Professional Documents

Culture Documents

Shell Tube Heat Exchanger - Leaking Gaskets 1

Shell Tube Heat Exchanger - Leaking Gaskets 1

Uploaded by

Mohammed TasifCopyright:

Available Formats

You might also like

- HJ Cooper Mains Pressure Duplex 2304 Stainless Steel CylindersDocument2 pagesHJ Cooper Mains Pressure Duplex 2304 Stainless Steel Cylindersshaun10No ratings yet

- Air Cooled Heat Exchangers - GEA BrochureDocument16 pagesAir Cooled Heat Exchangers - GEA BrochurenorthstarleoNo ratings yet

- Pipe Span ChartDocument4 pagesPipe Span ChartAnonymous oVRvsdWzfBNo ratings yet

- Plug Process Repair Heat Exchangers PDFDocument6 pagesPlug Process Repair Heat Exchangers PDFJOÃO CARLOS SILVANo ratings yet

- Alstom Process Gas CoolerDocument12 pagesAlstom Process Gas Coolerrajaramc100% (1)

- Tech Sheet 135Document4 pagesTech Sheet 135Camilo SantacruzNo ratings yet

- Layouts and HeatDocument25 pagesLayouts and Heatsarantapodarusa4009No ratings yet

- Plate Fin Heat Ex ChangersDocument16 pagesPlate Fin Heat Ex Changerscapricorno4694No ratings yet

- Plate & Frame / Shell & Tube Heat Exchangers Fact ManualDocument24 pagesPlate & Frame / Shell & Tube Heat Exchangers Fact ManualHolayilNo ratings yet

- Heat Exchangers: Kevin D. Rafferty, P.E. Gene Culver Geo-Heat CenterDocument7 pagesHeat Exchangers: Kevin D. Rafferty, P.E. Gene Culver Geo-Heat CenterscepterraNo ratings yet

- Chapter 13Document10 pagesChapter 13mapasabcNo ratings yet

- Boiler Pressure PartsDocument3 pagesBoiler Pressure PartsBedabyas DehuryNo ratings yet

- Heat Pipe HomeworkDocument4 pagesHeat Pipe Homeworkafetoeszs100% (1)

- All About The Design of HeatsinksDocument40 pagesAll About The Design of Heatsinks조용규No ratings yet

- Waste Heat Recovery Considering Environmental FactorsDocument7 pagesWaste Heat Recovery Considering Environmental FactorsrvnesariNo ratings yet

- Coil Catalog Version 09 - 01ADocument28 pagesCoil Catalog Version 09 - 01AblindjaxxNo ratings yet

- Air-Cooled Heat ExchangersDocument16 pagesAir-Cooled Heat Exchangersalex200301No ratings yet

- Application of HEat PipeDocument29 pagesApplication of HEat PipeNikhil ShahNo ratings yet

- Simplification of Isolation Product Selection Through Advanced Design GPT IndustriesDocument6 pagesSimplification of Isolation Product Selection Through Advanced Design GPT Industriespayam.ghafooriNo ratings yet

- Industrial Heating and Cooling CoilsDocument4 pagesIndustrial Heating and Cooling CoilsSME CoilsNo ratings yet

- Hopper Heating Design GuideDocument4 pagesHopper Heating Design GuideBadukwangNo ratings yet

- Brazed Aluminium Plate Fin Heat Exchangers-Construction, Uses Advantages in Cryogenic Refrigeration SystemsDocument31 pagesBrazed Aluminium Plate Fin Heat Exchangers-Construction, Uses Advantages in Cryogenic Refrigeration SystemsHitesh Panchal100% (1)

- General Information On Air-Cooled Heat ExchangersDocument5 pagesGeneral Information On Air-Cooled Heat ExchangersSrinivas BobbyNo ratings yet

- CHEVRON Shell and Tube Exchanger Component Design ConsiderationsDocument42 pagesCHEVRON Shell and Tube Exchanger Component Design Considerationsbabak mir83% (6)

- The Heat Sink Guide-Information About HeatsinksDocument6 pagesThe Heat Sink Guide-Information About HeatsinksTahseen Al-Sumayda'yNo ratings yet

- Shell and Plate Article Sept 2009 HCEDocument3 pagesShell and Plate Article Sept 2009 HCENgoVietCuongNo ratings yet

- PHEDocument2 pagesPHEImudia Omamuefe VictorNo ratings yet

- Vogt Valves Post Weld Heat Treatment of Socket Weld WalvesDocument7 pagesVogt Valves Post Weld Heat Treatment of Socket Weld Walvesgm_revankarNo ratings yet

- Specifying Shell and Tube Heat ExchangersDocument10 pagesSpecifying Shell and Tube Heat ExchangersMicheal BrooksNo ratings yet

- Heat Exchanger Failure CourseworkDocument4 pagesHeat Exchanger Failure Courseworkswqoqnjbf100% (2)

- Guide To Compact Heat Ex Changers - Plate Heat ExchangerDocument65 pagesGuide To Compact Heat Ex Changers - Plate Heat ExchangerFrank ChoiNo ratings yet

- ASTM A193 GR B7 Vs GR B7M Bolts For Sour Service HXDocument5 pagesASTM A193 GR B7 Vs GR B7M Bolts For Sour Service HXYoussef DaoudNo ratings yet

- How Long Should My Thermocouple Last - 2020-03-12 - Industrial HeatingDocument4 pagesHow Long Should My Thermocouple Last - 2020-03-12 - Industrial HeatingTS WongNo ratings yet

- 1973 BACKER Shaped Heat 20111009Document50 pages1973 BACKER Shaped Heat 20111009Hank MarvinNo ratings yet

- Heat Recovery From Exhaust GasesDocument6 pagesHeat Recovery From Exhaust GasesnaveenNo ratings yet

- Tap HoleDocument16 pagesTap HoleRAKESH RANJANNo ratings yet

- GIW Technical Series: Cold Weather Operation and StorageDocument2 pagesGIW Technical Series: Cold Weather Operation and StorageTravis SkinnerNo ratings yet

- Boiler Components: Super HeaterDocument2 pagesBoiler Components: Super Heaterponnivalavans_994423No ratings yet

- Immersion Heaters-Selection & Implementation-Article From Chemical Engineering January-2006Document5 pagesImmersion Heaters-Selection & Implementation-Article From Chemical Engineering January-2006John UrdanetaNo ratings yet

- 01 - Chemetics Gas-Gas Heat Exchanger InfoSheetDocument2 pages01 - Chemetics Gas-Gas Heat Exchanger InfoSheetWeb LogueandoNo ratings yet

- News Letter For Expansion Bellow PDFDocument4 pagesNews Letter For Expansion Bellow PDFAsma Khan100% (1)

- Schmidt-Bretten Brazed Plate Installation and Maintenance MaDocument12 pagesSchmidt-Bretten Brazed Plate Installation and Maintenance MacakendriNo ratings yet

- Solar Heat Exchanger ArticleDocument7 pagesSolar Heat Exchanger ArticlejimfanslerNo ratings yet

- Kiln Shell CoolingDocument4 pagesKiln Shell CoolingjmpbarrosNo ratings yet

- SB020Document2 pagesSB020Ko ZayNo ratings yet

- Gledhill Torrent Re Solar Installation GuideDocument16 pagesGledhill Torrent Re Solar Installation Guidecommando828No ratings yet

- Aosmith HeatersDocument48 pagesAosmith HeatersAli Kamel AkilNo ratings yet

- 2012 de Rijk Est Mechanical Tube Plug Technology For HP Heat ExchangersDocument6 pages2012 de Rijk Est Mechanical Tube Plug Technology For HP Heat ExchangersGuruchell ChellguruNo ratings yet

- PLATE & SHELL Heat Exchangers: A Shell & Tube AlternativeDocument4 pagesPLATE & SHELL Heat Exchangers: A Shell & Tube AlternativearianaseriNo ratings yet

- Common Questions Heat Pipes PDFDocument2 pagesCommon Questions Heat Pipes PDFTeo Pei San100% (1)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Innovation in Electric Arc Furnaces: Scientific Basis for SelectionFrom EverandInnovation in Electric Arc Furnaces: Scientific Basis for SelectionNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- The Art of Lead Burning: A practical treatise explaining the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatise explaining the apparatus and processesNo ratings yet

- Electroplating for Amateurs: Classic Reference for Small WorkshopsFrom EverandElectroplating for Amateurs: Classic Reference for Small WorkshopsNo ratings yet

- Refits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5From EverandRefits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5Rating: 3 out of 5 stars3/5 (1)

- The Art of Lead Burning: A practical treatisening the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatisening the apparatus and processesNo ratings yet

- Fishing TechnologyDocument64 pagesFishing TechnologyK K Verma100% (5)

- Chumacera Seal Master RPB-211-4Document6 pagesChumacera Seal Master RPB-211-4Gabriel RodriguezNo ratings yet

- Saeed Farokhi CVDocument20 pagesSaeed Farokhi CVAll time HitsNo ratings yet

- Comprehensive Plumbing Code - KeywordsDocument63 pagesComprehensive Plumbing Code - KeywordsMaribeth AbellaNo ratings yet

- G650 Maintenance Engine Run ChecklistDocument40 pagesG650 Maintenance Engine Run Checkliststive100% (1)

- Ficha Tecnica - Backing RingDocument1 pageFicha Tecnica - Backing RingFernando Rocca VillalobosNo ratings yet

- Ojee Engineering Cut Off 2011Document110 pagesOjee Engineering Cut Off 2011KaranGargNo ratings yet

- Sa01 Genxxx SDGG PRTS 0107 V00Document7 pagesSa01 Genxxx SDGG PRTS 0107 V00amini_mohiNo ratings yet

- Physics Key FormulasDocument4 pagesPhysics Key FormulasChidi BenedictNo ratings yet

- U-Tank Stabilization SystemDocument4 pagesU-Tank Stabilization SystemBurduja IonNo ratings yet

- Chiller Scroll YCAL (091-106)Document16 pagesChiller Scroll YCAL (091-106)Jhon Lewis PinoNo ratings yet

- TechPlasty - PE500 - Polyethylene 500 - 2019-08-06Document2 pagesTechPlasty - PE500 - Polyethylene 500 - 2019-08-06SDKNo ratings yet

- Lefty Technol OGYDocument11 pagesLefty Technol OGYMau RcabreraNo ratings yet

- Design Proposal IESL Suranga Dadallage - Version1 PDFDocument10 pagesDesign Proposal IESL Suranga Dadallage - Version1 PDFSuranga C.Dadallage100% (1)

- CSA Bolted Connection FatigueDocument3 pagesCSA Bolted Connection FatiguejurieskNo ratings yet

- Catalogo Motor VortecDocument3 pagesCatalogo Motor VortecgennnaroNo ratings yet

- Balancing CONCLUSIONDocument2 pagesBalancing CONCLUSIONSyahdi Rosli100% (1)

- Aerial Robotics Lecture 3B - 1 Time, Motion, and TrajectoriesDocument4 pagesAerial Robotics Lecture 3B - 1 Time, Motion, and TrajectoriesIain McCullochNo ratings yet

- Electric Sheet For 1200-350Document4 pagesElectric Sheet For 1200-350Alfiya AnamNo ratings yet

- Fine Dust Filters Airpanel Eco Synthetic Pleated Filter PDFDocument2 pagesFine Dust Filters Airpanel Eco Synthetic Pleated Filter PDFRaja Mohamed Hasan Allah PitchaiNo ratings yet

- Oh - Tank - Foundation As Per Indian Standard CodeDocument7 pagesOh - Tank - Foundation As Per Indian Standard Codedsananda100% (1)

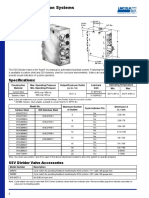

- Divider Valves: Quicklub Lubrication SystemsDocument4 pagesDivider Valves: Quicklub Lubrication SystemsBehi BshNo ratings yet

- ABB Seccionadores de Potencia HV: Caracteristicas Tecnicas y Aplicaciones EspecialesDocument52 pagesABB Seccionadores de Potencia HV: Caracteristicas Tecnicas y Aplicaciones EspecialesAndrea AtzeniNo ratings yet

- Steel SectionDocument1 pageSteel SectionRai RiveraNo ratings yet

- Basic Sheet MetalDocument3 pagesBasic Sheet MetalDH AfnanNo ratings yet

- Sous Réserve de Modifications! HAWE Hydraulik München © 2003, Page 1 Sur 3, (CD1 MRZ 2019-OP)Document3 pagesSous Réserve de Modifications! HAWE Hydraulik München © 2003, Page 1 Sur 3, (CD1 MRZ 2019-OP)GERALD SIMONNo ratings yet

- PHYSIC3Document47 pagesPHYSIC3Sofië0% (1)

- Turbulent FlowDocument15 pagesTurbulent FlowcrisjrogersNo ratings yet

- 2015 Ford 6.7L Diesel F 250 550 Supplement Version 1 - 60l6d - EN US - 02 - 2014 PDFDocument84 pages2015 Ford 6.7L Diesel F 250 550 Supplement Version 1 - 60l6d - EN US - 02 - 2014 PDFtonomart79No ratings yet

Shell Tube Heat Exchanger - Leaking Gaskets 1

Shell Tube Heat Exchanger - Leaking Gaskets 1

Uploaded by

Mohammed TasifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shell Tube Heat Exchanger - Leaking Gaskets 1

Shell Tube Heat Exchanger - Leaking Gaskets 1

Uploaded by

Mohammed TasifCopyright:

Available Formats

Monday, June 14th, 2021

Shell & Tube Heat Exchanger – Leaking

Gaskets

Monday Morning Minutes | by Norm Hall, June

14th, 2021

Shell and tube heat exchanger leaks can be very

frustrating. Occasionally we receive a call from a

frustrated contractor who swears he installed the

heat exchanger properly but finds occasional

leaks at the gasket.

Steam to Water Shell & Tube Heat Exchanger Duty

As complicated as we think it is, the steam to water heat

exchanger in commercial and institutional hydronic systems

has an easy job. Heat so many GPM of water from, for

example, 150⁰F to 180⁰F using 10 PSIG steam. No exotic

fluids and chemicals. No extreme high pressures.

The Bell and Gossett installation and operation manual

(IOM) instructs the contractor to tighten the bolts to a

specific torque and in a specific pattern once the heat

exchanger is at operating conditions. I assume other

manufacturers have similar requirements. The same IOM

clearly states that, during an operational shutdown, the hot

side fluid must be shut down before the cold side. All these

requirements are designed to avoid leaking or drips as the

temperatures in the heat exchanger change from cold to operational temperature.

The contractor does everything right but finds occasional leaks.

Heat Exchanger Thermal Cycling

One possible issue is thermal cycling of the heat exchanger. If the heat exchanger is heated

to design and then shut down over regular periods, the gasket between the cast iron heads

and steel tube sheet may drip. The gasket’s “seating force” may drop due to expansion and

contraction.

As the heat exchanger operates, the head, tube sheet, bolts, and gasket materials are

affected by the temperature. That is why the contractor is asked to re-tighten the bolts

once the operating conditions are achieved.

The heat exchanger manufacturer provides gasket material to meet the design conditions

specified. Here is an example I ran into many years ago. A university built an addition with a

new Bell & Gossett SU heat exchanger. The design conditions were the numbers I

mentioned earlier in the blog. For some reason, at night, they shut the system down. I am

not sure why they did it, but they did it. This exchanger cycled from the hot conditions to

room temperature regularly. The gaskets leaked.

The Gasket Solution that Saved the Day

The solution was to replace the compressed fiber gaskets with Elastagraph gaskets. These

gaskets combine graphite and metals to provide a gasket that responds much better to

cycling. That was the solution that satisfied the university problem.

Today, Bell & Gossett standardizes on these gaskets in the 14” to 20” steam to water

U-tube model SU heat exchangers. There is a large enough gasket to head surface to

provide them as a type of insurance against wide temperature swings. On smaller diameter

heat exchangers, these gaskets are optional and have a higher cost and delivery time.

Please be careful in specifications. Asking for “metal” or “spiral wound” gasket brands may

cause issues. Not all gasket materials and types are recommended with the head, bolt, and

shell materials used on the heat exchanger brands used in our industry. Make sure you

coordinate the specification and talk to your local representative.

You might also like

- HJ Cooper Mains Pressure Duplex 2304 Stainless Steel CylindersDocument2 pagesHJ Cooper Mains Pressure Duplex 2304 Stainless Steel Cylindersshaun10No ratings yet

- Air Cooled Heat Exchangers - GEA BrochureDocument16 pagesAir Cooled Heat Exchangers - GEA BrochurenorthstarleoNo ratings yet

- Pipe Span ChartDocument4 pagesPipe Span ChartAnonymous oVRvsdWzfBNo ratings yet

- Plug Process Repair Heat Exchangers PDFDocument6 pagesPlug Process Repair Heat Exchangers PDFJOÃO CARLOS SILVANo ratings yet

- Alstom Process Gas CoolerDocument12 pagesAlstom Process Gas Coolerrajaramc100% (1)

- Tech Sheet 135Document4 pagesTech Sheet 135Camilo SantacruzNo ratings yet

- Layouts and HeatDocument25 pagesLayouts and Heatsarantapodarusa4009No ratings yet

- Plate Fin Heat Ex ChangersDocument16 pagesPlate Fin Heat Ex Changerscapricorno4694No ratings yet

- Plate & Frame / Shell & Tube Heat Exchangers Fact ManualDocument24 pagesPlate & Frame / Shell & Tube Heat Exchangers Fact ManualHolayilNo ratings yet

- Heat Exchangers: Kevin D. Rafferty, P.E. Gene Culver Geo-Heat CenterDocument7 pagesHeat Exchangers: Kevin D. Rafferty, P.E. Gene Culver Geo-Heat CenterscepterraNo ratings yet

- Chapter 13Document10 pagesChapter 13mapasabcNo ratings yet

- Boiler Pressure PartsDocument3 pagesBoiler Pressure PartsBedabyas DehuryNo ratings yet

- Heat Pipe HomeworkDocument4 pagesHeat Pipe Homeworkafetoeszs100% (1)

- All About The Design of HeatsinksDocument40 pagesAll About The Design of Heatsinks조용규No ratings yet

- Waste Heat Recovery Considering Environmental FactorsDocument7 pagesWaste Heat Recovery Considering Environmental FactorsrvnesariNo ratings yet

- Coil Catalog Version 09 - 01ADocument28 pagesCoil Catalog Version 09 - 01AblindjaxxNo ratings yet

- Air-Cooled Heat ExchangersDocument16 pagesAir-Cooled Heat Exchangersalex200301No ratings yet

- Application of HEat PipeDocument29 pagesApplication of HEat PipeNikhil ShahNo ratings yet

- Simplification of Isolation Product Selection Through Advanced Design GPT IndustriesDocument6 pagesSimplification of Isolation Product Selection Through Advanced Design GPT Industriespayam.ghafooriNo ratings yet

- Industrial Heating and Cooling CoilsDocument4 pagesIndustrial Heating and Cooling CoilsSME CoilsNo ratings yet

- Hopper Heating Design GuideDocument4 pagesHopper Heating Design GuideBadukwangNo ratings yet

- Brazed Aluminium Plate Fin Heat Exchangers-Construction, Uses Advantages in Cryogenic Refrigeration SystemsDocument31 pagesBrazed Aluminium Plate Fin Heat Exchangers-Construction, Uses Advantages in Cryogenic Refrigeration SystemsHitesh Panchal100% (1)

- General Information On Air-Cooled Heat ExchangersDocument5 pagesGeneral Information On Air-Cooled Heat ExchangersSrinivas BobbyNo ratings yet

- CHEVRON Shell and Tube Exchanger Component Design ConsiderationsDocument42 pagesCHEVRON Shell and Tube Exchanger Component Design Considerationsbabak mir83% (6)

- The Heat Sink Guide-Information About HeatsinksDocument6 pagesThe Heat Sink Guide-Information About HeatsinksTahseen Al-Sumayda'yNo ratings yet

- Shell and Plate Article Sept 2009 HCEDocument3 pagesShell and Plate Article Sept 2009 HCENgoVietCuongNo ratings yet

- PHEDocument2 pagesPHEImudia Omamuefe VictorNo ratings yet

- Vogt Valves Post Weld Heat Treatment of Socket Weld WalvesDocument7 pagesVogt Valves Post Weld Heat Treatment of Socket Weld Walvesgm_revankarNo ratings yet

- Specifying Shell and Tube Heat ExchangersDocument10 pagesSpecifying Shell and Tube Heat ExchangersMicheal BrooksNo ratings yet

- Heat Exchanger Failure CourseworkDocument4 pagesHeat Exchanger Failure Courseworkswqoqnjbf100% (2)

- Guide To Compact Heat Ex Changers - Plate Heat ExchangerDocument65 pagesGuide To Compact Heat Ex Changers - Plate Heat ExchangerFrank ChoiNo ratings yet

- ASTM A193 GR B7 Vs GR B7M Bolts For Sour Service HXDocument5 pagesASTM A193 GR B7 Vs GR B7M Bolts For Sour Service HXYoussef DaoudNo ratings yet

- How Long Should My Thermocouple Last - 2020-03-12 - Industrial HeatingDocument4 pagesHow Long Should My Thermocouple Last - 2020-03-12 - Industrial HeatingTS WongNo ratings yet

- 1973 BACKER Shaped Heat 20111009Document50 pages1973 BACKER Shaped Heat 20111009Hank MarvinNo ratings yet

- Heat Recovery From Exhaust GasesDocument6 pagesHeat Recovery From Exhaust GasesnaveenNo ratings yet

- Tap HoleDocument16 pagesTap HoleRAKESH RANJANNo ratings yet

- GIW Technical Series: Cold Weather Operation and StorageDocument2 pagesGIW Technical Series: Cold Weather Operation and StorageTravis SkinnerNo ratings yet

- Boiler Components: Super HeaterDocument2 pagesBoiler Components: Super Heaterponnivalavans_994423No ratings yet

- Immersion Heaters-Selection & Implementation-Article From Chemical Engineering January-2006Document5 pagesImmersion Heaters-Selection & Implementation-Article From Chemical Engineering January-2006John UrdanetaNo ratings yet

- 01 - Chemetics Gas-Gas Heat Exchanger InfoSheetDocument2 pages01 - Chemetics Gas-Gas Heat Exchanger InfoSheetWeb LogueandoNo ratings yet

- News Letter For Expansion Bellow PDFDocument4 pagesNews Letter For Expansion Bellow PDFAsma Khan100% (1)

- Schmidt-Bretten Brazed Plate Installation and Maintenance MaDocument12 pagesSchmidt-Bretten Brazed Plate Installation and Maintenance MacakendriNo ratings yet

- Solar Heat Exchanger ArticleDocument7 pagesSolar Heat Exchanger ArticlejimfanslerNo ratings yet

- Kiln Shell CoolingDocument4 pagesKiln Shell CoolingjmpbarrosNo ratings yet

- SB020Document2 pagesSB020Ko ZayNo ratings yet

- Gledhill Torrent Re Solar Installation GuideDocument16 pagesGledhill Torrent Re Solar Installation Guidecommando828No ratings yet

- Aosmith HeatersDocument48 pagesAosmith HeatersAli Kamel AkilNo ratings yet

- 2012 de Rijk Est Mechanical Tube Plug Technology For HP Heat ExchangersDocument6 pages2012 de Rijk Est Mechanical Tube Plug Technology For HP Heat ExchangersGuruchell ChellguruNo ratings yet

- PLATE & SHELL Heat Exchangers: A Shell & Tube AlternativeDocument4 pagesPLATE & SHELL Heat Exchangers: A Shell & Tube AlternativearianaseriNo ratings yet

- Common Questions Heat Pipes PDFDocument2 pagesCommon Questions Heat Pipes PDFTeo Pei San100% (1)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Innovation in Electric Arc Furnaces: Scientific Basis for SelectionFrom EverandInnovation in Electric Arc Furnaces: Scientific Basis for SelectionNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- The Art of Lead Burning: A practical treatise explaining the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatise explaining the apparatus and processesNo ratings yet

- Electroplating for Amateurs: Classic Reference for Small WorkshopsFrom EverandElectroplating for Amateurs: Classic Reference for Small WorkshopsNo ratings yet

- Refits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5From EverandRefits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5Rating: 3 out of 5 stars3/5 (1)

- The Art of Lead Burning: A practical treatisening the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatisening the apparatus and processesNo ratings yet

- Fishing TechnologyDocument64 pagesFishing TechnologyK K Verma100% (5)

- Chumacera Seal Master RPB-211-4Document6 pagesChumacera Seal Master RPB-211-4Gabriel RodriguezNo ratings yet

- Saeed Farokhi CVDocument20 pagesSaeed Farokhi CVAll time HitsNo ratings yet

- Comprehensive Plumbing Code - KeywordsDocument63 pagesComprehensive Plumbing Code - KeywordsMaribeth AbellaNo ratings yet

- G650 Maintenance Engine Run ChecklistDocument40 pagesG650 Maintenance Engine Run Checkliststive100% (1)

- Ficha Tecnica - Backing RingDocument1 pageFicha Tecnica - Backing RingFernando Rocca VillalobosNo ratings yet

- Ojee Engineering Cut Off 2011Document110 pagesOjee Engineering Cut Off 2011KaranGargNo ratings yet

- Sa01 Genxxx SDGG PRTS 0107 V00Document7 pagesSa01 Genxxx SDGG PRTS 0107 V00amini_mohiNo ratings yet

- Physics Key FormulasDocument4 pagesPhysics Key FormulasChidi BenedictNo ratings yet

- U-Tank Stabilization SystemDocument4 pagesU-Tank Stabilization SystemBurduja IonNo ratings yet

- Chiller Scroll YCAL (091-106)Document16 pagesChiller Scroll YCAL (091-106)Jhon Lewis PinoNo ratings yet

- TechPlasty - PE500 - Polyethylene 500 - 2019-08-06Document2 pagesTechPlasty - PE500 - Polyethylene 500 - 2019-08-06SDKNo ratings yet

- Lefty Technol OGYDocument11 pagesLefty Technol OGYMau RcabreraNo ratings yet

- Design Proposal IESL Suranga Dadallage - Version1 PDFDocument10 pagesDesign Proposal IESL Suranga Dadallage - Version1 PDFSuranga C.Dadallage100% (1)

- CSA Bolted Connection FatigueDocument3 pagesCSA Bolted Connection FatiguejurieskNo ratings yet

- Catalogo Motor VortecDocument3 pagesCatalogo Motor VortecgennnaroNo ratings yet

- Balancing CONCLUSIONDocument2 pagesBalancing CONCLUSIONSyahdi Rosli100% (1)

- Aerial Robotics Lecture 3B - 1 Time, Motion, and TrajectoriesDocument4 pagesAerial Robotics Lecture 3B - 1 Time, Motion, and TrajectoriesIain McCullochNo ratings yet

- Electric Sheet For 1200-350Document4 pagesElectric Sheet For 1200-350Alfiya AnamNo ratings yet

- Fine Dust Filters Airpanel Eco Synthetic Pleated Filter PDFDocument2 pagesFine Dust Filters Airpanel Eco Synthetic Pleated Filter PDFRaja Mohamed Hasan Allah PitchaiNo ratings yet

- Oh - Tank - Foundation As Per Indian Standard CodeDocument7 pagesOh - Tank - Foundation As Per Indian Standard Codedsananda100% (1)

- Divider Valves: Quicklub Lubrication SystemsDocument4 pagesDivider Valves: Quicklub Lubrication SystemsBehi BshNo ratings yet

- ABB Seccionadores de Potencia HV: Caracteristicas Tecnicas y Aplicaciones EspecialesDocument52 pagesABB Seccionadores de Potencia HV: Caracteristicas Tecnicas y Aplicaciones EspecialesAndrea AtzeniNo ratings yet

- Steel SectionDocument1 pageSteel SectionRai RiveraNo ratings yet

- Basic Sheet MetalDocument3 pagesBasic Sheet MetalDH AfnanNo ratings yet

- Sous Réserve de Modifications! HAWE Hydraulik München © 2003, Page 1 Sur 3, (CD1 MRZ 2019-OP)Document3 pagesSous Réserve de Modifications! HAWE Hydraulik München © 2003, Page 1 Sur 3, (CD1 MRZ 2019-OP)GERALD SIMONNo ratings yet

- PHYSIC3Document47 pagesPHYSIC3Sofië0% (1)

- Turbulent FlowDocument15 pagesTurbulent FlowcrisjrogersNo ratings yet

- 2015 Ford 6.7L Diesel F 250 550 Supplement Version 1 - 60l6d - EN US - 02 - 2014 PDFDocument84 pages2015 Ford 6.7L Diesel F 250 550 Supplement Version 1 - 60l6d - EN US - 02 - 2014 PDFtonomart79No ratings yet