Professional Documents

Culture Documents

Pias Self Drilling Screw TDS

Pias Self Drilling Screw TDS

Uploaded by

ChangHangWing0 ratings0% found this document useful (0 votes)

14 views16 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

14 views16 pagesPias Self Drilling Screw TDS

Pias Self Drilling Screw TDS

Uploaded by

ChangHangWingCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 16

WORLD CLASS FASTENERS

MADE IN JAPAN

PIAS SELF-DRILLING SCREW

INTRODUCTION

The Technical Data presented in thisdocument i

areall conducted under laboratory conditions.

‘As national or international regulations do not cover all possible types of applications, on-site technical support and technical consulting

services are required for different types of applications and base material.

based on the numerous i

-house tests conducted by the Fasten Technical Department and

Base Material

There are mary types of material available onsite that requires fasteners of different materials PIAS Self Dilling Screws were designed to be

the fastening solution for most ofthe different types of Bose Material

(On-site Testing maybe requited to verify the sutability or the loading capacity ofthe selected screw.

eae Saleclon 1) Head Types: The crcice of Head Types is based on te different types of applications fortne SDS

Head and the desired finshed appearance of the fastened surface

TP] __2)TPI:T_he choice of the number of Threads per Inch (TP is based on the thickness ofthe base

materia.

3) Drill Point: The Dril Point is essential to the diiling capacity ofthe Self Dlling Screw.

Itis important that specification of the appropriate fastaner to be based on the required loading and

base material used

— rill Point

‘Types of Drill Point

i as |

PIAS: PIAS PIAS PIAS PIAS PIAS:

Reduced Self Dill Metal No. 5 Point Reamer Self Dill “S'Point Timber Type 17

Paint Upto 13mm Metal Timber io Metal ToLightMetal __Seff Dri Timber|

Drilling Capacity and Base Material Thickness Screw Size / Drilling Capacity and Base Material Thickness

#1 point / Reduced Point <2.6mm

#2 Pont 4.5mm to 3.5mm,

#3 Pont 2.5mm to 6.0mm

#5 Point Up to 13.0mm

Features of a PIAS Screw

1) PIAS Logo on the head of the serew: The criginal PIAS logo has 2 shallow imprint of the “P* ightly marked on

the head with a nonstandard fort and is stamped lke a watermark on the head,

2) The PIAS Patented Dril Point: PIAS Screws feature a second-generation symmetrical precision point.

‘This point is formed perfectly and ensures that the screw drills with speed and precision

“walking” of the screw during installation and gives the installer more contrcl over the screw. This effect is even

more pronounced when the screw is being installed on a roof with a steeper profile or it ie awkward angle.

4) High Hex: Another distinguishing feature found on the PIAS screws is the high hex éri makes itharder for the

screw lo pop out of the socket during installation by giving ita better siting.

oa

ae 3) The “S" Point: PIAS Screws all feature the ‘S' point on the tip of the drilling point. This feature eliminates

|

Ie —

PIAS SELF-DRILLING SCREW

THE RUSPERT COATING

(CERAMIC TOPCOAT ——~ ‘CHROMEMATE

|_— CONVERSION

ewer

XN ELECTROPLATED ZINC LAYER

| The substrate is protected from |

corrosion by the self-sacrificial

{galvanic effect of zinc.

The Ruspert™ coating is orgznic in nature and itis ceramic based. Highly advanced chemicals and resins are utilized to achieve the

abilly to provide unsurpassed corrosion resistanca. The mast remarkable feature of the Ruspert™ coating is that while the cating is

extremely resistant to corrosion, itis very thin in nature (about 15-20 microns}. This enables it to drill and cut through whatever

materials with minimal resistance, preserving dill point integrity and ensuring maximum thread life. The Ruspert™ coating on the:

PIAS Carbon-Sieel series conforms and exceeds the AS3566 - Australian Standard for Sel-criling screws for the building and

‘construction industrias (corrosion resistance) and exceeds the requirements for Ciass 3.

Tho Rusport™ coating consists mainly of 3 layors. While tho layors are independent and separate in nature, they aro fusod

together by secondery chemical reactions which occur in between the layers, thus resulting in stronger adhesion and also

‘consistency in thickness throughout the whole screw. Ths spacial process is patented and Is a special feature on PIAS carbon

steel screws,

The first layer isa layer of electroplated Zinc. This layer of Zinc gives the Ruspert™ coating its ability to “seif-neal” in the event

that tho topccat of coramic layor is broached. This layer alco protects the baso steo! matorial by tho salf-cactifcing nature of Zinc.

‘The second layers he Chromate conversion phase. This effect is commonly observed on Zinc piated products which have a

yellowish-greenish appearance. The chrorrate conversion film inactivates/passivates the surface of the zinc layer by preventing it

{rom forming the fne/near invisioe layer of Zinc Oxide (ZnO) when it come in contact with air

The topmost layer is the ceramic layer. This layer acts as like a tough ‘jackst" and protects the 2 layers below it It intercepts any

‘materials or circumstances that threaten to breech any layers and cause corrosion, It is non-metalic in nature which means that the

screw is insulated from electrolytic or galvanic corrosion as well.

Test Type Test Method

Alterating Anti-Corrosion Test 3200 Gyles of ris Sa Mie > Bre Drying at 60°C > Humid at 60% mn. 96% FH

ass Test 10 Cycles of 16Hrs of Salt Mist using concertation of salt and Acetic Acid adjusted to

PH3.0-31 oné idling of BHre

‘50OHrs Consecutive lighting from a carbon rod and repetitive water mist spray -no

crumbling of coating

‘Aczelerated Environment Condition | Product soaked in 5% Acid concentration for 24H and in 3% Alkali concentration for

‘Acid/Alkall Resistance Test

Test 724ts showed nether disintegration nor wrnkling of coating,

Heat Resistance Test 7Trs of continuous of Hot Air environment at 250°C.

Coating Hardness Test onira stot acheive ary pe of cons, iii of eve oink

(Odd Contour Adhesion Test 4lirs Hardness Test with the Pencil Scratch Method

PIAS SELF-DRILLING SCREW

PIAS FASTENERS PRODUCT RANGE

PIAS Fasteners Ran Head, Par Of Torque Transfer And Welding | Thread Part For Taping And Selt-

Faster Range Bearing Surface Joint Drilling Point

IAB Gane ilardened Carbon | Cove Prdened -GWOIITOA5IE C2690 | ye | Case hardened - OWOI1I0A IG 69609

‘Stel Fasteners Or AISI 1018 grade of Gatbon Steel ‘OVS! 1018 grade of Cabon Steel

PIAS 410 Marensiic Stahiess

Lo MarensticS Stainless Stoo! SUS 410 x Stainess steel SUS 410

PIASTA Br-eial Aston

Stantss Ste! + Case Case hardened - SWCHIeAwIS 63599

atdened Garton Stee! esta Silos Stal 22 © | “ora! 10%8 grade of Caton Stel

Fasteners

SUPER PIASTA Bv-tieial

Austents + Mertens, Austente Stanless Sie a4 © _| Hardened siainess Stes sus 42002

Stainless Stel Fasteners

Accelerated Environmental Tests Complianc:

a

ieee gerezeer- | ow soosar | sana ace

canons Sorasapaanes | SMSMNDAT | Smtr ae,

cont na resumes ct saturated Ultraviolet (UV) Lamp

Property Coatings in 100% yresence of sulfur Exposure of

tests Neutral salt Relative Humidity |S OCae~ in Blister | Nonmetac Materials

spray (NSS) test- | (Less than 5% ree | eS eS | ee acting eking

Cesethan sired Rust) ‘avd peeing)

(Ruspert Grey)

efustente Natenstic | apeo ts 4,000 rs scycks 2.000 Hrs

ees

Ie —

PIAS SELF-DRILLING SCREW

TECHNICAL DATA

Pull Out Resistance:

‘Test method: The fasteners were drivon into cold rolled steel test plates of

the stated thickness then pulled by the laboratory tensile machine til

failure. The stated values were obtained under faboratory conditions.

PIAS «ny

Thickness of Steel Material (ren)

Screw Se/Gauge [3am omm 23mm [32mm | 42mm 6omm

ma5766 150 220 3.50 : = 5

M4/ 6G 1.60 240 3.90 aro 3.0 i

M5/ 10G 170 2.40 4.00 680 10.50 zi

5.57 126 180 2.60 4.20 730 71.10 1820

M6! 146 - 5 440 7.30 12.80 20.80)

PIAS ato ony

Thickness of Steel Material (rm)

Screw Size / Gauge iamn mm 23 mm 32mm | 42mm éomm

M357 66 150 220 3.50 5 : 5

M4/ 8G 160 240 3.90 a70 310 ,

M51 106 240 4.00 0.80 10.50 i

W557 126 : = 420 740 11.10 E90

M6! 146 5 : 4.40 7.30 12.80 21.79)

PIASTA ony

screw Sue /oauye “Thickness of Steel Material (mm)

72mm ema 23mm | aamm_ | 42mm comm

W4766 1.60 2.30 4.10 610 : i

M5 106 : 2.30 420 640 300 5

W557 126 = 2.08 4.40 690 9.10 7020

MG! 146 7 2.05 4.40 7.90 2.50 12.80)

SUPER PIASTA un

“Thickness of Steel Material (mm

Screw Size / Gauge Tamm emm 23 mm aamm | 42mm é0mm

ma/6G 1.60 2.30 4.10 610 : i

M5/ 106 ~ 2.30 430 6.40 360 ~

W557 126 : 2.05 4.40 690 9.10 7020

“All values obtained under laborstory condtions

Ie — o

PIAS SELF-DRILLING SCREW

TECHNICAL DATA

Tensile Rosstene a,

=r Screw Sie/ Gauge] PIAS [PIAS aio | PIRSTA| SUPER PIASTA

i M35/6G 4.50 490 - -

Ma73e i130 | 940 70 70

M5/10G 13.80 14.30 9.50 9.50

M55/ 12G 18.20 19.40 13.60 13.60

Nera4G 2080 | 2250} 1660 :

Shear Resistance: (kN)

" Sciew Slee/ Gauge |S | PIAS Ao | PIRSTA| SUPER PIASTA

M3.5/ 6G 3.10 3.20 : =

M4! 8G 7.40 5.60 4.90 4.90

M5/10G 9.00 8.60 6.10 610

M55/12G 12.30 10.10 8.80 880

M6/14G 14.60 43.20 10.80 -

Torque Resistance: (Nm)

Seow Size/ Gauge] PIAS [PIAS 0 | PINSTA| SUPERIASTA

mas/eG 405 | 487 : :

M4! 8G 6.82 6.93 3.90 3.90

M5/10G 11.36 12.50 6.20 6.20

mes 126 1872 | iets 080 a0

Me/14G 2198 | 2752 | 7890 :

“avon cd dno eon

iaATERIAT CHEMICAL COMPOTION

carbon | suasess | sasinece | stantece | staitess | stariess

swentea — | Steel410: JIS | ceeciaoa:sis | steel 305: sis Stee! 316: pean

Stacey | C408/Ais1 | S*SySuea'® | Susans | JSSHS | ISCAS

ABT O18

Gabon | c | 018-073 | maxois | mocoos | mmo12 | mmoos | 076-040

Silicon Si max 0.10 max 1.00 max 1.00 ‘max 1.00 max 1.00 max 1.00

manganese | wn | 030-060 | maxtoo | mexz0o | mexzoo | mex200 | maio0

Preaphorws | P| waxo0o | moxoo | maocts | macooss | macoots | moot

sue | 6 | mmxo0as | moxo0s | mors | moxoos | mocoos | maroos

Alur Al min 0.02 - - . - -

wit | wi | - | mocoso | 800-1080 | 1060-1800 1000-1400) -

cwromun | ce] - | 1180-1320 | re00-z000 | v7.00 00 | 00-1800 | 1200-1400

Molybdenum | vo : -

2.00~3.00 -

Ie —

PIAS SELF-DRILLING SCREW

Installation Guidelines

- Atorque-controllad serewgun with a depth sensitive nosepiece should be used to install the self driling screws. For optimal

fastener performance, tho scrov:gun should have a minimum rating of 6 amps and have a RPM range of 0-2600. Overdriving ray

result in torsional falure of the fastener or stripout ofthe substrate,

- To ensure secure fastening, the selection of the screw length must be made with provision for atleast 3 threads to extrude trom

the base material

Recommended Drill Speed

Cate screw Recommended Drill Speed for Recommended Drill Speed for

4 Metal Sheet under 6mm ‘Metal Sheet thicker than 6mm

Gauge Size

gd (mm) (rpm) (rpm)

35 #6 2,200 ~ 2,500 - 25 mm

3.9 7 2,200 ~ 2,500 5 2.5 mm

42 8 2,200 ~ 2,500 = 45 mim

48 m0 2,200 ~ 2,500 : 8.0mm

35 #2 1,800 ~ 2,500 7,600 ~ 1,800 730mm

63 ma 41,600 ~ 1,800 41,800 ~ 1,800 13.0 mm

Force Required For Installation:

Head-Height: 10kgi ‘Overhead: 13kgf ‘Shoulder-Height: 1Skgf| Downhand: 20kgf

DRILLING THICKNESS

Before we go into how to determine the thickness of material tobe drilled, we have to understand that the drill point has to finish

driling and clear all the different layers before the screw thread can start to engage the matarial. With this in mind, we can now go

into details on hovr to determine the bese material thickness so as to select the appropriate drill point.

Single Layer

Ina staightforward application where a single metetial is involved, the thickness to be dilled is simply the thickness

Of the material, expressed as

Single Sheot

In reality however, we always have to consider fastening something to something else. Thus in a practical

application, if we need to fasien say a roofing sheet to the purln, he combined thickness of both the sheel and

uri would have to be considered in determining t.

Pre-drilled top layer

Inthe event that the overal thickness exceeds the maximum dill capcily of the screw, itis possible to fasten this

‘application by pre driling the tep most layer(a). Thus ‘or thie ease, , to be considered would be limited to only

those layers that were not been pre drilled

Multiple layers

Inother applications where insulation or other materials ike architectural or composite panels are involved, we have

to.consider al the layers as one thick layer to be dried through.

Layers with Void

In applications with a void in between the fastened sheet members, we have to consider the whole assembly as ona

thick layer,

Fate A oops:

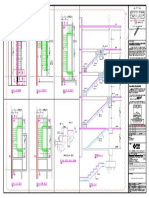

PIAS SELF-DRILLING SCREW

i super Fastening Thickness

For fixing of Auminum to Steel Structure Pi

‘in Fagade or Curtain Wall Applications. Plesta ‘asia Plas od

nee

Wiatbsa Sworn cme acia

= = Es

;

©] | #) [4] Be] AH

Se

=

‘SCREW SELECTION CHART

Plt tamgh_| Nt | nd tins | Fae OE | pg

9d (mm) (mm) @dk (mm) (mm) (mm)

3.5 25 70 28 18.0 41

40 13 82 29 5.0 2

5.0 40 95 33 29.0 2

d e—

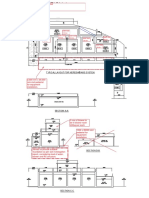

PIAS SELF-DRILLING SCREW

COUNTERSUNK HEAD

- For fixing of Aluminum to Stee! Structure Super

in Fagade or Curtain Wall Applications. Piasta

"The Gountersune Hea fish onfastenings

Aanditfinshos with a fat surface whch oe

tnabies other members to clea itr move

overit.

Piasta —Pias

Fastening Thickness

ro

savings, “Arcus "canny sala

cre} lay lab)

g)(8 t

@| | H) | 8] A

Pig Oi Gomme ‘Hoan HOMO

Sette

SCREW SELECTION CHART

Length | Head Diameter | Woad Thickness (h) | Fastening Thickness | pa pony

el (mmm) (mm) ‘ak (mm) A (mm) (mm)

40 40 80 23 40 1

30 73 30 23 50) 2

40 16 80 23 70 2

40 18 30 23 70.0 2

40 25 80 23 16.0 2

40 30 30 23 21.0 2

40 235 80) 23 26.0 2

40 40 20 23 31.0 2

40 46 80) 23 36.0 2

40 50 80 23 41.0 2

40 60 80) 23 5.0 2

50 78 100 28 30 2

50 25 10.0 28 14.0 2

50 30 10.0 28 19.0 2

30 3 10.0 28 24.0 2

50 45 100 28 340 2

30 30 10.0 28 33.0 2

50 60 100 28 49.0 2

%-

PIAS SELF-DRILLING SCREW

COUNTERSUNK HEAD - REAMER

‘Super

= For fixing of wood! panel to stee! srvcture. The Bee inca ag

special Reamer drill point has wings to bore a

slightly bigger hole through the wood and upon

contact with the sieel underneath, the wings will | Zs)

‘snap off to enable a snug tapping g

Fastening Thickness

go

©) | 8) | 8]

I

= i ES

=a

en ee

9d (mm) L (mm) @ak (mm) Ah (mm) (mm)

40 45 70 28 29.0 2

5.0 32, 95 39 15.0 2

5.0 42 95 39 25.0 2

J 2

PIAS SELF-DRILLING SCREW

WAFER HEAD

“For fingof ofp and ocking rot ystemsend S22 asia pag osterng Tiss

‘secret fx sysiems to Steel Stucture. The Wefer

Head combines secure fastening power and a

low profile head so that clip locking or secret fx

‘systams can simply lock or clip over it

Mingenet— rOvS0D 8 Sing "eas Sioa!

Siem ina) (eriadb) Gra)

lijele@@eeson

L

6} (#2) (2) ey

=

een sero

Diameter Length Head Diameter Head Thickness (h) Fastening Thickness Drill Point

9d (mm) L (mm) ‘Ddk (mm) hmm) {mm

5.0 19 1 25 80 3

J 2

PIAS SELF-DRILLING SCREW

‘HEXAGONAL HEAD

For fxing of Roofing and Cladding }

on to Strutural Steel Piasta asia

fa;

=) oe

“Sm Tv senese = onoey ovata)

.

OIA

ae ee

a =

ET

| PT VT TS

9d (mm) L (mm) ‘Ddk (mm) h(mm) {mm

2 s 3 3 ue wat

5.5 75 13 48 64.0 Type 17,

J 2

PIAS SELF-DRILLING SCREW

HEXAGONAL HEAD

= For fixing of Roofing and Cladding Super

Piasta

on to Strutural Steel,

Pasta

@S ON

ienians) ims) tae)

OT

Fepgre! Dobe al DITO

‘Owe Thaw

SCREW SELECTION CHART

Diameter Length Head Diameter [Head Thickness (h) | Fastening Thickness | 1 pong

9a (mm) (mmm ‘Bak (mam) (mm) (mm)

55. 45 B 48 23.0 3

55 50 3 48 28.0 3

55 55 3 48 33.0 3

55 65 13 48 16.0 3

55 75 3 48 43.0 3

55 85 13 48 3.0 3

J 2

PIAS SELF-DRILLING SCREW

THIN TRUSS HEAD

- For easy fixing of thin Steel Sheet. Fully-threaded shark

‘engages the ertire lengtt of the fastener, providing a secure

‘connection between the roof! facade end wall framing members.

- PIAS Sharp’S’ Dril Points designed to improve driling abiity

through thin sheet metal

~ Tho Thin Truss Head allows the fastening of low profle sheat

metal clips and ensures proper installation of metal oof panels

Fasioring Thickness

j

SCREW SELECTION CHART

Diameter | Length Head Diameter | Head Thickness (h) | Fastening Thickness Max Drill

a (mm) L (mm) ‘ak (mm) 1 (mm) (mmm) |_ Thickness

35 0 400 +9 60 420m

35 2 100) 18 13.0 2mm

a2 16 110 30 30 16mm

a2 78 110 30 TK} 1.6 rm

Ie —

PIAS SELF-DRILLING SCREW

WASHERS

Molded Washers

These are the simple normal types of washers. Our washers are all injection moldea and they provide a secure

and snug fit for our range of screws and for most applications.

tem Natesal Dimensions

Gauge 10

wie Pou Cag 10 ae

50 form a Ba

ware epow Gago 12

cog a<—_

waa crow Gages

Bonded Washers

Teco ate POM ner bonded to @ meta Bacing when proves more suppor Tora

beter sea Tooele

tem Seaing Material —«SupportMaterat——_—bimensions

unin

pues EPDM Galvanised Sieel, 7

‘ASI. Stainless Stee! 304 9.0 16mm,

BW10/12-12 Aluminum, Gauge 10/12

Mion crow aivanoed See, a |

Stanees Stee 304

Aurioun

ewiaret4 Gauge 124

N crow Gatanced See

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mason Wedge AnchorDocument5 pagesMason Wedge AnchorChangHangWingNo ratings yet

- RAPID SCAFFOLDING-Test Reports 25.08.2022Document16 pagesRAPID SCAFFOLDING-Test Reports 25.08.2022ChangHangWingNo ratings yet

- PUB POWS - UserManual - FrontendDocument31 pagesPUB POWS - UserManual - FrontendChangHangWingNo ratings yet

- For Submission: Date of Issue: Jan 2022Document1 pageFor Submission: Date of Issue: Jan 2022ChangHangWingNo ratings yet

- Stress Distribution - DraftDocument4 pagesStress Distribution - DraftChangHangWingNo ratings yet

- Drafts - Concrete - Feb 19, 2023Document16 pagesDrafts - Concrete - Feb 19, 2023ChangHangWingNo ratings yet

- Attachment 1 - Preliminary Layout For CivilDocument1 pageAttachment 1 - Preliminary Layout For CivilChangHangWingNo ratings yet

- Bs 8539 - Standard On The Use of Post-Installed Anchors For Structures Requiring Plan ApprovalDocument6 pagesBs 8539 - Standard On The Use of Post-Installed Anchors For Structures Requiring Plan ApprovalChangHangWingNo ratings yet

- Eff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!Document4 pagesEff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!ChangHangWingNo ratings yet

- Beam To Beam Connection (Bending & Shear)Document15 pagesBeam To Beam Connection (Bending & Shear)ChangHangWingNo ratings yet

- Beam To Beam Connection (Shear Only) - 1 RowDocument30 pagesBeam To Beam Connection (Shear Only) - 1 RowChangHangWingNo ratings yet

- Eff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!Document5 pagesEff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!ChangHangWingNo ratings yet

- Beam To Beam Connection (Shear Only) - 2 RowDocument45 pagesBeam To Beam Connection (Shear Only) - 2 RowChangHangWingNo ratings yet

- 00 Divider PDFDocument1 page00 Divider PDFChangHangWingNo ratings yet

- Eff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!Document2 pagesEff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!ChangHangWingNo ratings yet

- Eff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!Document5 pagesEff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!ChangHangWingNo ratings yet

- Bolt Punching Block Shear AnchorageDocument3 pagesBolt Punching Block Shear AnchorageChangHangWingNo ratings yet