Professional Documents

Culture Documents

Case Study Week 11

Case Study Week 11

Uploaded by

iwaleedwasimCopyright:

Available Formats

You might also like

- Supply Chain Management Mba Project DownloadDocument7 pagesSupply Chain Management Mba Project DownloadAhamed Ibrahim100% (2)

- Fourpracticesystem Unit2Document15 pagesFourpracticesystem Unit2Hari BahadurNo ratings yet

- HBL Training and DevelopmentDocument18 pagesHBL Training and Developmentkiran-mahmood-6943No ratings yet

- Study of Supply Chain Management at Britannia Industries.Document95 pagesStudy of Supply Chain Management at Britannia Industries.Satender Kumar75% (8)

- Venky 3Document39 pagesVenky 3Uday GowdaNo ratings yet

- Supply Chain Management in Renata LimitedDocument9 pagesSupply Chain Management in Renata LimitedbbakumNo ratings yet

- Assignment 1Document7 pagesAssignment 1Sivaramakrishnan KasiviswanathanNo ratings yet

- Project Report On SCMDocument16 pagesProject Report On SCMmanas sibal0% (2)

- OT Congruence Model Nadler TushmanDocument17 pagesOT Congruence Model Nadler Tushmang1twin100% (2)

- BOW - Organization & ManagementDocument4 pagesBOW - Organization & ManagementLeonardo Danag100% (2)

- Oil Spill ExercisesDocument52 pagesOil Spill Exercisesbudiazis100% (1)

- Sap Fund MGMTDocument21 pagesSap Fund MGMTRupang ShahNo ratings yet

- LSCM Chap 1 NotesDocument32 pagesLSCM Chap 1 Notesprasanna murthyNo ratings yet

- Chapter 9 Supply Chain Management and Facility LocationDocument27 pagesChapter 9 Supply Chain Management and Facility Locationopio jamesNo ratings yet

- Thesis Pran RFLDocument7 pagesThesis Pran RFLziniaafrin1988No ratings yet

- Supply Chain Management: Name-Diksha Patial CLASS-MBA (4sem) ROLL-NO-1710 Submitted To-Mr. Sachin SharmaDocument16 pagesSupply Chain Management: Name-Diksha Patial CLASS-MBA (4sem) ROLL-NO-1710 Submitted To-Mr. Sachin SharmaShivani KakkerNo ratings yet

- Exam Prep Short Answer QuestionsDocument16 pagesExam Prep Short Answer Questionsطه احمدNo ratings yet

- Dissertation - Quality in Supply Chain ManagementDocument30 pagesDissertation - Quality in Supply Chain ManagementAbhishek JainNo ratings yet

- Rahul Final Project Final PDFDocument72 pagesRahul Final Project Final PDFNandan KesariNo ratings yet

- Unit 2Document17 pagesUnit 2Maze RunnerNo ratings yet

- Good HabitsDocument9 pagesGood HabitsAman Kumar ThakurNo ratings yet

- Assignment 2Document7 pagesAssignment 2Abhijeet BoseNo ratings yet

- Bullwhip EffectDocument35 pagesBullwhip EffectKrishnaditya Singh Rathore100% (1)

- What Are The Major Foundational Areas and Challenges of Supply Chain Management in Electronics IndustryDocument7 pagesWhat Are The Major Foundational Areas and Challenges of Supply Chain Management in Electronics IndustryjackNo ratings yet

- Aditonal Notes - 1Document8 pagesAditonal Notes - 1yeteday615No ratings yet

- Kaweesa Strategic SCMDocument45 pagesKaweesa Strategic SCMdavid.kaweesa352No ratings yet

- Unit II SCM MBADocument52 pagesUnit II SCM MBARaghav SharmaNo ratings yet

- Opportunities and Challenges of Supply Chain ManagementDocument7 pagesOpportunities and Challenges of Supply Chain ManagementSandeep67% (3)

- Supply Study TvsDocument20 pagesSupply Study TvsSiva RatheeshNo ratings yet

- WK 6 Supply ChainDocument8 pagesWK 6 Supply ChainpthavNo ratings yet

- Britinia Industries Case Study.Document95 pagesBritinia Industries Case Study.PrajaktaNo ratings yet

- Keywords: 1. Supply Chain ManagementDocument6 pagesKeywords: 1. Supply Chain Managementmushtaque61No ratings yet

- Supply Chain MnagementDocument5 pagesSupply Chain MnagementDanish AhsanNo ratings yet

- Future Trends in Supply Chain ManagementDocument4 pagesFuture Trends in Supply Chain ManagementAtima HoodaNo ratings yet

- Title: Analyzing Impact of Information Technology On Supply Chain Management and Manufacturing StrategyDocument3 pagesTitle: Analyzing Impact of Information Technology On Supply Chain Management and Manufacturing StrategyPiyush PDNo ratings yet

- Key Issues in SCMDocument4 pagesKey Issues in SCMAnkita MudgalNo ratings yet

- Supply Chain ManagementDocument16 pagesSupply Chain ManagementSnigdho Shokal100% (1)

- SCLMDocument45 pagesSCLMkeerthana chandrasekarNo ratings yet

- Priya Anand PG20101207 E-SCMDocument38 pagesPriya Anand PG20101207 E-SCMPriya AnandNo ratings yet

- Supply ChainDocument4 pagesSupply ChainNiño Rey LopezNo ratings yet

- SCM Technologies and Their Applicability in The SC Operations AisDocument11 pagesSCM Technologies and Their Applicability in The SC Operations AisaiswaryaNo ratings yet

- Changes in SCM Globally by Rupa RathiDocument10 pagesChanges in SCM Globally by Rupa RathiavinashjhamechxNo ratings yet

- Chapter 1 IntroductionDocument19 pagesChapter 1 IntroductionNazia EnayetNo ratings yet

- Investigating The Trends and Challenges in The Supply Chain and How It Is Impacted by The Digital RevolutionDocument7 pagesInvestigating The Trends and Challenges in The Supply Chain and How It Is Impacted by The Digital RevolutionHira WaliNo ratings yet

- The Supply ChainDocument7 pagesThe Supply ChainDesie NayreNo ratings yet

- Cat Two Principles of Supply Chain ManagementDocument9 pagesCat Two Principles of Supply Chain ManagementRashid De RadianceNo ratings yet

- Assignment SCMDocument12 pagesAssignment SCMnaziaNo ratings yet

- Supply Chain Principles and ApplicationsDocument12 pagesSupply Chain Principles and ApplicationsRicky KristandaNo ratings yet

- MD Ashiq and DR Arun - Article 2008 IJME Binary UniversityDocument23 pagesMD Ashiq and DR Arun - Article 2008 IJME Binary Universitykj0850226No ratings yet

- Global Supply Chain Business ProcessDocument5 pagesGlobal Supply Chain Business ProcessDeepthi PakalapatiNo ratings yet

- Supply Chain ManagementDocument8 pagesSupply Chain Managementaryan_hrsNo ratings yet

- Syntoemer LogisticsDocument6 pagesSyntoemer LogisticsMiron 6053No ratings yet

- SupplyDocument3 pagesSupplyRuru Kumar SahuNo ratings yet

- Term Paper OF Operation Management (O.M) : TopicDocument15 pagesTerm Paper OF Operation Management (O.M) : TopicreyazmbaNo ratings yet

- Sai Aswathy. SCM 2 03Document8 pagesSai Aswathy. SCM 2 03sudeepptrNo ratings yet

- Engineering ManagementDocument19 pagesEngineering Managementveil davidNo ratings yet

- SCM and Its EffectsDocument4 pagesSCM and Its EffectsfatimaNo ratings yet

- Defining Supply Chain ManagementDocument7 pagesDefining Supply Chain ManagementVampyPhanNo ratings yet

- Critique Paper 4Document6 pagesCritique Paper 4Shayma MokamadNo ratings yet

- Operations Management Gyan CapsuleDocument6 pagesOperations Management Gyan CapsuleAnandbabu RadhakrishnanNo ratings yet

- Research Proposal Supply Chain Management Life Cycle Considerations of Supply Chain Strategies Suresh Yerra (9985337741)Document3 pagesResearch Proposal Supply Chain Management Life Cycle Considerations of Supply Chain Strategies Suresh Yerra (9985337741)Shireesha YerraNo ratings yet

- Military Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceFrom EverandMilitary Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceNo ratings yet

- The Accredited Supply Chain ProfessionalFrom EverandThe Accredited Supply Chain ProfessionalRating: 5 out of 5 stars5/5 (1)

- Supply Chain Business Startup Guide: Step-by-Step Tips for SuccessFrom EverandSupply Chain Business Startup Guide: Step-by-Step Tips for SuccessNo ratings yet

- BAC-5051E TB150701A RecoveringIPaddressInDocument2 pagesBAC-5051E TB150701A RecoveringIPaddressIniwaleedwasimNo ratings yet

- Network GuideDocument24 pagesNetwork GuideiwaleedwasimNo ratings yet

- Nabers Ew Rules-July 2010Document144 pagesNabers Ew Rules-July 2010iwaleedwasimNo ratings yet

- Lab RollingDocument26 pagesLab RollingiwaleedwasimNo ratings yet

- FLEKS Model Summary Guide 2022 - ENGLISHDocument21 pagesFLEKS Model Summary Guide 2022 - ENGLISHBrunoNo ratings yet

- MBA 1 MiscommunicationDocument19 pagesMBA 1 Miscommunicationathoratt100% (1)

- BUAD 304 Fall 2014 Syllabus ADocument11 pagesBUAD 304 Fall 2014 Syllabus Atony4dongNo ratings yet

- de Soto - The Challenge of Connecting Informal and Formal Property Systems Some Reflections Based On The Case of TanzaniaDocument41 pagesde Soto - The Challenge of Connecting Informal and Formal Property Systems Some Reflections Based On The Case of TanzanialahoozNo ratings yet

- Dilemmas of Managing Participation - 1982 - Organizational DynamicsDocument23 pagesDilemmas of Managing Participation - 1982 - Organizational DynamicsLily HamiltonNo ratings yet

- Manager Versus Leader. Why Are Both Roles Valuable?Document4 pagesManager Versus Leader. Why Are Both Roles Valuable?drg. Shely OktaviaNo ratings yet

- Trends in PMSDocument14 pagesTrends in PMSMUSKAN CHHAPARIA 2127747No ratings yet

- Assignment Acm Code of EthicDocument7 pagesAssignment Acm Code of EthicMahboob AhmadNo ratings yet

- HEI P U 0543 - SelfLearning - 20210729103348Document8 pagesHEI P U 0543 - SelfLearning - 20210729103348sapit90No ratings yet

- Civil Society-In Democracy: Prepared byDocument9 pagesCivil Society-In Democracy: Prepared bySHANMUKH BACHUNo ratings yet

- Strategic Design Lens PDFDocument20 pagesStrategic Design Lens PDFShamoon AlamNo ratings yet

- Operations STRATEGY AND CompetitivenessDocument36 pagesOperations STRATEGY AND CompetitivenessYaredNo ratings yet

- Nestle Pakistan Research Project!!Document29 pagesNestle Pakistan Research Project!!Hassan Naeem89% (18)

- Dissertation Topics For MSC EconomicsDocument4 pagesDissertation Topics For MSC EconomicsCanYouWriteMyPaperForMeLasVegas100% (1)

- Foreign PolicyDocument10 pagesForeign PolicyDE-CHOICE COMPUTER VENTURENo ratings yet

- XXX Marketing StrategyDocument9 pagesXXX Marketing StrategyJoel MitchellNo ratings yet

- Organisational BehaviourDocument41 pagesOrganisational BehaviourDr-Isaac JNo ratings yet

- Theory X and Theory Y NewDocument10 pagesTheory X and Theory Y Newmustaf mohamedNo ratings yet

- Enneagram and Myers BriggsDocument87 pagesEnneagram and Myers BriggsJoseph MboyaNo ratings yet

- Chapter 4. 7 ESDocument13 pagesChapter 4. 7 ESKenneth CuetoNo ratings yet

- Brochure Carbon Footprint (Engels)Document4 pagesBrochure Carbon Footprint (Engels)Tan Hong TatNo ratings yet

- Title Project Report On How To Reduce Traffic Congestion in Our TownDocument2 pagesTitle Project Report On How To Reduce Traffic Congestion in Our TownImti RahmanNo ratings yet

- Introduction To OBDocument36 pagesIntroduction To OBNarayana ReddyNo ratings yet

- Seminar On Personnel PoliciesDocument60 pagesSeminar On Personnel PoliciesSudha YadavNo ratings yet

Case Study Week 11

Case Study Week 11

Uploaded by

iwaleedwasimOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Study Week 11

Case Study Week 11

Uploaded by

iwaleedwasimCopyright:

Available Formats

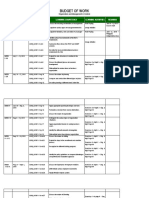

ENGG 939 Case Study Week 11

Name: Waleed Wasim

Student Number: 5176694

Word Count: 725 words

Designing and operating effective global networks is a fundamental source of competitive advantage

for manufacturers. As networks have become increasingly complex and fragmented, it is more

important than ever that international manufacturers are able to ‘make the right things in the right

places’, have agile and resilient supply chains, and the right people and processes to run them.

Companies that neglect the important aspect of developing the supply chain often pay the price with

cost, quality, lead time and customer retention. It is sometimes difficult to let the top managers

understand the significance of supply chain management as it often comes down very low in their

priorities. However, progressive companies do understand that managing the supply chains improve

lead times, decrease costs of warehousing and inventory control, and increase the overall control

against unknown variables.

Supply chain management is essential to organization success and customer satisfaction because it

includes all of the activities that lead to the success of the organization from beginning of planning,

management of all activities and operations of create the sources, the procurement and logistics

(transport, warehouse management ,inventory management And so on) and marketing operations

as well as coordination and cooperation between all parties involved in the supply chains of

suppliers and service providers and client.

Since supply chain management is essentially the control of all activities performed by the

organization from beginning i.e. planning, procurement to operations and finally the logistics and

delivery of the final product to the consumers. It is therefore, not possible to integrate any new

innovative techniques/procedures or equipment without altering the supply chain itself and thus

newer innovative techniques would have to be ingrained within the supply chain itself in order to

actually reap the benefits of the newer technologies that have been acquired by the organization.

[Lambert et al]

Also, it is also important that newer and contemporary ideas within the supply chain network itself,

since smaller improvements to the network can have huge results due to the very nature of the

supply chain network, since a small improvement in a particular process will create a ripple effect

within the whole system. Newer trends such as lean manufacturing, just-in-time inventory, reduced

product lifecycles, outsourcing, and supplier consolidation have yielded compelling business

benefits, they have also introduced new kinds of supply chain risk and reduced the margin for error.

One step towards innovation in supply chain management is simply to break the rules. Sabath and

Sherman encourage supply chain managers to break these rules:

1. Supply chain is not strategic

2. All customers are created equal

3. Manage for minimum cost

4. Always use optimization models to determine the location and level for manufacturing and

inventory

5. Ship very parcel order the day the order is received [Sherman & Sabath et al.]

In order to stay competitive globally and remain on the cutting edge of a complex business world,

more companies are incorporating technology into their supply chain management systems today. In

recent years, consumers have become increasingly demanding, setting their expectations high when

it comes to quality and service. At the same time, supply chain managers have come to realize that

the latest technology can help them ensure better accountability and visibility, allowing them to

maintain tight control and stay ahead of the pack.

Today’s technology has extensive capability when it comes to keeping a company’s production on

track, anticipating and repairing mistakes, and making modifications that guarantee a top-quality

product. Every link in the supply chain can be monitored simultaneously, and automated notification

systems are especially valuable for sending a single message to many players through a variety of

media channels.

Computerized shipping and tracking, and electronic invoicing, are also core components of a modern

supply chain management system that is designed to keep customers satisfied. [Wu, Kim & Cavusgil

et al]

References:

Sherman, R. and Sabath, B. (2013). Want to Innovate? Break the Rules. Supply Chain

Management Review.

Lambert, Douglas M., Martha C. Cooper, and Janus D. Pagh. "Supply chain management:

implementation issues and research opportunities." The international journal of logistics

Management 9.2 (1998): 1-20.

Wu, F., Yeniyurt, S., Kim, D., & Cavusgil, S. T. (2006). The impact of information technology

on supply chain capabilities and firm performance: A resource-based view. Industrial

Marketing Management, 35(4), 493-504.

You might also like

- Supply Chain Management Mba Project DownloadDocument7 pagesSupply Chain Management Mba Project DownloadAhamed Ibrahim100% (2)

- Fourpracticesystem Unit2Document15 pagesFourpracticesystem Unit2Hari BahadurNo ratings yet

- HBL Training and DevelopmentDocument18 pagesHBL Training and Developmentkiran-mahmood-6943No ratings yet

- Study of Supply Chain Management at Britannia Industries.Document95 pagesStudy of Supply Chain Management at Britannia Industries.Satender Kumar75% (8)

- Venky 3Document39 pagesVenky 3Uday GowdaNo ratings yet

- Supply Chain Management in Renata LimitedDocument9 pagesSupply Chain Management in Renata LimitedbbakumNo ratings yet

- Assignment 1Document7 pagesAssignment 1Sivaramakrishnan KasiviswanathanNo ratings yet

- Project Report On SCMDocument16 pagesProject Report On SCMmanas sibal0% (2)

- OT Congruence Model Nadler TushmanDocument17 pagesOT Congruence Model Nadler Tushmang1twin100% (2)

- BOW - Organization & ManagementDocument4 pagesBOW - Organization & ManagementLeonardo Danag100% (2)

- Oil Spill ExercisesDocument52 pagesOil Spill Exercisesbudiazis100% (1)

- Sap Fund MGMTDocument21 pagesSap Fund MGMTRupang ShahNo ratings yet

- LSCM Chap 1 NotesDocument32 pagesLSCM Chap 1 Notesprasanna murthyNo ratings yet

- Chapter 9 Supply Chain Management and Facility LocationDocument27 pagesChapter 9 Supply Chain Management and Facility Locationopio jamesNo ratings yet

- Thesis Pran RFLDocument7 pagesThesis Pran RFLziniaafrin1988No ratings yet

- Supply Chain Management: Name-Diksha Patial CLASS-MBA (4sem) ROLL-NO-1710 Submitted To-Mr. Sachin SharmaDocument16 pagesSupply Chain Management: Name-Diksha Patial CLASS-MBA (4sem) ROLL-NO-1710 Submitted To-Mr. Sachin SharmaShivani KakkerNo ratings yet

- Exam Prep Short Answer QuestionsDocument16 pagesExam Prep Short Answer Questionsطه احمدNo ratings yet

- Dissertation - Quality in Supply Chain ManagementDocument30 pagesDissertation - Quality in Supply Chain ManagementAbhishek JainNo ratings yet

- Rahul Final Project Final PDFDocument72 pagesRahul Final Project Final PDFNandan KesariNo ratings yet

- Unit 2Document17 pagesUnit 2Maze RunnerNo ratings yet

- Good HabitsDocument9 pagesGood HabitsAman Kumar ThakurNo ratings yet

- Assignment 2Document7 pagesAssignment 2Abhijeet BoseNo ratings yet

- Bullwhip EffectDocument35 pagesBullwhip EffectKrishnaditya Singh Rathore100% (1)

- What Are The Major Foundational Areas and Challenges of Supply Chain Management in Electronics IndustryDocument7 pagesWhat Are The Major Foundational Areas and Challenges of Supply Chain Management in Electronics IndustryjackNo ratings yet

- Aditonal Notes - 1Document8 pagesAditonal Notes - 1yeteday615No ratings yet

- Kaweesa Strategic SCMDocument45 pagesKaweesa Strategic SCMdavid.kaweesa352No ratings yet

- Unit II SCM MBADocument52 pagesUnit II SCM MBARaghav SharmaNo ratings yet

- Opportunities and Challenges of Supply Chain ManagementDocument7 pagesOpportunities and Challenges of Supply Chain ManagementSandeep67% (3)

- Supply Study TvsDocument20 pagesSupply Study TvsSiva RatheeshNo ratings yet

- WK 6 Supply ChainDocument8 pagesWK 6 Supply ChainpthavNo ratings yet

- Britinia Industries Case Study.Document95 pagesBritinia Industries Case Study.PrajaktaNo ratings yet

- Keywords: 1. Supply Chain ManagementDocument6 pagesKeywords: 1. Supply Chain Managementmushtaque61No ratings yet

- Supply Chain MnagementDocument5 pagesSupply Chain MnagementDanish AhsanNo ratings yet

- Future Trends in Supply Chain ManagementDocument4 pagesFuture Trends in Supply Chain ManagementAtima HoodaNo ratings yet

- Title: Analyzing Impact of Information Technology On Supply Chain Management and Manufacturing StrategyDocument3 pagesTitle: Analyzing Impact of Information Technology On Supply Chain Management and Manufacturing StrategyPiyush PDNo ratings yet

- Key Issues in SCMDocument4 pagesKey Issues in SCMAnkita MudgalNo ratings yet

- Supply Chain ManagementDocument16 pagesSupply Chain ManagementSnigdho Shokal100% (1)

- SCLMDocument45 pagesSCLMkeerthana chandrasekarNo ratings yet

- Priya Anand PG20101207 E-SCMDocument38 pagesPriya Anand PG20101207 E-SCMPriya AnandNo ratings yet

- Supply ChainDocument4 pagesSupply ChainNiño Rey LopezNo ratings yet

- SCM Technologies and Their Applicability in The SC Operations AisDocument11 pagesSCM Technologies and Their Applicability in The SC Operations AisaiswaryaNo ratings yet

- Changes in SCM Globally by Rupa RathiDocument10 pagesChanges in SCM Globally by Rupa RathiavinashjhamechxNo ratings yet

- Chapter 1 IntroductionDocument19 pagesChapter 1 IntroductionNazia EnayetNo ratings yet

- Investigating The Trends and Challenges in The Supply Chain and How It Is Impacted by The Digital RevolutionDocument7 pagesInvestigating The Trends and Challenges in The Supply Chain and How It Is Impacted by The Digital RevolutionHira WaliNo ratings yet

- The Supply ChainDocument7 pagesThe Supply ChainDesie NayreNo ratings yet

- Cat Two Principles of Supply Chain ManagementDocument9 pagesCat Two Principles of Supply Chain ManagementRashid De RadianceNo ratings yet

- Assignment SCMDocument12 pagesAssignment SCMnaziaNo ratings yet

- Supply Chain Principles and ApplicationsDocument12 pagesSupply Chain Principles and ApplicationsRicky KristandaNo ratings yet

- MD Ashiq and DR Arun - Article 2008 IJME Binary UniversityDocument23 pagesMD Ashiq and DR Arun - Article 2008 IJME Binary Universitykj0850226No ratings yet

- Global Supply Chain Business ProcessDocument5 pagesGlobal Supply Chain Business ProcessDeepthi PakalapatiNo ratings yet

- Supply Chain ManagementDocument8 pagesSupply Chain Managementaryan_hrsNo ratings yet

- Syntoemer LogisticsDocument6 pagesSyntoemer LogisticsMiron 6053No ratings yet

- SupplyDocument3 pagesSupplyRuru Kumar SahuNo ratings yet

- Term Paper OF Operation Management (O.M) : TopicDocument15 pagesTerm Paper OF Operation Management (O.M) : TopicreyazmbaNo ratings yet

- Sai Aswathy. SCM 2 03Document8 pagesSai Aswathy. SCM 2 03sudeepptrNo ratings yet

- Engineering ManagementDocument19 pagesEngineering Managementveil davidNo ratings yet

- SCM and Its EffectsDocument4 pagesSCM and Its EffectsfatimaNo ratings yet

- Defining Supply Chain ManagementDocument7 pagesDefining Supply Chain ManagementVampyPhanNo ratings yet

- Critique Paper 4Document6 pagesCritique Paper 4Shayma MokamadNo ratings yet

- Operations Management Gyan CapsuleDocument6 pagesOperations Management Gyan CapsuleAnandbabu RadhakrishnanNo ratings yet

- Research Proposal Supply Chain Management Life Cycle Considerations of Supply Chain Strategies Suresh Yerra (9985337741)Document3 pagesResearch Proposal Supply Chain Management Life Cycle Considerations of Supply Chain Strategies Suresh Yerra (9985337741)Shireesha YerraNo ratings yet

- Military Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceFrom EverandMilitary Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceNo ratings yet

- The Accredited Supply Chain ProfessionalFrom EverandThe Accredited Supply Chain ProfessionalRating: 5 out of 5 stars5/5 (1)

- Supply Chain Business Startup Guide: Step-by-Step Tips for SuccessFrom EverandSupply Chain Business Startup Guide: Step-by-Step Tips for SuccessNo ratings yet

- BAC-5051E TB150701A RecoveringIPaddressInDocument2 pagesBAC-5051E TB150701A RecoveringIPaddressIniwaleedwasimNo ratings yet

- Network GuideDocument24 pagesNetwork GuideiwaleedwasimNo ratings yet

- Nabers Ew Rules-July 2010Document144 pagesNabers Ew Rules-July 2010iwaleedwasimNo ratings yet

- Lab RollingDocument26 pagesLab RollingiwaleedwasimNo ratings yet

- FLEKS Model Summary Guide 2022 - ENGLISHDocument21 pagesFLEKS Model Summary Guide 2022 - ENGLISHBrunoNo ratings yet

- MBA 1 MiscommunicationDocument19 pagesMBA 1 Miscommunicationathoratt100% (1)

- BUAD 304 Fall 2014 Syllabus ADocument11 pagesBUAD 304 Fall 2014 Syllabus Atony4dongNo ratings yet

- de Soto - The Challenge of Connecting Informal and Formal Property Systems Some Reflections Based On The Case of TanzaniaDocument41 pagesde Soto - The Challenge of Connecting Informal and Formal Property Systems Some Reflections Based On The Case of TanzanialahoozNo ratings yet

- Dilemmas of Managing Participation - 1982 - Organizational DynamicsDocument23 pagesDilemmas of Managing Participation - 1982 - Organizational DynamicsLily HamiltonNo ratings yet

- Manager Versus Leader. Why Are Both Roles Valuable?Document4 pagesManager Versus Leader. Why Are Both Roles Valuable?drg. Shely OktaviaNo ratings yet

- Trends in PMSDocument14 pagesTrends in PMSMUSKAN CHHAPARIA 2127747No ratings yet

- Assignment Acm Code of EthicDocument7 pagesAssignment Acm Code of EthicMahboob AhmadNo ratings yet

- HEI P U 0543 - SelfLearning - 20210729103348Document8 pagesHEI P U 0543 - SelfLearning - 20210729103348sapit90No ratings yet

- Civil Society-In Democracy: Prepared byDocument9 pagesCivil Society-In Democracy: Prepared bySHANMUKH BACHUNo ratings yet

- Strategic Design Lens PDFDocument20 pagesStrategic Design Lens PDFShamoon AlamNo ratings yet

- Operations STRATEGY AND CompetitivenessDocument36 pagesOperations STRATEGY AND CompetitivenessYaredNo ratings yet

- Nestle Pakistan Research Project!!Document29 pagesNestle Pakistan Research Project!!Hassan Naeem89% (18)

- Dissertation Topics For MSC EconomicsDocument4 pagesDissertation Topics For MSC EconomicsCanYouWriteMyPaperForMeLasVegas100% (1)

- Foreign PolicyDocument10 pagesForeign PolicyDE-CHOICE COMPUTER VENTURENo ratings yet

- XXX Marketing StrategyDocument9 pagesXXX Marketing StrategyJoel MitchellNo ratings yet

- Organisational BehaviourDocument41 pagesOrganisational BehaviourDr-Isaac JNo ratings yet

- Theory X and Theory Y NewDocument10 pagesTheory X and Theory Y Newmustaf mohamedNo ratings yet

- Enneagram and Myers BriggsDocument87 pagesEnneagram and Myers BriggsJoseph MboyaNo ratings yet

- Chapter 4. 7 ESDocument13 pagesChapter 4. 7 ESKenneth CuetoNo ratings yet

- Brochure Carbon Footprint (Engels)Document4 pagesBrochure Carbon Footprint (Engels)Tan Hong TatNo ratings yet

- Title Project Report On How To Reduce Traffic Congestion in Our TownDocument2 pagesTitle Project Report On How To Reduce Traffic Congestion in Our TownImti RahmanNo ratings yet

- Introduction To OBDocument36 pagesIntroduction To OBNarayana ReddyNo ratings yet

- Seminar On Personnel PoliciesDocument60 pagesSeminar On Personnel PoliciesSudha YadavNo ratings yet