Professional Documents

Culture Documents

Annex 6.2. BRS-19 Bis - Operations Summary Report (Open Wells)

Annex 6.2. BRS-19 Bis - Operations Summary Report (Open Wells)

Uploaded by

mann_974Copyright:

Available Formats

You might also like

- M&D Foundations & Building Services Limited: SHOREHAM - 79-81 Brighton Road, BN43 6RHDocument10 pagesM&D Foundations & Building Services Limited: SHOREHAM - 79-81 Brighton Road, BN43 6RHNitaiGauranga108No ratings yet

- Wellbore Schematic: GOK-12 - End of Well ReportDocument5 pagesWellbore Schematic: GOK-12 - End of Well Report-BloodSeeker-No ratings yet

- Cementing Job Model 001Document6 pagesCementing Job Model 001islam atifNo ratings yet

- T-101 D ZoneDocument24 pagesT-101 D ZoneAtom InsideNo ratings yet

- Pile Capacity Calc in Rock IRC78Document2 pagesPile Capacity Calc in Rock IRC78arif_rubinNo ratings yet

- KickDocument2 pagesKickChung NguyenNo ratings yet

- Synthetic-Based Mud Report No. 39: LLOG ExplorationDocument1 pageSynthetic-Based Mud Report No. 39: LLOG Explorationadvantage025No ratings yet

- Exercise 4 AnswersDocument12 pagesExercise 4 AnswersadeelsnNo ratings yet

- Egyptian Mud Engineering & Chemicals Company: Page 1 of 1Document1 pageEgyptian Mud Engineering & Chemicals Company: Page 1 of 1GPCNo ratings yet

- Purlin Design-Continous SpanDocument107 pagesPurlin Design-Continous SpanPallavi GurnuleNo ratings yet

- Sub Surface Pump Design TAP-099 Sumur: I. Input DataDocument1 pageSub Surface Pump Design TAP-099 Sumur: I. Input DataNova ArifienNo ratings yet

- Well ControlDocument56 pagesWell Control56962645No ratings yet

- BHA (m3) : Surface CPDocument2 pagesBHA (m3) : Surface CPLaureat NgomaNo ratings yet

- Casing Data Bit Data Mud Data: Hours RemarksDocument8 pagesCasing Data Bit Data Mud Data: Hours RemarksdiegoNo ratings yet

- Daily Morning Report No.92 (C0002N) - 131214Document1 pageDaily Morning Report No.92 (C0002N) - 131214Ines NaserNo ratings yet

- ADVANTAGE T&D Calculation - Summary Report: Case - BERENICE-19X - 8.5'' Hole Pend. Assy - R#3Document1 pageADVANTAGE T&D Calculation - Summary Report: Case - BERENICE-19X - 8.5'' Hole Pend. Assy - R#3Mostafa ElghifaryNo ratings yet

- Well Control Worksheet - Surface BOPDocument2 pagesWell Control Worksheet - Surface BOPstevebeardsleyNo ratings yet

- Pertamina Ep Asset 1 Field Ramba: Rig Operation ActivitiesDocument2 pagesPertamina Ep Asset 1 Field Ramba: Rig Operation ActivitiesBayu Eko AriestaNo ratings yet

- Egyptian Mud Engineering & Chemicals Company: Page 1 of 1Document1 pageEgyptian Mud Engineering & Chemicals Company: Page 1 of 1GPCNo ratings yet

- Daily Operations Report (DOR)Document3 pagesDaily Operations Report (DOR)Dheeraj KapoorNo ratings yet

- 16-126 Fire Water F Optimasisc1Document1 page16-126 Fire Water F Optimasisc1Sandi ApriandiNo ratings yet

- Ducts Pressure Losses Board: Project: Unit - No.: General Data Airflow (L/S) ESP (Pa) Calculated Specified ProposedDocument15 pagesDucts Pressure Losses Board: Project: Unit - No.: General Data Airflow (L/S) ESP (Pa) Calculated Specified Proposedkarthy ganesanNo ratings yet

- Simulacion Torque y ArrastreDocument1 pageSimulacion Torque y ArrastrejosephbenettonNo ratings yet

- End of Well Summary of Karjisan-04: ObjectiveDocument3 pagesEnd of Well Summary of Karjisan-04: ObjectiveSahil BalistiNo ratings yet

- Item Wise QtyDocument257 pagesItem Wise QtyArif AhmedNo ratings yet

- Cement Plug: Hole Size CSG Size Bottom of Plug Length of Plug Estimated TempsDocument3 pagesCement Plug: Hole Size CSG Size Bottom of Plug Length of Plug Estimated Tempsislam atifNo ratings yet

- 23 - Well Control Worksheet-Surface BOPDocument2 pages23 - Well Control Worksheet-Surface BOPJunaid MateenNo ratings yet

- Morning Report 03 - 08 April 2012Document1 pageMorning Report 03 - 08 April 2012tolstoy potemkinNo ratings yet

- SLB COSL 223 Morning Report 12-Jul-2020) REV.01Document2 pagesSLB COSL 223 Morning Report 12-Jul-2020) REV.01Jusman Van SitohangNo ratings yet

- 23mse015 Slender ColumnDocument2 pages23mse015 Slender Column19CEF082 SHANMATHY SNo ratings yet

- Log BorDocument2 pagesLog BorWilly Akhdes AgusmayandraNo ratings yet

- DMR FgchyuihducDocument2 pagesDMR FgchyuihducB fattahiNo ratings yet

- Cálculo de Diseño de SeparadoresDocument4 pagesCálculo de Diseño de SeparadoresEdwardNo ratings yet

- Throughput Vs RTDocument6 pagesThroughput Vs RTJulio Wacas BangguiyaoNo ratings yet

- Field Measurements of Annular Pressure and Temperature During Primary CementingDocument5 pagesField Measurements of Annular Pressure and Temperature During Primary CementingDoni KurniawanNo ratings yet

- Screenshot 2024-02-15 at 06.55.31Document21 pagesScreenshot 2024-02-15 at 06.55.31yusuf oktoviyantoNo ratings yet

- Cost Drilling 2 FDPDocument3 pagesCost Drilling 2 FDPZuhairi ZakariaNo ratings yet

- Ecoprocesstm SBR Design NotesDocument3 pagesEcoprocesstm SBR Design NotesTrilok ChandraNo ratings yet

- DMR-1. Dated 9-10-2022Document1 pageDMR-1. Dated 9-10-2022Gulzar AhmedNo ratings yet

- Hvac Calc.Document4 pagesHvac Calc.karun agrawalNo ratings yet

- Report EmptyDocument1 pageReport Emptynaiem akbariNo ratings yet

- Daily WOV Report N°01 OMP-47 ENF-30Document2 pagesDaily WOV Report N°01 OMP-47 ENF-30Ayoub BouchemaNo ratings yet

- Actual-Planned Days GraphDocument6 pagesActual-Planned Days GraphAnitya KuchhalNo ratings yet

- Pru - Oseil-29 - 40 Aft - March 19, 2020Document2 pagesPru - Oseil-29 - 40 Aft - March 19, 2020Abang GaffiNo ratings yet

- Dif Pressure CalcDocument1 pageDif Pressure CalcemiljuchiacNo ratings yet

- Py51a06h DDR 04 02mar05Document3 pagesPy51a06h DDR 04 02mar05Cleevh MabialaNo ratings yet

- ROG Pemakain BBM 08-02-24Document3 pagesROG Pemakain BBM 08-02-24citramilandari119No ratings yet

- Master Mud TestDocument74 pagesMaster Mud TestSaravanaNo ratings yet

- Bending Moment Calc For Slab - FoundationsDocument1 pageBending Moment Calc For Slab - Foundationsamanpreet_ahujaNo ratings yet

- Time Hrs From To: G.P.C Daily Drilling Report Att. Eastern DesertDocument1 pageTime Hrs From To: G.P.C Daily Drilling Report Att. Eastern DesertMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Fan Static PressureDocument4 pagesFan Static PressureomarNo ratings yet

- ktl02 Workover Completion ReportDocument14 pagesktl02 Workover Completion ReportashadNo ratings yet

- 11 Hydraulics & Well Control Calculations - QuartzDocument29 pages11 Hydraulics & Well Control Calculations - QuartzRebarNo ratings yet

- DSR Semen Belini 22 NovDocument24 pagesDSR Semen Belini 22 Novaswar160122No ratings yet

- Free SpanDocument1 pageFree Spanatma82419No ratings yet

- Well Control Exercise 4Document12 pagesWell Control Exercise 4adeelsnNo ratings yet

- DISCHARGE SEQ - Iron OreDocument1 pageDISCHARGE SEQ - Iron OreMamunNo ratings yet

- Plan Do & Act 220219 RDMDocument1 pagePlan Do & Act 220219 RDMDidi MelkybudiantoroNo ratings yet

- Pump Head Calculation - Waste Water PumpDocument8 pagesPump Head Calculation - Waste Water PumpChoon Zhe ShyiNo ratings yet

- 07 Rawlbolts Plugs Anchors PDFDocument1 page07 Rawlbolts Plugs Anchors PDFRIFASNo ratings yet

- Standards Norms Used For Industrial ValvesDocument3 pagesStandards Norms Used For Industrial ValvesLuis PereiraNo ratings yet

- Mitutoyo Hardness Tester-Symbols and ChartDocument1 pageMitutoyo Hardness Tester-Symbols and ChartAdithya PrabhasNo ratings yet

- Effect of Brazing On Mech Prop of Al Alloys For Automotive HXDocument92 pagesEffect of Brazing On Mech Prop of Al Alloys For Automotive HXThejaswiniNo ratings yet

- Fit Up Inspection Report-10Document57 pagesFit Up Inspection Report-10rizky youlandaNo ratings yet

- Process Control Plan SCM100113Document20 pagesProcess Control Plan SCM100113Rohit MakhijaNo ratings yet

- Canara SpringsDocument25 pagesCanara SpringsAshfaq MasoodNo ratings yet

- Grapple Releasing SpearDocument7 pagesGrapple Releasing SpearALEX MAKANGANo ratings yet

- Performance of Cryogenically Treated Tungsten Carbide ToolsDocument6 pagesPerformance of Cryogenically Treated Tungsten Carbide Toolsiskricaman7No ratings yet

- MEK Cure Test PDFDocument1 pageMEK Cure Test PDFImam Prayogi SNo ratings yet

- 3.6 VGO - HDT Unit:: Process DescriptionDocument4 pages3.6 VGO - HDT Unit:: Process DescriptionAkankshya MishraNo ratings yet

- Primary Sedimentation TankDocument7 pagesPrimary Sedimentation TankKareen AmlosNo ratings yet

- APS ThinsulatorsDocument3 pagesAPS ThinsulatorsBobbie RuckNo ratings yet

- Delayed-Coking Process UpdateDocument17 pagesDelayed-Coking Process UpdateLindsey BondNo ratings yet

- 3M (Scotchkote) SK Abrasion Resistant 328Document3 pages3M (Scotchkote) SK Abrasion Resistant 328johnNo ratings yet

- CG 30Document2 pagesCG 30DarynSmithNo ratings yet

- Senior Certified Coatings Inspector EPGDocument8 pagesSenior Certified Coatings Inspector EPGdapidmsNo ratings yet

- ASTM A536 Grade 60-40-18 Ductile Cast IronDocument2 pagesASTM A536 Grade 60-40-18 Ductile Cast IronbaladiroyaNo ratings yet

- Addendum March Project Proposal For Improvement of Principals OfficeDocument2 pagesAddendum March Project Proposal For Improvement of Principals OfficeJoanne Sapla De LeonNo ratings yet

- Introduction Machine ToolsDocument28 pagesIntroduction Machine ToolsMobassher Al HasanNo ratings yet

- STP ShaliFloor SL 3CESDocument3 pagesSTP ShaliFloor SL 3CESRana MahatoNo ratings yet

- Paper Bags Making MachineDocument59 pagesPaper Bags Making MachinePotluri Vraja Kishore100% (1)

- 2211Document4 pages2211liuyx866No ratings yet

- Basic Bone Screw Set 2Document26 pagesBasic Bone Screw Set 2Bambang ApryantoNo ratings yet

- Sandvik Saf 31803 Tube and Pipe, Seamless: DatasheetDocument9 pagesSandvik Saf 31803 Tube and Pipe, Seamless: DatasheetPaul NeedhamNo ratings yet

- Section 8 - Arc Equipment & Processes266 - 27344Document36 pagesSection 8 - Arc Equipment & Processes266 - 27344dbircs2010No ratings yet

- Footmotion PDFDocument8 pagesFootmotion PDFavillouNo ratings yet

- Astm A193-22Document14 pagesAstm A193-22Gary Cabello100% (1)

- EN 10208-1 Pipe dimensions-EXTRASDocument1 pageEN 10208-1 Pipe dimensions-EXTRASPaulNo ratings yet

- SAP PARTS: Installation Guidelines For Installation Guidelines For Duo-Cone SealsDocument5 pagesSAP PARTS: Installation Guidelines For Installation Guidelines For Duo-Cone SealsRavi MirzaNo ratings yet

Annex 6.2. BRS-19 Bis - Operations Summary Report (Open Wells)

Annex 6.2. BRS-19 Bis - Operations Summary Report (Open Wells)

Uploaded by

mann_974Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annex 6.2. BRS-19 Bis - Operations Summary Report (Open Wells)

Annex 6.2. BRS-19 Bis - Operations Summary Report (Open Wells)

Uploaded by

mann_974Copyright:

Available Formats

GBRS

1 General

1.1 Customer Information

Company GBRS

Representative OiLSERV Oilfield Services (BVI) Ltd – Algeria PE

Address

1.2 Well Information

Well BRS-19bis

Project GBRS Site BRS-19

Rig Name/No. T212/T212 Event ORIG DRILLING

Start date 7/20/2019 End date

Spud date 7/20/2019 UWI

Active datum RT @140.10m (above Ground Level)

Afe No./Description /

2 Summary

2.1 Operation Summary

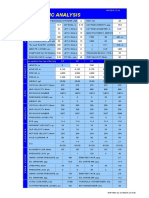

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

7/20/2019 0:00 2:00 2.00 36 1.3 P Spud well BRS-19 bis 20-July-2019 00:00:00 hrs , Meeting w/ Rig

crew & GBRS drilling Department Head. P/U & M/U 36” BHA .

2:00 20:00 18.00 36 1.1 1 P 0.00 Drill 36" hole section to 50m with spud mud 1.05sg 100%

circulation returned.

** Start drilling with reduced parameters then increased same

gradually.

** Q=100-1400 lpm, P= 70-90 psi, Rpm= 20-80, WOB= 0-7T.

** While Reaming the drilled stand found bit balled @ 39m, Clean

same and resume drililing

** Ream each joint drilled twice.

** Pump 5m3 of Hi-vis pill

** No drilling progress @ 50m

20:00 23:45 3.75 36 1.3 P 50.00 POOH to surface.

** Found the bit balled 100% with clays. Cleaned out the bit, RIH

back to bottom (circulated last simple)

23:45 0:00 0.25 36 1.1 1 P 50.00 Resume drilling from 50m to 52m

** Q=1400 lpm, P=70 Psi, RPM=80-85 , WOB=3-4 T

7/21/2019 0:00 2:00 2.00 36 1.1 1 P 52.00 Drilling from 52 to 64m ** Q=-1400 lpm, P= 85 psi, Rpm= 86,

WOB= 3-7T.

2:00 4:15 2.25 36 1.5 P Pumped 5 m3 Hi Vis pill and circulate Hole clean, Spot 20m3 hi-vis

pill on bottom, Dropped Totco.

4:15 6:00 1.75 36 1.3 P POOH from bottom to surface.

** No tight hole ** Found bit 100% balled up.

6:00 6:45 0.75 36 1.3 P Bit & bit sub service.

** Recovered Totco; Hole incl.: 0 deg.

** Bit dull grade 1-2- WT-A- 2- I- BU- TD.

** Clean Bit & Rig floor.

6:45 7:00 0.25 36 3.1 P Prepare csg running surface equipment.

7:00 11:00 4.00 36 3.1 P HPJSM. Pick up and run 30``conductor pipe csg from surface to

61m.

** Surface test the float shoe with mud ok.

** Used cutting torch to cut the pad eyes on rig floor

** Filling up every joint with Mud.

11:00 15:00 4.00 36 3.1 P HPJSM, Empty cellar, centralize 30” CP. In Rotary table, Cut 42”

20 cm from the bottom of cellar & weld brace between 42” x 30”.

15:00 17:00 2.00 36 3.2 P Pick up & RIH stinger on two stds 5" HWDP.

** Spaced out.

17:00 18:15 1.25 36 3.2 P Pick & make up one 5" pup joint 4.5m, circulating sub, Safety

valve & 5" pup joint 1.5m.

18:15 19:15 1.00 36 3.2 P Connect & pressure test cemetnt line @ 500/2000 psi during

5/10min

January 23, 2020 at 9:12 pm 1 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

19:15 19:45 0.50 36 3.2 P Sting in, fill up annulus 5" x 30" & test stinger sealing ok.

19:45 20:15 0.50 36 3.2 P Cirulate prior cement job. 800 lpm, 90psi.

20:15 21:15 1.00 36 3.2 P HJPSM. 30' csg cementing

** Preflush with 6m3 water, mix & pump 11.3 m3 slurry 1.90,

displaced with 450 l Water.

** Got cement return on surface

21:15 21:30 0.25 36 3.2 P Sting out, checked float shoe holding ok.

21:30 22:15 0.75 36 3.2 P Disconnect line, POOH stinger to surface

** lay down stinger , two 5" pup joint, circulating sub & safety valve.

22:15 0:00 1.75 36 3.1 P Empty & Clean cellar, preparing to cut 30" C.P

7/22/2019 0:00 3:00 3.00 36 3.1 P Empty landing joint from mud & cut 30" Conductor below landing

joint connection,

3:00 3:30 0.50 36 3.1 P Lay down landing joint & clean cellar.

3:30 6:30 3.00 36 3.1 P Install riser & weld same on 30” conductor pipe.

6:30 11:00 4.50 36 1.3 P RIH 22” BHA to 58m with Picked up: New 22” TCI bit ES14V,

#1623696, bit sub, Shock sub, Stabilizer.

** Tag cement at this depth

11:00 14:00 3.00 36 1.1 P Pattern the bit & drilling out cement & shoe from 58m to 63m.

** Fr= 200 - 1000lpm, Pr=60 - 100, RPM= 20 – 60, WOB= 0 –

5T.

** Returned hard cement on shale shakers

14:00 23:15 9.25 22 1.1 1 P 64.00 Drill 22" hole section from 64 to 110m

** Start Drilling with reduced parameters (40-50 RPM, 1-2 T,

300-1000 lpm, 90-100 Psi)

** Gradually increased drilling parametersfrom (40-50 RPM, 2-5 T,

1000 lpm, 120 Psi) to (40-50 RPM, 2-5 T, 1500 lpm, 260 Psi)

** Noticed partial mud losses from 90m, 2-12 m3

23:15 0:00 0.75 22 1.5 P 110.00 Spotted 10m3 LCM (800 lpm), POOH to shoe

7/23/2019 0:00 1:00 1.00 22 1.5 P Circulated above shoe, Fr=1000 lpm, P=90 Psi, No losses while

circulation.

1:00 1:30 0.50 22 1.3 4 P Run back to bottom (110m)

1:30 6:00 4.50 22 1.1 P 110.00 Resume drilling 22” hole section (0-3 T, 40-65 RPM, 1350-1450

lpm, 220-255 Psi) from 110m to 136m.

** Partial losses rate decreased from 12 m3 to 4 - 6 m3.

6:00 7:00 1.00 22 1.5 P Spot 10m3 LCM pill 200kg/m on bottom (400lpm, 40 psi).

7:00 7:30 0.50 22 1.3 4 P 136.00 Pooh to 83m and circulate meanwhile LCM soak, Fr=1000 lpm,

P=90 Psi.

7:30 9:00 1.50 22 1.3 P 83.00 Make up 03 jts 8-1/4” DC & one stand of 5” HWDP.

9:00 0:00 15.00 22 1.1 P 136.00 Resume drilling from 136m to 222m.

** Fr=1500 lpm, Pr=280 Psi, Rpm= 65, WOB=0-3 T, losses 2.5

m3/hr.

** Partial losses rate increased to 20 m3/hour while increasing flow

rate to 1800 lpm.

** Reduced Flow rate to 1600lpm & continue drilling.

** Fr=1600 lpm, Pr= 320-350 Psi, Rpm=65-75, WOB= 0-5 T,

Losses=5-6 m3/h

** Pumped 3m3 Hi Vis pill at the end of each stand drilled.

** Mio-Pliocene 100% sand.

7/24/2019 0:00 3:15 3.25 22 1.1 P 222.00 Continue drilling from 222m to 250m.

** Fr=1600 lpm, Pr=350 Psi, Rpm= 70, WOB=0-10 T,

** Partial losses 5-6 m3/hr.

3:15 4:45 1.50 22 1.5 P Pump 5m3 Hi Vis pill and circulate hole clean prior entering

Eocene Carbonate

** Fr=1600 lpm, Pr=330 Psi.

January 23, 2020 at 9:12 pm 2 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

4:45 0:00 19.25 22 1.1 P 250.00 Drilling 22” Hole section with partial losses with 1.05sg spud mud

from 250m to 357m.

** Fr=1600 - 2000 lpm, Pr=350 - 500 Psi, Rpm= 70, WOB=0-15 :

Partial losses decreased from 5-6 to 0m3/hour

** Lost return @ 328m; Reduced flow rate to 1000 lpm, got back

partial return.

** Increased gradually flowrate to 1700 lpm & continue drillling with

partial losses 0-2.5 m3/h.

** Pumped a 3 m3/h Hi Vis pill @ each std drilled.

** Formation: Eocene Carbonate @ 257m; Senonien Carbonate

@ 302m. (Dolomite 80-100% , Claystone 0-20%).

7/25/2019 0:00 0:00 24.00 22 1.1 P 357.00 Continue drilling 22" hole section with 1.05 spud mud from 357m

to 471m.

** Fr=1700 -1800 lpm, Pr=350 - 500 Psi, Rpm= 80 - 100,

WOB=5-15 T,

** Load active tank with LCM

** Partial losses rate decreased from 2.5 to 0 m3/hr.

** Pump 03 m3 Hi-Vis sweep pills before connection @ 366m @

395m

** Last Sample: Senonien Carbonate: Dolomite, Limestone,

Claystone, Anhydrite.

7/26/2019 0:00 17:30 17.50 22 1.1 1 P 471.00 Drilling 22 hole section from 471 m to csg point @ 518 m

** 1800-1900 lpm, 500-590 Psi, 5-20 T, 90-110 RPM

** Partial losses rate not sable 0–0.8 m3/hr.

** Ream each stand drilled.

17:30 20:45 3.25 22 1.5 P Pumped a 6m3 Hi Vis pill and circulate hole clean. Spot 10 m3 Hi

Vis pill. Drop Totco.

** 1900 lpm, 550 Psi.

20:45 0:00 3.25 22 1.3 3 P 518.00 POOH 22" BHA to 107m

** Tight hole noticed : @ 470-370m, worked intervals and @

366-362m, 17T overpull, backreamed (1800 lpm, 80-500 Psi, 60

RPM) .

7/27/2019 0:00 2:45 2.75 22 1.3 3 P 107.00 Continue POOH 22" BHA from 107m to surface. ** Bit and

Stabilizer 100% balled up ** Cleaned out Bit and Stabilizer and

recover Totco

** Bit dull grading 1-1-WT-A-2-I-BU-TD

** Inclination 1.5 deg.

2:45 6:45 4.00 22 1.3 4 P Run back 22" BHA for Wiper Trip to bottom.

** Tag obstruction at 380m (set 7T), Connect TD & work ingiterval

to 395m.

** Wash down last joint.

6:45 8:45 2.00 22 1.5 P Pump 6m3 Hi Vis pill & circulate hole clean. ** Fr= 1850lpm Pr=

500psi.

** Partial Losses 2.5 m3/hour.

8:45 14:00 5.25 22 1.3 3 P POOH from bottom to Surface

** Pulled up 1st std with circulation.

14:00 15:30 1.50 22 1.3 3 P Lay down stabilizer, 22" Bit, Bit sub and shock sub

** Meanwhile cut 30" conductor pipe @ 1.73 m from top of cellar

15:30 16:15 0.75 22 3.1 P P/U 30" Riser running tool, Pull up and L/D Riser

16:15 17:45 1.50 22 3.1 P Rig up WFD 18-5/8" power tong & handling tools.

17:45 18:15 0.50 22 HPJSM

18:15 21:45 3.50 22 3.1 P 0.00 Pick up and RIH 18 5/8"-87.5#-P110-BTC csg to 75m (7th joint)

** Make up torque csg shoe on first csg joint

** Test Float shoe @ surface, ok ** Tag obstruction @ 75m.

21:45 0:00 2.25 22 2.1 P 76.00 Rig up circulating head and run csg with circulate from 76m to 79

(7th joint). ongoing.

** 1200 lpm, 200 Psi.

7/28/2019 0:00 4:00 4.00 22 3.1 P 77.00 Run csg with circulation from 77 to 87m (1500 lpm, 280 Psi).

** Couldn't pass. ** The dicsision has been made to pull out

4:00 7:00 3.00 22 3.1 L 87.00 L/D circulating head and POOH CSG from 87 to surface. ** Lost in

hole one centralizer, stop collar & one blade.

7:00 8:15 1.25 22 3.1 L Rig down WFD 18-5/8" power tong & handling tools.

January 23, 2020 at 9:12 pm 3 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

8:15 11:00 2.75 22 1.3 L 0.00 Pick up & run with 9-1/2 fishing magnet two passes To 61m &

88m.

** No metal recovered.

11:00 13:00 2.00 22 1.3 L Pick & make up 9-1/2” Shock sub, 21-7/8” IBS, Bit sub & RR 22”

MT bit; L115J #233165.

13:00 15:45 2.75 22 1.3 L 0.00 Rih 22” wiper trip to 333m. set 7T at this point

15:45 16:15 0.50 22 1.4 L 333.00 Connect top drive & work interval 333 to 363m.** Fr=1500lpm,

Pr=300Psi, Rpm= 60, WOB=5 T.

16:15 19:00 2.75 22 1.3 L 365.00 Continue Rih from 363m to bottom.

** Tag centralizer @ 516.2m,

** Push down to 518m using rotation & circulation

19:00 20:00 1.00 22 1.5 L Circulate hole clean. ** Fr=1850lpm, Pr=510Psi,

20:00 23:00 3.00 22 1.3 L 518.00 HPJSM, Pull out wiper trip string from bottom to surface.

** Hole in good shape.

23:00 0:00 1.00 22 1.3 L 0.00 Lay down 21-7/8" stabilizer, Bit sub, 22" MT Bit and shock sub,

ongoing.

** Stabilizer 2/3 balled up. Bit dull gade; 2-2-WT-A-E-I-NO-TD.

7/29/2019 0:00 0:30 0.50 22 1.3 L Bit service. ** Bit dull grading 2-2-WT-A-E-I-NO-TD

0:30 1:30 1.00 22 3.1 L Rig up WFD power tong and surface csg running equipment.

1:30 10:15 8.75 22 3.1 L 0.00 Run 18 5/8” csg to 257m (joint 23).

** M/U Circulating head and break circulation (joint 19).

** Couldn’t make up joint 22, changed it.

** Tag obstruction @ this depth (257m, Top of Eocene Carbonate)

10:15 13:45 3.50 22 3.1 L M/U Circulating head and try to run csg with circulation,

unsuccessful.

** Working column up and down and rotate column ¼ turn to

change its position, no success.

** Weight on M/D: 70 T (TD 25T + column 45T) ** Max slack-off

weight 45T

13:45 14:15 0.50 22 3.1 L Disconnect circulation house & lay down Circulating head.

14:15 19:00 4.75 22 3.1 L 257.00 Pull out 18-5/8" CSG from 257m to surface.

** Lost in hole one centralizer & one stop collar.

19:00 19:45 0.75 22 Rig down WFD 18-5/8" power tong.

19:45 22:45 3.00 22 1.3 L Pick & make up 9-1/2” Shock sub, 21-7/8” IBS, Bit sub & RR 22”

MT bit; L115J #233165.

** L/D 1 x 9 1/2" DC

22:45 0:00 1.25 22 1.3 L 0.00 Rih 22” wiper trip to 243m ongoing.

7/30/2019 0:00 1:30 1.50 22 1.3 3 L 243.00 Continue wiper trip with reaming down from 243 to 305m.

** Worked interval 245 to 272m twice,

** Worked interval 272 to 305m one time.

1:30 2:30 1.00 22 1.3 4 L 305.00 Continue Run 22” wiper trip string from 305 to 503m

** Hole in good shape

2:30 3:15 0.75 22 1.4 L 503.00 Connect top drive & wash down the last joint from 503 to 513m

** Tag Centralizer at 511m.

3:15 5:15 2.00 22 1.4 L 513.00 Reaming & Push down the lost centralizer from 513 to 517.70m.

** Fr= 1700lpm Pr= 140psi, Rpm= 30, Wob=2T.

5:15 7:15 2.00 22 1.5 L 517.70 Circulate to clean hole.

** Fr= 1800lpm Pr= 470psi

7:15 10:15 3.00 22 1.3 L 517.70 POOH from bottom to surface

** Hole in good conditions

10:15 12:15 2.00 22 1.3 L Lay down, 22" MT Bit, Bit sub, 21-15/16" stabilizer, shock sub &

01 9-1/2” DC

** Bit dull grade; 2-2-WT-A-E-I-NO-TD.

12:15 13:15 1.00 22 3.1 L Pick up the GBRS 18-5/8” shoe joint & test the stinger Ok.

** Change Master bushings

13:15 14:15 1.00 22 3.1 L Rig up WFD 18-5/8" power tong & handling tools.

14:15 20:00 5.75 22 3.1 L 0.00 Run 18 5/8"-87.5#-J55-BTC csg to 268m

** Filling up : The first 10 joints: @ every joint; joints 11-20: every

2 joints.

** Tagged obstruction @ 268m,

January 23, 2020 at 9:12 pm 4 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

20:00 22:30 2.50 22 3.1 L Run 18-5/8" CSG with sluck off all column weight from 268 to

285m

** Make up circulating head on Jt 25 to fill up column & break

circulation (20min).

** M/up joint 26 & try to run casing without success, try to pull out

no success.

** Casing stuck at 285m,

22:30 0:00 1.50 22 9.6 L L/D joint 26, M/U circulating Head & Try unstuck csg using

circulation with working up/down, no success.

** Fr=500 - 1200 lpm, Pr=90 - 200 Psi

** Max P/Up weight reached 180T.

** Increasing over pull by steps on going.

7/31/2019 0:00 16:00 16.00 22 9.6 L Continue work column Up & down with increasing Over pull using

circulation to unstuck same, no success.

** Kept column under tension (50T) & Pump 5m3 Hi PH pill &

displace same in annulus by steps, with working up & down.

** Max pick up weight reached 220T

** Max slack off weight 25t.

** Column weight 40T.

** Top drive & travelling block weight 25T.

** Fr= 1500lpm, P= 210psi.

16:00 16:30 0.50 22 9.6 L L/D circulating head

16:30 20:30 4.00 22 1.3 4 L M/U and Run 5" stinger, space out

20:30 21:30 1.00 22 9.6 L M/U circulating head. Connect Pumping line.

21:30 22:00 0.50 22 9.6 L Sting in, test stinger sealing , ok.

22:00 22:30 0.50 22 9.6 L HPJSM. Test line @ 500/1800 Psi, ok

22:30 0:00 1.50 22 9.6 L HPJSM. 1st Acid job;

** Pump 1 m3 water, pump 3m3 Acid 15% HCl, displace with water

by Steps:

Step1: 0.5m3 (surface line volume), Step 2: after 20min cont

disp by 1m3 (noticed static losses), Step 3: after 20min displace

the last step 1.5m3.

** Column @ 130 T on M/D (TD 25 + Column 35 + Overpull 65)

** Wait on acid to soak and react Meanwhile work string up/down.

8/1/2019 0:00 0:30 0.50 22 9.6 L Circulate and dump acid; got back mud returns after pumping

10m3.

0:30 1:45 1.25 22 9.6 L Pump 1st LCM pill:

** Pump 6 m3 LCM, displace with 4.8 m3

** Wait on soaking (15mn).

** Got returns after pumping 6.3 m3. Circulate 09 m3 (800 lpm, 35

Psi), no loss.

1:45 2:00 0.25 22 9.6 L 2nd ACID JOB:

** Pump 1m3 water, 4 m3 Acid. Displace with 3 m3 water

(500-600 lpm, 150-200 Psi), no loss.

2:00 3:00 1.00 22 9.6 L Wait to soak; Worked column Up/Down during the last 15 mn, no

success.

3:00 3:30 0.50 22 Circulate to dump Acid (800 lpm, 35 Psi), got back mud returns

after pumping 5.5 m3.

3:30 5:15 1.75 22 9.6 L Pump 2nd LCM pill:

** Pump 6 m3 LCM, displace with 4.8 m3 mud. ** Wait To soak

(15mn). Got return after pumping 1.5 m3. Circulate 09 m3 (800

lpm, 35 Psi), no loss.

5:15 5:30 0.25 22 9.6 L 3rd ACID JOB:

** Pump 1m3 water, 4 m3 Acid. Displace with 3 m3 water

(500-600 lpm, 150-200 Psi), no loss.

5:30 7:15 1.75 22 9.69.6 L Wait to soak; Worked column Up/Down during the last 15 min, no

success.

7:15 8:15 1.00 22 9.6 L Circulate to dump Acid (800 lpm, 40 Psi), got back mud returns

after pumping 1.5 m3.

8:15 8:45 0.50 22 9.6 L 4th ACID JOB:

** Pump 1m3 water, 6 m3 Acid. Displace with 3 m3 water (500

lpm, 120-160 Psi),

8:45 11:00 2.25 22 9.6 L Wait to soak; Worked column Up/Down.

January 23, 2020 at 9:12 pm 5 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

11:00 12:00 1.00 22 9.6 L Circulate to eject Acid, Fr= 850lpm, Pr= 120psi

12:00 14:00 2.00 22 9.6 L Work to free stucked casing

14:00 15:00 1.00 22 9.6 L Disconnect pumping line & L/D circulating head. ** Sting out

15:00 17:30 2.50 22 9.6 L POOH stinger to surface & L/D same.

17:30 18:45 1.25 22 9.6 L Work string Up/ Down; no progress.

18:45 0:00 5.25 22 9.6 L 0.00 Pick up & Rih with 18-5/8 internal casing cutter to 182m ongoing.

** P/U Taper mill, Hydr. Internal csg cutter, XO, IBS, XO, Fishing

Jar

** Csg cutter surface test, OK

** Before start running the cutter, filled the annulus with 3.7 m3

mud to regain the static level

8/2/2019 0:00 1:45 1.75 22 9.6 L 182.00 Continue Rih with 18-5/8 internal casing cutter from 182 to 251m.

** Fill up the anulus with 2 m3 to regain the static level before start

cut job.

1:45 6:00 4.25 22 9.6 L First attempt to cut 18-5/8” csg @ 249 m.

** Cutting parameters: Fr= 375-450 lpm, Pr= 340-860 Psi, Rpm=

50, Trq= 900-3500 lbs.ft.

6:00 7:15 1.25 22 9.6 L Stop Cut operation rack back one stand 5” DP & try to pick up

18-5/8” CSG to check if cut was done. No success. Max P/U.W

200T.

7:15 9:45 2.50 22 9.6 L Second attempt to cut 18-5/8” csg @ 249 m.

** Fr= 375-450 lpm, Pr= 340-860 Psi, Rpm= 50, Trq= 2500-3500

lbs.ft.

9:45 12:30 2.75 22 9.6 L 251.00 Pooh 18-5/8 internal casing cutter to surface.

** Rack back Casing cutter BHA on mast.

12:30 13:00 0.50 22 9.6 L Try to pull out 18-5/8” casing increasing over pull gradually from 50

to 160T (225T Hook load) were casing start move slowly

13:00 18:00 5.00 22 9.6 L 249.00 Pull out the recovered 18-5/8” casing to surface.

18:00 18:30 0.50 22 9.6 L R/D WFD power tong

18:30 21:15 2.75 22 9.6 L R/D Csg cutter BHA (Taper mill, Csg cutter, XO, IBS, XO, Fishing

jar)

21:15 0:00 2.75 22 9.6 L 0.00 R/U Releasing spear & Bumper sub and Run BHA to 176m In

progress

8/3/2019 0:00 1:00 1.00 22 9.6 L 172.00 Continue run Releasing spear BHA from 172 to 240m, wash down

to 247 m, Circulate (top of fish @ 249m).

1:00 1:30 0.50 22 9.6 L 247.00 Engage and catch the fish and work string up to 295 T (25/TD +

27/string + 243/overpull), Free the fish.

1:30 4:45 3.25 22 250.00 POOH to surface, 20 T drag on the 10 first meters then free.

** Found top fish covered (balled up) with cutting (formation)

** While cleaning the joint, found a small piece of centralizer metal

(10 cm x 04 cm)

4:45 5:30 0.75 22 9.6 L Rig up WFD 18-5/8” power tong

5:30 6:45 1.25 22 9.6 L Weld pad eyes on 18 5/8” csg

6:45 8:30 1.75 22 9.6 L Try to release fish from releasing spear without success.

8:30 10:45 2.25 22 9.6 L Pull up Top of fish 2m above rotary table & welded other pad eyes

then cut the joint stuck with releasing spear.

** L/D fishing BHA with one single 5” HWDP

** Found 18-5/5" Stop collar hanged between spear grapple &

Csg.

10:45 12:00 1.25 22 9.6 L Pooh with L/D three csg jts 18-5/8”.

12:00 13:00 1.00 22 9.6 L L/D WFD 18-5/8” Csg power tong & handling tools.

13:00 14:00 1.00 22 9.6 L P/U the ensemble releasing spear / BHA with one joint HWDP &

dismantle same.

14:00 15:45 1.75 22 9.6 L Pick & M/U 2 jts 9-1/2” DC, 9-1/2” Shock sub, 21-15/16” IBS, Bit

sub & RR 22” MT bit; L115J #23316

15:45 0:00 8.25 22 9.6 L 0.00 Rih 22” Wiper trip to 518m.

** Worked interval 250m - 305m

** Tagged obstruction (slack-off 5-7 T) several times, from 376m to

bottom (518m), worked each interval till running free.

8/4/2019 0:00 1:15 1.25 22 9.6 L Pumped 6m3 Hi Vis pill and circulated hole clean at different

flowrates (estimated losses: 4 to 5 m3/h), too much cuttings on the

shakers

January 23, 2020 at 9:12 pm 6 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

1:15 2:15 1.00 22 9.6 L 518.00 L/D one joint DP and POOH from bottom (518m) to 330m.

2:15 3:00 0.75 22 9.6 L Spot 20 m3 LCM pill to cover interval 330m to 250m.

3:00 3:30 0.50 22 9.6 L 330.00 POOH to 240m.

3:30 4:15 0.75 22 9.6 L Circulate, No loss.

** Fr= 1600-1800-1900Lpm, Pr= 300-400psi

4:15 6:15 2.00 22 9.6 L 240.00 Continue Pooh to surface

6:15 8:15 2.00 22 9.6 L Lay down 21-15/16” IBS & replace same with 23-14/16” IBS, L/D

22” Bit & bit sub. No wear on IBS

8:15 10:15 2.00 22 9.6 L Pick up riser & weld same on 30” conductor.

10:15 13:15 3.00 22 9.6 L Pick up & Rih 24” BHA with 24” RR bit T41A #D240742.

** Pick up one joint 9-1/2” DC,

** Lay down one joint 8-1/4” DC to space out.

** Tag at 59m.

13:15 13:30 0.25 22 9.6 L Drill out cement inside 30" from 59 to 61m

13:30 0:00 10.50 24 9.6 L 61.00 22” to 24” Hole section enlargenment from 61m to 146 m.

** Fr= 800-1200lpm, Pr= 200psi, Rpm= 40-80 WOB= 0-5T

** Applied slow parameters until IBS out of 30" shoe

** Partial losses rates not stable, 2 to 4 m3/h.

8/5/2019 0:00 11:30 11.50 24 9.6 L 146.00 Continue 22” to 24” Hole section enlargenment from 146 to 260 m

(1200 lpm, 0 – 3 T, 60 – 80 rpm, 200 Psi). Partial losses noticed :

0.6 to 1 m3/h.

11:30 13:30 2.00 24 9.6 L Pump 6 m3 Hi-Vis & Circulate Hole Cleaning (1200 lpm, 200 psi,

No losses).

13:30 17:15 3.75 24 9.6 L 260.00 Drop Totco & POOH to surface with L/D 2 DC 9-1/2".

* IBS gage : 23-15/16".

* Totco reading : misrun.

* Bit grading : 2-1-WT-A-E-I-NO-BHA.

17:15 21:30 4.25 24 9.6 L 0.00 Changed bit from TCI to MT; P/U & RIH with new 24” BHA to

260m.

** with 24” RR bit T11 #D242025

** with Picking up second 23-15/16" IBS (WFD) + 9-1/2" SDC

** Washed down last 10 m

21:30 0:00 2.50 24 9.6 L 260.00 Resume hole enlargement from 22" to 24", from 260 to 270m.

** 1400 lpm, 230 Psi, 40-70 RPM, 0-3 T, No loss

8/6/2019 0:00 0:00 24.00 24 9.6 L 270.00 Hole enlargement from 22" to 24", from 270 to 477m.

** 1400-1750 lpm, 230-520 Psi, 40-90 RPM, 0-9 T, No loss

8/7/2019 0:00 8:15 8.25 24 9.6 L 477.00 Continue Hole enlargement from 22" to 24", from 477 to 518 m.

** 1750 lpm, 450-520 Psi, 75-90 RPM, 3-9 T, Partial losses +/-

1.5 m*/h

8:15 10:00 1.75 24 9.6 L Pump 6 m3 Hi-vis & CHC. No loss.

10:00 15:00 5.00 24 9.6 L 518.00 Short trip to 250 m (top of Eocene Carbonate).

** Observed Overpull 6 t at 364 m, work interval (364 to 347 m) till

free.

** RIH back to Bottom hole 518 m, freely-

15:00 17:00 2.00 24 9.6 L Pump 6 m3 Hi-vis & CHC.

** 1700 lpm, 450 Psi, No loss.

17:00 17:30 0.50 24 9.6 L Spot 15 m3 Hi Vis pill on bottom & drop Totco.

17:30 21:45 4.25 24 9.6 L 250.00 POOH to surface.

** Upper stabilizer 1/3 balled up; lower stabilizer 100% balled up.

No wear.

** Bit: 100% balled up. Dull grading : 2-1-BU-A-E-I-NO-TD

(noticed as RIH).

** Totco reading : 1.7 degree

21:45 0:00 2.25 24 9.6 L 24.00 L/D two stabilizers, 9 1/2" S.DC, 9 1/2" DC, shock sub and bit:

ongoing.

8/8/2019 0:00 1:00 1.00 24 9.6 L Continue L/D 24” BHA.

1:00 2:15 1.25 24 9.6 L P/U Riser running tool, Cut riser @ 1.73m bellow ground level,

P/U & L/D riser.

2:15 3:30 1.25 24 9.6 L P/U WFD power tong & handling tool

3:30 3:45 0.25 24 9.6 L HPJSM with all personnel.

3:45 10:30 6.75 24 9.6 L 0.00 P/U 1st csg joint with shoe, Test float shoe ok, Run 18 5/8” csg to

280 m (23 jts). Fill up every joint.

January 23, 2020 at 9:12 pm 7 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

10:30 17:00 6.50 24 3.1 P 280.00 Continue Run 18 5/8” csg to bottom (tagged bottom, 518m, 42

joints total) & confirmed several times.

* Observed 5 m stick up above rotary table, theoritical stick up

0.90 m @ 516 m.

17:00 19:15 2.25 24 13.1 L Investigate : found mistake was made during running last 4 joints.

POOH & L/D 4 jts and run back last 4 joints as per tally.

19:15 19:45 0.50 24 2.1 P Break circulation

19:45 20:15 0.50 24 3.1 P R/D WFD/TRS Casing Power tong and accessories.

20:15 21:00 0.75 24 3.1 P Centralize column and weld braces 18-5/8" x 30".

21:00 23:30 2.50 24 3.1 P 0.00 P/U & Run stinger to 516 m.

23:30 0:00 0.50 24 3.1 P Space out.

8/9/2019 0:00 0:30 0.50 24 3.2 P M/U cementing line and cementing head. Sting in.

0:30 0:45 0.25 24 3.2 P PJSM

0:45 1:00 0.25 24 3.2 P Pressure test cementing line @ 500/2000 Psi, ok

1:00 2:45 1.75 24 3.2 P Circulate, 1300-1550 lpm, 450 Psi, no loss.

2:45 5:30 2.75 24 3.2 P CEMENT JOB:

** Pump 6 m3 water ahead, mix and pump 69.17 m3 lead slurry

1.58 sg (return on surface) then 18.04 m3 tail slurry 1.90 sg.

Displaced by 3.6 m3 water. Max pressure 640 Psi during the job.

No loss.

** Bleed off pressure, check, no return -float holding-.

5:30 5:45 0.25 24 3.2 P L/D cementing head and cement line.

5:45 6:00 0.25 24 3.2 P Sting out, P/U 10 m and circulate 6 m3 (1.5 inner stinger string

volume), 1200 lpm.

6:00 10:00 4.00 24 3.2 P POOH Stinger To surface.

10:00 12:00 2.00 24 3.3 1 P M/U & install base plate, Cut (1.27m BLG) & L/D landing joint,

beveled 18/5/8” csg.

12:00 15:00 3.00 24 3.3 1 P M/U & Install 20 ¾ ”3K psi x 18 5/8” slip lock CHH & test @ 500

psi ok.

15:00 0:00 9.00 24 3.3 1 P N/U BOP stack (Mud cross 20 ¾” 3K + 20 ¾ (3Kx2K) DSA + 21

¼” 2K Annular) & M/U kill & choke lines.

** Meanwhile cement top job (1m3 slurry, 1.90 sg)

8/10/2019 0:00 5:00 5.00 24 3.3 2 P P/U Tester cup, flush circuit, HPJSM. Pressure test Annular BOP,

kill & choke lines, Master valves @ 250 / 1000 Psi, OK. L/D Tester

cup.

5:00 7:00 2.00 24 3.3 2 P P/U & install Wear Bushing, L/D wear bushing running tool.

7:00 0:00 17.00 24 1.3 4 P P/U 5" DPs & rack back on derrick.

** Picked up: 186 jts (62 stds). Total on derrick: 228 jts (76 stds).

8/11/2019 0:00 1:30 1.50 24 1.3 4 P P/U 2 DC 9 1/2", bit sub, P/U 16" Varel MT Bit (ES1V) .

1:30 5:15 3.75 24 1.3 4 P 0.00 RIH with drill out BHA, wash down last stand, tagged cement @

514m.

* L/D one 8 ¼” DC & P/U 8” D. Jar

5:15 6:00 0.75 24 1.5 P Displace to OBM 1.18 sg. (2500 lpm 400 psi).

6:00 14:30 8.50 24 3.4 P 514.00 Drill out Cement + Shoe + Cement from 514 to 518 m. Hard

cement (2-7 T, 40 RPM, 2500 lpm, 1800 psi).

14:30 16:45 2.25 16 1.1 1 P 518.00 Drilling formation 16” hole section f/518 to 520 m (10-12 T, 80-100

RPM, 2500 lpm, 1850 psi).

16:45 18:00 1.25 16 1.5 P Pump 5m3 Hi-Vis & CHC

18:00 21:00 3.00 16 1.3 4 U 520.00 Pooh 16” drill out string to surface.

21:00 0:00 3.00 16 1.3 4 U 0.00 P/U two junk baskets and RIH back to 230m.

8/12/2019 0:00 2:00 2.00 16 1.3 4 U 230.00 RIH with junk baskets from 230 to 520m; washed down last

meters.

2:00 3:15 1.25 16 2.1 U Pump 5m3 Hi Vis pill and CHC, work basket.

3:15 4:45 1.50 16 1.3 4 U 520.00 Pull out Junk baskets to surface.

4:45 5:30 0.75 16 1.3 4 U Baskets service.

** Recovered 1.920 gr of junk .

5:30 7:30 2.00 16 1.3 4 U 0.00 RIH junk baskets with same BHA to bottom, 520m. Washed down

last meters

7:30 8:30 1.00 16 2.1 U Pumped 5m3 Hi Vis pill, worked basket.

8:30 11:00 2.50 16 1.3 4 U 520.00 POOH to surface.

January 23, 2020 at 9:12 pm 8 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

11:00 13:45 2.75 16 1.3 4 U Baskets service.

** Recovered 1 kg of junk .

13:45 19:00 5.25 16 1.3 4 U 0.00 P/U & RIH 16” Varel TCI Bit (ES14V) to bottom (520m).

** @ bottom, P/U & M/U one DP joint to adjust depth (in order to

drill a complete stand without interruption).

** Took slow circulating rates.

19:00 0:00 5.00 16 1.1 1 P 520.00 Drill 16” hole section from 520 to 524 m.

** Pump 5m3 Hi Vis pill, then 5m3 heavy pill prior start drilling.

** Start drilling with reduced parameters (6-7 T, 50-60 RPM)

** Drilling with OBM 1.18 sg.

** Recovered 340 gr of ditch magnet on the shakers @ 00:00.

** Formation : Anhydrite (40-95%), Dolomitic limestone (60-5%).

8/13/2019 0:00 14:45 14.75 16 1.1 1 P 524.00 Drilling 16” Hole section with 1.18 sg OBM from 524 to 548 m.

** Recovered 640 gr of ditch magnet @ 05:00 (drilling f/ 524 to

529 m).

** Pump 3 m3 Hi-Vis Pill @ 535 m.

** Recovered 1300 gr of dich magnet @ 10:30 (drilling f/529 to

537 m).

14:45 16:00 1.25 16 1.5 U Pump 5 m3 Hi-vis pill & displace with 15 m3 Mud at 3000 lpm,

Pump the 2nd 5 m3 Hi-vis pill & CHC till get Hi-vis at surface. **

Recovered 1023 gr of dich magnet @ 16:00 (drilling f/537 to 548

m).

16:00 19:00 3.00 16 1.3 1 U 548.00 Pooh 16” Drill string to surface & L/D 16” TCI Bit.

** Dull bit grading: 1-1-WT-A-E-I-NO-BHA

** Upper & lower stabilizers pulled up 15 15/16" 9wear: 1/16")

** NV400 Near bit: pulledup ingage

19:00 22:30 3.50 16 1.3 2 U 0.00 P/U 16” NOV New PDC TFH916S SN:E245489 & RIH, Wash

down last meters

22:30 23:00 0.50 16 1.5 U Pump 5m3 Hi Vis pill then 5 m3 heavy pill, CHC

23:00 0:00 1.00 16 1.1 1 P 548.00 Drilled 16" hole section from 548 to 552m *** High torque with

small drilling parameters (3-5 T, 40-80 RPM, 3000 lpm,

2000-18000 lbs.ft)

8/14/2019 0:00 1:00 1.00 16 1.1 1 P 552.00 Continue drilling from 552 to 553 m with low parameters and high

erratic torque (4-7 T, 40-80 RPM, 3000 lpm, 2000-18 000 ft.lbs).

1:00 1:45 0.75 16 1.5 U CHC and pumped a Hi Vis pill till getting it on surface.

** Recovered 110 gr of junk on ditch magnet

1:45 11:45 10.00 16 1.1 1 P 553.00 Resume drilling to 685 m.

** Drilling Parameters: 4-14 T, 60-130 RPM, 9000-18000 lbs.ft,

3000 lpm, 1700 Psi.

** Recovered 500 gr on ditch magnet @ 13:00 when drilled to 697

m.

** Recovered 100 gr on ditch magnet @ 22:00 when drilled to 758

m.

11:45 12:00 0.25 16 1.5 P Pumped a Hi Vis pill & took SCR.

12:00 0:00 12.00 16 1.1 1 P 685.00 Resume drilling to 767 m.

** Drilling parameters : 5-15 T, 40-140 RPM, 8000-18000 lbs.ft,

3000 lpm, 1700-1950 Psi

** Recovered 100 gr on ditch magnet @ 22:00 when drilled to 758

m.

** Last lithology sample @ 760 m : 95 % Anhydrites + 5 %

Claystone

8/15/2019 0:00 0:00 24.00 16 1.1 1 P 767.00 Continue drilling from 767 to 937 m (5-8 T, 110-130 RPM, 2800

lpm, 1850 psi, 10 000-18 000 ft.lbs).

** Pump Hi-Vis pill every 4 stands drilled.

** Reamed every stand drilled.

** Tight spots while reaming up drilled stand : 831 – 827 m & 872 –

856 m, worked till get free.

** Recovered 125 grs Junk on magnet ditch @ 13:30 (drilling f/800

to 865 m.) & 80 gr @ 00:00 (drill @937m).

** Turonien: Top @ 808 m ; drilled with 2800 lpm.

** Cenomanien, top @ 910 m. Last simple @ 930 m: 40 %

Anhydrite, 40 % Claystone, 20 % Dolomite.

8/16/2019

January 23, 2020 at 9:12 pm 9 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

0:00 15:00 15.00 16 1.1 1 P 937.00 Drill 16" Hole section from 937 m to 1042 m

** 7-14 T, 150-160 RPM, 12000-15000 Ft.Lbs, 3000 lpm, 2400

Psi.

** Pump Hi-Vis pill every 4 stands drilled.

** Reamed every stand drilled.

** Formation : Cenomanien, top @910 m. Lithology: Last sample

1030m, 40% clay, 50% limestone, 10% anhydrite.

** Suspect Drill string twist off while drilling: Pressure suddenly

dropped from 2400 to 1400 Psi & string weight dropped from 80 to

56 T (-24 T).

15:00 15:30 0.50 16 9.9 L Try to screw on fish, no success.

15:30 16:15 0.75 16 9.9 3 L Circulate bottom's up.

16:15 18:15 2.00 16 9.9 3 L 923.00 POOH to surface.

** Observed Drilling Jar parted at the lower section of mandrel

(only 2.43m of Jar recovered).

** Length of fish: 119m (fish: BHA below jar + 7.25m of jar)

** Top Of Fish @ 923m

18:15 19:15 1.00 16 9.9 3 L L/D 2 DC 8 1/4" and the jar recovered part.

19:15 20:30 1.25 16 9.9 3 L 0.00 RIH with Safety string 5’’DP stands to 300 m.

20:30 21:30 1.00 16 9.9 3 L Wait on WFD fishing equipment

21:30 22:15 0.75 16 9.9 3 L 300.00 POOH safety string to surface

22:15 0:00 1.75 16 9.9 3 L P/U an rack back 9 DC 8 1/4"

8/17/2019 0:00 1:00 1.00 16 9.9 L Continue P/U 8-1/4" DCs (7 jts) & Rack back on derrick.

1:00 4:30 3.50 16 9.9 L R/U & M/U fishing BHA w/ 11 3/4” Overshot (w/ all components &

accessories), Bumper sub & Fishing Jar. (BHA #1)

4:30 8:15 3.75 16 9.9 L 0.00 RIH w/fishing BHA to 815 m.

** P/U Intensifier

** Tag obstruction (6 T).

8:15 9:00 0.75 16 9.9 L Try to pass several times (w/circulation), no success.

9:00 11:15 2.25 16 9.9 L 815.00 Pull out to surface.

11:15 12:30 1.25 16 9.9 L Change Overshot oversize guide 15” to guide 11-3/4”. (BHA #2)

12:30 15:45 3.25 16 9.9 L 0.00 RIH back; Washed down last stand, Tagged fish @ 923 m.

** Theoritical T.O.F. @ 923.3 m; Tagged @ 923.6 m

15:45 16:30 0.75 16 9.9 L Attempt to catch fish, no success.

** Tagged with 5T, got pressure increased from 80 to 680 Psi (540

lpm); slacked off from 923.6 to 926.4 m with 20 T on fish. Shut off

pumps, pressure stable @ 680 Psi. Pull up, no overpull (no

success). Repeated several times, same.

16:30 19:00 2.50 16 9.9 L 923.00 Pull out to surface.

** Found the basket dies slightly used and the packer (MCP)

damaged

19:00 21:30 2.50 16 9.9 L Changed overshot basket grapple from 8" to 7-7/8".

** The MC (Mill Control) is kept as the previous run, an 8'.

** Run without packer (MCP). (BHA #3)

21:30 0:00 2.50 16 9.9 L 0.00 RIH back to 530 m.

8/18/2019 0:00 2:00 2.00 16 9.9 3 L 530.00 Continue RIH with overshot, washed down last stand (820 lpm,

170 Psi), tagged fish (confirmed with 5T) @ 923m, caught fish

(confirmed catch with increase of pressure from 170 to 230 Psi @

820 lpm).

2:00 5:00 3.00 16 9.9 L 1,042.00 POOH with overpull (got till 60 T overpull, 1042 - 1038 m), worked

string and POOH with circulate (400-1200 lpm, 150-550 Psi), max

drag 5-10 T. POOH to 875 m

** Overpull (15 to 65 T) f/ 948 to 875 m.

** Stuck @ 875 m.

** Fishing string (923 m) + Fish (119 m) = 1042 m.

5:00 7:00 2.00 16 9.9 L Overpull gradually up to 112 T (200 T on MD, String weight 88 T),

Work string up and down, jarring up, No success.

7:00 12:15 5.25 16 9.9 L 875.00 Alternatively circulate (3000 lpm, 1900 Psi), Jarring up and work

string up & down f/ 875 to 858 m.

12:15 21:00 8.75 16 9.9 L Alternatively circulate (3000 lpm, 1900 Psi), Jarring up and work

string up & down @ 858 m, unsuccessful.

21:00 21:30 0.50 16 9.9 L HPJSM for acid job, with all personnel.

January 23, 2020 at 9:12 pm 10 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

21:30 0:00 2.50 16 9.9 L L/D one 5" DPs, M/U Circulating head, connect cement line. Test

cementing line @ 300/5000 Psi.

8/19/2019 0:00 1:30 1.50 16 9.9 L 1st ACID JOB:

** Pump 1 m3 diesel, 3 m3 acid 15% HCL, 1 m3 Diesel. Displaced

with 3.2 m3 Mud 1.25 sg.

Wait on soak, string in tension (160 T). Jarring up. Drawworks

down (at the end of jarring, and the string remains in tension).

1:30 3:00 1.50 16 10.1 L Repair on Drawwoks meanwhile : displaced 2nd m3 of Hcl acid to

annulus, wait on soak.

* string still in tension (150T) when displacing.

3:00 4:00 1.00 16 9.9 L Displaced 3rd m3 of Hcl acid to annulus, wait on soak, jarred up

(165 T). Worked bumber-sub down.

4:00 5:30 1.50 16 9.9 L Circulate the acid pill out. ( 2500 lpm, 1500 Psi.)

5:30 7:45 2.25 16 9.9 L 2nd ACID JOB:

** Pump 1 m3 diesel, 3 m3 acid 15% HCL, 1 m3 Diesel. Displaced

with 3.2 m3 Mud 1.25 sg.

Wait on soak, string in tension (150 T).

Displaced the 2nd m3 of Hcl acid to annulus, wait on soak, Jarred

only once then drawwork down.

7:45 8:30 0.75 16 10.1 L Reapir on Drawworks (String still in tension).

8:30 9:15 0.75 16 9.9 L Displace the 3rd m3 of Hcl Acid to annulus, wait to soak & jarred

up (150 T).

9:15 10:15 1.00 16 9.9 L Circulated the acid pill out.

* 3000 lpm, 1890 Psi

10:15 16:30 6.25 16 9.9 L Try to Release overshot from the fish several times - No success -

:

* String weight 67 T, Bump down from 80 to 30T, Rotate to

maximum Torq (15000 to 20000 ft/lbs), with circulation (1000 lpm/

250 psi - 3000 lpm/1800 psi) & with out circulation.

16:30 20:30 4.00 16 9.9 L 3rd ACID JOB:

* Pump 1m3 diesel, 3m3 acid 15% HCL, 1m3 Diesel. Displaced

with 3.2 m3 Mud 1.25 sg.

Wait on soak (1 hr), string in tension (150 T).

Jarring up & work string.

Displaced the 2nd & 3rd m3 of Hcl acid,Wait on soak (1 hr), string

in tension (150 T).

Jarring up & work string.

20:30 21:45 1.25 16 9.9 L Circulated Hcl acid out ( 3000 lpm, 1700 psi)

21:45 0:00 2.25 16 9.9 L Work string & jarring up - No success -.

8/20/2019 0:00 0:00 24.00 16 9.9 L Try to Release overshot from the fish several times - No success -

:

* String weight 67 T, Bump down from 80 to 30T, Rotate to

maximum Torq (19000 ft/lbs), with circulation (1500 lpm / 500 psi).

* Work string & Jarring up (70T Over string weight) – No success.

8/21/2019 0:00 14:00 14.00 16 9.9 L Try to Release overshot from the fish several times - No success

* String weight 67 T, Bump down from 80 to 30T, Rotate to

maximum Torq (19000 ft/lbs), with circulation (1500 lpm / 500 psi)

* Work string & Jarring up (70T Over string weight) – No success.

* Got the joint connected to TDS bent during moving string

up/down, L/D same, investigation on going.

14:00 21:00 7.00 16 9.9 L Oilserv CT crew on location.

Held PJSM.

Spot coil tunbing unit and related equipment.

RU CT unit:

- Function test BOP Rams and CT equipment .

- Install CT connector.

- R/U pumping lines to reel manifold & pressure test (low test

300psi, 10min OK; High test 5000psi, 15 min Ok).

- M/U MHA, Knockle joint, and nozzle.

- M/U injector head onto BOP.

* Prior to start RIH, found CT Data cable out of service (request a

new cable from HMD base)

21:00 0:00 3.00 16 9.9 L Waiting on CT Data cable meanwhile circulting hole @ 400lpm.

8/22/2019

January 23, 2020 at 9:12 pm 11 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

0:00 8:00 8.00 16 9.9 3 L Wait for CT Data cable (Got the CT data cable damaged while rig

up) from HMD base, meanwhile circulate hole . (Lost time for

OS/CT).

8:00 9:00 1.00 16 9.9 3 L R/U, Connect & check CT data cable.

9:00 9:45 0.75 16 9.9 3 L Fill up CT with 24 bbl of OBM.

9:45 10:00 0.25 16 9.9 3 L Correlate CT depth Electronic & Mechanical depth counter to Zero

depth, Set up injector head.

10:00 11:15 1.25 16 9.9 3 L RIH with CT as per OS CT operating procedures to 845 m.

11:15 11:45 0.50 16 9.9 3 L Circulate & check return (0.7 bpm, 3800 psi) -ok-.

11:45 12:30 0.75 16 9.9 3 L Spot Hcl acid: pump 0.5 m3 diesel + 3 m3 of 15% Hcl Acid + 0.5

m3 diesel.

12:30 12:45 0.25 16 9.9 3 L Displace Acid with 22 bbl of Mud (1 bpm, 3750 to 4300 psi).

12:45 13:45 1.00 16 9.9 3 L POOH CT to surface.

13:45 14:15 0.50 16 9.9 3 L Flush CT w/ water.

14:15 15:45 1.50 16 9.9 3 L R/D CT BOP & injector head.

15:45 17:30 1.75 16 9.9 3 L Work string with slack off down several times – No success, jarring

up with fishing jar, no success.

17:30 19:00 1.50 16 9.9 3 L Circulate acid out of Hole (2000 lpm, 850 psi)

19:00 0:00 5.00 16 9.9 3 L Work string with slack off down several times – No success, jarring

up with fishing jar, no success.

8/23/2019 0:00 0:30 0.50 16 9.9 3 L L/D 1 joint & M/U 4-1/2" IF pin x 5-3/4" ACME XO on Top of

string.

0:30 2:00 1.50 16 9.9 3 L M/U Injector head on BOP + 5-3/4" ACME x 6-1/2" OTIS X-Over

2:00 3:15 1.25 16 9.9 3 L R/U CT injection Head on top of string.

3:15 4:00 0.75 16 9.9 3 L Fill up CT with 24 bbl of OBM.

4:00 4:15 0.25 16 9.9 3 L Correlate CT depth Electronic & Mechanical depth counter to Zero

depth, Set up injector head.

4:15 5:30 1.25 16 9.9 3 L RIH with CT as per OS CT operating procedures to 845 m.

5:30 6:00 0.50 16 9.9 3 L Circulate & check return (0.7 bpm, 3800 psi) -ok-.

6:00 6:45 0.75 16 9.9 3 L Spot Hcl acid: pump 0.5 m3 diesel + 4 m3 of 15% Hcl Acid + 0.5

m3 diesel.

6:45 7:00 0.25 16 9.9 3 L Displace 2m3 of Acid with 12 bbl of Mud (1 bpm, 3750 to 4300

psi). (keep 2m3 HCL acid inside CT)

7:00 8:00 1.00 16 9.9 3 L wait for HCL acid to soak.

8:00 8:15 0.25 16 9.9 3 L Displace 2nd 2m3 Acid to formation with Mud (1 bpm, 3750 to

4300 psi).

8:15 8:45 0.50 16 9.9 3 L wait for HCL acid to soak.

8:45 10:00 1.25 16 9.9 3 L POOH CT to surface.

10:00 10:15 0.25 16 9.9 3 L Flush CT w/water.

10:15 11:15 1.00 16 9.9 3 L R/D CT BOP & injector head.

11:15 13:15 2.00 16 9.9 3 L Work string with slack off down several times – Nosuccess-.

13:15 14:00 0.75 16 9.9 3 L Circulate Hcl Acid out (3000 lpm, 1700 Psi)

14:00 0:00 10.00 16 9.9 3 L Hand over Rig to KCA for drawworks maintenance (2 hrs) & repair

(8 hrs).

8/24/2019 0:00 2:30 2.50 16 9.9 3 L KCA Continue drawworks repair (2.5 hrs).

2:30 7:00 4.50 16 9.9 3 L Displace hole MW from 1.25 sg to 1.40 sg progressively - No

losses -.

7:00 10:00 3.00 16 9.9 3 L Circulate to homogenise mud : MW in = MW out = 1.40 sg.

10:00 12:00 2.00 16 9.9 3 L M/U one single DP, Work string with slack off down several times

& Jarring up – No success -.

12:00 14:45 2.75 16 9.9 3 L Circulate (3000 lpm, 1850 psi).

14:45 15:00 0.25 16 9.9 3 L Jarring up – No success -.

15:00 15:30 0.50 16 9.9 3 L Circulate (3000 lpm, 1800 psi).

15:30 15:45 0.25 16 9.9 3 L Work string – No success -.

15:45 17:00 1.25 16 9.9 3 L Circulate (1500 lpm, 530 psi).

17:00 18:30 1.50 16 9.9 3 L Displace hole MW to 1.25 sg .

18:30 20:00 1.50 16 9.9 3 L Circulate to homogenise mud : MW in = MW out = 1.25 sg.

20:00 0:00 4.00 16 9.9 3 L Work string, Try to release Overshot – No success -

8/25/2019 0:00 0:00 24.00 16 11.5 L Cont Work string &Try to release Overshot – No success,

Meanwhile wait on Explosives Escort for Eletrical Back off.

January 23, 2020 at 9:12 pm 12 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

8/26/2019 0:00 0:00 24.00 16 11.5 L Cont Work string &Try to release Overshot – No success.

Meanwhile wait on Explosives Escort for Eletrical Back off.

8/27/2019 0:00 10:00 10.00 16 11.5 L Cont Work string &Try to release Overshot –No success-,

Meanwhile wait on Explosives Escort for Eletrical Back off.

10:00 10:30 0.50 16 9.9 L Pump 6 m3 of Avatensio pill & displace to annulus (spot) by 7 m3

of 1.25 sg OBM.

10:30 12:30 2.00 16 9.9 L Wait on Avatensio pill to soak (displace in annulus w/ 0.5 bbl of

OBM every 30 min / total 2 bbl of displacement in annulus).

12:30 13:30 1.00 16 9.9 L Work string & Try to release Overshot – No success -.

13:30 14:15 0.75 16 9.9 L Circulate & displace out Avatensio pill.

14:15 0:00 9.75 16 11.5 L Work string &Try to release Overshot – No success -. Meanwhile

wait on Explosives Escort for Eletrical Back off.

8/28/2019 0:00 0:00 24.00 16 11.5 L Cont Work string &Try to release Overshot -No success-

Meanwhile wait on Explosives Escort for Eletrical

Back off.

8/29/2019 0:00 5:00 5.00 16 11.5 L Cont Work string & Try to release Overshot -No success-,

Meanwhile wait on Explosives Escort for Eletrical Back off.

5:00 7:15 2.25 16 9.9 L HPJSM, Rig up SLB Wire line equipment.

7:15 9:15 2.00 16 9.9 L Dummy run with 1-11/16" drift and CCL to 853 m ok , POOH &

L/D drift tool.

9:15 12:00 2.75 16 9.3 L Rig up & Calibrate FPIT. (Lost time due to SLB FPIT failure)

12:00 17:00 5.00 16 9.3 L RIH FPIT, Stations: 100 m (free), 600 m (stuck), 459 m (no

reading), back to 600 m (stuck), repeat at 100 m (free), 150 m

(stuck), 200 m (stuck), 250 m (stuck).

* As the result was not satisfying, decision made to POOH and

RIH with FPIT back up tool

* POOH & L/D.

* Military escort left location at 17:00.

* Lost time due to SLB FPIT failure: 5 hrs.Total lost time (SLB):

7.75 hrs.

17:00 18:45 1.75 16 9.9 L M/U FPIT back up, surface check & calibrate.

18:45 0:00 5.25 16 9.9 L RIH Back up FPIT tool and record at the following stations:

* 100 m (free), 150 m (free), 600 m (free), 723 m (free), 759 m

(free), 804 m (free), 840 m (Stuck) - just on the 9-1/2" DC bellow

the upper stabilizer in the drilling BHA

* Logging in progress.

* NB: (stuck point located between 840 & 820 m, just on the upper

STB on the drilling BHA).

8/30/2019 0:00 1:00 1.00 16 9.9 L Cont FPIT logging at the last station @ 820 m (free).

NB: (stuck located between 840 & 820 m, just on the upper STB

on the drilling BHA)

1:00 3:00 2.00 16 9.9 L POOH FPIT tool to surface & R/D SLB Wire line equipment.

3:00 19:30 16.50 16 9.9 L Cont Work string &Try to release Overshot – No success.

19:30 20:00 0.50 16 9.9 L Held PJSM with all crew for mechanical back off & discuss the

hazards, secure TDS & elevator.

20:00 21:00 1.00 16 9.9 L Proceed with Mechanical back off:

* M/U string Torq to 26000 ft.lbs.

* P/U string weight to 110 T & apply left hand torq 10000 ft.lbs

* Slack off weight by gradualy while inreasing LH torq by increment

of 5000 Ft.lbs.

* At 95 T& 21000 Ft.lbs, start increasing LH torq by increment of

1000 Ft.lbs to 23000 Ft.lbs (Observe string rotating 7 turns to the

left).

* Cont inreasing torq by increment & work string U/D 85-95 T.

* At 28000 Ft.lbs, string rotate free to the left 10 turns, 65 T of the

string recovered free.

21:00 0:00 3.00 16 9.9 L L/D 1 jt 5" DP, POOH w/ recovered string & rack back while

checking every single connection: break connection, clean, visual

check, apply dope and tight back. In pgrogress @ 100 m.

NB: Recovered all fishing String except 11-3/4" Over Shot +

extension & initial fish. Total recovered : 54 DP 5" + 12 HWDP 5"

+ 7-3/4" Accelerator + 9 DC 8-1/4" + 8" Fishing Jar &

Bumper-Sub. TOF @ 735 m.

January 23, 2020 at 9:12 pm 13 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

8/31/2019 0:00 2:00 2.00 16 9.9 L POOH w/ recovered string & rack back while checking every

single connection: break connection, clean, visual check, apply

dope and tight back. (recovered 54 DP 5" + 12 HWDP 5" + 7-3/4"

Accelerator (L/D) + 9 x DC 8-1/4" (1 DC 8-1/4" L/D, thread on Box

side was excentred) + 8" Fishing Jar & Bumper sub).

2:00 2:30 0.50 16 9.9 L L/D WDF 8" Fishing Jar & Bumper sub.

2:30 6:00 3.50 16 9.9 4 L P/U & M/U 16” Varel milled tooth Bit (SN: 1549290) + BS + XO +

6 DC 8-1/4" + 8" D.Jar + 2 DC 8-1/4" + XO + 12 HWDP 5" & RIH

to TOF @ (735 m).

* L/D one DC 8-1/4", P/U & M/U 8" Drilling Jar.

6:00 8:45 2.75 16 9.9 4 L Circulate to recondition & homogenise mud.

8:45 10:00 1.25 16 9.9 4 L Pull out to 18-5/8" Csg shoe (516 m).

10:00 11:00 1.00 16 9.9 4 L Top Drive service & inspection.

11:00 17:00 6.00 16 9.9 4 L Cont POOH (connections overtight) with L/D: 12 jts of 5" HWDP +

3 DC 8-1/4". For inspection.

* L/D 6 Joints of 5" HWDP racked back on Derrick.

* L/D: bit sub + bit.

17:00 17:30 0.50 16 9.9 4 L P/U & RIH wear bushing running tool. Retreive wear bushing.

17:30 20:30 3.00 16 9.9 4 L P/U Tester cup, flush circuit, HPJSM. Pressure test Annular BOP,

kill & choke lines, Master valves @ 250 / 1000 Psi, OK. L/D Tester

cup.

20:30 21:00 0.50 16 9.9 4 L RIH & set wear bushing.

21:00 23:30 2.50 16 9.9 4 L P/U RIH 3-1/2 cmt stinger + 16 DP 3-1/2 to 154 m.

23:30 0:00 0.50 16 9.9 4 L Cont RIH w/ 5" DP to 380 m -in progress-

9/1/2019 0:00 0:45 0.75 16 9.9 4 L Cont RIH w/ 5" DP to 733 m

0:45 2:15 1.50 16 9.9 4 L Circulate Hole Clean @ 3000 lpm.

2:15 2:30 0.25 16 9.9 4 L Spot 2 m3 Hi-Vis Pill.

2:30 2:45 0.25 16 9.9 4 L POOH 10 m (to 723 m @ Top of Hi-Vis) & space out.

2:45 3:30 0.75 16 9.9 4 L R/U surface line & pressure test to 5000 psi -10 min- Ok.

3:30 5:30 2.00 16 9.9 4 L Cont circulate meanwhile Batch mix 17.89 m3 of slurry 2.10 SG.

5:30 6:30 1.00 16 9.9 4 L Perform Cmt job as follows:

• 05 m3 Spacer.

• 17.9 m3 cmt 2.10 SG.

• Displace w/ 0.320 m3 spacer + 4.7 m3 mud 1.25 SG.

Bleed off pressure, check for return, -No return-

6:30 7:45 1.25 16 9.9 4 L L/D cement head & cement line + pup joint . POOH slowly 8 STDs

to 500 m (03 STDs above TOC).

7:45 9:15 1.50 16 9.9 4 L Circulate (2 bottom up) @ 2800 lpm , 1350 psi.

9:15 10:15 1.00 16 9.9 4 L Cont pull out with 5" DP to 154 m.

10:15 12:15 2.00 16 9.9 4 L Cont pull out to surface with L/D 3-1/2" DP (16 jts + stinger).

* Change handling equipments & jaws tongs from 5" to 3-1/2".

12:15 14:30 2.25 16 9.9 4 L Picked up 12 jts of 5" HWDP & Racked back on derrick.

* Change handling equipments & jaws tongs from 3-1/2" to 5".

14:30 20:30 6.00 16 9.9 4 L Picked up 16" Clean out assembly: 16" MT bit + bit sub + 2 DC

9-1/2" + 15-15/16" STB + DC 9-1/2" + 15-15/16" STB + 3 DC

8-1/4" & RIH to 516 m (18-5/8" csg shoe)

20:30 21:00 0.50 16 9.9 4 L Circulate & wash down from 516 to 550 m (Get Hold: 5 T @ this

depth).

21:00 21:30 0.50 16 9.9 4 L Clean out from 550 to 582 m.

21:30 23:15 1.75 16 9.9 4 L Drill out Cement from 582 to 596 m @ WOB: 5 T, RPM: 50, FR:

2700 lpm, P: 2500 psi.as follow:

* From: 584 to 589 m: average ROP: 15 m/h.

* From: 589 to 596 m: average ROP: 4 m/h (15min/m). Good cmt,

(WFD required 4 min/m)

23:15 23:30 0.25 16 9.9 4 L Perform Hardness test @ WOB: 15T , FR: 2700 lpm, 15 min -OK-

(WDF DS witness)

23:30 0:00 0.50 16 9.9 4 L Sweep hole with 4m3 H-Vis and Circulate hole clean

9/2/2019 0:00 1:30 1.50 16 9.9 4 L Cont CHC @ 3000 lpm.

* Once HI-Vis at surface: 80% cement + 20 % clay stone.

1:30 5:00 3.50 16 9.9 4 L POOH 16" Dress off cement BHA.

January 23, 2020 at 9:12 pm 14 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

5:00 8:15 3.25 16 9.9 4 L Prepare, Check & Make up (P/U) WDF 16" SideTrack BHA #1

(HyperLine 250 Drilling Motor (Low Speed, 6/5 lobes, 5 stages,

0.032 rev/ltr, bent 1.83 deg) + Mule shoe + xo + MWD tool carrier)

8:15 8:30 0.25 16 9.9 4 L Test Motor (shallow test): 1500 lpm / 250 psi , 1750 lpm / 300 psi.

8:30 10:45 2.25 16 9.9 4 L M/U MWD & Test MWD Signal -negative-. Tried several times:

(NPT on WFD DS : 2,25 hrs).

* Tried with differents flow : 1000 / 1400 / 1500 / 1700 lpm -

Negative -.

* Switch to pump 2, then to pump 3 - Negative -.

10:45 11:00 0.25 16 9.9 4 L Change the Orifice of flow in MWD, test with 1500 lpm / 215 psi,

got signal.

11:00 11:30 0.50 16 9.9 4 L Bit service, RR TCI ES14V SN: 1563652. Scribe Line.

11:30 15:15 3.75 16 9.9 4 L RIH with P/U: N.M DC + Circualting sub + 10 DC 8-1/4" + 8" Hyd

Drlg Jar + 2 DC 8-1/4" + XO + 6 HWDP 5" + DP 5" to 520 m.

15:15 17:30 2.25 16 9.9 4 L Cont Running in open hole with survey every 20 m (520, 540, 560

& 580 m) to 596 m (TOC).

17:30 0:00 6.50 16 9.9 4 L Time drill (1 cm/min) @ 2400 lpm / 1550 psi, from 596 to 597.69

m.(60% Cement, 40 % Claystone)

9/3/2019 0:00 0:00 24.00 16 9.9 4 L Sidetrack time drill with WFD Motor from 597.69 To 606.62m.:

Time drill ROP: 0.3 m/h (f/ 596 to 599 m), 0.5 m/h (f/599 to 603

m), 0.3 m/h (f/603 to 606 m).

WOB: 1 - 2 T, Flow rate: 2400 lpm, Pr: 1500 psi., TF: 90 deg

Right.

At 606m, 80% cement, 20% Formation.

PDM: Low Speed, BH 1.83 deg, 6/7 lobes, 5 stages, 0.032 rev/ltr

with sleeve stabilizer 15-3/4".

Bit to survey sensor : 14.9 m.

Daily // Cumul Circulation time = 24 // 31.3 Hrs.

9/4/2019 0:00 14:30 14.50 16 9.9 4 L Sidetrack time drill with WFD Motor from 606.62 To 610.20 m:

Time drill ROP : 0.3 m/h. WOB: 1 - 2 T, Flow rate: 2300 lpm, Pr:

1350 psi., TF: 90 deg Right. At 610m, 90% cement, 10%

formation.

14:30 17:30 3.00 16 9.9 4 L Pull out sidetrack drill string to surface.

* Take survey before POOH (sensor depth = 595 m, incl = 1 deg,

Az = 67.94 deg)

* Drop ball, circulate & open circulating sub @ 18-5/8" Csg shoe.

* Bit dual grading = 1-1-WT-A-E-I-NO-BHA.

17:30 19:45 2.25 16 9.9 4 L D.D equipment service (Motor & MWD). Adjust Bent Housing to

2.38 deg & Scribe line.

* Motor Bearing clerance = 2 mm.

19:45 21:15 1.50 16 9.9 4 L Test Motor (2000 lpm / 230 Psi) & MWD (1500 lpm / 250 Psi) -ok

-.

21:15 21:30 0.25 16 9.9 4 L Bit service. RR TCI ES14V SN: 1563652

21:30 0:00 2.50 16 9.9 4 L Run Sidetrack drill string in hole to 580 m.

* PDM : Low Speed, BH 2.38 deg, 6/7 lobes, 5 stages, 0.032

rev/ltr with sleeve stabilizer 15-3/4".

* Bit to survey sensor: 14.9 m.

* Bit revolution Daily // Total : 67 185 // 286 112.

* Daily // Cumul Circulation time = 14.44 // 45.74 Hrs.

9/5/2019 0:00 0:15 0.25 16 9.9 4 L Cont RIH Sidetrack drill string to BTM (610 m).

0:15 1:15 1.00 16 9.9 4 L Depth calibration.

Took survey (549 m, incl = 1.20 deg, Az = 66.81 deg).

Oriented tool face.

1:15 0:00 22.75 16 9.9 4 L Sidetrack time drill with WFD Motor from 610.10 To 617 m:

Time drill ROP : 0.3 m/h.

WOB: 1 - 2 T, Flow rate: 2020 lpm, Pr: 1100 psi., TF: 90 deg

Right.

* PDM : Low Speed, BH 2.38 deg, 6/7 lobes, 5 stages, 0.032

rev/ltr with sleeve stabilizer 15-3/4".

* Bit to survey sensor: 14.9 m.

* Bit revolution Daily // Total : 92554 // 378666.

* Daily // Cumul Circulation time = 23.20 // 68.94 Hrs.

9/6/2019

January 23, 2020 at 9:12 pm 15 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

0:00 0:00 24.00 16 9.9 4 L Sidetrack time drill with WFD Motor from 617 To 624.7 m:

Time drill ROP : 0.3 m/h till 622 m, then 0.7 m/h.

WOB: 1 - 5 T, Flow rate: 2020 lpm, Pr: 1100 psi., TF: 90 deg

Right.

* PDM : Low Speed, BH 2.38 deg, 6/7 lobes, 5 stages, 0.032

rev/ltr with sleeve stabilizer 15-3/4"

* Bit to survey sensor : 14.9 m.

* Bit revolution Daily // Total : 94 826 // 473 492.

* Circulation time Daily // Cumul : 24 // 92.94 Hrs.

9/7/2019 0:00 2:00 2.00 16 9.9 4 L 624.70 Sidetrack time drill with WFD Motor from 624.7 To 626 m.

** Time drill ROP : 0.7 m/h .

** WOB : 2 T, Flow rate : 2020 lpm, Pr : 1100 psi., TF : 90 deg

Right.

** @ 625 m; 05 % Cement; 95 % Formation.

@ 626 m; 100 % Formation

** KOP: 596 m

** PDM : Low Speed, BH 1.83 deg, 6/7 lobes, 5 stages, 0.032

rev/ltr with sleeve stabilizer 15-3/4"

** Bit to survey sensor : 14.9 m.

** Bit revolution Daily // Total : 7828 // 481320.

** Circulation time Daily // Cumul : 2 // 94.94 Hrs.

2:00 6:30 4.50 16 9.9 L 626.00 Sidetrack time drill with WFD Motor from 626 To 630 m ( 100%

Formation )

** Got 100% formation @ 626 m

** Time drill ROP : 1 m/h.

** WOB : 1-5 T, Flow rate : 2000 lpm, Pr : 1100 psi., TF : 90 deg

Right.

6:30 7:00 0.50 16 9.9 L Take survey

** Survey : Sensor depth = 614.10 m, incl = 2.69 deg, Az = 76.24

deg, Vs = 6.08 m

** Circulate : 2000 lpm, 1100 psi.

7:00 11:00 4.00 16 9.9 L 630.00 Pull out sidetrack drill string to surface.

** Drop ball, circulate & open circulating sub @ 18-5/8" Csg shoe.

** Varel ES14V bit dull grading = 1-1-WT-A-E-I-NO-BHA.

11:00 14:30 3.50 16 9.9 4 L D.D equipment service (Motor & MWD).

** L/D PDM (BH 2.38 deg); bearing clearance : 6 mm.

** P/U new PDM (BH 1.83 deg)

** Scribe line.

14:30 15:00 0.50 16 9.9 L Test Motor (2000 lpm / 300 Psi) & MWD (1500 lpm / 250 Psi) -ok

-.

15:00 15:15 0.25 16 9.9 L Bit service.

** 16" New NOV TCI bit, Type : T 41A, SN# D160895, IADC :

415, TFA : 0.942 in2.

15:15 20:30 5.25 16 9.9 L 0.00 Run Sidetrack drill string in hole to 630 m.

** Adjust TF @ 580 m.

20:30 0:00 3.50 16 9.9 L 630.00 Sidetrack drill with WFD Motor from 630 To 637.5 m.

** Sliding 630-632.5 m : ROP: 2.08 m/h; TF: 90 deg Right.

** Rotary: 632.5-637.5 m; ROP: 3.05 m/h

** WOB : 4-10 T, 2450-2500 lpm, 1550-1650 Psi, Surface RPM:

30, Total RPM: 111.

** Survey: Sensor MD: 621.5 m, incl.: 3.71 deg, Az.: 80.32 deg,

VS: 6.48 m.

KOP = 596 m.

PDM: Low Speed, BH 1.83 deg, 6/7 lobes, 5 stages, 0.032 rev/ltr

with sleeve stabilizer 15 3/4"

Bit to survey sensor : 14.9 m.

9/8/2019 0:00 17:30 17.50 16 9.9 4 L 637.50 Motor drilling with WFD PDM from 637.58 To 690 m.

** (7-15 T, 2500 – 2900 lpm, 1750 – 2100 psi ).

** Sliding mode, 8.6% : 642 to 645 m & 686.6 to 688.6 m, Average

ROP: 1.20 m/h.

** Rotary mode (30 RPM), 81% : 638-642 m, 645-686.6m,

688.6-690 m, average ROP : 3.52 m/h

** Last survey : MD 671.30 m, incl = 5.33, Az = 88.04, TVD =

671.06, Vs = 10.51 m

17:30 18:45 1.25 16 9.9 4 L Pump 4 m3 Hi Vis pill & CHC.

January 23, 2020 at 9:12 pm 16 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

18:45 23:00 4.25 16 9.9 4 L 690.00 POOH to surfqce

** Drop ball at 18 5/8" shoe and circulate to open circulating sub.

23:00 23:15 0.25 16 9.9 4 L Bit service

** TCI T41A bit dull grading: 1-1-WT-A-E-I-LT-PR

** L/D bit

23:15 0:00 0.75 16 9.9 4 L D.D. equipment service (PDM & MWD)

** PDM bearing clearance : 1 mm

9/9/2019 0:00 3:45 3.75 16 9.9 4 L D.D equipment service (Motor & MWD).

** R/D one 9 1/2 ' DC.

** R/D PDM Stabilizer & replaced by sleeve.

** M/U 3 XO + 15-15/16" IBS Stabilizer.

** M/U one 9 1/2 ' DC.

3:45 4:30 0.75 16 9.9 4 L SHallow Test :

Mud Motor (2000 lpm / 300 Psi) & MWD (1500 lpm / 250 Psi) -ok

-.

4:30 4:45 0.25 16 9.9 4 L Bit service.

** 16" Bit Baker PDC Rerun HC609Z, 9x13, TFA: 1.167, SN:

7210340)

4:45 7:15 2.50 16 9.9 4 L 0.00 Run Sidetrack BHA to 51 m.

7:15 8:00 0.75 16 9.9 4 L 51.00 POOH Sidetrack BHA to 26 m & adjust Azimut reference (MWD)

& RIH Back to 51 m (45min NPT on WDF DD)

8:00 10:15 2.25 16 9.9 4 L 51.00 Run Sidetrack BHA to 615m (get hold).

10:15 11:00 0.75 16 9.9 4 L 615.00 Set 5T try to pass -no success- Work interval till free.

11:00 13:00 2.00 16 9.9 4 L 615.00 Reaming f/ 615 to 690 m.

13:00 0:00 11.00 16 9.9 4 L 690.00 Sidetrack drill with WFD Motor from 690 To 750 m.

** Rotary: 690-738.8 m; ROP: 9.21 m/h

** Sliding: 738.8 -742.17 m : ROP: 1.98 m/h; TF: 160 deg Left.

** Rotary: 742.17-750 m; ROP: 4.89 m/h

** WOB : 4-8 T, 3200-3480 lpm, 2500-2700 Psi, Surface RPM:

30.

** Survey: Sensor MD: 728.44 m, incl.: 4.52 deg, Az.: 87.54 deg,

VS: 15.52 m.

** KOP = 596 m. PDM: Low Speed, BH 1.83 deg, 6/7 lobes, 5

stages, 0.032 rev/ltr .

*" Bit to survey sensor : 20.66m.

9/10/2019 0:00 0:00 24.00 16 9.9 4 L 750.00 Sidetrack drill with WFD Motor from 750 To 805 m.

• Sliding f/750 to 753.58 m : ROP = 1.59 m/h.

• Rotary f/ 753.58 to 760.13 m : ROP = 2.18 m/h.

• Sliding f/760.13 to 763.29 m : ROP = 1.4 m/h.

• Rotary f/763.29 to 770.15 m.: ROP = 4.01 m/h.

• Sliding f 770.15 to 777.85 m : ROP = 4.4 m/h.

• Rotary f/777.85 to 779.85 m.: ROP = 1.6 m/h.

• Sliding f/ 779.85 to 787.31 m : ROP = 2.98 m/h.

• Rotary f/787.31 to 795.22 m.: ROP = 3.51 m/h.

• Sliding f/ 795.22 to 800.11 m : ROP = 1.22 m/h.

• Rotary f/800.11 to 803.75 m.: ROP = 2.91 m/h.

• Sliding f/ 803.75 to 805 m : ROP = 1.25 m/h.

** WOB : 4-14 T, 2600 - 3500 lpm, 1800-3000 Psi, Surface

RPM: 30.

** Survey: Sensor MD: 782.10 m, incl.: 2.25 deg, Az.: 89.73 deg,

VS: 18.89 m.

** KOP = 596 m. PDM: Low Speed, BH 1.83 deg, 6/7 lobes, 5

stages, 0.032 rev/ltr .

*" Bit to survey sensor : 20.66 m.

9/11/2019 0:00 9:00 9.00 16 9.9 4 L 805.00 Sidetrack drill with WFD Motor from 805 To 840 m.

• Sliding f/ 805 to 807.58 m : ROP = 3.87 m/h.

• Rotary f/ 807.58 to 840 m : ROP = 3.93 m/h.

** WOB : 4 -14 T, 2600 - 3500 lpm, 1800-3000 Psi, Surface

RPM: 30.

9:00 10:00 1.00 16 10.1 L 840.00 Change bleed off valve of pump two ( SPP decreased due to wash

out on bleed off valve of mud pump two) / Lost time (NPT) 1 hr for

KCA.

January 23, 2020 at 9:12 pm 17 OpenWells

GBRS

2.1 Operation Summary (Continued)

Date Time Duration Phase Code Sub Class MD from Operation

Start-End (hr) (m)

10:00 20:00 10.00 16 9.9 4 L 840.00 Cont Sidetrack drill with WFD Motor (Rotary mode ) from 840 To

874 m.

• Pump 4 m3 Hi-vis pill every stand drilled.

** ROP = 3.4 m/h.

** WOB : 4-15 T, 3000 - 3150 lpm, 2700 - 3050 Psi, Surface

RPM: 30.

** Survey: Sensor MD: 844 m, incl.: 1.53 deg, Az.: 84.17 deg, VS:

9.3 m.

** KOP = 596 m. PDM: Low Speed, BH 1.83 deg, 6/7 lobes, 5

stages, 0.032 rev/ltr .

*" Bit to survey sensor : 20.66 m.

20:00 21:30 1.50 16 9.9 4 L 874.00 Pum 4 m3 Hi-Vis Pill & CHC.

21:30 21:45 0.25 16 9.9 4 L 874.00 POOH to 16" Side track BHA to 831m - get un overpull 10 T-

21:45 23:00 1.25 16 9.9 4 L 831.00 Connect TDS and back Reaming from 831 to 816 m (hard back

reaming from 828.5 to 827.5 m).

23:00 0:00 1.00 16 9.9 4 L 816.00 Cont POOH to 16" Side track BHA from 816 to 645 m.

9/12/2019 0:00 4:00 4.00 16 9.9 4 L 645.00 Cont POOH to 16" Side track BHA from 645m to surface.

** Drop boll & circulate to open circulating sub @ 18-5/8" shoe.

** Bit grading : 2-4-BT-A-X-I-PN-BHA (04 Nozles plugged).

4:00 8:00 4.00 16 9.9 4 L 0.00 DD equipment service

** L/D Motor Bearing clearance5mm.

** L/D MWD, Mule shoe N.M DC & crossover.

** R/U new Motor with slick sleeve.

** Adjust bent housing to 0 deg.

** Test motor at surface Ok: 1500/2000 Lpm 250/300 Psi.

8:00 14:45 6.75 16 9.9 4 L 0.00 Rih 16” Motor BHA with RR NOV PDC Bit; TK76 # E244960 to

820m.

** Tight hole at 674m, connect top drive & wash down the stand.

** At bottom Pump 4m3 hi vis pill & circulate to clear same.

14:45 0:00 9.25 16 9.9 4 L 874.00 Pattern the bit & drill 16” hole section with motor from 874m to 936

m

** Drilling Parameters: 4-12 T, 50 RPM, 2-15 T, 3000 lpm,

2400-2800 Psi.

** Pump 4m3 Hi-Vis Pill each two stands drilled.

9/13/2019 0:00 18:45 18.75 16 9.9 4 L 936.00 Cont drill 16” hole section with motor from 936 m to 1042 m

** Drilling Parameters: 4-17 T, 50-80 RPM, 2800 - 3000 lpm,

2400-2700 Psi.

** Pump 4m3 Hi-Vis Pill each two stands drilled.

** Ream each stand drilled.

18:45 0:00 5.25 16 1.1 2 P 1,042.00 Cont drill 16” hole section with motor from 1042 m to 1074 m

** Drilling Parameters: 75 RPM, 2-15 T, 2800 lpm, 2100-2400

Psi.

** Pump 4m3 Hi-Vis Pill each two stands drilled.

** Ream each stand drilled.

9/14/2019 0:00 8:00 8.00 16 1.1 2 P 1,074.00 Cont drill 16” hole section with motor from 1074 m to 1113 m

** Drilling Parameters: 75 RPM, 2-15 T, 2800 lpm, 2100-2400

Psi.

** Pump 4m3 Hi-Vis Pill each two stands drilled.

** Ream each stand drilled.

8:00 10:00 2.00 16 10.1 L 1,113.00 While traying to disconnect TD Found the sever sub over torqued

with string & unscrew the connection above I BOP.

** Try to use the drilling tongs to disconnect without success .

** Remove sever sub clamp & use Iron rough neck _OK_ .

10:00 0:00 14.00 16 1.1 2 P 1,113.00 Cont drill 16” hole section with motor from 1113 m to 1314 m

** Drilling Parameters: 75 RPM, 2-15 T, 2800 lpm, 2100-2450

Psi.

** Pump 2m3 Hi-Vis Pill each stands drilled.

** Ream each stand drilled one time.

** Pump 5m3 Hi-Vis pill @ 1118m prior before entering the Albian

formation.

** Pump 5m3 Hi-Vis pill @ 1313m before entering the Aptian

formation & reduce drilling parameters ( FR : 2700 lpm, RPM : 50)

to optimize bit life.

9/15/2019

January 23, 2020 at 9:12 pm 18 OpenWells