDocument8 pagesLightning Performance of 500-kV Double-Circuit Line Schemes For The Three-Gorge ProjectAlcides NetoNo ratings yet

- 1994 - Implicit and Dynamic Explicit Solutions of Blade Forging Using The Finite Element MethodDocument6 pages1994 - Implicit and Dynamic Explicit Solutions of Blade Forging Using The Finite Element MethodNguyen Hoang DungNo ratings yet

- LED Technology - 2024-03-21 - Chapter2 - Lecture2Document22 pagesLED Technology - 2024-03-21 - Chapter2 - Lecture2hmd4637rmzNo ratings yet

- Corona Treatment in PracticeDocument8 pagesCorona Treatment in PracticeHuy Tuan QuachNo ratings yet

- Effects of Scan Rate On The Potentiodyn... L Slopes and Corrosion Current DensityDocument7 pagesEffects of Scan Rate On The Potentiodyn... L Slopes and Corrosion Current DensitySiva PrasadNo ratings yet

- Yu 2022 Plasma Sources Sci. Technol. 31 035012Document15 pagesYu 2022 Plasma Sources Sci. Technol. 31 035012Golam ZakariaNo ratings yet

- ARL MSMEJaramillo BoteroetalDocument58 pagesARL MSMEJaramillo Boteroetalramadhanifarahum19No ratings yet

- Olsson Presentation PDFDocument16 pagesOlsson Presentation PDFneomindxNo ratings yet

- Dlala2009 PDFDocument10 pagesDlala2009 PDFthiagovt2No ratings yet

- Comparison of Models For Estimating Magnetic Core Losses in Electrical Machines Using The Finite-Element MethodDocument10 pagesComparison of Models For Estimating Magnetic Core Losses in Electrical Machines Using The Finite-Element MethodSuda KrishnarjunaraoNo ratings yet

- Miladic JelenaDocument6 pagesMiladic JelenaEdy JjNo ratings yet

- Modeling Transformers With Internal Incipient FaultsDocument10 pagesModeling Transformers With Internal Incipient FaultsVirnaNo ratings yet

- Compact Bipolar Transistor Modeling - Issues and Possible SolutionsDocument15 pagesCompact Bipolar Transistor Modeling - Issues and Possible Solutionskaran007_mNo ratings yet

- Organic Photovoltaic DevicesDocument19 pagesOrganic Photovoltaic DevicesSamarth AgarwalNo ratings yet

- ActiveCircuits Lec03Document23 pagesActiveCircuits Lec03OPTICALMIMOOFDMNo ratings yet

- Baterie Reincarcabila ImprimataDocument22 pagesBaterie Reincarcabila ImprimataMaur13No ratings yet

- Crippling Analysis of Composite Stringers PDFDocument9 pagesCrippling Analysis of Composite Stringers PDFDhimas Surya NegaraNo ratings yet

- Electro FormingDocument16 pagesElectro Formingfrans william100% (1)

- Plate Finite Element Modeling OF Laminated Plates: PergamonDocument12 pagesPlate Finite Element Modeling OF Laminated Plates: Pergamonsubhra_civ658No ratings yet

- Hintennach 2011Document7 pagesHintennach 2011peneeeNo ratings yet

- Development of A Dynamic Semi-Empirical Model For Simulation of Copper Electrowinning ProcessesDocument13 pagesDevelopment of A Dynamic Semi-Empirical Model For Simulation of Copper Electrowinning ProcessesJuan Reyes PasteneNo ratings yet

- Lumped Model To Explain and Approximate Dimensional Effects in Ferrite Cores (Charles Sullivan, Dartmouth)Document25 pagesLumped Model To Explain and Approximate Dimensional Effects in Ferrite Cores (Charles Sullivan, Dartmouth)djyNo ratings yet

- Qin 2021 J. Phys. Conf. Ser. 1995 012011Document7 pagesQin 2021 J. Phys. Conf. Ser. 1995 012011Vivek Kumar Saroj Res. Scholar, Ceramic Engg., IIT(BHU)No ratings yet

- Projected Phase-Change Memory Devices: ArticleDocument7 pagesProjected Phase-Change Memory Devices: Articlesabrine hamriNo ratings yet

- Bahrami Et Al. - 2005 - Pressure Drop of Fully Developed, Laminar Flow inDocument6 pagesBahrami Et Al. - 2005 - Pressure Drop of Fully Developed, Laminar Flow inOliver HouNo ratings yet

- Models - Acdc.submarine Cable 01 IntroductionDocument64 pagesModels - Acdc.submarine Cable 01 Introductionisai.diaz2995No ratings yet

- 2003 Jcoma GT PF KKDocument7 pages2003 Jcoma GT PF KKAdrià TejeroNo ratings yet

- NESS - Nano-Electronic Simulation SoftwareDocument20 pagesNESS - Nano-Electronic Simulation SoftwareGurrampati Manikanta ReddyNo ratings yet

- Computationally Efficient Memristor Model With Hann Window FunctionDocument12 pagesComputationally Efficient Memristor Model With Hann Window FunctionAmmuNo ratings yet

- The Dimensional Effect of Breakdown Field in Zno Varistors: Shengtao Li, Jianying Li, Fuyi Liu, M A Alim and G ChenDocument5 pagesThe Dimensional Effect of Breakdown Field in Zno Varistors: Shengtao Li, Jianying Li, Fuyi Liu, M A Alim and G Chenluciferr49No ratings yet

- Hyperelastic Model For Large Deformation Analyses of 3D Interlock Composites PreformsDocument9 pagesHyperelastic Model For Large Deformation Analyses of 3D Interlock Composites PreformsLouis GrouNo ratings yet

- JamesDocument10 pagesJamesyuchun chouNo ratings yet

- Pattamad PanedpojamanDocument13 pagesPattamad PanedpojamanAli IsmaelNo ratings yet

- Modelling Concrete Structures Applying XFEM With A Mixed Mode Constitutive ModelDocument6 pagesModelling Concrete Structures Applying XFEM With A Mixed Mode Constitutive ModelAsma BousameNo ratings yet

- Earth Potential Rise (EPR) Computation For A Fault On Transmission Mains PoleDocument6 pagesEarth Potential Rise (EPR) Computation For A Fault On Transmission Mains PolenassarkiNo ratings yet

- Conducting Polymer Composites: Relation Between Electrical and Mechanical Properties ofDocument6 pagesConducting Polymer Composites: Relation Between Electrical and Mechanical Properties ofMiroslav PavlovićNo ratings yet

- M2-01 Interconnect ParasiticsDocument14 pagesM2-01 Interconnect ParasiticsCyrille MagdiNo ratings yet

- Jotun Thinner For Support StructuresDocument6 pagesJotun Thinner For Support Structuresthahir1429No ratings yet

- WWW ScribdDocument1 pageWWW ScribdArjun Dev P SNo ratings yet

- 2022 06 Poster Lmps NajjarDocument1 page2022 06 Poster Lmps Najjarعمر نجارNo ratings yet

- 3-1 Modelling ConsiderationsDocument18 pages3-1 Modelling Considerationsluis900000No ratings yet

- Filtre AerDocument2 pagesFiltre AerSilviu AlexandruNo ratings yet

- 350204011ws Class 4Document62 pages350204011ws Class 4Namita Sahu100% (1)

- RCB-4H Data SheetDocument15 pagesRCB-4H Data SheetjaliltaghdarehNo ratings yet

- Counters WBTS WN8 0 AlldataDocument273 pagesCounters WBTS WN8 0 Alldatakkchin86No ratings yet

- Radar Level Meter CatalogueDocument15 pagesRadar Level Meter CatalogueagusNo ratings yet

- Sign T10471Document2 pagesSign T10471Syed Hamzah Al-IdrusNo ratings yet

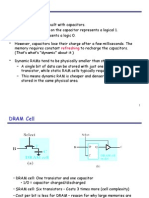

- 14-RAM&ROM - Dynamic Memory Is Built With Capacitors. A Stored Charge On The Capacitor Represents A Logical 1. No Charge Represents A Logic 0.Document8 pages14-RAM&ROM - Dynamic Memory Is Built With Capacitors. A Stored Charge On The Capacitor Represents A Logical 1. No Charge Represents A Logic 0.Nava KrishnanNo ratings yet

- UT Dallas Syllabus For cs2305.002.07s Taught by Simeon Ntafos (Ntafos)Document5 pagesUT Dallas Syllabus For cs2305.002.07s Taught by Simeon Ntafos (Ntafos)UT Dallas Provost's Technology GroupNo ratings yet

- Exam-Style Question:: Mathematical ModellingDocument4 pagesExam-Style Question:: Mathematical ModellingFadi AyyoubNo ratings yet

- DX DiagDocument33 pagesDX DiagsamihaNo ratings yet

- Earth'S Orbit Path Around The Sun EssayDocument3 pagesEarth'S Orbit Path Around The Sun EssaySebastián VegaNo ratings yet

- SOA and BPM - Architectural ViewDocument30 pagesSOA and BPM - Architectural ViewVithaya SuharitdamrongNo ratings yet

- Defects in MaterialDocument15 pagesDefects in MaterialSumit Kumar JhaNo ratings yet

- 12th Chemistry Vol.1 Book Back One Mark Questions English Medium PDF DownloadDocument19 pages12th Chemistry Vol.1 Book Back One Mark Questions English Medium PDF Downloadteddygamingyt201No ratings yet

- Flat Plate Collector IntroDocument4 pagesFlat Plate Collector IntrogcrupaNo ratings yet

- Introduction To Management Science 11th Edition Taylor Solution ManualDocument26 pagesIntroduction To Management Science 11th Edition Taylor Solution Manualharry100% (28)

- Centr Eur J BiolDocument8 pagesCentr Eur J Bioldhafer alhaidaryNo ratings yet

- Ch5 - CPU SchedulingDocument33 pagesCh5 - CPU SchedulingAditya ThakurNo ratings yet

- Microfinish VM 601Document14 pagesMicrofinish VM 601VCNo ratings yet

- Master Boot Record: Usman Mansoor Junaid Ali Husnain Manzoor Fahad AliDocument10 pagesMaster Boot Record: Usman Mansoor Junaid Ali Husnain Manzoor Fahad AliJunaidAliNo ratings yet

- TeleDNA SMSC Acceptance Test Plan UnitechDocument30 pagesTeleDNA SMSC Acceptance Test Plan Unitechankush_apjNo ratings yet

- Experiment No 3 - BOOLEAN ALGEBRA AND DE MORGANS THEOREMDocument8 pagesExperiment No 3 - BOOLEAN ALGEBRA AND DE MORGANS THEOREMJhon Lhoyd CorpuzNo ratings yet

- AABC Test Balance Proc PDFDocument189 pagesAABC Test Balance Proc PDFemrahNo ratings yet

- Expansion, Factorization, Simplifications, Quadratic Equations and GraphsDocument7 pagesExpansion, Factorization, Simplifications, Quadratic Equations and GraphsBurhan AzharNo ratings yet

- Steam Turbine Servomotor For Main Description and Reheat Stop ValvesDocument1 pageSteam Turbine Servomotor For Main Description and Reheat Stop Valvesparthibanemails5779No ratings yet

- INV 4835E DatasheetDocument3 pagesINV 4835E DatasheetEsteban RamirezNo ratings yet

- Ahmed Abdel Fattah Mahmoud Ahmed. - Paper 12Document19 pagesAhmed Abdel Fattah Mahmoud Ahmed. - Paper 12puppyarav2726No ratings yet

- Fat Rich Dairy Products: B. Tech. (Dairy Technology) DT-2 ResourcesDocument13 pagesFat Rich Dairy Products: B. Tech. (Dairy Technology) DT-2 ResourcesEasy ways2017No ratings yet

- Tos Second GradingDocument2 pagesTos Second GradingNodelyn ReyesNo ratings yet

- Siemens 1FT SimoDrive Servo Motor Planning Guide PDFDocument632 pagesSiemens 1FT SimoDrive Servo Motor Planning Guide PDFswooshcmk100% (1)

Challenges of Renewall Baterry Cell

Challenges of Renewall Baterry Cell

Uploaded by

broneissalaso-3573Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Challenges of Renewall Baterry Cell

Challenges of Renewall Baterry Cell

Uploaded by

broneissalaso-3573Copyright:

Available Formats

Review and challenges of aging modeling techniques

for solid-state batteries

Md Sazzad Hosen

MOBI Battery Research Group, Vrije Universiteit Brussel, Pleinlaan 2, 1050 Brussel, Belgium

ABSTRACT: The state-of-the-art Gen 3 Li-ion battery degradation modeling methodologies span from electrochemical to black box approach.

The methodological selection is a trade-off between computational effort, accuracy, physical insight, and data requirement. The comparatively

recent Gen 4 solid-state battery aging requires advanced modeling techniques that are well-established and provide a reliable and accurate

prediction.

MAIN SSB AGING MECHANISMS CAPACITY FADE PREDICTION

• Outward diffusion of the free volume -

Continuum modeling[4]

➢ Polymer mobility: σ ↘ ⟹ 𝑅𝑖𝑛𝑡 ↗

𝑒𝑓𝑓

➢ Polymer matrix contraction: Effective contact area, 𝐴𝑐𝑜𝑛𝑡 ↘ ⟹ 𝑅𝑖𝑛𝑡 ↗ • LCO/Li with LiTFSI + poly(AN-co-BuA) electrolyte

• Cyclic deformation - • Three homogeneous domains → 1D model

𝑒𝑓𝑓 • 𝐴/𝐴0 ∝ 𝑉/𝑉0 ∝ free volume

➢ 𝐴𝑐𝑜𝑛𝑡 ↘ ⟹ 𝑅𝑖𝑛𝑡 ↗

• Relation between free volume and discharging capacity

➢ Electrolyte cracks

➢ Model of SPE aging

• Irreversible Li intercalation -

➢ Loss of active material

• Dendrites growth

• Electrode particles pulverization

𝑒𝑓𝑓

➢ Vacant cavities ⟹ 𝐴𝑐𝑜𝑛𝑡 ↘ ⟹ 𝑅𝑖𝑛𝑡 ↗ Electrochemical model

Fig 6 – 3D scheme of a solid-state battery with a solid polymer electrolyte

Fig 1 – Overview of some ageing mechanisms of solid-state batteries [1]

IDENTIFICATION OF A MECHANISM

Aging of solid polymer electrolyte[2]

• Poly(ethylene glycol) methacrylate with Al-PEG/B-PEG plasticizer & LiFTSI

• LFP/SPE/Li cells

Fig 7 – Effect of modelled polymer relaxation on its free volume and contact area Fig 8 – Effect of time-ageing on discharge curve at 1C rate

with electrode

✓ Time-domain aging model

✓ Impact of free volume decrease

➢ Loss of ionic conductivity

Fig 2 – NMR image of degraded SPE

➢ Loss of effective contact area

✓ Influence of other factors (T, C-rate, salt

✓ Pulverization of cathodic particles concentration, etc.)

➢ Decrease in thickness Fig 3 – (a) Cyclic performance of three identical cells (1C, 60°C);

➢ Vacant cavities: local issue (b) Variation of internal resistances with cycling

✓ Capacity fading and internal resistance rising related to cavities (loss of contact) and to

the local decomposition of the anions due to uneven electric flow (caused by cavities) Fig 9 – Effect of electrolyte time-aging on discharge capacity

RUL PREDICTION

TAKEAWAYS

A data-driven approach for aging model development[3]

• LFP/Li & NMC/Li cells ❖ Model-based approach: high interpretability, less complexity

• Cross-linked nanocomposite polymer electrolyte: PPO and PEO-based block polymer ❖ Data-driven approach: high accuracy, less interpretability

with SiO2 nanoparticles ❖ Most of the existing literature focus on understanding aging mechanisms and improving

• Machine Learning: Symbolic Regression the ionic conductivity

➢ Very few studies on modeling SSB aging

❖ Hybrid Solid Electrolyte (HSE): polymer matrix & inorganic filler

➢ Combines → the flexibility of polymer and advantages of inorganic electrolyte

➢ Promising but not mature → aging not still modeled

❖ Open-access dataset is rarely available for Gen 4 batteries.

FUTURE WORK & ACKNOWLEDGEMENT

Fig 4 - Discharge capacity of cycled solid-state batteries

➢ Prototyping of monolayer pouch cells of NMC811 cathode and HSE (inorganic and

polymer) for an experimental study.

➢ Develop cycling and performance data of SSB prototypes (anode-less) that are

reproducible and of high quality.

➢ Demonstrate model-based aging prediction with high accuracy within the scope of the

AM4BAT project framework.

➢ This project has received funding from the European Union’s Horizon Europe research

and innovation program under grant agreement No 101069756.

Fig 5 - Computational routine of Symbolic Regression model

REFERENCES

[1] B. S. Vishnugopi, E. Kazyak, J. A. Lewis, J. Nanda, M. T. McDowell, N. P. Dasgupta and P. P. Mukherjee. Challenges and Opportunities for Fast Charging of

✓ RUL of different battery types predicted Solid-State Lithium Metal Batteries. ACS Energy Letters 2021, 6, 3734 – 3749. doi.org/10.1021/acsenergylett.1c01352

✓ 𝑅2 = 0.91

[2] M. Nakayama, S. Wada, S. Kuroki and M. Nogami. Factors Affecting Cyclic Durability of All-Solid-State Lithium Polymer Batteries Using Poly(Ethylene

Oxide)-Based Solid Polymer Electrolytes. Energy & Environmental Science 2010, 3, 1995-2002. doi.org/10.1039/C0EE00266F

✓ Better prediction performance with respect to [3] D. Cheng, W. Sha, L. Wang, S. Tang, A. Ma, Y. Chen, H. Wang, P. Lou, S. Lu and Y.-C. Cao. Solid-State Lithium Battery Cycle Life Prediction Using Machine

Learning. Applied Sciences, 2021, 11, 4671. doi.org/10.3390/app11104671

other ML methods: GPR, EN and SVR. [4] X. Fang, Y. He, X. Fan, D. Zhang and H. Hu. Modeling and Simulation in Capacity Degradation and Control of All-Solid-State Lithium Battery Based on

Time-Aging Polymer Electrolyte. Polymers, 2021, 13, 1206. doi.org/10.3390/polym13081206

Fig 4 – Comparison of predicted and actual RUL

Md Sazzad Hosen

Senior Researcher

Md.Sazzad.Hosen@vub.be

You might also like

- Magnet Pole Shape Design of Permanent Magnet MachiDocument5 pagesMagnet Pole Shape Design of Permanent Magnet MachiAymen KammounNo ratings yet

- 2022 06 Poster Lmps NajjarDocument1 page2022 06 Poster Lmps Najjarعمر نجارNo ratings yet

- Lithium IonDocument16 pagesLithium Ionmaruthi prasad nNo ratings yet

- Cambridge 2019 Tugce IslerDocument1 pageCambridge 2019 Tugce IslerdmarandiNo ratings yet

- 2 Zero Gap CLOROSURRev1Document28 pages2 Zero Gap CLOROSURRev1Jesús Javier Antuña CouceiroNo ratings yet

- Machine Learning For Optimal Electrode Wettability in Lithium Ion BatteriesDocument12 pagesMachine Learning For Optimal Electrode Wettability in Lithium Ion BatteriesdaaanuNo ratings yet

- Digimat: The Material Modeling PlatformDocument24 pagesDigimat: The Material Modeling PlatformsuganthNo ratings yet

- Yao, Fujikubo, Nie - 1997 - Development of A Simple Dynamical Model To Simulate Collapse Behaviour of Plates With Welding Residual Stres-AnnotatedDocument12 pagesYao, Fujikubo, Nie - 1997 - Development of A Simple Dynamical Model To Simulate Collapse Behaviour of Plates With Welding Residual Stres-AnnotatedHugo AceNo ratings yet

- Candidato:: Corso Di Laurea Magistrale in Ingenieria ElettronicaDocument27 pagesCandidato:: Corso Di Laurea Magistrale in Ingenieria ElettronicacespalaciosariasNo ratings yet

- Thesis Mid-TermDocument16 pagesThesis Mid-TermPardhu NiharNo ratings yet

- J Jpowsour 2021 229884Document12 pagesJ Jpowsour 2021 229884Firman Adi RifansyahNo ratings yet

- Iwpsd Poster v1Document1 pageIwpsd Poster v1Laura Browning100% (1)

- Model Comparison and Selection For Battery DT Development Using PyBaMMDocument3 pagesModel Comparison and Selection For Battery DT Development Using PyBaMMREX MATTHEWNo ratings yet

- 13.30 Begum BozkayaDocument17 pages13.30 Begum BozkayaMaintenance PTGSNo ratings yet

- Using Abaqus To Model Delamination in Fiber-Reinforced Composite MaterialsDocument18 pagesUsing Abaqus To Model Delamination in Fiber-Reinforced Composite MaterialsdashatanliNo ratings yet

- Research of The Loss of Power Transformer StructurDocument8 pagesResearch of The Loss of Power Transformer StructurbenlahnecheNo ratings yet

- Characterizing Aging Effects of Lithium Ion Batteries by Impedance SpectrosDocument9 pagesCharacterizing Aging Effects of Lithium Ion Batteries by Impedance SpectrosGiova RossiNo ratings yet

- Compact Verilog-A Model of Phase-Change RAM Transient Behaviors For Mult...Document11 pagesCompact Verilog-A Model of Phase-Change RAM Transient Behaviors For Mult...이은지100% (1)

- Lightning Performance of 500-kV Double-Circuit Line Schemes For The Three-Gorge ProjectDocument8 pagesLightning Performance of 500-kV Double-Circuit Line Schemes For The Three-Gorge ProjectAlcides NetoNo ratings yet

- 1994 - Implicit and Dynamic Explicit Solutions of Blade Forging Using The Finite Element MethodDocument6 pages1994 - Implicit and Dynamic Explicit Solutions of Blade Forging Using The Finite Element MethodNguyen Hoang DungNo ratings yet

- LED Technology - 2024-03-21 - Chapter2 - Lecture2Document22 pagesLED Technology - 2024-03-21 - Chapter2 - Lecture2hmd4637rmzNo ratings yet

- Corona Treatment in PracticeDocument8 pagesCorona Treatment in PracticeHuy Tuan QuachNo ratings yet

- Effects of Scan Rate On The Potentiodyn... L Slopes and Corrosion Current DensityDocument7 pagesEffects of Scan Rate On The Potentiodyn... L Slopes and Corrosion Current DensitySiva PrasadNo ratings yet

- Yu 2022 Plasma Sources Sci. Technol. 31 035012Document15 pagesYu 2022 Plasma Sources Sci. Technol. 31 035012Golam ZakariaNo ratings yet

- ARL MSMEJaramillo BoteroetalDocument58 pagesARL MSMEJaramillo Boteroetalramadhanifarahum19No ratings yet

- Olsson Presentation PDFDocument16 pagesOlsson Presentation PDFneomindxNo ratings yet

- Dlala2009 PDFDocument10 pagesDlala2009 PDFthiagovt2No ratings yet

- Comparison of Models For Estimating Magnetic Core Losses in Electrical Machines Using The Finite-Element MethodDocument10 pagesComparison of Models For Estimating Magnetic Core Losses in Electrical Machines Using The Finite-Element MethodSuda KrishnarjunaraoNo ratings yet

- Miladic JelenaDocument6 pagesMiladic JelenaEdy JjNo ratings yet

- Modeling Transformers With Internal Incipient FaultsDocument10 pagesModeling Transformers With Internal Incipient FaultsVirnaNo ratings yet

- Compact Bipolar Transistor Modeling - Issues and Possible SolutionsDocument15 pagesCompact Bipolar Transistor Modeling - Issues and Possible Solutionskaran007_mNo ratings yet

- Organic Photovoltaic DevicesDocument19 pagesOrganic Photovoltaic DevicesSamarth AgarwalNo ratings yet

- ActiveCircuits Lec03Document23 pagesActiveCircuits Lec03OPTICALMIMOOFDMNo ratings yet

- Baterie Reincarcabila ImprimataDocument22 pagesBaterie Reincarcabila ImprimataMaur13No ratings yet

- Crippling Analysis of Composite Stringers PDFDocument9 pagesCrippling Analysis of Composite Stringers PDFDhimas Surya NegaraNo ratings yet

- Electro FormingDocument16 pagesElectro Formingfrans william100% (1)

- Plate Finite Element Modeling OF Laminated Plates: PergamonDocument12 pagesPlate Finite Element Modeling OF Laminated Plates: Pergamonsubhra_civ658No ratings yet

- Hintennach 2011Document7 pagesHintennach 2011peneeeNo ratings yet

- Development of A Dynamic Semi-Empirical Model For Simulation of Copper Electrowinning ProcessesDocument13 pagesDevelopment of A Dynamic Semi-Empirical Model For Simulation of Copper Electrowinning ProcessesJuan Reyes PasteneNo ratings yet

- Lumped Model To Explain and Approximate Dimensional Effects in Ferrite Cores (Charles Sullivan, Dartmouth)Document25 pagesLumped Model To Explain and Approximate Dimensional Effects in Ferrite Cores (Charles Sullivan, Dartmouth)djyNo ratings yet

- Qin 2021 J. Phys. Conf. Ser. 1995 012011Document7 pagesQin 2021 J. Phys. Conf. Ser. 1995 012011Vivek Kumar Saroj Res. Scholar, Ceramic Engg., IIT(BHU)No ratings yet

- Projected Phase-Change Memory Devices: ArticleDocument7 pagesProjected Phase-Change Memory Devices: Articlesabrine hamriNo ratings yet

- Bahrami Et Al. - 2005 - Pressure Drop of Fully Developed, Laminar Flow inDocument6 pagesBahrami Et Al. - 2005 - Pressure Drop of Fully Developed, Laminar Flow inOliver HouNo ratings yet

- Models - Acdc.submarine Cable 01 IntroductionDocument64 pagesModels - Acdc.submarine Cable 01 Introductionisai.diaz2995No ratings yet

- 2003 Jcoma GT PF KKDocument7 pages2003 Jcoma GT PF KKAdrià TejeroNo ratings yet

- NESS - Nano-Electronic Simulation SoftwareDocument20 pagesNESS - Nano-Electronic Simulation SoftwareGurrampati Manikanta ReddyNo ratings yet

- Computationally Efficient Memristor Model With Hann Window FunctionDocument12 pagesComputationally Efficient Memristor Model With Hann Window FunctionAmmuNo ratings yet

- The Dimensional Effect of Breakdown Field in Zno Varistors: Shengtao Li, Jianying Li, Fuyi Liu, M A Alim and G ChenDocument5 pagesThe Dimensional Effect of Breakdown Field in Zno Varistors: Shengtao Li, Jianying Li, Fuyi Liu, M A Alim and G Chenluciferr49No ratings yet

- Hyperelastic Model For Large Deformation Analyses of 3D Interlock Composites PreformsDocument9 pagesHyperelastic Model For Large Deformation Analyses of 3D Interlock Composites PreformsLouis GrouNo ratings yet

- JamesDocument10 pagesJamesyuchun chouNo ratings yet

- Pattamad PanedpojamanDocument13 pagesPattamad PanedpojamanAli IsmaelNo ratings yet

- Modelling Concrete Structures Applying XFEM With A Mixed Mode Constitutive ModelDocument6 pagesModelling Concrete Structures Applying XFEM With A Mixed Mode Constitutive ModelAsma BousameNo ratings yet

- Earth Potential Rise (EPR) Computation For A Fault On Transmission Mains PoleDocument6 pagesEarth Potential Rise (EPR) Computation For A Fault On Transmission Mains PolenassarkiNo ratings yet

- Conducting Polymer Composites: Relation Between Electrical and Mechanical Properties ofDocument6 pagesConducting Polymer Composites: Relation Between Electrical and Mechanical Properties ofMiroslav PavlovićNo ratings yet

- M2-01 Interconnect ParasiticsDocument14 pagesM2-01 Interconnect ParasiticsCyrille MagdiNo ratings yet

- Jotun Thinner For Support StructuresDocument6 pagesJotun Thinner For Support Structuresthahir1429No ratings yet

- WWW ScribdDocument1 pageWWW ScribdArjun Dev P SNo ratings yet

- 2022 06 Poster Lmps NajjarDocument1 page2022 06 Poster Lmps Najjarعمر نجارNo ratings yet

- 3-1 Modelling ConsiderationsDocument18 pages3-1 Modelling Considerationsluis900000No ratings yet

- Filtre AerDocument2 pagesFiltre AerSilviu AlexandruNo ratings yet

- 350204011ws Class 4Document62 pages350204011ws Class 4Namita Sahu100% (1)

- RCB-4H Data SheetDocument15 pagesRCB-4H Data SheetjaliltaghdarehNo ratings yet

- Counters WBTS WN8 0 AlldataDocument273 pagesCounters WBTS WN8 0 Alldatakkchin86No ratings yet

- Radar Level Meter CatalogueDocument15 pagesRadar Level Meter CatalogueagusNo ratings yet

- Sign T10471Document2 pagesSign T10471Syed Hamzah Al-IdrusNo ratings yet

- 14-RAM&ROM - Dynamic Memory Is Built With Capacitors. A Stored Charge On The Capacitor Represents A Logical 1. No Charge Represents A Logic 0.Document8 pages14-RAM&ROM - Dynamic Memory Is Built With Capacitors. A Stored Charge On The Capacitor Represents A Logical 1. No Charge Represents A Logic 0.Nava KrishnanNo ratings yet

- UT Dallas Syllabus For cs2305.002.07s Taught by Simeon Ntafos (Ntafos)Document5 pagesUT Dallas Syllabus For cs2305.002.07s Taught by Simeon Ntafos (Ntafos)UT Dallas Provost's Technology GroupNo ratings yet

- Exam-Style Question:: Mathematical ModellingDocument4 pagesExam-Style Question:: Mathematical ModellingFadi AyyoubNo ratings yet

- DX DiagDocument33 pagesDX DiagsamihaNo ratings yet

- Earth'S Orbit Path Around The Sun EssayDocument3 pagesEarth'S Orbit Path Around The Sun EssaySebastián VegaNo ratings yet

- SOA and BPM - Architectural ViewDocument30 pagesSOA and BPM - Architectural ViewVithaya SuharitdamrongNo ratings yet

- Defects in MaterialDocument15 pagesDefects in MaterialSumit Kumar JhaNo ratings yet

- 12th Chemistry Vol.1 Book Back One Mark Questions English Medium PDF DownloadDocument19 pages12th Chemistry Vol.1 Book Back One Mark Questions English Medium PDF Downloadteddygamingyt201No ratings yet

- Flat Plate Collector IntroDocument4 pagesFlat Plate Collector IntrogcrupaNo ratings yet

- Introduction To Management Science 11th Edition Taylor Solution ManualDocument26 pagesIntroduction To Management Science 11th Edition Taylor Solution Manualharry100% (28)

- Centr Eur J BiolDocument8 pagesCentr Eur J Bioldhafer alhaidaryNo ratings yet

- Ch5 - CPU SchedulingDocument33 pagesCh5 - CPU SchedulingAditya ThakurNo ratings yet

- Microfinish VM 601Document14 pagesMicrofinish VM 601VCNo ratings yet

- Master Boot Record: Usman Mansoor Junaid Ali Husnain Manzoor Fahad AliDocument10 pagesMaster Boot Record: Usman Mansoor Junaid Ali Husnain Manzoor Fahad AliJunaidAliNo ratings yet

- TeleDNA SMSC Acceptance Test Plan UnitechDocument30 pagesTeleDNA SMSC Acceptance Test Plan Unitechankush_apjNo ratings yet

- Experiment No 3 - BOOLEAN ALGEBRA AND DE MORGANS THEOREMDocument8 pagesExperiment No 3 - BOOLEAN ALGEBRA AND DE MORGANS THEOREMJhon Lhoyd CorpuzNo ratings yet

- AABC Test Balance Proc PDFDocument189 pagesAABC Test Balance Proc PDFemrahNo ratings yet

- Expansion, Factorization, Simplifications, Quadratic Equations and GraphsDocument7 pagesExpansion, Factorization, Simplifications, Quadratic Equations and GraphsBurhan AzharNo ratings yet

- Steam Turbine Servomotor For Main Description and Reheat Stop ValvesDocument1 pageSteam Turbine Servomotor For Main Description and Reheat Stop Valvesparthibanemails5779No ratings yet

- INV 4835E DatasheetDocument3 pagesINV 4835E DatasheetEsteban RamirezNo ratings yet

- Ahmed Abdel Fattah Mahmoud Ahmed. - Paper 12Document19 pagesAhmed Abdel Fattah Mahmoud Ahmed. - Paper 12puppyarav2726No ratings yet

- Fat Rich Dairy Products: B. Tech. (Dairy Technology) DT-2 ResourcesDocument13 pagesFat Rich Dairy Products: B. Tech. (Dairy Technology) DT-2 ResourcesEasy ways2017No ratings yet

- Tos Second GradingDocument2 pagesTos Second GradingNodelyn ReyesNo ratings yet

- Siemens 1FT SimoDrive Servo Motor Planning Guide PDFDocument632 pagesSiemens 1FT SimoDrive Servo Motor Planning Guide PDFswooshcmk100% (1)