Professional Documents

Culture Documents

Interline 399 (UK) - Folder

Interline 399 (UK) - Folder

Uploaded by

Roger SchvepperCopyright:

Available Formats

You might also like

- Sspc-Spcom PDFDocument32 pagesSspc-Spcom PDFRoger SchvepperNo ratings yet

- Manual Eaton Transmission FullerDocument45 pagesManual Eaton Transmission FullerMario Portes75% (4)

- Interline 399+br+eng PDFDocument2 pagesInterline 399+br+eng PDFMohamed NouzerNo ratings yet

- DATA SHEET Industrial Enamel BlancoDocument4 pagesDATA SHEET Industrial Enamel BlancoAlfredo OrellanaNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Protective & Marine Coatings: Industrial Enamel Voc ComplyingDocument4 pagesProtective & Marine Coatings: Industrial Enamel Voc ComplyingAna CabreraNo ratings yet

- ComlinDocument13 pagesComlinSammar AdhikariNo ratings yet

- HGF10R R4 ES - eDocument3 pagesHGF10R R4 ES - eNico RoisnerNo ratings yet

- Carboguard 60: Selection & Specification DataDocument5 pagesCarboguard 60: Selection & Specification Databalangce1No ratings yet

- Castrol Perfecto XDocument3 pagesCastrol Perfecto XHector Martin BarajasNo ratings yet

- Intergard 345: Fast Drying Direct To Metal EpoxyDocument2 pagesIntergard 345: Fast Drying Direct To Metal EpoxyAndri AjaNo ratings yet

- Hoja Tecnica Amerlock 400 PDFDocument3 pagesHoja Tecnica Amerlock 400 PDFJesy M. Maldonado SalinasNo ratings yet

- Interpon D1036 LSA Cool CoatingsDocument3 pagesInterpon D1036 LSA Cool Coatings120120120120No ratings yet

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocument4 pagesProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNo ratings yet

- Magna PM 220-Pds-EngDocument2 pagesMagna PM 220-Pds-EngVusal HasanovNo ratings yet

- Product Datasheet: Interpon 610 - NW300M/25KG ANTRACITE FERRO IP610Document2 pagesProduct Datasheet: Interpon 610 - NW300M/25KG ANTRACITE FERRO IP610Ina - EdenGarden UmbrellasNo ratings yet

- Rust Veto 342Document1 pageRust Veto 342diahNo ratings yet

- 07 Tiger Drylac R Primer 0973841 Zinc Free Ogf TDC en Aug 09 2016 FinalDocument3 pages07 Tiger Drylac R Primer 0973841 Zinc Free Ogf TDC en Aug 09 2016 FinalErikas KulpinasNo ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- PPG Amercoat 370 Data SheetDocument3 pagesPPG Amercoat 370 Data SheetAchraf Boudaya0% (1)

- Carboguard 890: Selection & Specification DataDocument5 pagesCarboguard 890: Selection & Specification DataMuthazhagan SaravananNo ratings yet

- Cloverdale Tds 86850A eDocument4 pagesCloverdale Tds 86850A eenaron777No ratings yet

- 3M Scotchkote Epoxy Primer GP220 - Rev2Document2 pages3M Scotchkote Epoxy Primer GP220 - Rev2satya ranjanNo ratings yet

- Thermaline Heat Shield PDSDocument4 pagesThermaline Heat Shield PDSfrosted296No ratings yet

- Non-Reactive Fire Protective Coating: PROMASPRAY®-P400 Product Data SheetDocument3 pagesNon-Reactive Fire Protective Coating: PROMASPRAY®-P400 Product Data SheetAji TidarNo ratings yet

- WBEpoxyCoating Data SheetDocument2 pagesWBEpoxyCoating Data SheetkaleshNo ratings yet

- DS 058-Rev-02 Epilux 155 High Build MIO CoatingDocument2 pagesDS 058-Rev-02 Epilux 155 High Build MIO CoatingsojeckNo ratings yet

- USA5892ps 10193Document5 pagesUSA5892ps 10193Mubashar HassanNo ratings yet

- Resicoat V - F R4 ESDocument3 pagesResicoat V - F R4 ESABHISHEK SINGHNo ratings yet

- Carboguard 893 PDSDocument2 pagesCarboguard 893 PDSNguyễn Thị Châu TâyNo ratings yet

- Thermaline 4700 Aluminum: Selection & Specification DataDocument4 pagesThermaline 4700 Aluminum: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Carbozinc 858 PDSDocument4 pagesCarbozinc 858 PDShuycongvuNo ratings yet

- Interline 850+br+eng PDFDocument2 pagesInterline 850+br+eng PDFMohamed NouzerNo ratings yet

- Thermaline 400: Selection & Specification DataDocument3 pagesThermaline 400: Selection & Specification DataJalaluddinNo ratings yet

- Tds - Jotun - Guard Classic EtDocument3 pagesTds - Jotun - Guard Classic Etvijh van niemannNo ratings yet

- Phenoline 1205 PDSDocument4 pagesPhenoline 1205 PDSonshore purchaseNo ratings yet

- Thermaline 4000 Aluminum: Selection & Specification DataDocument3 pagesThermaline 4000 Aluminum: Selection & Specification DataKatherine Marimón JiménezNo ratings yet

- Carboguard 60 PDSDocument5 pagesCarboguard 60 PDSvihor94213No ratings yet

- Ipd Pds Sikalastomer 95 UsDocument2 pagesIpd Pds Sikalastomer 95 Usernest manNo ratings yet

- Corro Zinc 97Document3 pagesCorro Zinc 97Diego RomeroNo ratings yet

- 751br UsDocument2 pages751br UsandreahankNo ratings yet

- Urethane Coating 165 PWDocument3 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- Material Product Data Sheet Zirconia - Polymer Ceramic Abradable PowdersDocument4 pagesMaterial Product Data Sheet Zirconia - Polymer Ceramic Abradable PowderskerbaubiruNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Fosroc Nitoflor FC 400 UH: Constructive SolutionsDocument4 pagesFosroc Nitoflor FC 400 UH: Constructive SolutionsVincent JavateNo ratings yet

- PVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Document2 pagesPVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Jitendra PatelNo ratings yet

- HJF24R R4 ES - eDocument3 pagesHJF24R R4 ES - evincatesNo ratings yet

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- AS200 Elastomeric Spray Product Data SheetDocument3 pagesAS200 Elastomeric Spray Product Data SheetJhon DewantoNo ratings yet

- Steel PuttyDocument1 pageSteel PuttySiva SubramaniNo ratings yet

- Scotchkote FBE 134W - TDSDocument4 pagesScotchkote FBE 134W - TDSPietro ViganNo ratings yet

- 3M Scotchkote Epoxy Primer GP 120+Document2 pages3M Scotchkote Epoxy Primer GP 120+satya ranjanNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- AkzoNobel - QN102QF - Interpon ACE 2000Document3 pagesAkzoNobel - QN102QF - Interpon ACE 2000Eslam FaroukNo ratings yet

- Product Datasheet: BU Powder CoatingsDocument1 pageProduct Datasheet: BU Powder CoatingsVasudev BhanajiNo ratings yet

- AkzoNobel EN2007 Interpon F2010Document2 pagesAkzoNobel EN2007 Interpon F2010muvinkumarNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- COLD GALVANISING Spray - GBDocument2 pagesCOLD GALVANISING Spray - GBANIL PLAMOOTTILNo ratings yet

- Technical Data Sheet: Neotec PP 200Document2 pagesTechnical Data Sheet: Neotec PP 200Ecaterina RusuNo ratings yet

- Product Information: Kemperol V210Document3 pagesProduct Information: Kemperol V210sri projectssNo ratings yet

- Trusted Technology For Total Tank Inspection, An Ebook by EddyfiDocument44 pagesTrusted Technology For Total Tank Inspection, An Ebook by EddyfiRoger SchvepperNo ratings yet

- API653 Open Book Qrev1Document11 pagesAPI653 Open Book Qrev1Roger SchvepperNo ratings yet

- Folder Intershield 4000USPDocument4 pagesFolder Intershield 4000USPRoger SchvepperNo ratings yet

- Pds Sikasil Gasket Black e 06-14Document2 pagesPds Sikasil Gasket Black e 06-14Roger SchvepperNo ratings yet

- Comprehending Pull-Off Adhesion Testing: by Rob Francis, R A Francis Consulting Services Pty LTDDocument9 pagesComprehending Pull-Off Adhesion Testing: by Rob Francis, R A Francis Consulting Services Pty LTDRoger SchvepperNo ratings yet

- ASTM D610 - Standard Practice For Evaluating Degree of Rusting On Painted Steel SurfacesDocument6 pagesASTM D610 - Standard Practice For Evaluating Degree of Rusting On Painted Steel SurfacesRoger SchvepperNo ratings yet

- Architecture Portfolio - Architect Nicola DoglieroDocument60 pagesArchitecture Portfolio - Architect Nicola Doglieronicola doglieroNo ratings yet

- Mud MortarDocument2 pagesMud MortarHisham AlthafNo ratings yet

- Project 3 - Enamine Reactions 2-AcetylcyclohexanoneDocument3 pagesProject 3 - Enamine Reactions 2-Acetylcyclohexanonexmyka37100% (1)

- Halliburtos SAND TRAPDocument2 pagesHalliburtos SAND TRAPAnonymous JdPYHGmWNo ratings yet

- En10222 4-1999Document12 pagesEn10222 4-1999Dumitru SorinaNo ratings yet

- SSP 204 EspDocument64 pagesSSP 204 Espภูเก็ต เป็นเกาะNo ratings yet

- Project Semester Training - 2012 Mechanical EnggDocument7 pagesProject Semester Training - 2012 Mechanical EnggAbhikrit GoelNo ratings yet

- European Practice On Design&Construction of Concrete PavementsDocument103 pagesEuropean Practice On Design&Construction of Concrete Pavementsshakirhamid6687No ratings yet

- Thesis On Financial Problems of Small Scale Industries in IndiaDocument6 pagesThesis On Financial Problems of Small Scale Industries in Indiacarolynostwaltbillings100% (2)

- Passivity - Definitions and Influencing ParametersDocument5 pagesPassivity - Definitions and Influencing ParametersrrameshsmitNo ratings yet

- Advanced Dry Bottom Ash TechnologyDocument47 pagesAdvanced Dry Bottom Ash TechnologyDimas Febrian SaputraNo ratings yet

- Building Materials 4Document143 pagesBuilding Materials 4NabeelNo ratings yet

- IZM World's SmallestDocument1 pageIZM World's Smallestgaurav110790No ratings yet

- SPDI Refresher Test PaperDocument12 pagesSPDI Refresher Test PaperJohn Rey PelobelloNo ratings yet

- 20a Torque CalculationDocument11 pages20a Torque CalculationRiyan EsapermanaNo ratings yet

- Bergerac Systems: The Challenge of Backward Integration: Group 02, Section - CDocument5 pagesBergerac Systems: The Challenge of Backward Integration: Group 02, Section - CSaumya GautamNo ratings yet

- 9ABS103 Engineering ChemistryDocument4 pages9ABS103 Engineering ChemistrysivabharathamurthyNo ratings yet

- DP Test ProcedureDocument2 pagesDP Test ProcedurePallav ChatterjeeNo ratings yet

- Operator Manual MaxiDocument12 pagesOperator Manual Maxiesteban marinkovicNo ratings yet

- Air Changes Per HourDocument2 pagesAir Changes Per HourjjzoranNo ratings yet

- 815 Plus Single HingeDocument2 pages815 Plus Single HingeSaepul RochmanNo ratings yet

- M15A40Document4 pagesM15A40shubhamtandon01No ratings yet

- ITB-KEOH-2016-009 - Section V - Annex D (Ii) - Electrical Works DrawingsDocument29 pagesITB-KEOH-2016-009 - Section V - Annex D (Ii) - Electrical Works DrawingsSefaNo ratings yet

- Liebherr Brochure Mobilmix enDocument12 pagesLiebherr Brochure Mobilmix enyankNo ratings yet

- 3ply FRP APPLICATION MANUAL - RipoxyDocument5 pages3ply FRP APPLICATION MANUAL - Ripoxyavv.architects02No ratings yet

- 7 Swift Vol2 HvacDocument48 pages7 Swift Vol2 Hvacdin1978100% (1)

- Tatb HMX PBXDocument11 pagesTatb HMX PBXwyngo68No ratings yet

- Three Phase Voltage Monitor - Ae1313Document4 pagesThree Phase Voltage Monitor - Ae1313Ben_Yu_9137No ratings yet

- 7.01 Lime and CementDocument21 pages7.01 Lime and CementRobert MaddenNo ratings yet

Interline 399 (UK) - Folder

Interline 399 (UK) - Folder

Uploaded by

Roger SchvepperOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Interline 399 (UK) - Folder

Interline 399 (UK) - Folder

Uploaded by

Roger SchvepperCopyright:

Available Formats

Interline 399

Thin film lining for elevated temperatures

Interline® 399 uses a thin film, two component epoxy • Thin film chemically resistant epoxy novolac tank lining

novolac lining, that is applied in three coats to give high

• Excellent heat and solvent resistance

temperature and chemical resistance.

• Suitable for the storage of hot water up to 95°C (203°F)

• Suitable for lining storage and gas separator vessels

operating at up to 130°C (268°F)

• Resistant to sour crude oil

• Good resistance to aromatic and aliphatic solvents

A high performance, highly cross-linked

two component epoxy novolac tank lining,

with excellent heat and solvent resistance

High temperature storage Chemical resistance

Suitable for the internal lining of storage vessels and process Interline 399 is resistant to a wide range of aromatic

vessels in petrochemical plants where exposure to sour and aliphatic solvents.

crude oil and water from gas separator processing vessels

at elevated temperatures up to 130°C (268°F) is envisaged.

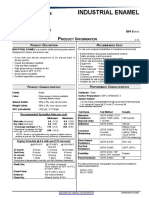

Test data

TEST METHOD REFERENCE SPECIFICATION DETAILS TYPICAL RESULT

Pull-off adhesion ISO 4624 2 x 100μm (4mils) applied directly Typically 10Mpa (1,450psi)

to Sa2.5 blasted steel

Immersion ISO 2812 Part 2 2 x 100μm (4mils) applied directly No film defects following

to Sa2.5 blasted steel 4,200 hours exposure

Immersion NACE TM-01-74 2 x 100μm (4mils) applied directly to Sa2.5 No blistering, rusting, cracking or flaking

blasted steel (stoved & unstoved @ 220°C [428°F]) following rust 504 hours exposure

Impact resistance ASTM D2794 2 x 100μm (4mils) applied directly Direct impact resistance - 2 Joules

to Sa2.5 blasted steel

Cathodic protection ASTM G42 2 x 100μm (4mils) applied directly No coating disbondment after 30 days exposure

to Sa2.5 blasted steel at 60°C (140°F), 80°C (176°F) and 90°C (194°F)

Condensation ISO 6270 2 x 100μm (4mils) applied directly No film defects following

to Sa2.5 blasted steel 4,200 hours exposure

The above performance data has been compiled based on present experience of in-service product performance and upon performance data obtained under laboratory test conditions.

Actual performance of the product will depend upon the conditions in which the product is used.

www.international-pc.com | pc.communication@akzonobel.com

All trademarks mentioned in this publication are owned by the AkzoNobel group of companies. © Akzo Nobel 2015.

G2_399_UK

AkzoNobel has used its best endeavors to ensure that the information contained in this publication is correct at the time of printing.

06/15

Please contact your local representative if you have any questions.

Unless otherwise agreed by us in writing, any contract to purchase products referred to in this brochure and any advice which

we give in connection with the supply of products are subject to our standard conditions of sale.

You might also like

- Sspc-Spcom PDFDocument32 pagesSspc-Spcom PDFRoger SchvepperNo ratings yet

- Manual Eaton Transmission FullerDocument45 pagesManual Eaton Transmission FullerMario Portes75% (4)

- Interline 399+br+eng PDFDocument2 pagesInterline 399+br+eng PDFMohamed NouzerNo ratings yet

- DATA SHEET Industrial Enamel BlancoDocument4 pagesDATA SHEET Industrial Enamel BlancoAlfredo OrellanaNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Protective & Marine Coatings: Industrial Enamel Voc ComplyingDocument4 pagesProtective & Marine Coatings: Industrial Enamel Voc ComplyingAna CabreraNo ratings yet

- ComlinDocument13 pagesComlinSammar AdhikariNo ratings yet

- HGF10R R4 ES - eDocument3 pagesHGF10R R4 ES - eNico RoisnerNo ratings yet

- Carboguard 60: Selection & Specification DataDocument5 pagesCarboguard 60: Selection & Specification Databalangce1No ratings yet

- Castrol Perfecto XDocument3 pagesCastrol Perfecto XHector Martin BarajasNo ratings yet

- Intergard 345: Fast Drying Direct To Metal EpoxyDocument2 pagesIntergard 345: Fast Drying Direct To Metal EpoxyAndri AjaNo ratings yet

- Hoja Tecnica Amerlock 400 PDFDocument3 pagesHoja Tecnica Amerlock 400 PDFJesy M. Maldonado SalinasNo ratings yet

- Interpon D1036 LSA Cool CoatingsDocument3 pagesInterpon D1036 LSA Cool Coatings120120120120No ratings yet

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocument4 pagesProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNo ratings yet

- Magna PM 220-Pds-EngDocument2 pagesMagna PM 220-Pds-EngVusal HasanovNo ratings yet

- Product Datasheet: Interpon 610 - NW300M/25KG ANTRACITE FERRO IP610Document2 pagesProduct Datasheet: Interpon 610 - NW300M/25KG ANTRACITE FERRO IP610Ina - EdenGarden UmbrellasNo ratings yet

- Rust Veto 342Document1 pageRust Veto 342diahNo ratings yet

- 07 Tiger Drylac R Primer 0973841 Zinc Free Ogf TDC en Aug 09 2016 FinalDocument3 pages07 Tiger Drylac R Primer 0973841 Zinc Free Ogf TDC en Aug 09 2016 FinalErikas KulpinasNo ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- PPG Amercoat 370 Data SheetDocument3 pagesPPG Amercoat 370 Data SheetAchraf Boudaya0% (1)

- Carboguard 890: Selection & Specification DataDocument5 pagesCarboguard 890: Selection & Specification DataMuthazhagan SaravananNo ratings yet

- Cloverdale Tds 86850A eDocument4 pagesCloverdale Tds 86850A eenaron777No ratings yet

- 3M Scotchkote Epoxy Primer GP220 - Rev2Document2 pages3M Scotchkote Epoxy Primer GP220 - Rev2satya ranjanNo ratings yet

- Thermaline Heat Shield PDSDocument4 pagesThermaline Heat Shield PDSfrosted296No ratings yet

- Non-Reactive Fire Protective Coating: PROMASPRAY®-P400 Product Data SheetDocument3 pagesNon-Reactive Fire Protective Coating: PROMASPRAY®-P400 Product Data SheetAji TidarNo ratings yet

- WBEpoxyCoating Data SheetDocument2 pagesWBEpoxyCoating Data SheetkaleshNo ratings yet

- DS 058-Rev-02 Epilux 155 High Build MIO CoatingDocument2 pagesDS 058-Rev-02 Epilux 155 High Build MIO CoatingsojeckNo ratings yet

- USA5892ps 10193Document5 pagesUSA5892ps 10193Mubashar HassanNo ratings yet

- Resicoat V - F R4 ESDocument3 pagesResicoat V - F R4 ESABHISHEK SINGHNo ratings yet

- Carboguard 893 PDSDocument2 pagesCarboguard 893 PDSNguyễn Thị Châu TâyNo ratings yet

- Thermaline 4700 Aluminum: Selection & Specification DataDocument4 pagesThermaline 4700 Aluminum: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Carbozinc 858 PDSDocument4 pagesCarbozinc 858 PDShuycongvuNo ratings yet

- Interline 850+br+eng PDFDocument2 pagesInterline 850+br+eng PDFMohamed NouzerNo ratings yet

- Thermaline 400: Selection & Specification DataDocument3 pagesThermaline 400: Selection & Specification DataJalaluddinNo ratings yet

- Tds - Jotun - Guard Classic EtDocument3 pagesTds - Jotun - Guard Classic Etvijh van niemannNo ratings yet

- Phenoline 1205 PDSDocument4 pagesPhenoline 1205 PDSonshore purchaseNo ratings yet

- Thermaline 4000 Aluminum: Selection & Specification DataDocument3 pagesThermaline 4000 Aluminum: Selection & Specification DataKatherine Marimón JiménezNo ratings yet

- Carboguard 60 PDSDocument5 pagesCarboguard 60 PDSvihor94213No ratings yet

- Ipd Pds Sikalastomer 95 UsDocument2 pagesIpd Pds Sikalastomer 95 Usernest manNo ratings yet

- Corro Zinc 97Document3 pagesCorro Zinc 97Diego RomeroNo ratings yet

- 751br UsDocument2 pages751br UsandreahankNo ratings yet

- Urethane Coating 165 PWDocument3 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- Material Product Data Sheet Zirconia - Polymer Ceramic Abradable PowdersDocument4 pagesMaterial Product Data Sheet Zirconia - Polymer Ceramic Abradable PowderskerbaubiruNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Fosroc Nitoflor FC 400 UH: Constructive SolutionsDocument4 pagesFosroc Nitoflor FC 400 UH: Constructive SolutionsVincent JavateNo ratings yet

- PVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Document2 pagesPVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Jitendra PatelNo ratings yet

- HJF24R R4 ES - eDocument3 pagesHJF24R R4 ES - evincatesNo ratings yet

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- AS200 Elastomeric Spray Product Data SheetDocument3 pagesAS200 Elastomeric Spray Product Data SheetJhon DewantoNo ratings yet

- Steel PuttyDocument1 pageSteel PuttySiva SubramaniNo ratings yet

- Scotchkote FBE 134W - TDSDocument4 pagesScotchkote FBE 134W - TDSPietro ViganNo ratings yet

- 3M Scotchkote Epoxy Primer GP 120+Document2 pages3M Scotchkote Epoxy Primer GP 120+satya ranjanNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- AkzoNobel - QN102QF - Interpon ACE 2000Document3 pagesAkzoNobel - QN102QF - Interpon ACE 2000Eslam FaroukNo ratings yet

- Product Datasheet: BU Powder CoatingsDocument1 pageProduct Datasheet: BU Powder CoatingsVasudev BhanajiNo ratings yet

- AkzoNobel EN2007 Interpon F2010Document2 pagesAkzoNobel EN2007 Interpon F2010muvinkumarNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- COLD GALVANISING Spray - GBDocument2 pagesCOLD GALVANISING Spray - GBANIL PLAMOOTTILNo ratings yet

- Technical Data Sheet: Neotec PP 200Document2 pagesTechnical Data Sheet: Neotec PP 200Ecaterina RusuNo ratings yet

- Product Information: Kemperol V210Document3 pagesProduct Information: Kemperol V210sri projectssNo ratings yet

- Trusted Technology For Total Tank Inspection, An Ebook by EddyfiDocument44 pagesTrusted Technology For Total Tank Inspection, An Ebook by EddyfiRoger SchvepperNo ratings yet

- API653 Open Book Qrev1Document11 pagesAPI653 Open Book Qrev1Roger SchvepperNo ratings yet

- Folder Intershield 4000USPDocument4 pagesFolder Intershield 4000USPRoger SchvepperNo ratings yet

- Pds Sikasil Gasket Black e 06-14Document2 pagesPds Sikasil Gasket Black e 06-14Roger SchvepperNo ratings yet

- Comprehending Pull-Off Adhesion Testing: by Rob Francis, R A Francis Consulting Services Pty LTDDocument9 pagesComprehending Pull-Off Adhesion Testing: by Rob Francis, R A Francis Consulting Services Pty LTDRoger SchvepperNo ratings yet

- ASTM D610 - Standard Practice For Evaluating Degree of Rusting On Painted Steel SurfacesDocument6 pagesASTM D610 - Standard Practice For Evaluating Degree of Rusting On Painted Steel SurfacesRoger SchvepperNo ratings yet

- Architecture Portfolio - Architect Nicola DoglieroDocument60 pagesArchitecture Portfolio - Architect Nicola Doglieronicola doglieroNo ratings yet

- Mud MortarDocument2 pagesMud MortarHisham AlthafNo ratings yet

- Project 3 - Enamine Reactions 2-AcetylcyclohexanoneDocument3 pagesProject 3 - Enamine Reactions 2-Acetylcyclohexanonexmyka37100% (1)

- Halliburtos SAND TRAPDocument2 pagesHalliburtos SAND TRAPAnonymous JdPYHGmWNo ratings yet

- En10222 4-1999Document12 pagesEn10222 4-1999Dumitru SorinaNo ratings yet

- SSP 204 EspDocument64 pagesSSP 204 Espภูเก็ต เป็นเกาะNo ratings yet

- Project Semester Training - 2012 Mechanical EnggDocument7 pagesProject Semester Training - 2012 Mechanical EnggAbhikrit GoelNo ratings yet

- European Practice On Design&Construction of Concrete PavementsDocument103 pagesEuropean Practice On Design&Construction of Concrete Pavementsshakirhamid6687No ratings yet

- Thesis On Financial Problems of Small Scale Industries in IndiaDocument6 pagesThesis On Financial Problems of Small Scale Industries in Indiacarolynostwaltbillings100% (2)

- Passivity - Definitions and Influencing ParametersDocument5 pagesPassivity - Definitions and Influencing ParametersrrameshsmitNo ratings yet

- Advanced Dry Bottom Ash TechnologyDocument47 pagesAdvanced Dry Bottom Ash TechnologyDimas Febrian SaputraNo ratings yet

- Building Materials 4Document143 pagesBuilding Materials 4NabeelNo ratings yet

- IZM World's SmallestDocument1 pageIZM World's Smallestgaurav110790No ratings yet

- SPDI Refresher Test PaperDocument12 pagesSPDI Refresher Test PaperJohn Rey PelobelloNo ratings yet

- 20a Torque CalculationDocument11 pages20a Torque CalculationRiyan EsapermanaNo ratings yet

- Bergerac Systems: The Challenge of Backward Integration: Group 02, Section - CDocument5 pagesBergerac Systems: The Challenge of Backward Integration: Group 02, Section - CSaumya GautamNo ratings yet

- 9ABS103 Engineering ChemistryDocument4 pages9ABS103 Engineering ChemistrysivabharathamurthyNo ratings yet

- DP Test ProcedureDocument2 pagesDP Test ProcedurePallav ChatterjeeNo ratings yet

- Operator Manual MaxiDocument12 pagesOperator Manual Maxiesteban marinkovicNo ratings yet

- Air Changes Per HourDocument2 pagesAir Changes Per HourjjzoranNo ratings yet

- 815 Plus Single HingeDocument2 pages815 Plus Single HingeSaepul RochmanNo ratings yet

- M15A40Document4 pagesM15A40shubhamtandon01No ratings yet

- ITB-KEOH-2016-009 - Section V - Annex D (Ii) - Electrical Works DrawingsDocument29 pagesITB-KEOH-2016-009 - Section V - Annex D (Ii) - Electrical Works DrawingsSefaNo ratings yet

- Liebherr Brochure Mobilmix enDocument12 pagesLiebherr Brochure Mobilmix enyankNo ratings yet

- 3ply FRP APPLICATION MANUAL - RipoxyDocument5 pages3ply FRP APPLICATION MANUAL - Ripoxyavv.architects02No ratings yet

- 7 Swift Vol2 HvacDocument48 pages7 Swift Vol2 Hvacdin1978100% (1)

- Tatb HMX PBXDocument11 pagesTatb HMX PBXwyngo68No ratings yet

- Three Phase Voltage Monitor - Ae1313Document4 pagesThree Phase Voltage Monitor - Ae1313Ben_Yu_9137No ratings yet

- 7.01 Lime and CementDocument21 pages7.01 Lime and CementRobert MaddenNo ratings yet