Professional Documents

Culture Documents

Volta Belt Vietnam

Volta Belt Vietnam

Uploaded by

tuannhocutOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Volta Belt Vietnam

Volta Belt Vietnam

Uploaded by

tuannhocutCopyright:

Available Formats

Conveying Solutions

‘V’ & Round Profiles

The Next Step in Belting

V & Round Pro

o es

Round RTB RFC RL RLC RLB RLW RO ROS RPZ RPZS RPD-AS** RPN RPS RPB RPBS RM RMS RMDS***

* RW RMW RMWN RH RHN RCW* Hollow RFC - HL RO - HL RPN - HL

Hardness 72A 76A 80A 80A 80A 80A 83A 83A 86A 86A 88A 88A 88A 88A 88A 90A 90A 95A 95A 95A 95A 100A 100A 63D 76A 83A 88A/37D

O.D

D Temp. Range -40º C to +50º C -40º C to +55º C -30º C to +80º C

I.D

CoF (Steel) 0.85 0.65 0.40 0.65 0.55 0.50

Certifications No No No Yes No

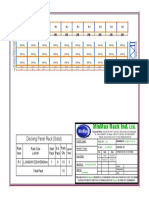

Diameter MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg Size (mm) MPD PF kg MPD PF kg MPD PF kg

Inch mm (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (0.5%) (mm) (1%) (mm) (0.3%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (0.5%) (mm) (0.5%) (mm) (1%) (mm) (1%) (mm) (0.5%) O.D I.D (mm) (1%) (mm) (1%) (mm) (1%)

5/64 2 15 0.06 15 0.06 15 0.06 20 0.13 19 0.13 20 0.26 40 0.60 4.80 1.80

/81 3 20 0.14 20 0.14 20 0.14 20 0.14 30 0.31 29 0.31 29 0 .31 30 0.60 60 1.40 6.30 2.40

5/ 4 20 0.23 20 0.20 30 0.25 30 0.25 30 0.25 30 0.25 40 0.54 38 0.54 38 0.54 40 1 40 1 50 1.25 80 2.50 8 3.20

32

3/ 5 25 0.35 25 0.30 50 0.85 60 2.00 100 3.90 9.50 4

16

15/ 6 30 0.40 38 0.55 54 1.16 60 1.22 57 1.22 60 16 57 1.22 60 16 75 3.25 12.50 5.30

64

1/ 6.30 30 0.50 60 2.60 60 2.60 75 10 75 10 125 6.20 100 13 15 5.30

4

9/ 7 18 7.80

32

5/ 8 40 0.95 40 0.75 55 1 55 1 55 1 48 1.06 54 5 72 2.05 80 2.18 76 2.18 80 19 76 2 .18 80 19 80 4.20 80 4.20 95 5.25 95 17 160 10 20 7.80

16

9/ 9

32

3/ 9.50 45 1.13 95 5.90 110 7.37 110 18 190 14 190 14 150 20

8 4.80

23/ 10 70 1.55 89 3.20 95 19.50 95 3.40 100 22 95 3.40 100 22 130* 55

64 6.30

15/ 12

32

1/

8

2 12.50 65 1.50

9/ 9.50

16 14

19/ 15 100 3.50 100 3.50 100 3.50 135 7.25 140 24 143 7.65 150 27 143 7.65 150 27 150 14.60 150 14.60 175 30 300 23 300 23 12.50

32

5/ 16 15

8

23/ 18 120 5.10 120 5.10 125 27 171 11 180 37 180 21 210 32 360 34 360 34

32 80A 18

3/ 19

4 19.30 20

25/ 20 190 13.6 200 25.90

32 5.50 Notes: Connectors

1 25 *RFC-HL & RO-HL -15/18/20 Not standard

8

V-Profiles VFC 40 VL VLC VLB VLW VO VO - GT** VOS** VPZ VPZS VPY *** VPYS VPN VPNS VPF VPFS VMF VM VMS VMW** VMW-NK**** VH VHB

W Hardness 76A 80A

Yes 80A 80A 80A 83A 83A 83A 86A/35D 86A/35D 86A/35D 86A/35D 88A/37D 88A/37D 88A/37D 88A/37D 90A/40D 90A/40D 90A/40D 95A/46D 95A/46D 100A/55D 100A/55D

Temp. Range -40º C to +50º C -40º C to +55º C -40º C to +55º C -40º C to +55º C -40º C to +55º C -40º C to +55º C -40º C to +55º C -40º C to +55º C -20º C to +50º C -20º C to +50º C -20º C to +50º C -20º C to +50º C -30º C to +60º C -30º C to +60º C -30º C to +60º C -30º C to +60º C -30º C to +60º C -30º C to +60º C -30º C to +60º C -30º C to +60º C -30º C to +60º C -20º C to +75º C -20º C to +75º C

H CoF (Steel) 0.65 0.55 0.55 0.55 0.55 0.55 0.55 0.55 0.40 0.40 0.40 0.40 0.38 0.38 0.38 0.38 0.45 0.45 0.45 0.36 0.36 0.28 0.28

Certifications No Yes Yes Yes Yes Yes Yes Yes No No No No No No No No No Yes Yes Yes Yes Yes Yes

Inch Size (mm) MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg

Size Width Heigth (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (0.5%) (mm) (1%) (mm) (1%) (mm) (0.5%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (1%) (mm) (0.5%) (mm) (0.5%) (mm) (1%) (mm) (1%)

Y 6 4 20 0.28 25 0.30 25 3.10

M 8 5.20 25 0.49 40 0.70 40 0.70 60 3 60 3 125 4.80

3L 9.50 5.50 30 0.64 45 0.90 40 5

Z 10 6.50 45 1 45 1 45 1 60 2.70 65 4.10 65 4.10 65 4.10 75 12 130 6.60

A 13 8 40 1.23 50 1.60 50 1.60 50 1.60 50 12 50 1.60 53 12 72 3.30 88 26 72 3.30 88 26 76 3.50 92 28 76 3.50 92 28 80 6.7 80 6.70 80 6.70 75 14 100 16 160 10.70 160 10.70

B 17 11.50 75 2.90 75 2.90 75 2.90 75 18 75 2.90 75 2.90 72 17 103 6.10 112 39 103 6.10 112 39 110 6.40 118 43 110 6.40 118 43 115 12.10 115 12.10 115 12.10 100 27 140 30 230 19.50 230 19.50

- 20 12.50 85 3.90 125 15. 90 250 25.50

C 22 14.50 100 4.80 100 4.80 100 4.80 100 22 100 4.60 100 4.60 100 22 130 10 142 44 130 10 142 44 138 10.50 150 49 138 10.50 150 49 145 20 145 20 130 36 200 40 290 32 290 32

- 25 16.50 110 6.30 155 16.80 165 25.90 210 45 330 41.50

D 32 21.50 145 10.40 145* 24 145 10.40 215 43 270 55

E 40 27 180 16.30 270 67.30

DVOS DVM

80A 80A 83A 83A 90A/40D

W

Inch Size (mm) MPD PF kg MPD PF kg MPD PF kg MPD PF kg MPD PF kg

Size (mm) (1%) (mm) (0.5%) (mm) (1%) (mm) (0.5%) (mm) (1%)

45 2 45 2

50 3.20 50 22 50 3.20 53 22 80 13.40

Index: MPD - Minimum Pulley Diameter - Measurements for butt welding. In case of overlap welding please check the MPD with your local distributor. Notes: *VL -/VLC -/VM - RT - Height 28.5mm. **VO-GT, VOS - Inch sizes only. ***VPY – Not standard. Notes: *RCW - also available with Steel, Stainless Steel & Kevlar (Aramid) reinforcement.

PF - Pull Force (Kg) at minimum pretention (%). CoF Notes: * VLW-32 - Height 19mm. **VMW - Cogged. **** VMW - NK -Not Cogged. VMW - NK - 32 Height - 20mm. ***RMDS - Diameter 10.5mm. *** RMDS - High UV Resistance ** RPD-AS: ESD - ratio 109-1010 OHMS per square.

Volta Belting Technology Ltd. www.voltabelting.com

V & Round Pro

o es

Guides

Products

Shore Hardness

Color

Cogged

Certifications

Size (mm)

Add To Minimum Pulley Diameter

Width Height

6 4 NR 25 NR NR NR NR NR 15

8 5.20 30 40 NR 60 NR NR NR 25

10 6 35 45 50 65 55 70 22 30

13 8 40 50 60 85 60 80 28 35

17 11.50 60 75 85 115 85 110 40 50

20 12.50 NR 85 NR 125 NR NR NR NR

22 14.50 75 100 110 145 110 150 NR 65

Note: Special guides: CFC, CFB, CLSC, VLSB-LT for low temperature (LT) belts; VLB-MD for metal detectable (MD) belts.

Special Profiles

Products SPN - 1000 SPY - 1000 SPF-MP SM - 1400 TO - 9.5 TO 1/2 TO 9/16 SO 3/4 UO - 9.5

W W W W

Illustration H H H H

w w

w w w

Hardness 88A

Top Width 15.70

Size

Height 13.60

(mm)

Bottom Width 3.10 8.35 9.50 8 7

MPD (mm) NR

Certifications No No Yes Yes Yes Yes Yes Yes Yes

Products SH - 1200 TEMB - 25 SLW ¾ TLB - 10 TLB - 15 TLW - 30 SLC - 2300 SLC - 2104 TTB - 15

W

H W W W W W

w

Illustration H H H H

TEMW - 25 w

W w w H w

H

w

Hardness 80A 72A

Top Width 19.30 15

Size

Height 2.2 5.50 5

(mm)

Bottom Width 4 8 3.10 6.50 22 22 10.30 6.50

MPD (mm) 40 27

Certifications No Yes Yes Yes Yes Yes Yes Yes Yes

Size (W x H) Minimum Pulley Cert.

Width Height Diameter

SH - 1300 16 1.70 50

SH - 1301 18 1.70 50

SH - 1302 20 1.70 50

SH - 1305 25 1.70 50

SH - 1306 W 14 1.70 50

SH - 1310 16 2 60

100A/55D No

SH - 1311 18 2 60

H

SH - 1312 20 2 60

SH - 1313 8 2 60

SH - 1314 8 3 80

SH - 1320 10 4 95

SH - 1325 17 1.50 45

Notes: *TLW/30 - Cogged.

Belt Coating Materials for the Food Industry

Products FEMB/FEMW-SP

Illustration

Description Super Grip Multi Grip Wood Grip High Grip Spikes Spikes Saw Tooth

Hardness 62A 62A 62A 62A 95A 80A 80A

Width* 50 50 70 1524 1524 1524 1524

Size (mm)

Thickness 4 6 4 2/ 2.5/ 3/ 4 2/ 2.5/ 3** 2/ 2.5/ 3** 4***

CoF (Steel) 0.98 1.08 1.05 0.95 0.25 0.45 0.45

Temperature Range -20º C to +40º C -30º C to +60º C -40º C to +50º C -40º C to +50º C

Note: Width* - Maximum available width. **Height of Spikes above base belt is 2.8 mm. *** FELB-IST - Total belt thickness.

Belt Coating Materials

FSTF - ST

Products Strips GWG - 4

Illustration

Foam & High Foam & High

Description Wood Grip

Grip Top Grip Strips

Hardness

Width*

Size(mm)

Thickness

CoF (Steel)

Temp. Range -40º C to +55º C

Notes: Width* - Maximum available width. **Foam - Made from 65A shore material, actual hardness is lower.

Mini Pliers R - 8 F-51 Pliers for standard V and Round profile Easy Overlap Welding Tool

Corporate Headquarters USA EUROPE

Sales and Manufacturing Tel: +1 973 276 7905 Tel: +31-546-580166

sales@voltabelting.com Fax: +1 973 276 7908 Fax: +31-546-579508

USA EUROPE

Toll Free: 1-877-VOLTAUS www.voltabelting.com

Tel: +1 973 276 7905 Tel: +31-546-580166

Fax: +1 973 276 7908 Fax: +31-546-579508 www.voltabelting.com

Toll Free: 1-877-VOLTAUS

Volta Belting makes no warranty with respect to any of its products for a particular Copyright©2015 Volta Belting Technology Ltd.

purpose. See Volta General Terms and Conditions. CAT503EN00 - Ver.I - August 2016 tions.

You might also like

- 6505 MHDocument10 pages6505 MHJulio Güissa57% (7)

- iNUKE NU6000DSP PDFDocument45 pagesiNUKE NU6000DSP PDFDiogo SilvaNo ratings yet

- Aps 348 349 350Document3 pagesAps 348 349 350Andres AlegriaNo ratings yet

- Working Between The Hook and The Load: 2014 Product Catalogue For UK & ROWDocument68 pagesWorking Between The Hook and The Load: 2014 Product Catalogue For UK & ROWDiego RNo ratings yet

- CASE 1 Royal DSM N.V. Group ITStalwarts-FinalDocument16 pagesCASE 1 Royal DSM N.V. Group ITStalwarts-FinalGary Kwong100% (4)

- Material Transfer Request Form: ﺔﺑوﻠطﻣﻟا ﺔﻣدﺧﻟا لﯾﺻﺎﻔﺗ -1 1-Required service DetailsDocument1 pageMaterial Transfer Request Form: ﺔﺑوﻠطﻣﻟا ﺔﻣدﺧﻟا لﯾﺻﺎﻔﺗ -1 1-Required service DetailsbaraahNo ratings yet

- Dig 525 (061017)Document19 pagesDig 525 (061017)Bernard MendisNo ratings yet

- Krp-Cd-Ele-1404-002 - Platform Level Plan Equipment LayoutDocument1 pageKrp-Cd-Ele-1404-002 - Platform Level Plan Equipment LayoutGourishankar MishraNo ratings yet

- 30lbf11br001-Rev 2Document1 page30lbf11br001-Rev 2Mohd Effiezool YaserNo ratings yet

- 30lbe51br001-Rev 2 - 2Document1 page30lbe51br001-Rev 2 - 2Mohd Effiezool YaserNo ratings yet

- 30lae25br004-Rev 2Document1 page30lae25br004-Rev 2Mohd Effiezool YaserNo ratings yet

- 10lab12br001-Rev 1 - 1Document1 page10lab12br001-Rev 1 - 1Mohd Effiezool YaserNo ratings yet

- B737 800 DigitalDocument1 pageB737 800 DigitalmohammedredhadjoudiNo ratings yet

- Módulo Megacharge 2500 Esquema PDFDocument2 pagesMódulo Megacharge 2500 Esquema PDFJoao Raffagnato CaldasNo ratings yet

- Chassis TH2983A Diagrama PDFDocument1 pageChassis TH2983A Diagrama PDFWilmer PerezNo ratings yet

- 115/13.8kV TRANSFORMER (T602) PROTN. SET-1 PANEL-1 +TRPA.21Document1 page115/13.8kV TRANSFORMER (T602) PROTN. SET-1 PANEL-1 +TRPA.21Anonymous BZQOJwWIh6No ratings yet

- Pre Tsa 420Document1 pagePre Tsa 420Antonio Fernandes de JesusNo ratings yet

- Utilaje Depozite Frigorifice Compresor Tip 1 Compresor Tip 2Document1 pageUtilaje Depozite Frigorifice Compresor Tip 1 Compresor Tip 2Anda Angheluș PetrescuNo ratings yet

- 3-ModelDocument1 page3-Modeljoselito navarroNo ratings yet

- Módulo Megacharge 2500 EsquemaDocument2 pagesMódulo Megacharge 2500 EsquemaMarcosNo ratings yet

- Módulo Megacharge 2500 EsquemaDocument2 pagesMódulo Megacharge 2500 EsquemaManoel BonfimNo ratings yet

- Módulo Megacharge 2500 EsquemaDocument2 pagesMódulo Megacharge 2500 EsquemaJoao Raffagnato CaldasNo ratings yet

- 1C17 (KSS021-D-541) - Column-R0.1Document1 page1C17 (KSS021-D-541) - Column-R0.1mo3azNo ratings yet

- 1K2 PotDocument1 page1K2 PotcbsomtecladosNo ratings yet

- OPTIM778 Schematic Diagram: AmamcDocument2 pagesOPTIM778 Schematic Diagram: AmamcGabriel MirciuNo ratings yet

- CCE Microonda M-190 120V Diagrama Esquematico PDFDocument1 pageCCE Microonda M-190 120V Diagrama Esquematico PDFJose UzcateguiNo ratings yet

- SBGR - Rnav Vovbi 1a Rwy 09l - Sid - 20190912 PDFDocument1 pageSBGR - Rnav Vovbi 1a Rwy 09l - Sid - 20190912 PDFRodrigo HalzenthNo ratings yet

- iNUKE NU6000DSP: Service ManualDocument45 pagesiNUKE NU6000DSP: Service ManualRicardoCassanovaNavaNo ratings yet

- 30lbe51br002-Rev 1Document1 page30lbe51br002-Rev 1Mohd Effiezool YaserNo ratings yet

- Job 00000Document1 pageJob 00000Mostakim RahmanNo ratings yet

- 10lab12br001-Rev 1 - 2Document1 page10lab12br001-Rev 1 - 2Mohd Effiezool YaserNo ratings yet

- Transformer /175W Line Safety Line: MotorDocument1 pageTransformer /175W Line Safety Line: Motororo plataNo ratings yet

- LK3 LMF3 CLCW Flowsheet Revise 0Document1 pageLK3 LMF3 CLCW Flowsheet Revise 0chakree53No ratings yet

- Simetri Class HDocument1 pageSimetri Class HSamijat YtNo ratings yet

- EE12Document1 pageEE12Mamad SoheNo ratings yet

- BASSMONSTER DISCRETE Ver.1 - UcD BCA Class D Amplifier With IGBTDocument1 pageBASSMONSTER DISCRETE Ver.1 - UcD BCA Class D Amplifier With IGBTRhenz TalhaNo ratings yet

- DWC7894 11 05 - 00Document1 pageDWC7894 11 05 - 00nthekkumpuramNo ratings yet

- TC 1424 Diagrama EsquematicoDocument1 pageTC 1424 Diagrama Esquematicomasava03No ratings yet

- Carvin C-1644 4 Bussmaster Audio 2002 SCHDocument1 pageCarvin C-1644 4 Bussmaster Audio 2002 SCHAndres GuerreroNo ratings yet

- Ethiopian Electric Power (Eep) : Submission ofDocument6 pagesEthiopian Electric Power (Eep) : Submission ofjie zhangNo ratings yet

- G Board Schematic Diagram For 32" ModelDocument1 pageG Board Schematic Diagram For 32" Modeljose luisNo ratings yet

- Subway LevelDocument1 pageSubway LevelManojNo ratings yet

- Lower DevelopmentDocument1 pageLower DevelopmentManojNo ratings yet

- 2220-PW-6"-C1E2A-21269: Diametro Largo Total (M) ItemDocument1 page2220-PW-6"-C1E2A-21269: Diametro Largo Total (M) ItemAlonso FarfanNo ratings yet

- UcD-XLite2FB - Discrete Fullbridge V.3Document1 pageUcD-XLite2FB - Discrete Fullbridge V.3Joel GomesNo ratings yet

- Arvin: System Master Bx600, Bx1200Document1 pageArvin: System Master Bx600, Bx1200Nguyễn Quang TrânNo ratings yet

- Balcon C1Document1 pageBalcon C1Laura GeorgianaNo ratings yet

- Carvin Schematic - RX1200 System Master Rev D EDocument4 pagesCarvin Schematic - RX1200 System Master Rev D EdodNo ratings yet

- Clay Tiles Shop Drawing - SDDocument1 pageClay Tiles Shop Drawing - SDAhmed MohamedNo ratings yet

- Threading Catalog: CAT2016THD FRONTCOVER - Indd 1 8/24/16 10:37 AMDocument156 pagesThreading Catalog: CAT2016THD FRONTCOVER - Indd 1 8/24/16 10:37 AMagung wijayaNo ratings yet

- 19 Schematic Diagram: CD Servo CircuitDocument12 pages19 Schematic Diagram: CD Servo CircuitRuben Dario Dulcey LeonNo ratings yet

- Boss RV 5 Digital Reverb SchematicDocument1 pageBoss RV 5 Digital Reverb Schematictofu157No ratings yet

- CCE Audio MD-3000E Diagrama EsquematicoDocument3 pagesCCE Audio MD-3000E Diagrama EsquematicoMarceloNo ratings yet

- Tmpe2 Ev Er20Document1 pageTmpe2 Ev Er20Marko BradvicaNo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- Mac - Tar-Ndl - Ac Layout-052923Document1 pageMac - Tar-Ndl - Ac Layout-052923Jay MarkNo ratings yet

- Canned-Cray DocumentationDocument4 pagesCanned-Cray DocumentationnemoNo ratings yet

- AC Schematic Diagram For 13233kV Transformer Protection+GT1Document1 pageAC Schematic Diagram For 13233kV Transformer Protection+GT1sreeagile.esNo ratings yet

- Existing - Earthing - Layout For Bogra 230kV SubstationDocument1 pageExisting - Earthing - Layout For Bogra 230kV SubstationRashad SarwarNo ratings yet

- Philips Az1047Document10 pagesPhilips Az1047loc nguyenNo ratings yet

- MAV3208 Rev0 ENDocument2 pagesMAV3208 Rev0 ENtuannhocutNo ratings yet

- Home Admin Web Hoplongtech - Com Public HTML Uploads Download 1531963154 SCHNEIDER-IPAVS-XMLADocument104 pagesHome Admin Web Hoplongtech - Com Public HTML Uploads Download 1531963154 SCHNEIDER-IPAVS-XMLAtuannhocutNo ratings yet

- RfN-4051 USDocument6 pagesRfN-4051 UStuannhocutNo ratings yet

- RPT RINGFEDER Shrink Discs RFN 4051 HT ENDocument2 pagesRPT RINGFEDER Shrink Discs RFN 4051 HT ENtuannhocutNo ratings yet

- XAHS SeriesDocument114 pagesXAHS SeriestuannhocutNo ratings yet

- Dong Ho Chi Bao Do Lech Ap Loai Lon 1b894aa0 Fd2e 46c3 b4d3 B4fd2a65512aDocument1 pageDong Ho Chi Bao Do Lech Ap Loai Lon 1b894aa0 Fd2e 46c3 b4d3 B4fd2a65512atuannhocutNo ratings yet

- Phao Xa Nuoc Tu Dong sm9100 Aok-16b 6304a39b 7fd7 4c6c 8133 510a56b9d2b7Document1 pagePhao Xa Nuoc Tu Dong sm9100 Aok-16b 6304a39b 7fd7 4c6c 8133 510a56b9d2b7tuannhocutNo ratings yet

- VR820Document1 pageVR820tuannhocutNo ratings yet

- Dong Ho Chi Bao Do Lech Ap Loai Nho 8697b3ab 58aa 4ca7 889e B7d5a3f8f4f7Document1 pageDong Ho Chi Bao Do Lech Ap Loai Nho 8697b3ab 58aa 4ca7 889e B7d5a3f8f4f7tuannhocutNo ratings yet

- PARTSDocument61 pagesPARTStuannhocutNo ratings yet

- HyundaiDocument91 pagesHyundaituannhocutNo ratings yet

- R-05 Hydraulics ValveDocument1,706 pagesR-05 Hydraulics ValvetuannhocutNo ratings yet

- Form 8972EDocument180 pagesForm 8972EtuannhocutNo ratings yet

- Valeoscope - Transmission Syst. Clutch Hydraulics CSC CMC CRDocument32 pagesValeoscope - Transmission Syst. Clutch Hydraulics CSC CMC CRtuannhocutNo ratings yet

- SRD150 EngDocument2 pagesSRD150 EngtuannhocutNo ratings yet

- Dim OilsealDocument12 pagesDim OilsealtuannhocutNo ratings yet

- SV12 EngDocument2 pagesSV12 EngtuannhocutNo ratings yet

- SV35DA EngDocument2 pagesSV35DA EngtuannhocutNo ratings yet

- Ervina Aprianti, Budi Suharjo, Dan Istiqlaliyah MuflikhatiDocument9 pagesErvina Aprianti, Budi Suharjo, Dan Istiqlaliyah MuflikhatisafaNo ratings yet

- Online Summer Training ReporDocument224 pagesOnline Summer Training ReporDhruvi PatelNo ratings yet

- ACN Case Workbook PDFDocument25 pagesACN Case Workbook PDFAkshay AnandNo ratings yet

- Compass 2024GlobalConstructionCostsDatabase Watermark 01-24Document18 pagesCompass 2024GlobalConstructionCostsDatabase Watermark 01-24Ali YıldırımNo ratings yet

- Project Report - M&A - Krishna PatelDocument69 pagesProject Report - M&A - Krishna PatelKrishnaNo ratings yet

- Suppliers-221229Document443 pagesSuppliers-221229ahmed aliNo ratings yet

- P189963.67.9271.05-C3006 MM-04209Document4 pagesP189963.67.9271.05-C3006 MM-04209Aswindana Ibnu SenaNo ratings yet

- Useful SAP FI Related Transaction Codes Organizational StructureDocument12 pagesUseful SAP FI Related Transaction Codes Organizational StructurePavan Kumar k.No ratings yet

- Tariffs On E-Bikes From China Derailing U.S. Market: Sales Increasing SteadilyDocument5 pagesTariffs On E-Bikes From China Derailing U.S. Market: Sales Increasing SteadilyVimi ImNo ratings yet

- Joint Press Release January 22 2021 - Re PFAS - The Chemours Company - DuPont, Corteva, and Chemours Announce Resolution of Legacy PFAS ClaimsDocument3 pagesJoint Press Release January 22 2021 - Re PFAS - The Chemours Company - DuPont, Corteva, and Chemours Announce Resolution of Legacy PFAS ClaimsKirk HartleyNo ratings yet

- Poka Yoke - Mistake Proofing SystemDocument23 pagesPoka Yoke - Mistake Proofing Systemkvk301712No ratings yet

- Stock StatementDocument2 pagesStock StatementABDUL KHALIKNo ratings yet

- All About Msmed Act 2006: CA. Manish ChowdhuryDocument4 pagesAll About Msmed Act 2006: CA. Manish ChowdhurySUNIL PUJARINo ratings yet

- Maruti Suzuki AnalysisDocument22 pagesMaruti Suzuki AnalysisSayan KunduNo ratings yet

- Estimated Daily U.S. Slaughter Capacity by Plant HPDDocument1 pageEstimated Daily U.S. Slaughter Capacity by Plant HPDSteven CollinsNo ratings yet

- Acquaa ParkDocument104 pagesAcquaa ParkHACHALU FAYENo ratings yet

- BSFIDocument2 pagesBSFIsamcqNo ratings yet

- Tutorial Job Costing CADocument4 pagesTutorial Job Costing CAmiranti dNo ratings yet

- FordDocument45 pagesFordkavyansh mainiNo ratings yet

- List of Companies 2022.06.24 WebsiteDocument25 pagesList of Companies 2022.06.24 WebsiteEugene Lau100% (1)

- Technology and Livelihood Education Quarter 1, Wk.2 - Module 2 Afa-Agri Crop Production-Sharpening ToolsDocument12 pagesTechnology and Livelihood Education Quarter 1, Wk.2 - Module 2 Afa-Agri Crop Production-Sharpening Toolsjose ariel barroa jrNo ratings yet

- Group 2 ECONOMIC BASE 2Document46 pagesGroup 2 ECONOMIC BASE 2Maria Cristina ImportanteNo ratings yet

- SS16 Order Practice 1 1Document29 pagesSS16 Order Practice 1 1K59 Huynh Kim NganNo ratings yet

- Audit Report Korangi Factory 16 Aug 2021Document58 pagesAudit Report Korangi Factory 16 Aug 2021sajid waqasNo ratings yet

- Insights Mind Maps: Issues Related To MSPDocument2 pagesInsights Mind Maps: Issues Related To MSPrushikesh dharmadhikariNo ratings yet

- Tractors in IndiaDocument3 pagesTractors in IndiaNikhil MohaneNo ratings yet

- Cemcap: Grant Agreement NumberDocument35 pagesCemcap: Grant Agreement NumberSiraj AL sharifNo ratings yet