Professional Documents

Culture Documents

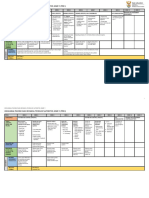

Scope For Skills Automotive Technology 2023

Scope For Skills Automotive Technology 2023

Uploaded by

Nigel EvertsonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scope For Skills Automotive Technology 2023

Scope For Skills Automotive Technology 2023

Uploaded by

Nigel EvertsonCopyright:

Available Formats

1

Western Cape Education Department

Mr. Kevin Malan

Directorate: Curriculum FET

Kevin.Malan2@westerncape.gov.za

Tel: +27 21 830 3854 Cell: 084 657 3946

REFERENCE: 06/07/2023

ENQUIRIES: KP MALAN

PRACTICAL SKILLS COMPETITION 02 SEPTEMBER 2023: MECHANICAL

TECHNOLOGY

The PRACTICAL SKILLS COMPETITION by a resolution of the Competitions Committee and

following the set guidelines, the Standing Competition Rules, has adopted the following minimum

requirements for the Skills Competition.

INTRODUCTION:

The PRACTICAL SKILLS COMPETITION 2023 includes all SCHOOLS offering

TECHNICAL EDUCATION in the Western Cape. The subject of Mechanical Technology consists

of three subject disciplines Automotive, Fitting & Machining and Welding & Metalwork Technology.

Purpose:

To develop competency and skills in the field of Mechanical Technology.

Positive competition motivates students and inspires them to strive for excellence.

To integrate technology and career instruction with a chosen career path or field of study.

The competition will evaluate each participant's skills and recognize outstanding learners for their

excellence in their field of Mechanical Technology.

All participating schools will enter ONE Grade 11 learner to compete and demonstrate their

competence and skills in various tasks and activities.

THE AUTOMOTIVE TECHNOLOGY ACTIVITIES

c e d o n lin e .w e ste rn c a p e .g o v.za

Em p lo ym e n t a n d sa la ry e n q u irie s: 0861 819 919 | Sa fe Sc h o o ls: 0800 45 46 47

We ste rn C a p e Ed u c a tio n De p a rtm e n t

2

Activity 1: HAND SKILLS – MANUFACTURING OF ARTEFACT

Activity 2: ENGINE COMPONENTS MEASURING.

Activity 3: FRONT DISC BRAKE ASSESSMENT

Activity 4: SELECT AND USE VEHICLE LIFTING EQUIPMENT

THE RELEVANCE AND SIGNIFICANCE OF THIS DOCUMENT

This document contains information about the standards required to compete in this skills competition,

and the assessment principles, methods, and procedures that govern the competition. The competitor

must ensure they familiarise themselves with the scope of work and understand what is expected from

them.

GENERAL SKILLS COMPETITION INFORMATION

The Bellville Technical High School will host the skills competition on 02 September 2023,

which is open to all learners and free of charge.

Each participant must be accompanied by a teacher from their school.

On the day of the contest, participants must sign an attendance register between 08h00 and 08h30.

A basic lunch and a beverage will be provided for contestants and teachers, but those with special

dietary requirements should bring their food (all food provided will be Halaal).

Participants are required to bring their toolbox, equipped with all the necessary tools & equipment

to complete the tasks allocated task.

All the materials required for the competition will be provided.

Participants must wear appropriate personal protective equipment (PPE) and will not be allowed

to compete without it.

Each school may only enter ONE learner to participate in the competition.

The contest will last for 5 HOURS.

AUTOMOTIVE TECHNOLOGY - PRACTICAL TASK

Competitor’s knowledge and skills will be assessed based on the following criteria:

Participating schools may only enter ONE learner, who should practice the two activities under the

teacher’s guidance. These activities will incorporate similar procedures and skills to those that will

c e d o n lin e .w e ste rn c a p e .g o v.za

Em p lo ym e n t a n d sa la ry e n q u irie s: 0861 819 919 | Sa fe Sc h o o ls: 0800 45 46 47

We ste rn C a p e Ed u c a tio n De p a rtm e n t

3

be given at the competition.

Participants are required to bring their toolbox containing all the tools necessary tools and equipment

required on the day of the competition. Participants will not be allowed to use sandpaper.

COMPETITOR’S TOOLBOX AND SUGGESTED TOOLS REQUIRED:

BMS mild steel plate 100 x 50 x 5 mm

Competitors must bring their toolbox as listed below however they may add to the list any other

tool/s they may want to include.

AUTOMOTIVE COMPETITORS TOOLBOX CONTENT:

Hacksaw with blades, Marking blue

Steel rule 300mm, G-clamps,

Soft face Vice grips

Ball pein hammer, Tap set M12 x 1.75 mm.

Scriber, Stock & die M12 x 1.75mm

Centre punch, Tapmatic cutting fluid.

Drill bits, 6mm, 6.5mm, Vernier calliper,

Portable drilling machine Micrometer,

Hand files, Telescopic gauges,

Engineers square, Dial gauge,

Combination square, PPE.

c e d o n lin e .w e ste rn c a p e .g o v.za

Em p lo ym e n t a n d sa la ry e n q u irie s: 0861 819 919 | Sa fe Sc h o o ls: 0800 45 46 47

We ste rn C a p e Ed u c a tio n De p a rtm e n t

4

SAFETY

Safety is a priority at the provincial skills competition:

Ensuring safety is of utmost importance at the provincial skills competition:

Participants failing to adhere to basic safety requirements will be warned and subsequently

halted by the judges to prevent harm to themselves or participants.

Participants are obligated to wear the necessary personal protective equipment.

Loose apparel, jewellery, and long hair must be tied back or secured with a hairnet.

As a school event, all school regulations must be followed and respected.

SPECTATORS

Spectators must not interact with participants or teachers during the competition for safety

reasons and fairness.

Although entrance to the competition is free, overcrowding in the workshops will not be

allowed to ensure safety.

There will be a tuck shop and exhibitors showcasing their products at the venue.

The judges' decision is final, and entrants’ spectators and teachers may not enter negotiations or

correspondence.

AUTOMOTIVE ACTIVITIES

ACTIVITY No 1: HYDRAULIC DISC BRAKES

c e d o n lin e .w e ste rn c a p e .g o v.za

Em p lo ym e n t a n d sa la ry e n q u irie s: 0861 819 919 | Sa fe Sc h o o ls: 0800 45 46 47

We ste rn C a p e Ed u c a tio n De p a rtm e n t

5

ACTIVITY No 2: MEASURING OF ENGINE COMPONENTS

ACTIVITY No 3: MARKING OFF AND MANUFACTURING ACTIVITY

Participants will jack up the front of a motor car and place it on two tressles in the front of the car.

After the judges have assessed the jacking up procedure, you will be asked to lower it again the way

you found it. All equipment used must be made safe. Good housekeeping practices and safety

c e d o n lin e .w e ste rn c a p e .g o v.za

Em p lo ym e n t a n d sa la ry e n q u irie s: 0861 819 919 | Sa fe Sc h o o ls: 0800 45 46 47

We ste rn C a p e Ed u c a tio n De p a rtm e n t

6

precautions will be assessed throughout the activity.

MARKING OFF AND MANUFACTURING ACTIVITY - SCORING Marks

1 Assessment of the interpretation of the design brief. 5

2 Accuracy of marking off and applying marking blue. 5

3 The safe and correct application of hand tools. 5

4 The completion and accuracy of all filing done. 5

4 The safe and correct application of using the drilling machine. 5

c e d o n lin e .w e ste rn c a p e .g o v.za

Em p lo ym e n t a n d sa la ry e n q u irie s: 0861 819 919 | Sa fe Sc h o o ls: 0800 45 46 47

We ste rn C a p e Ed u c a tio n De p a rtm e n t

7

5 The safe and correct use of the tapping procedure. 5

6 Accuracy and squareness of slotted holes. 5

7 Accuracy and squareness of final product. 5

8 Safe working procedures. 5

9 Application of good housekeeping procedures. 5

TOTAL 50

HYDRAULIC DISC BRAKE - SCORING Marks

1 Interpreting the design brief and doing the marking off. 5

2 Level of competence in changing brake pads. 10

3 Aptitude and competence in using measuring instruments. 10

4 Accuracy of measurements taken as per instructions. 10

5 Assessment of the completed condition report. 5

6 Safe working procedures. 5

7 Application of good housekeeping procedures. 5

TOTAL 50

MEASURING OF ENGINE COMPONENTS - SCORING Marks

1 Assessment and interpretation of the design brief. 5

2 Application of the correct tool for the correct activity 5

3 Aptitude and competence with the use of measuring instruments. 5

4 Assessment of recorded measurements. 5

5 Assessment of the accuracy of readings taken. 10

6 Assessment of safe working procedures. 10

c e d o n lin e .w e ste rn c a p e .g o v.za

Em p lo ym e n t a n d sa la ry e n q u irie s: 0861 819 919 | Sa fe Sc h o o ls: 0800 45 46 47

We ste rn C a p e Ed u c a tio n De p a rtm e n t

8

7 Application of good housekeeping procedures. 10

TOTAL 50

JACKING-UP OF CAR - SCORING Marks

1 Assessment of the interpretation of the design brief. 5

2 Application of the correct use of lifting equipment. 10

3 Aptitude and competence with the use of tressles. 5

4 Aptitude and competence with removing the tressles. 5

5 Aptitude and competence of swopping wheels. 10

6 Aptitude and competence in using the torque wrench. 5

7 Assessment of safe working procedures. 5

8 Application of good housekeeping procedures. 5

TOTAL 50

c e d o n lin e .w e ste rn c a p e .g o v.za

Em p lo ym e n t a n d sa la ry e n q u irie s: 0861 819 919 | Sa fe Sc h o o ls: 0800 45 46 47

We ste rn C a p e Ed u c a tio n De p a rtm e n t

You might also like

- ETCP Electrical Handbook V2Document28 pagesETCP Electrical Handbook V2Will HarridgeNo ratings yet

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingFrom EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNo ratings yet

- PE 11 MODULE Quarter 2 Week 1 4Document9 pagesPE 11 MODULE Quarter 2 Week 1 4Maria Elena ViadorNo ratings yet

- Bantu DictionaryDocument468 pagesBantu DictionaryNaja Nzumafo Mansakewoo100% (5)

- Human Resource EthicsDocument21 pagesHuman Resource Ethicskamdica100% (3)

- Adobe Scan 05 Aug 2022Document2 pagesAdobe Scan 05 Aug 2022Nitjot kaurNo ratings yet

- PCN Examination and Training Fee StructureDocument3 pagesPCN Examination and Training Fee StructureKarthik Karunanidhi67% (3)

- Gme Xii Prospectus Feb 2014Document24 pagesGme Xii Prospectus Feb 2014Vijay BhaskarNo ratings yet

- CV Dinesh 07-06-2023Document4 pagesCV Dinesh 07-06-2023Dinesh MNo ratings yet

- Vacancy - Electrician - Instrument TechnicianDocument2 pagesVacancy - Electrician - Instrument Technicianfrimponglawrence073No ratings yet

- Rakesh Resume UpdatedDocument3 pagesRakesh Resume UpdatedFactology With JeetNo ratings yet

- Document (3) ParthDocument24 pagesDocument (3) Parth413 YASH MANENo ratings yet

- Course Syllabus For ElectricalDocument8 pagesCourse Syllabus For ElectricalovoNo ratings yet

- 127 Memo Step GuideDocument7 pages127 Memo Step GuideaphrodisiacoNo ratings yet

- Electrical and Electronic Quiz June 2019Document17 pagesElectrical and Electronic Quiz June 2019Piccolo OrsoNo ratings yet

- 111, NDT BrochureDocument4 pages111, NDT Brochuresmsunil12345No ratings yet

- Vinay Admit Card PDFDocument2 pagesVinay Admit Card PDFAkansha SinghNo ratings yet

- 5th Sem Admit Card DevendraDocument2 pages5th Sem Admit Card Devendradev singhNo ratings yet

- MCC-Business & Technology WELD 120Document5 pagesMCC-Business & Technology WELD 120chris mcwilliamsNo ratings yet

- 2 - Electrical Unit Standards For Master Installation Electrician - 2023Document5 pages2 - Electrical Unit Standards For Master Installation Electrician - 2023straussamcNo ratings yet

- Sachin U. SonkusareDocument3 pagesSachin U. Sonkusarepbw123No ratings yet

- Saanu SwepDocument16 pagesSaanu Swepdaniel ayobamiNo ratings yet

- Naukri Maheshwali (8y 0m)Document4 pagesNaukri Maheshwali (8y 0m)3asNo ratings yet

- Jaipur National UniversityDocument4 pagesJaipur National Universitysushil kumarNo ratings yet

- ATTAR Hands On Intro To NDTDocument3 pagesATTAR Hands On Intro To NDTRony Prayitno Simeon0% (1)

- Rajasthan Technical University, Kota: (Subject To Clearence of Rtu/Exam Centre) (Please Take Color Print Out Preferebly)Document2 pagesRajasthan Technical University, Kota: (Subject To Clearence of Rtu/Exam Centre) (Please Take Color Print Out Preferebly)Gaddam ManiNo ratings yet

- MEENA Internation NDT TrainingDocument45 pagesMEENA Internation NDT Trainingahmzahid100% (1)

- Course Syllabus For Basic Maintenance and Light RepairDocument2 pagesCourse Syllabus For Basic Maintenance and Light RepairovoNo ratings yet

- Hasan 313 PDFDocument3 pagesHasan 313 PDFHasan MulaniNo ratings yet

- Course 1676190248Document1 pageCourse 1676190248rezwan.itNo ratings yet

- Resume Chethan PDFDocument5 pagesResume Chethan PDFchakramsNo ratings yet

- Wote Technical Training Institute: Office of The RegistrarDocument13 pagesWote Technical Training Institute: Office of The RegistrarMWANGA PRODUCTIONNo ratings yet

- National Council For Training & Social Research: WebsiteDocument14 pagesNational Council For Training & Social Research: WebsiteAshutoshBhattNo ratings yet

- SYL Mechanic Motor Vehicle 08-06-14Document43 pagesSYL Mechanic Motor Vehicle 08-06-14swami061009No ratings yet

- Abhi Admit CardDocument2 pagesAbhi Admit CardAkash singhNo ratings yet

- MC ASC Q9719 Auto e Rickshaw Driver Assistant Service TechnicianDocument18 pagesMC ASC Q9719 Auto e Rickshaw Driver Assistant Service TechnicianALEX BSANo ratings yet

- QU - NO-16, AC Guards, Police Quarters, Near Nelofer Hospital Lane, Lakdikapul, Hyd,-500004Document3 pagesQU - NO-16, AC Guards, Police Quarters, Near Nelofer Hospital Lane, Lakdikapul, Hyd,-500004Manoj MadduriNo ratings yet

- Wa0024.Document40 pagesWa0024.nnabuchichideraNo ratings yet

- Test 1 Mech610 - MQDocument2 pagesTest 1 Mech610 - MQferasNo ratings yet

- National Apprentice & Industrial Training AuthorityDocument30 pagesNational Apprentice & Industrial Training AuthorityTharindu RanathungaNo ratings yet

- SOP For RecruitmentDocument8 pagesSOP For RecruitmentSHRUTINo ratings yet

- Parashuram: Career AspirationDocument4 pagesParashuram: Career AspirationKomal ZopeNo ratings yet

- Am2 Assessment of Occupational Competence Candidates Accordingly The Am2 ProvidesDocument26 pagesAm2 Assessment of Occupational Competence Candidates Accordingly The Am2 Providesdvt2365No ratings yet

- Eto FaqDocument5 pagesEto Faqkosalsuresh5No ratings yet

- Nptel: National Programme On Technology Enhanced LearningDocument2 pagesNptel: National Programme On Technology Enhanced LearningRohit YadavNo ratings yet

- The Impact of Customer Service Managemen PDFDocument43 pagesThe Impact of Customer Service Managemen PDFDiaby Ndem100% (1)

- Trenton High School: 2601 Charlton Trenton, MI. 48180 734-6924530 Ext 1307Document5 pagesTrenton High School: 2601 Charlton Trenton, MI. 48180 734-6924530 Ext 1307Hasan AkdagNo ratings yet

- Electrical Supervisor Resume 2022Document3 pagesElectrical Supervisor Resume 2022Ahmed NasserNo ratings yet

- 06 StOff DRDO EngDocument7 pages06 StOff DRDO Engjai vermaNo ratings yet

- Anglo-Eastern Maritime Academy: Pre Sea Training For Graduate Engineers (GME) CourseDocument27 pagesAnglo-Eastern Maritime Academy: Pre Sea Training For Graduate Engineers (GME) CourseDeepak RameshNo ratings yet

- Curriculum Vitae: Ravi Ranjan Prakash Mobile Number: 9160994604,7903191741,8297013425 Mail IdDocument3 pagesCurriculum Vitae: Ravi Ranjan Prakash Mobile Number: 9160994604,7903191741,8297013425 Mail IdRAVINo ratings yet

- E4d Expand Knowledge & Build SkillsDocument1 pageE4d Expand Knowledge & Build SkillsHenryScheinCanadaNo ratings yet

- Cable Avoidance Tool (C.A.T) and Genny Training: What Does The Course Involve?Document2 pagesCable Avoidance Tool (C.A.T) and Genny Training: What Does The Course Involve?Ronald AranhaNo ratings yet

- Https WWW - Rtuexam.net Student ChecKAdmitcarD - PHPDocument2 pagesHttps WWW - Rtuexam.net Student ChecKAdmitcarD - PHPAkshay KumarNo ratings yet

- NDT Training BrochureDocument4 pagesNDT Training BrochureSafiq UddinNo ratings yet

- Rajasthan Technical University, KotaDocument2 pagesRajasthan Technical University, KotaSaloni SaxenaNo ratings yet

- Jto NotificationDocument4 pagesJto NotificationAnonymous DVvU2cP100% (1)

- 2024 Graduate Traineeship Intake and One Assistant - 231221 - 151029Document1 page2024 Graduate Traineeship Intake and One Assistant - 231221 - 151029Modesty GumbieNo ratings yet

- Suryamitra Curriculum GuideDocument19 pagesSuryamitra Curriculum GuideKetan WarikooNo ratings yet

- Jet Alexandra '24 Rulebook.Document11 pagesJet Alexandra '24 Rulebook.kanimozhiumakanthan16No ratings yet

- CINDE Course Calendar - Feb 3, 2016Document32 pagesCINDE Course Calendar - Feb 3, 2016PeterNo ratings yet

- Myo Lwin Oo: Address Phone Email Personal InformationDocument7 pagesMyo Lwin Oo: Address Phone Email Personal InformationMyolwinooNo ratings yet

- Ecs CarteDocument59 pagesEcs Cartevranceanu bogdanNo ratings yet

- 1.210 ATP 2023-24 GR 12 Mech Tech Aut FinalDocument4 pages1.210 ATP 2023-24 GR 12 Mech Tech Aut FinalNigel EvertsonNo ratings yet

- 1.060 ATP 2023-24 GR 11 Mech Tech Aut FinalDocument4 pages1.060 ATP 2023-24 GR 11 Mech Tech Aut FinalNigel EvertsonNo ratings yet

- Task No 3 - Front Disc Brake AssessmentDocument1 pageTask No 3 - Front Disc Brake AssessmentNigel EvertsonNo ratings yet

- Task No 2-Engine Components MeasuringDocument3 pagesTask No 2-Engine Components MeasuringNigel EvertsonNo ratings yet

- MSW SyllabusDocument64 pagesMSW SyllabusLakshmi KingNo ratings yet

- STGY5900 - CourseDocument18 pagesSTGY5900 - CourseRajeshNo ratings yet

- TOEFL ListeningDocument26 pagesTOEFL ListeningKhalid MuhammadNo ratings yet

- LittleSeedSeed OverviewDocument Jan29Document9 pagesLittleSeedSeed OverviewDocument Jan29Trang Ngô ThuNo ratings yet

- The Merciad, April 9, 1976Document6 pagesThe Merciad, April 9, 1976TheMerciadNo ratings yet

- EL 102.04 Course SyllabusDocument3 pagesEL 102.04 Course SyllabusElif ErdemNo ratings yet

- Lab Report-1Document5 pagesLab Report-1Tekalegn DemsisNo ratings yet

- Metaphor Homework Year 5Document4 pagesMetaphor Homework Year 5cfhfp6dd100% (1)

- Tugas 13 - Kelompok 9 - Chapter 16Document16 pagesTugas 13 - Kelompok 9 - Chapter 16Mochammad AriefNo ratings yet

- IELTS Express Upper-Intermediate Unit 1 SBDocument8 pagesIELTS Express Upper-Intermediate Unit 1 SBRigoberto Carbajal ValdezNo ratings yet

- Proofreading Exercise - ANSWERSDocument2 pagesProofreading Exercise - ANSWERSnindyNo ratings yet

- Biology Module 2020 2021Document266 pagesBiology Module 2020 2021Titser G.No ratings yet

- T.A.Pai Management Institute (Tapmi), Manipal: Consumer BehaviourDocument8 pagesT.A.Pai Management Institute (Tapmi), Manipal: Consumer Behaviourparvathi chandramohanNo ratings yet

- Kra4 Objective 12 For QualityefficiencyDocument5 pagesKra4 Objective 12 For QualityefficiencyBryan SmileNo ratings yet

- JooHee Jhee's Career PlanDocument1 pageJooHee Jhee's Career Planca3joohee12No ratings yet

- Vignan's Institute of Engineering For WomenDocument2 pagesVignan's Institute of Engineering For WomenandhracollegesNo ratings yet

- Rizal SyllabusDocument6 pagesRizal SyllabusMari Joy MarañoNo ratings yet

- q3 Slm7 English 4 FinalDocument24 pagesq3 Slm7 English 4 FinalCleanne FloresNo ratings yet

- The Homework MachineDocument8 pagesThe Homework Machinecjcq3442100% (1)

- Theories of Second Language Acquisition: Input Hypothesis (Krashen)Document15 pagesTheories of Second Language Acquisition: Input Hypothesis (Krashen)Shi Ze100% (1)

- Chapter1 EnrichmentDocument10 pagesChapter1 Enrichmentapi-238096556No ratings yet

- Jhs-Tos Science 8 Q2Document1 pageJhs-Tos Science 8 Q2richardsamranoNo ratings yet

- Professional Ethics - Course Outline - LW404 - 03-04 PDFDocument11 pagesProfessional Ethics - Course Outline - LW404 - 03-04 PDFBillionarbyTwentfive100% (2)

- MOA Transpo Brgy-Pinsao-ProperDocument3 pagesMOA Transpo Brgy-Pinsao-ProperChester Bagwan MadongitNo ratings yet

- Cambridge International A Level: Chinese 9715/22 May/June 2022Document19 pagesCambridge International A Level: Chinese 9715/22 May/June 2022janicechuNo ratings yet

- CA Intermediate Paper-7BDocument202 pagesCA Intermediate Paper-7BAnand_Agrawal19No ratings yet

- PROJECT WATCH Action Plan. 1Document1 pagePROJECT WATCH Action Plan. 1Danica Cascabel Lpt96% (23)