Professional Documents

Culture Documents

RA For Tightness Test

RA For Tightness Test

Uploaded by

Ab DoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RA For Tightness Test

RA For Tightness Test

Uploaded by

Ab DoCopyright:

Available Formats

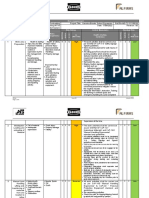

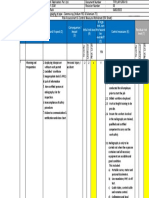

WASTE WATER TREATMENT PROJECT

Hazard Identification, Risk Assessment & Risk Control

Register

RISK ASSESSMENT FOR TIGHTNESS TEST

Download HSE Docs hseprof.com

INITIAL RESUDIAL

Sr. Process Potential

1-25

Risk Involved Risk Control Measure

1-5

1-5

Risk Level 1-25

1-5

1-5Probability

No Activity Hazards

Probability

Risk Level

Severity

Severity

1.0 Preparation Injury of non- 3 2 6 Permits with relevant information 1 2 2

Injury,

for awareness of should be available (drawing,

Property

Tightness Hazards connection joint, Marked up P&ID)

damage.

Test Barricade the area properly & provide

signage, warning signs and information

of the hazard to other personnel using

megaphone/ whistle.

Inspection of equipment, tools,

connection of hoses is required. All

temporary hose and piping connections

should be pressure rated and inspected

for damage/ defects prior to use.

TBT for all personnel involved in activity

should be conducted; discussion

includes hazards and precautions for

particular activity.

2.0 Tightness Equipment Injury 4 3 12 All equipment such as hoses & 1 3 3

test failure compressors to be inspected prior to

Execution use. Daily inspection of equipment such

as compressors should be filled up prior

to use.

Keep Safe distance (compressor area:

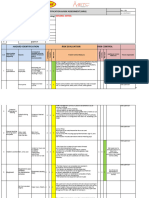

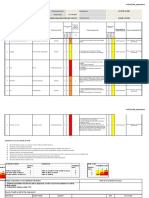

THE BAHRAIN PETROLEUM COMPANY B.S.C. (CLOSED)

BAPCO Doc. No.: RP- 053735

WASTE WATER TREATMENT PLANT PROJECT (WWTPP) Page 2 of 8

RISK ASSESSMENT FOR TIGHTNESS TEST Doc. No.: 100210-HSE-RA-050 Rev. 02

Download HSE Docs hseprof.cim

WASTE WATER TREATMENT PROJECT

Hazard Identification, Risk Assessment & Risk Control

Register

RISK ASSESSMENT FOR TIGHTNESS TEST

Download HSE Docs hseprof.com

INITIAL RESUDIAL

Sr. Process Potential

1-25

Risk Involved Risk Control Measure

1-5

1-5

Risk Level 1-25

1-5

1-5Probability

No Activity Hazards

Probability

Risk Level

Severity

Severity

3m, manifold area: 3m, temp. pipe

area: 2m); barricade and warning signs

such as (PRESSURE TEST-NO ENTRY) to

be installed & avoid approaching the

equipment unnecessarily.

Failure of 4 3 12 Keep safe distance (compressor area: 1 3 3

Injury,

Temporary 3m, manifold area: 3m, temp. pipe

Property

and area: 2m); anchor & shoe to be

damage.

permanent installed for keeping the pipe on

piping position.

caused by Appropriate check of valves position,

over pressure temporary pipe connections and proper

or improper line-up prior to start of test.

bolt / gasket Before starting the air compressor,

at flange ensure that pressure gauge/ Pressure

joints, etc. Relief Valve are in place and in proper

working condition. Calibration

certificate shall be made available.

LOCK-OUT/TAG-OUT will be

implemented on system under test if

required.

Job watchman acquainted with

THE BAHRAIN PETROLEUM COMPANY B.S.C. (CLOSED)

BAPCO Doc. No.: RP- 053735

WASTE WATER TREATMENT PLANT PROJECT (WWTPP) Page 3 of 8

RISK ASSESSMENT FOR TIGHTNESS TEST Doc. No.: 100210-HSE-RA-050 Rev. 02

Download HSE Docs hseprof.cim

WASTE WATER TREATMENT PROJECT

Hazard Identification, Risk Assessment & Risk Control

Register

RISK ASSESSMENT FOR TIGHTNESS TEST

Download HSE Docs hseprof.com

INITIAL RESUDIAL

Sr. Process Potential

1-25

Risk Involved Risk Control Measure

1-5

1-5

Risk Level 1-25

1-5

1-5Probability

No Activity Hazards

Probability

Risk Level

Severity

Severity

necessary information regarding

compressor operation and piping

system knowledge to stand by.

Person in charge of valve handling and

compressor operation should keep the

right position and away from line of

fire.

Injury of 3 3 9 Whip arrestor to be used on hose 1 3 3

Injury,

personnel connection.

Property

caused by Keep safe distance (compressor area:

damage.

detachment/ 3m, manifold area: 3m, temp. pipe

vibration of area: 2m) anchor & shoe to be installed

connected for keeping the pipe on position.

hoses Barricade the area properly & provide

signage and warning signs such as

(PRESSURE TEST-NO ENTRY) near

temporary pipelines, compressor,

manifold and system/line under test.

3.0 Holding of Repair of Injury 3 2 6 Installation of barriers & warning tags 1 2 2

Pressure, Leaks in at all flange connections with proper

inspection pressurize signage e.g. (PRESSURE TEST-NO

and repair system ENTRY)

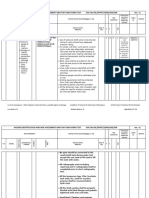

THE BAHRAIN PETROLEUM COMPANY B.S.C. (CLOSED)

BAPCO Doc. No.: RP- 053735

WASTE WATER TREATMENT PLANT PROJECT (WWTPP) Page 4 of 8

RISK ASSESSMENT FOR TIGHTNESS TEST Doc. No.: 100210-HSE-RA-050 Rev. 02

Download HSE Docs hseprof.cim

WASTE WATER TREATMENT PROJECT

Hazard Identification, Risk Assessment & Risk Control

Register

RISK ASSESSMENT FOR TIGHTNESS TEST

Download HSE Docs hseprof.com

INITIAL RESUDIAL

Sr. Process Potential

1-25

Risk Involved Risk Control Measure

1-5

1-5

Risk Level 1-25

1-5

1-5Probability

No Activity Hazards

Probability

Risk Level

Severity

Severity

of leaks Once leak/s found, no repair to be

conducted if the system is under

pressure. Depressurize, repair, re-

conduct test.

The inspector shall wear proper PPE.

Such as protective glasses, gloves and

full body harness if inspection in

scaffolding structure.

4.0 Discharge Improper Injury & 4 1 4 The system pressure once completed 1 1 1

of test discharge/ Damage to must be released gradually thru vents

medium disposal of existing or drains.

test medium facility Area shall be properly barricaded with

signs.

5.0 General 3 2 6 Check all tools and don’t use defective 1 2 2

Defective & Injuries.

Activity tools. Keep the tools clean and free

Greasy Tools.

from any lubricants like oil grease etc.

No improvised tools shall be used.

Employees shall ensure that tools are in

good condition and if a defect is

observed then it must be replaced.

Supervisor shall ensure that required

proper tools are available and they are

THE BAHRAIN PETROLEUM COMPANY B.S.C. (CLOSED)

BAPCO Doc. No.: RP- 053735

WASTE WATER TREATMENT PLANT PROJECT (WWTPP) Page 5 of 8

RISK ASSESSMENT FOR TIGHTNESS TEST Doc. No.: 100210-HSE-RA-050 Rev. 02

Download HSE Docs hseprof.cim

WASTE WATER TREATMENT PROJECT

Hazard Identification, Risk Assessment & Risk Control

Register

RISK ASSESSMENT FOR TIGHTNESS TEST

Download HSE Docs hseprof.com

INITIAL RESUDIAL

Sr. Process Potential

1-25

Risk Involved Risk Control Measure

1-5

1-5

Risk Level 1-25

1-5

1-5Probability

No Activity Hazards

Probability

Risk Level

Severity

Severity

in good condition.

Mushroom head tools shall be rectified

or replaced.

All hammers heads shall be fitted firmly

to the wooden handles.

Flogging spanners shall be kept clean

and in congested area, hammering

shall be done with extreme care.

Penetrating liquids shall be used for

unbolting process.

3 3 9 All tools and equipment must be 1 3 3

Improper Slips, Trips &

storage of Stress. properly stored.

tools and All spare parts must be identified,

spare parts. marked and stored correctly.

3 3 9 All employees must wear required PPE 1 3 3

Compressed Pressure

air. injury. for all jobs.

All employees must wear safety

goggles/respiratory mask while using

compressed air for any job. Note:

Compressed air must never be used for

drying or cleaning any individual. All

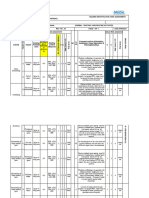

THE BAHRAIN PETROLEUM COMPANY B.S.C. (CLOSED)

BAPCO Doc. No.: RP- 053735

WASTE WATER TREATMENT PLANT PROJECT (WWTPP) Page 6 of 8

RISK ASSESSMENT FOR TIGHTNESS TEST Doc. No.: 100210-HSE-RA-050 Rev. 02

Download HSE Docs hseprof.cim

WASTE WATER TREATMENT PROJECT

Hazard Identification, Risk Assessment & Risk Control

Register

RISK ASSESSMENT FOR TIGHTNESS TEST

Download HSE Docs hseprof.com

INITIAL RESUDIAL

Sr. Process Potential

1-25

Risk Involved Risk Control Measure

1-5

1-5

Risk Level 1-25

1-5

1-5Probability

No Activity Hazards

Probability

Risk Level

Severity

Severity

connections shall be fitted with whip

check arrestors.

3 2 6 All slippery surfaces shall be cleaned 1 2 2

Slippery Slips and

surface. Falls. immediately using sawdust or sand.

All hose connections should be properly

arranged and provided with barricades

or warning tapes

4.0 Working at 4 3 12 Qualified personnel to erect scaffolding 1 3 3

Unsecured Collapse of

Height (standard) and green scaffold-tags

platform platform,

Injury. must be attached.

Ensure scaffold platforms are fit for

purpose (Working or Load Bearing). Do

not overload platforms with personnel

& equipment

4 3 12 Always use buckets to store tools, 1 3 3

Falling Injury and

objects. damage to consumables, and scrap materials.

equipment. Never carry any materials up a ladder.

Remove all unwanted materials as soon

as possible.

Always wear PPE.

Check toe boards, mid-rails & hand rails

are secured

THE BAHRAIN PETROLEUM COMPANY B.S.C. (CLOSED)

BAPCO Doc. No.: RP- 053735

WASTE WATER TREATMENT PLANT PROJECT (WWTPP) Page 7 of 8

RISK ASSESSMENT FOR TIGHTNESS TEST Doc. No.: 100210-HSE-RA-050 Rev. 02

Download HSE Docs hseprof.cim

WASTE WATER TREATMENT PROJECT

Hazard Identification, Risk Assessment & Risk Control

Register

RISK ASSESSMENT FOR TIGHTNESS TEST

Download HSE Docs hseprof.com

INITIAL RESUDIAL

Sr. Process Potential

1-25

Risk Involved Risk Control Measure

1-5

1-5

Risk Level 1-25

1-5

1-5Probability

No Activity Hazards

Probability

Risk Level

Severity

Severity

4 3 12 Never alter any scaffolding, only 1 3 3

Unauthorized Falls.

alterations scaffolding crew is allowed to make the

necessary alterations.

Notes:

1. Full time Safety / Supervisory coverage shall be ensured at site.

2. All the required permits shall be obtained before starting the job.

3. All issued work permits and copies of Risk Assessment shall be kept in a Permit Box at site.

4. The Supervisor shall conduct Tool Box Talk & explain the risks and control measures to all crew

members.

5. Before leaving the work site on completion of each day’s work, the area shall be checked for

proper house-keeping, elimination of all possible sources of fire, shutdown of all construction

equipments, proper storage of tools and tackles etc

6. All employees must know the emergency procedures of BAPCO.

7. Attendance sheet of Toolbox Talk shall be available for audit; subsequently it must be submitted to

GS.

8. Provide portable toilet, proper barricading of the work area with signage.

9. Cool down shelter and drinking water shall be available at site.

10.Ensure the work / resting area, shall be kept neat and clean and all rubbish is put into the waste

and shall be disposed on regular basic.

THE BAHRAIN PETROLEUM COMPANY B.S.C. (CLOSED)

BAPCO Doc. No.: RP- 053735

WASTE WATER TREATMENT PLANT PROJECT (WWTPP) Page 8 of 8

RISK ASSESSMENT FOR TIGHTNESS TEST Doc. No.: 100210-HSE-RA-050 Rev. 02

Download HSE Docs hseprof.cim

WASTE WATER TREATMENT PROJECT

Hazard Identification, Risk Assessment & Risk Control

Register

RISK ASSESSMENT FOR TIGHTNESS TEST

Download HSE Docs hseprof.com

GS E&C Commissioning. GS E &C GS E &C BAPCO

Prepared By : _____________ Reviewed By : ____________ Approved By : __________ Approved By : ___________

Ariel Dela Cruz H U Lee Ariel Dela Cruz C G Sudhakaran

Commissioning Manager HSE Manager F, H & S Department

THE BAHRAIN PETROLEUM COMPANY B.S.C. (CLOSED)

BAPCO Doc. No.: RP- 053735

WASTE WATER TREATMENT PLANT PROJECT (WWTPP) Page 9 of 8

RISK ASSESSMENT FOR TIGHTNESS TEST Doc. No.: 100210-HSE-RA-050 Rev. 02

Download HSE Docs hseprof.cim

You might also like

- HIRA For Civil WorkDocument11 pagesHIRA For Civil WorkYogesh Nath100% (3)

- RA 022 Risk Assessment - Coring of ManholeDocument8 pagesRA 022 Risk Assessment - Coring of Manholethomson100% (1)

- Radiography Work 004Document6 pagesRadiography Work 004BinayNo ratings yet

- Risk Assessment For BridgeDocument31 pagesRisk Assessment For BridgeMariam Mousa100% (2)

- The Chemistry of Process Development in Pharmaceutical Industry 1Document60 pagesThe Chemistry of Process Development in Pharmaceutical Industry 1Venugopal Rao Veeramaneni100% (1)

- Hightec Inc.Document10 pagesHightec Inc.anurag4u10No ratings yet

- RA For Air BlowingDocument8 pagesRA For Air BlowingMD AZHER ULLAH BAIG100% (1)

- Excavation Trenching & Pipe Laying R-ADocument18 pagesExcavation Trenching & Pipe Laying R-ANabil Abdelsamea100% (1)

- Risk Assessment - Rev - 00 (Construction of High Voltage Sub Station Autho R Arber Dogani - 01.01.2015Document8 pagesRisk Assessment - Rev - 00 (Construction of High Voltage Sub Station Autho R Arber Dogani - 01.01.2015Arber DoganiNo ratings yet

- Risk Assessment - SanitarywaresDocument9 pagesRisk Assessment - SanitarywaresJhOichriz Reginaldo CuevasNo ratings yet

- GASPP-RA-006 Form WorkDocument5 pagesGASPP-RA-006 Form WorkAdil HasanovNo ratings yet

- Risk Assessment - Fire Pump SetDocument8 pagesRisk Assessment - Fire Pump SetJhOichriz Reginaldo CuevasNo ratings yet

- Al Qooz Contracting LLC: Hazard Identification and Risk AssesmentDocument8 pagesAl Qooz Contracting LLC: Hazard Identification and Risk Assesmentشاز إياس100% (1)

- Risk Assessment Block WorksDocument11 pagesRisk Assessment Block WorkskannanjaduzzNo ratings yet

- Risk Assessment Concrete WorkDocument10 pagesRisk Assessment Concrete WorkkannanjaduzzNo ratings yet

- Excavation & Backfilling Risk - AssessmentDocument9 pagesExcavation & Backfilling Risk - AssessmentKashif RehmanNo ratings yet

- Hand Tools SHE Risk AssessmentDocument3 pagesHand Tools SHE Risk AssessmentMuhammed yahiyaNo ratings yet

- Decking Risk AssessmentDocument4 pagesDecking Risk AssessmentReagan MukeboNo ratings yet

- Cutting, Griding, WeldingDocument6 pagesCutting, Griding, WeldingAli SalihNo ratings yet

- RA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & TrenchesDocument11 pagesRA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & Trenchesthomson100% (2)

- AMB 172-016 LiftingDocument3 pagesAMB 172-016 LiftingRues AgNo ratings yet

- Hydro Test JSADocument4 pagesHydro Test JSArk3050037No ratings yet

- Risk Assessment - Plumbing Pump SetDocument8 pagesRisk Assessment - Plumbing Pump SetJhOichriz Reginaldo Cuevas100% (1)

- RA For Hydrostatic Pneumatic-Test and Flushing of Pipeline and Equipment - 17Document9 pagesRA For Hydrostatic Pneumatic-Test and Flushing of Pipeline and Equipment - 17alla malik100% (1)

- Risk Assesment (Service Staircase)Document2 pagesRisk Assesment (Service Staircase)Fawad KhanNo ratings yet

- Risk Assessment - Hvac SystemDocument8 pagesRisk Assessment - Hvac SystemJhOichriz Reginaldo Cuevas100% (1)

- Risk Assessment For NDTDocument14 pagesRisk Assessment For NDTNestor Mijares100% (1)

- Risk Assessment For Lifting OperationDocument2 pagesRisk Assessment For Lifting OperationROBIN GIBUNo ratings yet

- RA Flushing &Hydro-TestingDocument8 pagesRA Flushing &Hydro-Testingalla malikNo ratings yet

- Risk Assessment Aluminum CladdingDocument6 pagesRisk Assessment Aluminum Claddingkannanjaduzz100% (1)

- Risk Assessment - Foam SystemDocument8 pagesRisk Assessment - Foam SystemJhOichriz Reginaldo CuevasNo ratings yet

- Ra FormatDocument11 pagesRa Formatsafeer SulaimanNo ratings yet

- HEMP/JHA/RA/HITRA - Pneumatic TestingDocument7 pagesHEMP/JHA/RA/HITRA - Pneumatic TestingSidhanath SinghNo ratings yet

- Hazard Identification & Risk Assessment (Hira) /jsa: Hira & Jsa For Tri Butyl Phosphate (TBP) PlantDocument6 pagesHazard Identification & Risk Assessment (Hira) /jsa: Hira & Jsa For Tri Butyl Phosphate (TBP) PlantShariq KhanNo ratings yet

- RISK ASSESSMENT Interlock and KerbstoneDocument20 pagesRISK ASSESSMENT Interlock and KerbstonekannanjaduzzNo ratings yet

- Task /activity: Installation of Abseil HooksDocument10 pagesTask /activity: Installation of Abseil HooksfrancisbautistaNo ratings yet

- Lone Working Risk AssessmentDocument3 pagesLone Working Risk AssessmentMuhammed yahiyaNo ratings yet

- Forklift Truck OperationsDocument2 pagesForklift Truck OperationsaboroookaNo ratings yet

- 5.#hiradec - CWPDocument7 pages5.#hiradec - CWPPankaj PandeyNo ratings yet

- Ra Radiography 10Document1 pageRa Radiography 10alla malikNo ratings yet

- Risk Assesment - MobilisationDocument7 pagesRisk Assesment - Mobilisationشاز إياسNo ratings yet

- HIRAC CraneDocument2 pagesHIRAC CranetaufikNo ratings yet

- RA - HDPE Fire FittingDocument2 pagesRA - HDPE Fire FittingRAMY ABOU AL DAHABNo ratings yet

- RA Construction For Sub-Base & Road Base WorksDocument17 pagesRA Construction For Sub-Base & Road Base WorksBleep NewsNo ratings yet

- Risk Assessment (Night Shift) BND3Document11 pagesRisk Assessment (Night Shift) BND3Shazayn KhanNo ratings yet

- Risk Assessment Aluminum Curtainwalls, Doors & WindowsDocument13 pagesRisk Assessment Aluminum Curtainwalls, Doors & WindowskannanjaduzzNo ratings yet

- 67) DE54 ODME OperationDocument3 pages67) DE54 ODME Operationlatish salianNo ratings yet

- Risk Assessment Towercrane ErectionDocument6 pagesRisk Assessment Towercrane ErectionkannanjaduzzNo ratings yet

- Covid-19 Risk AssessmentDocument8 pagesCovid-19 Risk AssessmentMultiline Technical DEWA SITENo ratings yet

- Hot Work - Welding, Gas Cutting, Grinding, Buffing, Cutting - HIRADocument10 pagesHot Work - Welding, Gas Cutting, Grinding, Buffing, Cutting - HIRAAjay MedikondaNo ratings yet

- Forklift Operations - Risk Assessment & Hazard IdentificationDocument5 pagesForklift Operations - Risk Assessment & Hazard IdentificationSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- De-Shuttering Risk Assisment SICAST ProjectDocument3 pagesDe-Shuttering Risk Assisment SICAST ProjectKashif RehmanNo ratings yet

- 5.2.2.9 Laydown Drill Pipes1Document2 pages5.2.2.9 Laydown Drill Pipes1khrayzie bhone100% (1)

- RA 021 Risk Assessment - Installation of External Landscape Lighting WorksDocument13 pagesRA 021 Risk Assessment - Installation of External Landscape Lighting Worksthomson50% (2)

- ALBAZ General RA - Construction Well Pads-Rev A.Document2 pagesALBAZ General RA - Construction Well Pads-Rev A.Ali HadiNo ratings yet

- JSA of Sand Blasting of Pipe and Housekeeping 1Document8 pagesJSA of Sand Blasting of Pipe and Housekeeping 1Anish mazumderNo ratings yet

- Larsen & Toubro Limited Buildings and Factories Independent CompanyDocument5 pagesLarsen & Toubro Limited Buildings and Factories Independent CompanyabbasNo ratings yet

- Risk Assessment For The Installation of Mobile CrusherDocument6 pagesRisk Assessment For The Installation of Mobile CrusherArsh NazarNo ratings yet

- Confined Space Entry - SH&E Risk Assessment: Middle EastDocument5 pagesConfined Space Entry - SH&E Risk Assessment: Middle EastyahiyaNo ratings yet

- Hazards Identification and Risk Assessment - New FormatDocument2 pagesHazards Identification and Risk Assessment - New FormatBIIS QAQC Babu Siva100% (1)

- Risk Assessment For Installation of Cable Tray and TruckingDocument1 pageRisk Assessment For Installation of Cable Tray and Truckingazer50% (4)

- SAE FlangesDocument9 pagesSAE FlangesWalter JosephNo ratings yet

- ASU-100M 12F Cable SpecDocument3 pagesASU-100M 12F Cable SpecestebanNo ratings yet

- Hindustan Petroleum Corporation LimitedDocument1 pageHindustan Petroleum Corporation LimitedDinakarSatyaNo ratings yet

- Rcme 03.2022Document100 pagesRcme 03.2022Martijn HinfelaarNo ratings yet

- CASH FLOW & RAB Yakob 1A (1) (1) - DikonversiDocument23 pagesCASH FLOW & RAB Yakob 1A (1) (1) - DikonversiAHMAD FADILLAHNo ratings yet

- Chapter 21: Cellular RadioDocument9 pagesChapter 21: Cellular RadioDavid van TeeselingNo ratings yet

- Sero Prospekt SRZ eDocument8 pagesSero Prospekt SRZ esdafas dfNo ratings yet

- Siemens IGCC PlantDocument32 pagesSiemens IGCC PlantDeepak Gehlot100% (1)

- MSDS - CHIMEC 1038 - Gas Corr. InhibitorDocument6 pagesMSDS - CHIMEC 1038 - Gas Corr. InhibitorAnonymous LfeGI2hM0% (1)

- 1 3 4Document43 pages1 3 4JoeNo ratings yet

- Kriss Super V CRB So SBR SO ManualDocument32 pagesKriss Super V CRB So SBR SO ManualMichael LamNo ratings yet

- Carrier Frame PartsDocument40 pagesCarrier Frame PartsSales AydinkayaNo ratings yet

- Netmagic Solutions Private Limited: Memorandum of Association OFDocument19 pagesNetmagic Solutions Private Limited: Memorandum of Association OFbapun2007No ratings yet

- J10048-Nexus Parcel 1-C&S Concept Design Report - R00Document50 pagesJ10048-Nexus Parcel 1-C&S Concept Design Report - R00loc khaNo ratings yet

- AvailabilityWorkbench A4Document501 pagesAvailabilityWorkbench A4Rodrigo Vargas100% (1)

- Android Complete Reference by KavitaDocument35 pagesAndroid Complete Reference by KavitaKumar RajadhyakshNo ratings yet

- The Pit Bull's Guide To Successful TradingDocument25 pagesThe Pit Bull's Guide To Successful TradingRohit BiradarNo ratings yet

- Simon Haykin - Neural Networks - A Comprehensive FoundationDocument823 pagesSimon Haykin - Neural Networks - A Comprehensive Foundationleonardownknow63% (8)

- Schematic: SPR-16-12-P1-52-XX-P1-X 0 Conf General Installation 00Document1 pageSchematic: SPR-16-12-P1-52-XX-P1-X 0 Conf General Installation 00toto.gmbhNo ratings yet

- WWU Wade King Sustainable Case StudyDocument2 pagesWWU Wade King Sustainable Case StudyTABREZ MULLANo ratings yet

- Oracle EAM Failure AnalysisDocument4 pagesOracle EAM Failure AnalysisDock N DenNo ratings yet

- BSCITDocument34 pagesBSCITNilabjo Kanti PaulNo ratings yet

- Brochure EC250D EC300D T3 EN 30 20035491 CDocument28 pagesBrochure EC250D EC300D T3 EN 30 20035491 CLU YO100% (1)

- Chapter 2 Industrial Biotechnology-2Document114 pagesChapter 2 Industrial Biotechnology-2yoganandaNo ratings yet

- U DB Oracle11 v8r1.8 Checklist 20100827 PDFDocument130 pagesU DB Oracle11 v8r1.8 Checklist 20100827 PDFChidi OkerekeNo ratings yet

- Cap476september04 PDFDocument569 pagesCap476september04 PDFriversgardenNo ratings yet

- Lecture 4Document5 pagesLecture 4Rizki MurdowoNo ratings yet

- BD-815U Manual (English) - R0Document15 pagesBD-815U Manual (English) - R0Huguens DesrosiersNo ratings yet