Professional Documents

Culture Documents

RW Tew 22

RW Tew 22

Uploaded by

Yong TonghannOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RW Tew 22

RW Tew 22

Uploaded by

Yong TonghannCopyright:

Available Formats

The use of this standard is governed by the "Texas Engineering Practice Act.

" No warranty of any kind is made by TxDOT for any purpose whatsoever.

TxDOT assumes no responsibility for the conversion of this standard to other formats or for incorrect results or damages resulting from its use.

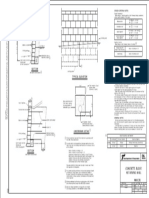

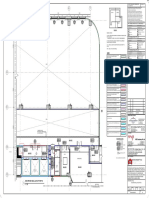

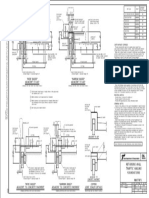

2'-0" Min

Roadway grade

DESIGN CRITERIA NOTES:

2H : 1V or flatter Design Parameters:

Crushed rock or

Base design of retaining walls on the following design parameters

cement stabilized

unless stated elsewhere in the plans:

backfill

Vertical and Top of wall

horizontal 2'-0"

Top mat 1 Random Backfill

Unit Weight = 120 pcf

control point (Embankment or

Existing Soils)

ϕ= 30° C = 0 psf

Unit Weight = 120 pcf

Select Backfill

ϕ= 30° C = 0 psf

2

Strut

1'-0" Strut 2 Limit allowable stresses and pullout of earth reinforcement in

accordance with current AASHTO Standard Specifications for Highway

Min Face mat

Filter fabric Bridges and Interim Specifications.

~ Stability Criteria:

Base design on the following factors of safety:

Sliding along the

Factor of Safety ≥ 1.5

base of the structure

Retained soil Face mat

Select backfill 3 Strut 2 Overturning Factor of Safety ≥ 2.0

Strut 2

~ Pullout of

Factor of Safety ≥ 1.5

Earth Reinforcement

Design the wall such that the base pressure resultant falls within

Earth reinforcement Reinforcing mat

the middle third of the retaining wall.

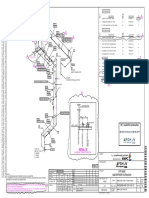

EARTH REINFORCEMENT:

Space vertical earth reinforcement at 24 inch maximum.

Provide earth reinforcement lengths adhering to the following:

2

2'-0" Max

Strut

6-foot minimum for walls 6 feet and shorter

8-foot minimum for walls over 6 feet tall,

Attach fabric to

or as shown elsewhere in the plans.

crosswire every 18"

Utilize a minimum W4.5 wire size for welded wire earth reinforcement.

Space longitudinal wire at maximum of 12 inches and transverse wire at

a maximum of 24 inches.

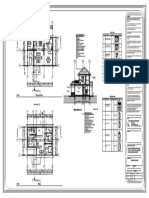

DETAIL OF WALL FACE

Geogrid earth reinforcement is permissible. If geogrid is to be used,

(Showing strut option.) provide a detail showing the connection between the welded wire face

basket and the geogrid earth reinforcement.

DISCLAIMER:

Provide non-metallic or galvanized reinforcement for any temporary

earth wall reinforcement that will be placed in the reinforced volume of

a permanent MSE wall.

Crushed rock or

Bottom of wall

cement stabilized

WALL FACE:

backfill 1 Provide top mat to stabilize top of wall. Contractor may propose

alternate method to stabilize top of wall for review. Provide welded wire in facing with a minimum W4.5 wire size. Space

2'-0"

wire at 6 inches maximum in both the horizontal and vertical directions.

2 Provide intermediate struts to stabilize face. Wall supplier may Design the facing to maintain a vertical position during wall backfilling.

propose alternate methods of face stabilization for review. Utilize wire struts, external bracing, or other means which provide

acceptable performance. Stop construction if the face does not remain

3 Shop drawings must include drainage provisions and details for vertical during wall backfilling until the system is modified to meet this

TYPICAL SECTION

backfill composed of: requirement.

(Showing top mat option.) Cement stabilized sand, Provide angled struts or a top mat to stabilize the top basket face.

Crushed concrete, or Space struts at 24 inch maximum.

Type CS fill with a fines content greater than 15%.

GENERAL NOTES:

Sections shown are for informational purposes only. Determine specific

geometry based on wall layouts and other plan information.

Extend the select backfill specified for use within the temporary earth

wall select volume a minimum of 1 foot horizontally beyond the end of the

earth reinforcement from the back of the 2-foot backfill zone.

Bridge

SPECIAL NOTE - FACE CONSTRUCTION Division

Standard

When constructing wire faced walls, it is critical that the area immediately behind the face mat be completely

filled. Failure to fill and compact this area will result in bulging of the face mats and settlement of the top of

wall. The filter fabric shall closely follow the contours of the face unit, with particular attention paid to the

lower corner of the basket. Pull the fabric into the corner and attach to the basket with hog rings or tie wire.

Extend the coarse rock or cement stabilized backfill in the 2-foot zone behind the face completely to the top

of the face mat. Take particular care not to leave a gap or void below the next layer of earth reinforcement. TEMPORARY EARTH

RETAINING WALL

RW(TEW)

FILE: RW-TEW-22.dgn DN: TxDOT CK: TxDOT DW: JER CK: RLE

C TxDOT June 2022 CONT SECT JOB HIGHWAY

REVISIONS

DATE:

FILE:

DIST COUNTY SHEET NO.

You might also like

- Recommended Practice: Windows™ Communication ApiDocument106 pagesRecommended Practice: Windows™ Communication Apijohn wright100% (1)

- HVACR Supermarket Piping DiagramDocument1 pageHVACR Supermarket Piping DiagramAngel sandovalNo ratings yet

- A13、A13A ServiceManual PDFDocument1,333 pagesA13、A13A ServiceManual PDFmultiservicios100% (1)

- How To Select A Rotary AirlockDocument1 pageHow To Select A Rotary Airlockshreemug100% (1)

- RW CB 22Document1 pageRW CB 22Yong TonghannNo ratings yet

- 2023-09-22 Link Bridge AIPDocument6 pages2023-09-22 Link Bridge AIPMorris KwokNo ratings yet

- D F PlanDocument1 pageD F PlanstanleyNo ratings yet

- It5 ElecDocument1 pageIt5 Elecmanhasr80No ratings yet

- Section R-R: Issued For ConstructionDocument1 pageSection R-R: Issued For ConstructionjafarNo ratings yet

- A.Typical Roadway Section: Pavement Design ParametersDocument1 pageA.Typical Roadway Section: Pavement Design ParametersrickNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- OC LeasedDocument4 pagesOC Leasedanoop.bigassetsinfraNo ratings yet

- Structural PlansDocument17 pagesStructural PlansRODEL YUNTINGNo ratings yet

- 9946Z - 0657-SP-SL-PL-C-G20-001 (P3) - Proposed Levels Plan (Sheet 1 of 2)Document1 page9946Z - 0657-SP-SL-PL-C-G20-001 (P3) - Proposed Levels Plan (Sheet 1 of 2)jmdavies.isNo ratings yet

- Basement DDA Car ParkingDocument1 pageBasement DDA Car Parkingrajen raghwaniNo ratings yet

- Amphi TheatreDocument1 pageAmphi TheatreanzaniNo ratings yet

- 4274-CD-VD-LG201000019D1004001 - US CommentedDocument1 page4274-CD-VD-LG201000019D1004001 - US CommentedUnmesh ShuklaNo ratings yet

- Ground Floor 1:100: Section S-01Document1 pageGround Floor 1:100: Section S-01Kamagara Roland AndrewNo ratings yet

- KH21029 00 GN DD FG501Document1 pageKH21029 00 GN DD FG501AHMED TAHERNo ratings yet

- Mefort Marondera ModelDocument1 pageMefort Marondera Modelbryan mutariNo ratings yet

- D01 D02 D03 W01 W02 Window and Door Schedule: Lobby DisabledDocument1 pageD01 D02 D03 W01 W02 Window and Door Schedule: Lobby DisabledIan ChumaNo ratings yet

- T-DAP-A2362-2D Manufacturing - Fabrication Drawing & GA Plan-REV-05Document5 pagesT-DAP-A2362-2D Manufacturing - Fabrication Drawing & GA Plan-REV-05radhi_rads89No ratings yet

- Tramo 0+00 - 1+200 PDFDocument1 pageTramo 0+00 - 1+200 PDFEnrique Antonio Saavedra VieyraNo ratings yet

- AMEC Future of OilsandsDocument16 pagesAMEC Future of OilsandsForexFFNo ratings yet

- Prepone AreaDocument1 pagePrepone Areasumit pandeyNo ratings yet

- DMH5Document1 pageDMH5Keyvin dela CruzNo ratings yet

- 1 J I:'a L / Gi: I I I I I I I I IDocument1 page1 J I:'a L / Gi: I I I I I I I I IShivendra KumarNo ratings yet

- Detail of Diversion Work Sections2Document1 pageDetail of Diversion Work Sections2RODEL YUNTINGNo ratings yet

- Bofinet-Gabs-Arch-Guard-141 Rev 5Document1 pageBofinet-Gabs-Arch-Guard-141 Rev 5zhong ganNo ratings yet

- Sewer Pipe Line (DIA: Ø1800MM)Document1 pageSewer Pipe Line (DIA: Ø1800MM)ashis maityNo ratings yet

- Section A-A: Issued For ConstructionDocument1 pageSection A-A: Issued For ConstructionjafarNo ratings yet

- F-04-2307-10.2-Partition Detail-F-04Document1 pageF-04-2307-10.2-Partition Detail-F-04Thinh NguyenNo ratings yet

- Vario GT 24: The Variable Girder Wall Formwork SystemDocument3 pagesVario GT 24: The Variable Girder Wall Formwork SystemLaw Chee SeongNo ratings yet

- Montgomery County, Maryland Basemap W/ WSSC Grid LinesDocument1 pageMontgomery County, Maryland Basemap W/ WSSC Grid LinesM-NCPPCNo ratings yet

- Begonia BrochureDocument2 pagesBegonia BrochureNorazmi Abdul RahmanNo ratings yet

- 3RD Storey Wall Layout Part BDocument1 page3RD Storey Wall Layout Part BDhrubajyoti BordoloiNo ratings yet

- Layout Bandung Peta 1Document1 pageLayout Bandung Peta 1Novan RizkyNo ratings yet

- Mlolongo Project Architectural PDFDocument1 pageMlolongo Project Architectural PDFNewtonNo ratings yet

- Mlolongo Project ArchitecturalDocument1 pageMlolongo Project ArchitecturalNewtonNo ratings yet

- APPROVALDocument1 pageAPPROVALPramodh ChandranNo ratings yet

- Sheet Title: Part Plan of Toilet: Working DrawingDocument1 pageSheet Title: Part Plan of Toilet: Working DrawingAditiNo ratings yet

- P6022mab Amd 128 11541 01 - S4Document1 pageP6022mab Amd 128 11541 01 - S4Alam MD SazidNo ratings yet

- Amit GuptaDocument1 pageAmit GuptaSaurabh PandeyNo ratings yet

- Aykut TeknikDocument3 pagesAykut TeknikMurat SuakNo ratings yet

- B C D E F G A: Motiongate ExpansionDocument6 pagesB C D E F G A: Motiongate ExpansionyosiboyNo ratings yet

- Stadium Auto Stair InfoDocument1 pageStadium Auto Stair Infokatar kumarNo ratings yet

- RW SFB 22 - 2Document1 pageRW SFB 22 - 2Yong TonghannNo ratings yet

- 006-Singh-SP.01-Site Plan & General NotesDocument1 page006-Singh-SP.01-Site Plan & General NotesLeonel DavalosNo ratings yet

- Dealer Copy - Not For Resale: S/N 512212001-16381 S/N 51244001 - 40358 (Printed March 2011) MC2532Document25 pagesDealer Copy - Not For Resale: S/N 512212001-16381 S/N 51244001 - 40358 (Printed March 2011) MC2532Sgly ZemogNo ratings yet

- KH21029 00 GN DD FG001Document1 pageKH21029 00 GN DD FG001AHMED TAHERNo ratings yet

- CDHC DWG SD 125 MB01 ST 2004 1Document1 pageCDHC DWG SD 125 MB01 ST 2004 1HAITHAM ALINo ratings yet

- BPS-STR-201-R1-Foundation Plan Other Details For Compound WallDocument1 pageBPS-STR-201-R1-Foundation Plan Other Details For Compound Wallsri projectssNo ratings yet

- R O A D SITE PLAN Scale 1: 500Document1 pageR O A D SITE PLAN Scale 1: 500Mercyline MaworereNo ratings yet

- Wheeled Excavator Electrical System Magnetic Controller: Harness and Wire Electrical Schematic SymbolsDocument2 pagesWheeled Excavator Electrical System Magnetic Controller: Harness and Wire Electrical Schematic Symbolsمهدي شقرونNo ratings yet

- Plans For Shop DrawingsDocument5 pagesPlans For Shop DrawingsApple CabreraNo ratings yet

- RW TRF 22Document1 pageRW TRF 22Yong TonghannNo ratings yet

- Drawing 3.Document1 pageDrawing 3.tiyaniNo ratings yet

- Bloques Dinamicos - recover-LAM1Document1 pageBloques Dinamicos - recover-LAM1Marcelino SalazarNo ratings yet

- Arch 1Document3 pagesArch 1Alfred BermudezNo ratings yet

- He608073 VFV HLG S02 - 2D - Schme DR Eo 0214Document1 pageHe608073 VFV HLG S02 - 2D - Schme DR Eo 0214loredana savoaiaNo ratings yet

- 0000gf Also AsloaDocument1 page0000gf Also AsloaAhmadjakwarNo ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: MathFrom EverandInstant Assessments for Data Tracking, Grade 1: MathRating: 4 out of 5 stars4/5 (1)

- RW SFB 22 - 2Document1 pageRW SFB 22 - 2Yong TonghannNo ratings yet

- RW SFB 22 - 2Document1 pageRW SFB 22 - 2Yong TonghannNo ratings yet

- GC Hurst - 07082022Document14 pagesGC Hurst - 07082022Yong TonghannNo ratings yet

- Easy & Jane Warehouse - 07142022Document14 pagesEasy & Jane Warehouse - 07142022Yong TonghannNo ratings yet

- CG TylerDocument5 pagesCG TylerYong TonghannNo ratings yet

- Renolds Lane 07122022Document36 pagesRenolds Lane 07122022Yong TonghannNo ratings yet

- Latest 2020 Microsoft AZ-400 Dumps Question & Answers - Microsoft AZ-400Document13 pagesLatest 2020 Microsoft AZ-400 Dumps Question & Answers - Microsoft AZ-400noranayelNo ratings yet

- System Resources On PC (IRQ, DMA, I-OAddress)Document4 pagesSystem Resources On PC (IRQ, DMA, I-OAddress)guilhangNo ratings yet

- 1110 ChemistryDocument6 pages1110 ChemistryPatrickNo ratings yet

- TTMO SyllabusDocument12 pagesTTMO SyllabusShavak SinananNo ratings yet

- Condition Monitoring Through Non Destructive TechniqueDocument27 pagesCondition Monitoring Through Non Destructive Techniquepraveenkumar_bs2005No ratings yet

- Using Skellam's Distribution To Assess Soccer Team PerformanceDocument9 pagesUsing Skellam's Distribution To Assess Soccer Team PerformanceBartoszSowulNo ratings yet

- Multiple Objetc Tracking Method Using Kalman FilterDocument5 pagesMultiple Objetc Tracking Method Using Kalman FiltermaxzoelNo ratings yet

- Miscellaneous Practice 4Document3 pagesMiscellaneous Practice 4Bryan Fury100% (2)

- HTML Viva QuestionsDocument6 pagesHTML Viva QuestionsSubha Sarah100% (2)

- Photosynthesis Review QuestionsDocument4 pagesPhotosynthesis Review Questionsdee eeNo ratings yet

- Power Eectronics Lab Manual#06Document8 pagesPower Eectronics Lab Manual#06Muhammad Salman ShahidNo ratings yet

- Service ManualDocument429 pagesService ManualChris CoulsonNo ratings yet

- 1mesh TrackDocument92 pages1mesh TrackAbdon CastroNo ratings yet

- 04 Laws of Motion Formula Sheets Quizrr PDFDocument7 pages04 Laws of Motion Formula Sheets Quizrr PDFAryan DeNo ratings yet

- How FACTS Controllers Function in An AC Transmission System: Series Controllers TopicsDocument16 pagesHow FACTS Controllers Function in An AC Transmission System: Series Controllers TopicsAwesomegalNo ratings yet

- Inferential StatisticsDocument10 pagesInferential StatisticsSapana SonawaneNo ratings yet

- Regression Analysis: Model Building: Learning ObjectivesDocument38 pagesRegression Analysis: Model Building: Learning ObjectivesAnh DoNo ratings yet

- GM OBD - OBD2 CodesDocument33 pagesGM OBD - OBD2 CodesAmir Danesh100% (1)

- Heat Transfer, Incopera 977 988Document12 pagesHeat Transfer, Incopera 977 988Rayhan HakimNo ratings yet

- 10.2 Oracle Statement-Level Triggers by Practical ExamplesDocument4 pages10.2 Oracle Statement-Level Triggers by Practical ExamplesFaiyaz RazaNo ratings yet

- Physics Learning MaterialDocument7 pagesPhysics Learning Materialasdfghjkl0118No ratings yet

- CHEG411 Chemical Reaction Engineeirng. F PDFDocument206 pagesCHEG411 Chemical Reaction Engineeirng. F PDFSarang GohNo ratings yet

- Keepers Smart Contracts Audit v0.1 GingerSecDocument60 pagesKeepers Smart Contracts Audit v0.1 GingerSecAbhishek ShuklaNo ratings yet

- GTSTRUDL 32 - Student Edition 13: Quick-Start InstructionsDocument3 pagesGTSTRUDL 32 - Student Edition 13: Quick-Start InstructionsVimalan KannanNo ratings yet

- Expert: Rotating MachineryDocument13 pagesExpert: Rotating MachineryJolito RamosNo ratings yet

- Operation Manual For ArcInfoDocument33 pagesOperation Manual For ArcInfoChristian ChacónNo ratings yet