Professional Documents

Culture Documents

MX2600 3100 Leaflet EU0805SP

MX2600 3100 Leaflet EU0805SP

Uploaded by

Gilberto XavierOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MX2600 3100 Leaflet EU0805SP

MX2600 3100 Leaflet EU0805SP

Uploaded by

Gilberto XavierCopyright:

Available Formats

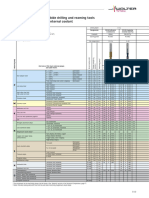

Multi-Tasking Turning Center

Machine Specifications NC Unit Specifications(Fanuc 31i-A)

Features Unit MX2600ST MX3100 AXES CONTROL - Tape format for FANUC Series15

- Controlled path 1 path /2 path - Work coordinate system G52 - G59

Max. machining dia. mm on Milling spindle 670 - Controlled axes X1, Z1, C1, Y, B, A, X2, Z2, C2 TOOL FUNCTION / TOOL COMPENSATION

- Simultaneous controlled axes - Automatic tool offset

Capacity Max. machining length mm 1500 - Angular axis control

4 ( 5-Only for Fanuc 31i-A5 / 310i-A5)axes - Direct input of offset value measured

- Direct input of offset value measured B

Max. bar working dia. mm 76 102 - Backlash compensation 0 ~ · 9999 pulses - T - code function T2 + 3 digits

X1/Z1-axis mm 630 / 1585 - Backlash compensation for each rapid traverse and cutting feed - Tool geometry / wear compensation

- Chamfering on/off - Tool life management

Y-axis mm 230 (· 115) 230 (· 115) - Synchronous / Composite control - Tool nose radius compensation

Travel - Superimposed Control - Tool offset G43, G44, G49

B-axis deg. 240 (120 to 120) 240 (120 to 120) - HRV2 control

- Inch / Metric conversion

- Tool offset pairs Upper :· 6 digits : 400 pairs

Lower :· 6 digits : 99 pairs

X2/Z2-axis mm 220 / 1535 - - Interference check for rotary area - Tool offset value counter input

- Interlock All axis / each axis - Y-axis offset

X1/Y/Z1/A-axis m/min 36 / 26 / 36 / 30 36 / 26 / 36 / 30 - Least input command 0.001 / 0.000 1 mm/inch EDITING OPERATION

Rapid - Machine lock All axis / each axis - Extended part program editing

traverse

X2/Z2-axis m/min 24 / 36 - - Mirror image - Number of registered programs 1000 ea

C/B-axis r/min 400 / 42 400 / 42 - Position switch

- Servo off

- Part program storage size 512 Kbyte

(Note) Specify total of part program storage size of each path

Max. spindle speed r/min 4000 3000 / - - Stored pitch error compensation - Memory card program edit & operation

Main - Stored stroke check 1 - Program protect

spindle

Spindle nose ASA A2-8 A2-11 / - - Torque control SETTING AND DISPLAY

Spindle bearing (front) mm 130 160 / - - Interference chek for rotary area - Actual cutting feedrate display

(Left / Right) - Unexpected disturbance torque detection function - Alarm history display

Main spindle motor kW 26 30 / - OPERATION

- DNC Operation with Memory card

- Periodic maintenance screen

- Display of spindle speed and T code at all screens

Max. spindle speed r/min 12000 - Buffer register - Optional path name display (Only for 2path)

Milling - Dry run - Multi-language display English

spindle

Spindle bearing (front) mm 70 - Handle incremental feed X1, X10, X100 - Operation history display

Milling spindle motor kW 22 - Program restart - Run hours / part count display

- Wrong operation prevention - Self-diagnosis function

Tool type CAPTO-C6 - JOG feed

- Manual pulse generator (Portable MPG) 1 ea

- Servo setting screen

- Spindle setting screen

ATC Tool capacity Tools 40 [80] - Manual reference position return DATA INPUT/OUTPUT

- Single block - External key input

(Automatic Max. tool diameter mm 90 - Tool direction handle feed (G68.1) - External data input

tool changer) Max. tool weight/length kg / mm 10 / 400 INTERPOLATION FUNCTIONS - External work number search 15 points

- Nano interpolation - Memory card input/output

Tool change time (T-T-T) s 1.8 - 1st. Reference position return

- 2nd. reference position return

Manual, G28

G30

- Reader/puncher interface

- RS232C interface

CH1.interface

Tool stations st 12 - - 3rd/4th reference position return - Automatic data backup

- Balance cutting (Only for 2 path) - Screen hard copy

Tool post OD tool size mm 25 - - Continuous threading (Incase of FANUC-310i-A5, This function can not be used)

(Lower turret) ID tool size mm 40 - - Cylindrical interpolation OTHERS

- Dwell (per sec.) G04 - Cycle start and lamp

Max. rotary tool spindle r/min 4000 - - Multiple threading - Display unit 10.4ˑ Color LCD

- Polar coordinate interpolation - Feed hold and lamp

Control type - Servo driven - Reference position return check

- Polygon machining with two spindle

G27 - MDI unit

- NC and servo ready

for 10.4ˑ LCD

Tail stock Quill type MT# - MT5 (Built-in) - Skip G31 - PMC system PMC-31iA

Travel mm 1500 - Thread cutting / Synchronous cutting - Reset / rewind

- Torque limit skip INTERFACE FUNCTION

Height mm 2805 2805 FEED FUNCTION - Ethernet function Embedded ethernet

Machine - AI Contour control (Look-ahead block no. is MAX.200) G5.1 Q1

dimensions

Length x Width mm 6010Ý 2606 6010Ý 2606 - Automatic acceleration / deceleration

- Cutting feedrate clamp

OPTIONAL SPECIFICATIONS

AXIS CONTROL

Machine mass kg 16000 15500 - Feed per minute - Stored stroke 2 and 3

Controller FANUC 31i-A [31i-A5 / 310i-A / 310i-A5] - Feed per revolution - Stroke limit check before move

- Feedrate override (10% unit) 0 - 200 % - Built-in 3D interference check function

Note : [ ] : option - Jog feed override (10% unit) 0 - 2 000 mm/min. Only for Fanuc 31i-A / 31i-A5

- Manual per revolution feed - CPS (DOOSAN Collision Protector System)

- Override cancel Only for Fanuc 310iA / 310i-A5

Standard Features - Rapid traverse override

AUXILIARY / SPINDLE SPEED FUNCTION

F0, 25, 100 % OPERATION

- DNC operation(Reader/puncher interface is required)

- Spindle orientation - Manual handle feed 2 units

̰ Absolute positioning coder ̰ Levelling jack screw & plates - Constant surface speed control - Manual handle interruption

̰ Air blast for chuck jaw cleaning ̰ Lubrication equipment - High speed M/S/T interface - Reference position shift

̰ Air gap sensor for tool on milling unit ̰ Manuals - M - code function M3 digits - Tool retract and recover

̰ Coolant supply equipment ̰ NC Controller FANUC 31i-A

- Multi spindle control OPERATION GUIDANCE FUNCTION

- Rigid tapping - EZ Guide-i (Conversational Programming Solution)

̰ Foot switch ̰ Safety precaution name plates - S - code function S4 / S5 digits INTERPOLATION FUNCTIONS

̰ Front guard door inter lock ̰ Soft jaws - Spindle serial output S4 / S5 digits - Circular threading

̰ Full enclosure chip and coolant shield ̰ Spindle oil cooling unit - Spindle speed override 0 - 150 % - Multi step skip

̰ Hand tool kit (including small tool for operations) ̰ Servo driven tail stock (Built-in center)*

- Spindle synchronous control - Variable lead threading

- Actual spindle speed output - High speed skip

̰ Hyd. chuck & actuating cylinder ̰ Through Spindle coolant (Milling spindle) PROGRAM INPUT FEED FUNCTION

̰ Hydraulic power unit ̰ Work light - 3D coordinate conversion - External deceleration

- Addition of custom macro common variables - Feed stop

#100~#199, #500~#999 PROGRAM INPUT

* : Except S/ST type MC - Canned cycle for turning - Addition of workpiece coordinate system pair 48 pairs

Optional Features - Circular interpolation by R programming

- Coordinate system setting G50

- G code system B/C

- Interruption type custom macro

- Coordinate system shift - Pattern data input

̰ Air gun ̰ NC

CONTROLLER : Fanuc 31i-A5 - Custom macro - Work coordinate system preset

̰ Automatic door with safety device Fanuc 310i-A / 310i-A5 - Decimal point programming - Optional block skip (Includs software operators panel) 9 piece

̰ Automatic measuring system (in process touch probe) ̰ Oil mist collector - Diameter/radius programming(X axis) TOOL FUNCTION / TOOL COMPENSATION

- Direct drawing dimension programming - Tool monitoring system

̰ Automatic power off ̰ Oil skimmer - Direct input of coordinate system shift EDITING OPERATION

̰ Bar feeder interface ̰ Pressure switch for chucking pressure check - G code system A - Part program storage size 1MB / 2MB

̰ Bar puller ̰ Parts unloader and conveyor - Input unit 10 time multiply - Play back

̰ Chip conveyor ̰ Servo driven steady rest (Nnone Lower turret)

- Label skip SETTING AND DISPLAY

- Macro executor - Directory display of floppy cassette

̰ Chip bucket ̰ Signal tower (yellow, red, green) - Manual absolute on and off DATA INPUT/OUTPUT

̰ Coolant blower ̰ Special chucks - Maximum program dimension · 9 digit - Data server

̰ Dual chucking pressure ̰ Through the spindle coolant (Left or Right spindle) - Multiple repetitive canned cycle G70 - G76 - DNC control

̰ Hardened & ground jaws ̰ Tool monitoring system

- Multiple repetitive canned cycleซ CONTOURING FUNCTION

- Optional block skip 1 piece - Tool center point control by 5 - axes : just on FANUC 31i-A5/310i-A5

̰ Linear scale (X1/X2/Y/Z1-axis) ̰ Tool pre-setter (Auto type-renishaw mode) - Plane selection G17, G18, G19 - High Speed machining (200 blocks)

̰ Minimum Quantity Lubrication (MQL) system - Program file name 32 characters ROBOT INTERFACE

- Programmable data input G10 - Robot interface with PMC I/O module

- Sequence number N8 digit (Hardware between PMC I/O mudules)

½ Design and specifications are subject to change without prior notice. - SUB program call 10 folds nested - Robot interface with PROFIBUS-DP

½ Doosan is not responsible for difference between the information in the catalogue and the actual machine. - Tape code : ISO / EIA auto recognition EIA RS422/ISO840

:Opt. : FANUC 31i-A5 / 310i-A / 310i-A5

Design and specifications are subject to change without prior notice.

i-ser EU0805SP

Head Office : Doosan Tower 22nd FL., 18-12, Euljiro-6Ga, Jung-Gu, Seoul, Korea 100-730

Tel : ++82-2-3398-8651 Fax : ++82-2-3398-8699 E-mail : master@domss.com

Doosan Infracore America Corp.: 8 York Avenue, West Caldwell, NJ 07006, U.S.A.

Tel : ++1-973-618-2500 Fax : ++1-973-618-2501

Doosan Infracore Germany GmbH : Hans-Böckler-Strasse 29, D-40764 Langenfeld-Fuhkamp, Germany.

Tel : ++49-2173-8509-10 Fax : ++49-2173-8509-60

China Representative Office : 9-101 Xinmao Building, 99 Tianzhou Road, Caohejing Hi-Tech Development Shanghai, China

For MX / TT open house 2008 Tel : ++86-21-5445-1155 (812,815) Fax : ++86-21-64403389

You might also like

- Specifications: VMC 4020 Table DimensionsDocument1 pageSpecifications: VMC 4020 Table DimensionsJhojan MuñozNo ratings yet

- Credit Memo Processing (1EZ - US) : Test Script SAP S/4HANA - 28-08-18Document32 pagesCredit Memo Processing (1EZ - US) : Test Script SAP S/4HANA - 28-08-18MihaiNo ratings yet

- Uniport 6000 EnglishDocument8 pagesUniport 6000 EnglishBunyamin OzdamarNo ratings yet

- Comet GB PDFDocument16 pagesComet GB PDFPelitamaju MsNo ratings yet

- XL 150 SeriesDocument2 pagesXL 150 SeriescoronaqcNo ratings yet

- PUMA TT1800 SeriesDocument28 pagesPUMA TT1800 SeriesSelvedin GudicNo ratings yet

- PCI Meteor3000 ENDocument2 pagesPCI Meteor3000 ENHX WEINo ratings yet

- Punzonadora Boschert CU Flex para CobreDocument2 pagesPunzonadora Boschert CU Flex para CobreBoschert MéxicoNo ratings yet

- UHM-630 800 - 130107英文小檔Document4 pagesUHM-630 800 - 130107英文小檔Marcos BustamanteNo ratings yet

- Brother TC S2ADocument4 pagesBrother TC S2ACleber Aparecidoo100% (1)

- OFFER UVI15 UMC-500SS 2022 02 01 MotorojusDocument7 pagesOFFER UVI15 UMC-500SS 2022 02 01 MotorojusMotorojus MotorojusNo ratings yet

- CNC Shop MachinesDocument15 pagesCNC Shop Machinesv2brotherNo ratings yet

- 3016FX SpecsDocument1 page3016FX SpecsChristian Justice GonzalezNo ratings yet

- KM-T20 CatalogDocument1 pageKM-T20 CatalogJackson SilvaNo ratings yet

- PCI MeteorTS900V ENDocument2 pagesPCI MeteorTS900V ENHX WEINo ratings yet

- Hi-TECH 230-4 (9.0)Document100 pagesHi-TECH 230-4 (9.0)Ойген ЁхNo ratings yet

- UMM English PDFDocument2 pagesUMM English PDFMarcos BustamanteNo ratings yet

- Universal Milling Machine: Powerful Milling Performance - Vertical, Horizontal and in Virtually Any Spindle AngleDocument2 pagesUniversal Milling Machine: Powerful Milling Performance - Vertical, Horizontal and in Virtually Any Spindle AngleHamza DZ-16No ratings yet

- Dyadic Systems SCN5Document2 pagesDyadic Systems SCN5Servo2GoNo ratings yet

- 75Nm Electrical InMax 50.75 S MDXDocument4 pages75Nm Electrical InMax 50.75 S MDXEscape ExistNo ratings yet

- Dyadic Systems SCN6Document2 pagesDyadic Systems SCN6Servo2GoNo ratings yet

- MMV 1300 1500 - EnglDocument2 pagesMMV 1300 1500 - EnglEmilian PopaNo ratings yet

- TX Catalogue EnglishDocument12 pagesTX Catalogue EnglishDjuraTheHarpYNo ratings yet

- X.mill M 900Document1 pageX.mill M 900Frederik HenderwanzaNo ratings yet

- Dyadic Systems RSADocument3 pagesDyadic Systems RSAServo2GoNo ratings yet

- PW BRO Compact Cladding Cell enDocument6 pagesPW BRO Compact Cladding Cell enKara WhiteNo ratings yet

- X.mill M 640Document1 pageX.mill M 640Frederik HenderwanzaNo ratings yet

- 7 CL500Document4 pages7 CL500santhoshkumar.sNo ratings yet

- VMC & HMC PDFDocument103 pagesVMC & HMC PDFNARENDER SINGHNo ratings yet

- Galaxy Midas 0Document2 pagesGalaxy Midas 0suresh0% (1)

- Surftest SV-3100Document12 pagesSurftest SV-3100صالح سميرNo ratings yet

- NMV106A 40x100cmDocument1 pageNMV106A 40x100cmAbhishek VelagaNo ratings yet

- Manual Del Usuario MaxxturnDocument14 pagesManual Del Usuario MaxxturnOlmetalNo ratings yet

- PUMA SMX Series (2100,2600,3100)Document48 pagesPUMA SMX Series (2100,2600,3100)Tiago PereiraNo ratings yet

- Doosanmt 40428 EsahtxDocument36 pagesDoosanmt 40428 Esahtxcajetan7777No ratings yet

- Mitutoyo - Formtracer Avant FTA - H4 C3000-D (MM)Document2 pagesMitutoyo - Formtracer Avant FTA - H4 C3000-D (MM)nyanaungNo ratings yet

- Machine Data SheetDocument3 pagesMachine Data SheetThaslimNo ratings yet

- Satellite XL - ENDocument2 pagesSatellite XL - ENanasNo ratings yet

- Mill 55Document4 pagesMill 55Manuel XamanNo ratings yet

- Mitutoyo New Products Guide - Mitutoyo America CorporationDocument20 pagesMitutoyo New Products Guide - Mitutoyo America CorporationMariangel Rodríguez GómezNo ratings yet

- PerformArc 250MDocument2 pagesPerformArc 250MLuis Gerardo Ibarra MuñozNo ratings yet

- Datasheet 5 Axis Flight Motion Simulator HD55H T35 50Document2 pagesDatasheet 5 Axis Flight Motion Simulator HD55H T35 50Hung Nguyen NgocNo ratings yet

- The Alternative Approach For Higher Productivity: An ISO 9001:2000 and ISO 14001:2004 Machine Tool ManufacturerDocument2 pagesThe Alternative Approach For Higher Productivity: An ISO 9001:2000 and ISO 14001:2004 Machine Tool Manufactureratishay shNo ratings yet

- 612sg Spec Sheet 0920Document1 page612sg Spec Sheet 0920Ben LernerNo ratings yet

- AV1-2 Tandem Vibrating Rollers 1.4 - 1.7 T: MachinesDocument8 pagesAV1-2 Tandem Vibrating Rollers 1.4 - 1.7 T: MachinesfernandoNo ratings yet

- 2018 - DVM 2017 - 5 AxesDocument16 pages2018 - DVM 2017 - 5 AxesAbhishek VelagaNo ratings yet

- Umill Series - English - 2019 09Document8 pagesUmill Series - English - 2019 09Kiril AngelovNo ratings yet

- Puma 2100 Doc MaintenanceDocument20 pagesPuma 2100 Doc Maintenancefuchs.kevin.67No ratings yet

- SCM Tech z1 z2 z5 en 2013Document28 pagesSCM Tech z1 z2 z5 en 2013JonathanNo ratings yet

- Tachyon Series - English - 2019 09Document4 pagesTachyon Series - English - 2019 09Kiril AngelovNo ratings yet

- Tsugami B0205 206 III Focus BrochureDocument8 pagesTsugami B0205 206 III Focus BrochureBakhtiar Permana50% (2)

- Vt-1150 User ManualDocument22 pagesVt-1150 User ManualAnne RodriguesNo ratings yet

- 22.2021 LM-TT Series ENG - v2.3Document30 pages22.2021 LM-TT Series ENG - v2.3vismaraNo ratings yet

- 1100m Spec Sheet - 0121Document1 page1100m Spec Sheet - 0121Ben LernerNo ratings yet

- Vertical Machining Center ModelDocument2 pagesVertical Machining Center Modelatishay shNo ratings yet

- Cold Milling Machine W 1900: Efficient Milling in The 2-m ClassDocument24 pagesCold Milling Machine W 1900: Efficient Milling in The 2-m ClassKhaleelNo ratings yet

- Direct: CNC Machining CentreDocument2 pagesDirect: CNC Machining CentreRivas IsaacNo ratings yet

- Long Z: User's ManualDocument60 pagesLong Z: User's Manualchinaaaa6No ratings yet

- Pt0uk13 ntx1000 2000 PDF DataDocument24 pagesPt0uk13 ntx1000 2000 PDF DataTiago PereiraNo ratings yet

- Surfcom C5Document2 pagesSurfcom C5AditiawarmanNo ratings yet

- HC400 500 Eu0806spDocument20 pagesHC400 500 Eu0806spGilberto XavierNo ratings yet

- HM1000 Eu0902spDocument12 pagesHM1000 Eu0902spGilberto XavierNo ratings yet

- Lynx220 EU0803SPDocument16 pagesLynx220 EU0803SPGilberto XavierNo ratings yet

- Lynx 300Document2 pagesLynx 300Gilberto XavierNo ratings yet

- Holemaking Cutting Data Solid Carbide Drilling Reaming Tools en UsDocument12 pagesHolemaking Cutting Data Solid Carbide Drilling Reaming Tools en UsGilberto XavierNo ratings yet

- NIKKEN NC303L - E - 220221-30mbDocument340 pagesNIKKEN NC303L - E - 220221-30mbGilberto XavierNo ratings yet

- Census Form IDocument1 pageCensus Form IRizwanNo ratings yet

- SMG Analog Gateway ManualDocument110 pagesSMG Analog Gateway ManualUzBatman ChannelNo ratings yet

- OEC CPQ IntegrationDocument68 pagesOEC CPQ Integrationneenu anna MathewNo ratings yet

- Fundamentals of Data Stuctures in C 2e - Horowitz, SahniDocument522 pagesFundamentals of Data Stuctures in C 2e - Horowitz, Sahnijely thakkarNo ratings yet

- SW Project Planning-Cost Estimation-Risk (2) ...Document113 pagesSW Project Planning-Cost Estimation-Risk (2) ...zig zagNo ratings yet

- Data Aire Dap4 Modbus TCP/IP Protocol Integration InstructionsDocument27 pagesData Aire Dap4 Modbus TCP/IP Protocol Integration InstructionscarlosNo ratings yet

- Reactive Streams PDFDocument4 pagesReactive Streams PDFJose Miguel Romero SevillaNo ratings yet

- Brain's Always Thinking: Common Core Activities For Free TimeDocument10 pagesBrain's Always Thinking: Common Core Activities For Free TimePaula BizzottoNo ratings yet

- Ezdxf Readthedocs Io en Master PDFDocument524 pagesEzdxf Readthedocs Io en Master PDFHybcon 18No ratings yet

- Python Program For CBSE PracDocument3 pagesPython Program For CBSE PracParth TakleNo ratings yet

- AutoCAD Shortcut Keys PDFDocument8 pagesAutoCAD Shortcut Keys PDFkochay yawazyNo ratings yet

- Pricelist Phone Kulim Gadget CentreDocument6 pagesPricelist Phone Kulim Gadget Centreaek176786No ratings yet

- Software Architecture Design - L01Document13 pagesSoftware Architecture Design - L01Fakibazz frndsNo ratings yet

- Ai Class 9 Unit 1Document26 pagesAi Class 9 Unit 1Aweaker TangixNo ratings yet

- Android Practical QuestionsDocument4 pagesAndroid Practical QuestionsRashika JainNo ratings yet

- Lec10 PerformanceDocument64 pagesLec10 PerformanceYilma AbiyNo ratings yet

- WWW 201003Document135 pagesWWW 201003Ruvarashe MunyaradziNo ratings yet

- CSC 443 - Database Management SystemsDocument18 pagesCSC 443 - Database Management SystemsShahbaz KhanNo ratings yet

- Character LightingDocument10 pagesCharacter LightingjosephsubinNo ratings yet

- AbsoluteDocument22 pagesAbsolutejiang haoNo ratings yet

- 8.3 PLSQL PPT Ch7 PDFDocument18 pages8.3 PLSQL PPT Ch7 PDFDunNo ratings yet

- Reopening Nishtha CoursesDocument4 pagesReopening Nishtha CoursesRahul BasakNo ratings yet

- Lab 1 - Introduction To Adobe XD PDFDocument12 pagesLab 1 - Introduction To Adobe XD PDF2029 jtsoftNo ratings yet

- Hoja de Especificaciones Serie IE340Document8 pagesHoja de Especificaciones Serie IE340Marco Antonio Hernandez IbarraNo ratings yet

- Software User GuideDocument213 pagesSoftware User Guidesaid.aitbeinNo ratings yet

- Group 08 Srs UpdatedDocument9 pagesGroup 08 Srs UpdatedJOANNA BABES FUNILASNo ratings yet

- U19EC416 DSP Lab SyllabusDocument2 pagesU19EC416 DSP Lab SyllabusRamesh MallaiNo ratings yet

- RAD (Rapid Application DevelopmentDocument3 pagesRAD (Rapid Application DevelopmentShammah ChishakweNo ratings yet

- Fifa Manager 13 - Graphics GuideDocument11 pagesFifa Manager 13 - Graphics GuideNawfal75% (4)