Professional Documents

Culture Documents

073 CLU4 Pulse Rev-5.0

073 CLU4 Pulse Rev-5.0

Uploaded by

Piotr StankiewiczOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

073 CLU4 Pulse Rev-5.0

073 CLU4 Pulse Rev-5.0

Uploaded by

Piotr StankiewiczCopyright:

Available Formats

RTA / RT-FLEX TRAINING

Function of the CLU4

Pulse Feed

Cylinder Lubrication System

1 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Overview

• The CLU4 Pulse Feed Lubrication System is based on a lubrication module with integrated electronics

and lubricators

• It fits liners of the RTA62, RTA72, RTA84T, RTA84C, RTA96C series and RT-flex engines

2 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Designation of Lube oil Systems

• (CLU1:) Cylinder lubricating pumps driven by hydraulic motor.

Feed rate adjusting by setting screws and lever position.

Load dependence controlled by lever on fuel linkage

• CLU2: Cylinder lubricating units hydraulically operated.

Controlled by pulses from remote control system

• CLU3: Cylinder lubricating pumps driven by electric motor

• CLU4: Pulse feed and pulse jet.

Cylinder lubricating oil injection controlled by electronic / hydraulics

• CLU5: Cylinder lubricating oil injection controlled by electronic / hydraulics for W-X35 and W-X40

engine types

• flexLube: Cylinder lubricating oil injection controlled by electronic / hydraulics applicable for all 2-stroke

engine types

3 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

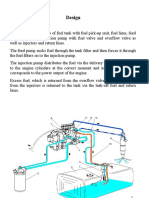

Description

• During engine operation, cylinder lubrication oil flows from the daily tank to the filter, measuring tank and

then to dosage pumps. Each of the cylinders is equipped with one pulse lubricating module and six or

eight lubricating quills

• The position of the working piston is continuously monitored by the crank angle sensors which are

connected to the CLU4 system. At defined angles of the working piston, the dosage pumps will be

activated and oil will be delivered to the cylinder

• The dosage pump in the pulse lubrication module is driven by servo oil

• Additional servo oil pumps are used to drive the lubricating module for RTA engines. On RT-flex engines,

the servo oil is taken from the servo oil common rail through a pressure reducing valve

4 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Description

• Crank angle sensors allow the CLU4 to deliver lubricating oil exactly defined sections of the piston. The

software provides the possibility to distribute the lube oil above the piston ring pack, into it and below it

• The feed rate can be adjusted by the operator via flexView

• The split of the distribution depends on the engine type and can be adjusted via flexView by

commissioning engineer

• The lubrication takes place during compression strokes only

5 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Components

The CLU4 pulse lubrication system consists of the following components:

• Lubricating oil filter with measuring tank

• Pulse lubricating module (dosage pump with its control module)

• Lubricating quills (six or eight in one level only)

• Control system and flexView

• Crank angle sensors (RPLS only)

• Servo oil supply unit (RPLS and PLS on RTA)

• Servo oil pressure reducing unit (PLS on RT-flex only)

6 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Arrangement

7 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Vertical Oil Distribution, Feed

Electronically Controlled Flexible Timing of Lube Oil Feed

Distribution to upper part Lube oil distribution to Distribution to the lower

of piston and first piston middle part of piston and piston rings and piston

ring piston ring package skirt

8 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Pulse Feed Distribution

Engine Above [%] Into [%] Below [%] Volume [mm3] Quills

RT-flex50-B 0 100 0 540 6

RT-flex58T 0 100 0 900 6

RT-flex60C 40 40 20 900 6

RT-flex68-D 0 100 0 1520 8

RTA82C 40 40 20 1520 8

RT-flex82C 40 40 20 1520 8

RTA82T 40 40 20 2480 8

RT-flex82T 40 40 20 2480 8

RTA84T 40 40 20 2480 8

RT-flex84T 40 40 20 2480 8

RTA96C-B 40 40 20 2480 8

RT-flex96C-B 40 40 20 2480 8

9 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Vertical Oil Distribution, Feed

Electronically Controlled Flexible Timing of Lube Oil Feed

Distribution to the Lube oil distribution to Distribution to the

cylinder liner above the middle part of piston and cylinder liner below the

piston by the jet-spray piston ring package by piston by the jet-spray

“feeding”

10 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Pulse Jet Distribution

Engine Above [%] Into [%] Below [%] Volume [mm3] Quills

RTA48T-D 60 20 20 540 6

RT-flex48T-D 70 25 5 540 6

RT-flex50-B 70 25 5 540 6

RT-flex50-D 70 25 5 540 6

RT-flex58T 70 25 5 900 6

RT-flex68-D 70 25 5 1520 8

RT-flex82 / X82 70 25 5 2480 8

RT-flex84T 60 20 20 2480 8

RT-flex96C-B 60 20 20 2480 8

11 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Spray

12 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Arrangement (RT-flex82)

13 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Arrangement (RT-flex96C)

14 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

PLS Schematic

15 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

RPLS Retrofit

16 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Control & Monitoring

17 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

ALM-20

18 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

CLU4 Lubricating Module

07 01

01 Lubrication oil outlet ports

02 Vent plug for lubrication oil

02

03 Vent plug for servo oil 03

04 Dosage pump

08

05 4/2-way solenoid valve

06 Diaphragm accumulator for servo oil

07 Cylinder Lubricating oil pressure sensor 09

04

08 Shut-off valve for lubrication oil 10

05

09 Lubrication oil inlet (L)

11

10 To servo oil return line (T) 12 06

11 Servo oil drain valve

12 Shut-off valve for servo oil

19 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

CLU4-C Lubricating Module

01 Lubrication oil outlet ports, vent plug for servo oil 01

02 4/2-way solenoid valve

07

03 Cylinder Lubricating oil Pressure Sensor 02

08 03

04 Shut-off valve for servo oil

05 Vent plug for lubrication oil 09

06 Dosage pump 10

04

07 Connection block 11

05

08 To servo oil return line

09 Lubrication oil inlet 06

10 Servo oil drain valve

11 Diaphragm accumulator for servo oil

20 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Cross Section

21 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Metering Piston

22 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Lubricators

Easy Replacement of

Accumulator type quill CLU3 the Lubricators

Lubricator CLU4

23 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Lub Card

Pulse Lubrication User Interface

If the engine is equipped with Pulse Feed Lubrication, in these fields manual lubrication to selected cylinder

units and the feed rate can be set. Feed rate adjustment is done by selecting the desired cylinder unit

24 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Feed Rate / Manual Lubrication

Cylinder Lubrication Feed Rate

• In these fields the feed rate can be set for each cylinder unit

• Feed rate adjustment is done by selecting the desired cylinder

unit and settings the specific consumption with «Shift» and

«Arrow up» or «Arrow down», then «Shift» and «Enter»

• The values can be adjusted between 0.6 g/kWh and 1.6

g/kWh, for special needs even from 0.2 g/kWh to 3.0 g/kWh

25 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Power Indication

• Power Indication (visual only with option for external load signal)

• The upper field indicates the estimated power

• If an external load reference from the shaft power meter is

used for the lubrication system, the lower field (Power for

Lubrication) will indicate measured power

• If the signal is lost, it will indicate estimated power

• Manual Lubrication

• In the upper field a single cylinder unit can be selected for

manual lubrication

• The number of pulses for manual lubrication is adjustable in

the lower field

26 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

LUB-Par Card

At each revolution of the crankshaft the lubrication oil is injected above, into or below the piston ring package

of every cylinder unit. This card displays the share rate distribution of lubrication pulses. This distribution ratio

can only be changed by service engineers.

27 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Pulse Counters

Pulse Counters

• The lubrication system sends pulses to the solenoid valves on the

lubrication units. Each pulse triggers a pump stroke and supplies a

defined quantity of lubrication oil for distribution along the piston rings

pack. The pulses are counted in the “Counter” column

• The “Memory” column shows the total number of lubricating strokes

over the selected time (Timer for Memory)

• The counter can be reset to zero by changing the “Reset Counter”

field from “ready” to “reset”

• The number shown in the column “Failed” indicates how many

lubricating strokes could not be executed, e.g. due to BUS

communication failures

28 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

ALM Status Indication

• This column shows the state of the lubrication modules on the

separate cylinder units

• The different indications are:

• OK Unit in normal operation

• Download FCM downloads software into ALM

• Failure No communication to the ALM module

• ??? No data available

• The measured peak pressure of the injected lubrication oil is

indicated in the column “Peak Pressure”

29 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

LUB-Par: Pulse Lubrication Parameters Settings for 3 Piston Ring Head type

• RT-189 Issue(Wartsila RTA96C,RTA96C-B,RT-flex96C-B)

30 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

LUB-Par: Pulse Lubrication Parameters Settings for 3 Piston Ring Head type

• RT-189 Issue(Wartsila RTA96C,RTA96C-B,RT-flex96C-B)

• 3-ring piston head - Benefits

• For the following reasons, a 3-ring piston head is leading to cleaner top land and less carbon deposits:

• • Decreased clearance between the liner and the piston top land

• • Increased top land height

• • Added gas-tight top ring

• In case of a worn out liner which was operated with a 4-ring piston, the lifetime of the liner can be

extended with the change to a 3-ring piston head due to the lower position of the top piston ring.

• Additionally, the parallel ring groove wear (decreased taper wear compared to 4-ring piston head) is

reduced by a stronger top piston ring (24mm instead of 20mm thickness).

31 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Running-in Feed Rate

For the running in and cylinder lubrication feed rates please refer to Service Bulletin 18.4

è SB 161

32 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

CLU4 PULSE FEED

Typical Pressure Curve

33 © Wärtsilä PUBLIC Feb-19 Clu4_Chapter_73 / Busan Training Centre

You might also like

- 6T70 PDFDocument146 pages6T70 PDFEd Kruse96% (23)

- SB 1002R29Document13 pagesSB 1002R29LUCASDOURADO180% (2)

- Engine 3066 - 3064 - SpecificationsDocument30 pagesEngine 3066 - 3064 - SpecificationsSegundo Francisco Jauregui Valencia91% (11)

- SB 13002 PDFDocument12 pagesSB 13002 PDFMichael Mitchell100% (1)

- Basic FuelDocument30 pagesBasic FuelMulyadi Tarchani100% (1)

- Winget Turner Compact Shuttle Transmission ManualDocument54 pagesWinget Turner Compact Shuttle Transmission ManualValeriy Valkovets100% (1)

- Motorcycle Mechanics - George LearDocument270 pagesMotorcycle Mechanics - George Leargrezmos100% (8)

- RT-124 Troubleshooting & Maintenance On Injection Control UnitDocument21 pagesRT-124 Troubleshooting & Maintenance On Injection Control UnitKhalid Najmi100% (2)

- RT 137A2 Issue2Document7 pagesRT 137A2 Issue2G_ARVALIS8470No ratings yet

- Air Force Institute of Technology: Basheer IbraheemDocument37 pagesAir Force Institute of Technology: Basheer IbraheembyibraheemNo ratings yet

- Husaberg 1999 Repair ManualDocument48 pagesHusaberg 1999 Repair ManualAndré Duestad100% (1)

- Management c1Document173 pagesManagement c1Winnie Pualon CejudoNo ratings yet

- Motor 1Document46 pagesMotor 1Ganesh Anand100% (1)

- 079 - Flexlube - CYL. LUB - SYSTEM v2Document29 pages079 - Flexlube - CYL. LUB - SYSTEM v2Антон Сорока100% (1)

- CTR Tubing Rotators Operating InstructionsDocument15 pagesCTR Tubing Rotators Operating InstructionsEvolution Oil ToolsNo ratings yet

- 78 - RT-Flex - CLU-4 Cylinder Lubricating SystemDocument19 pages78 - RT-Flex - CLU-4 Cylinder Lubricating SystemVignesh Krishnamoorthy100% (2)

- Lifting Device For Cilind. Liner RTADocument15 pagesLifting Device For Cilind. Liner RTArafael100% (1)

- Rta 54 PDFDocument8 pagesRta 54 PDFAnonymous d00A9zetNo ratings yet

- 04 RT Flex Comp SystDocument64 pages04 RT Flex Comp SystA MovahediNo ratings yet

- SB 10056845 3655Document12 pagesSB 10056845 3655Gianes Agurto EspinozaNo ratings yet

- Document Number 202044 Date of Issue 6 May 2016 Product RT-flex50 Conversion To DF Generic Manual A1Document21 pagesDocument Number 202044 Date of Issue 6 May 2016 Product RT-flex50 Conversion To DF Generic Manual A1Bilal al zeitawiNo ratings yet

- Piston Rod Gland Box VentiongDocument5 pagesPiston Rod Gland Box VentiongrafaelNo ratings yet

- Comp Carly Scre Refrig 2004Document52 pagesComp Carly Scre Refrig 2004Deco DluxeNo ratings yet

- 1002 R29Document13 pages1002 R29LUCASDOURADO18100% (1)

- CfeDocument14 pagesCfeVikrant RajputNo ratings yet

- Flywheel Lubrication Oil Pressure - TestDocument5 pagesFlywheel Lubrication Oil Pressure - TestMARTIN GONZALEZNo ratings yet

- Pressure Reducing Valve (Pilot Oil) - Test and AdjustDocument3 pagesPressure Reducing Valve (Pilot Oil) - Test and AdjustgeniusnetxxxxNo ratings yet

- Hose Management Guide: SN: 80Z Lines Group - Tilt CylinderDocument39 pagesHose Management Guide: SN: 80Z Lines Group - Tilt Cylinderjvp23894247No ratings yet

- Centralised Lubrication System For A Manitou MT 732 CompleteDocument35 pagesCentralised Lubrication System For A Manitou MT 732 CompleteChester Dalitso MwanzaNo ratings yet

- 06-4035-3600 - Rev15 - 03-03 TRONAIRDocument19 pages06-4035-3600 - Rev15 - 03-03 TRONAIRBruce PoloNo ratings yet

- Service Letter Cessna (CAL-79-02)Document16 pagesService Letter Cessna (CAL-79-02)anon_847285754No ratings yet

- Algebra Bald OrcDocument7 pagesAlgebra Bald OrcGilberto Morales CaldasNo ratings yet

- PDFDocument18 pagesPDFHernando SalamancaNo ratings yet

- 16-TR-83 Rev ADocument4 pages16-TR-83 Rev Aamin chaabenNo ratings yet

- Fuel System Pressure - TestDocument3 pagesFuel System Pressure - TestHAmir Alberto Mojica MojicaNo ratings yet

- 1U-5482 Pressure Adapter GroupDocument3 pages1U-5482 Pressure Adapter Groupvictor.cipriani0% (1)

- RT-91 Pressure Retaining Valve in Servo Oil Return PipingDocument6 pagesRT-91 Pressure Retaining Valve in Servo Oil Return PipingcataNo ratings yet

- 01 70002DMTS DL KitDocument6 pages01 70002DMTS DL KitFardos OmarNo ratings yet

- Recall Rover R2Document4 pagesRecall Rover R2Ingeniero SanchezNo ratings yet

- Ripper Lift Cylinder R&RDocument8 pagesRipper Lift Cylinder R&Rconnor.millsNo ratings yet

- Cat 988FDocument46 pagesCat 988FFilipe Gomes100% (3)

- Manual de Partes XJF-XJFDocument28 pagesManual de Partes XJF-XJFJose HernandezzNo ratings yet

- Relief Valve (Torque Converter Inlet) Pressure - TestDocument5 pagesRelief Valve (Torque Converter Inlet) Pressure - TestMARTIN GONZALEZNo ratings yet

- REHS0385 Installation of The Hydraulic Actuator System (Hydrax System) On G3612 and G3616 Engines PDFDocument73 pagesREHS0385 Installation of The Hydraulic Actuator System (Hydrax System) On G3612 and G3616 Engines PDFVictor NunezNo ratings yet

- Relief Valve (Torque Converter Outlet) Pressure - Test and AdjustDocument6 pagesRelief Valve (Torque Converter Outlet) Pressure - Test and AdjustMARTIN GONZALEZNo ratings yet

- Relief Valve (Transmission) - Test and AdjustDocument7 pagesRelief Valve (Transmission) - Test and AdjustMARTIN GONZALEZNo ratings yet

- Flywheel Lubrication Oil Pressure - Test: D8T Track-Type Tractor Power TrainDocument5 pagesFlywheel Lubrication Oil Pressure - Test: D8T Track-Type Tractor Power TrainEdwin Julcamoro AquinoNo ratings yet

- SEBF8054 - Procedure To Measure and Straighten Bent CrankshaftsDocument28 pagesSEBF8054 - Procedure To Measure and Straighten Bent Crankshaftsyahmanmahira4No ratings yet

- RT-161 A1 PDFDocument8 pagesRT-161 A1 PDFRaul Diaz100% (1)

- Cylinder Lubrication - WCH - rt-161 - A1 Appendix 1Document8 pagesCylinder Lubrication - WCH - rt-161 - A1 Appendix 1rafaelNo ratings yet

- Manual Cat Grader 24H 31-3-14Document29 pagesManual Cat Grader 24H 31-3-14Ahmad HandokoNo ratings yet

- Hydrostatic System - Test and AdjustDocument23 pagesHydrostatic System - Test and AdjustSanchez Gamarra AndyNo ratings yet

- 020 RT-flex Comp-Syst Rev-5.0Document186 pages020 RT-flex Comp-Syst Rev-5.0Piotr StankiewiczNo ratings yet

- RTA-56 Indicator ValvesDocument4 pagesRTA-56 Indicator ValvesCatalin CataNo ratings yet

- Procedimiento de Armado 785CDocument123 pagesProcedimiento de Armado 785CrubenNo ratings yet

- Jacking Oil SystemDocument15 pagesJacking Oil SystemSarah Frazier100% (1)

- 80 RT-flex Service-OperationDocument71 pages80 RT-flex Service-OperationConstantin ȘamataNo ratings yet

- Relief Valve (Line) - Test and Adjust - Hydraulic Hammer PDFDocument4 pagesRelief Valve (Line) - Test and Adjust - Hydraulic Hammer PDFjuan castaedaNo ratings yet

- GEAR BOX Service ManualDocument66 pagesGEAR BOX Service ManualJon Mo86% (7)

- PMChecklist ReportDocument3 pagesPMChecklist ReportmarquesgaloNo ratings yet

- Caterpillar Cat 225 EXCAVATOR (Prefix 76U) Service Repair Manual (76U00001-00693)Document28 pagesCaterpillar Cat 225 EXCAVATOR (Prefix 76U) Service Repair Manual (76U00001-00693)rpoy9396615No ratings yet

- Engine RT-flex Operation Practical AdvancedDocument3 pagesEngine RT-flex Operation Practical AdvancedPiotr StankiewiczNo ratings yet

- Prueba y Ajuste de Valvula de PrioridadDocument6 pagesPrueba y Ajuste de Valvula de PrioridadHenry MonteagudoNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Engine RT-flex Operation Practical AdvancedDocument3 pagesEngine RT-flex Operation Practical AdvancedPiotr StankiewiczNo ratings yet

- Linki YT ADocument1 pageLinki YT APiotr StankiewiczNo ratings yet

- Linki YTDocument1 pageLinki YTPiotr StankiewiczNo ratings yet

- Technicalupdate-HotWorkPermitandSafety Precautions in Connection With Welding and Cutting Work OnboardDocument39 pagesTechnicalupdate-HotWorkPermitandSafety Precautions in Connection With Welding and Cutting Work OnboardPiotr StankiewiczNo ratings yet

- 2.03 Moduł PDFDocument25 pages2.03 Moduł PDFPiotr StankiewiczNo ratings yet

- HWE (Weichai) CSP290623-WP10DE2-E2-NRMM Emission-2923-EDocument46 pagesHWE (Weichai) CSP290623-WP10DE2-E2-NRMM Emission-2923-EAlberto F. Apablaza Meza100% (1)

- Air CompressorDocument25 pagesAir CompressorMariappan Na100% (1)

- Leaflet PS 2018 FA Proof PrintDocument2 pagesLeaflet PS 2018 FA Proof PrintRicky HidayatNo ratings yet

- 10 Generator EbookDocument15 pages10 Generator EbookPurryWidiarko100% (1)

- Model Hot Air EngineDocument4 pagesModel Hot Air EngineJim100% (4)

- CHAPTER 5 Internal Combustion EngineDocument49 pagesCHAPTER 5 Internal Combustion EngineYann YeuNo ratings yet

- Calibracion Actuador Valvula Variable c11Document5 pagesCalibracion Actuador Valvula Variable c11Jordan RaveloNo ratings yet

- Two Stroke EngineDocument5 pagesTwo Stroke Enginedwarika2006No ratings yet

- Kubota Engine SpecsDocument84 pagesKubota Engine SpecsSzilárd Szabó33% (3)

- IC Engines Lab Manual StudyDocument26 pagesIC Engines Lab Manual StudyKaka Drishti100% (1)

- ME (H4SO) Mechanical PDFDocument98 pagesME (H4SO) Mechanical PDFAnonymous wpUyixsjNo ratings yet

- Module 5: Combustion Technology Lecture 40: Internal Combustion EngineDocument9 pagesModule 5: Combustion Technology Lecture 40: Internal Combustion EngineAryyama JanaNo ratings yet

- IC ENGINES NOTES Unit 2Document41 pagesIC ENGINES NOTES Unit 2Satya NarayanaNo ratings yet

- Atkinson Cycle 1Document10 pagesAtkinson Cycle 1api-677483315No ratings yet

- Thermodynamic CyclesDocument32 pagesThermodynamic CyclesYunus Emre GüzelelNo ratings yet

- Training Report On Diesel EnginesDocument34 pagesTraining Report On Diesel EnginesAniket PrasadNo ratings yet

- Operation and Mantenance Manual Perkins 1103 and 1104c Engines SystemsDocument92 pagesOperation and Mantenance Manual Perkins 1103 and 1104c Engines SystemsDiego Barbas83% (6)

- Ic EnginesDocument46 pagesIc Enginesranjith kumarNo ratings yet

- ThermodynamicsDocument23 pagesThermodynamicsMuhammad Junaid TabassumNo ratings yet

- Bajaj Auto Limited Vs - TVSDocument5 pagesBajaj Auto Limited Vs - TVSShivam Tiwari100% (1)

- IC Engines Course OutlineDocument16 pagesIC Engines Course OutlineratchagarajaNo ratings yet

- Ppu QBDocument26 pagesPpu QBAnonymous JDXbBDBNo ratings yet

- AnjiDocument6 pagesAnjiKatinti YellaiahNo ratings yet