Professional Documents

Culture Documents

Basketball Hoop

Basketball Hoop

Uploaded by

Jason LadeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basketball Hoop

Basketball Hoop

Uploaded by

Jason LadeCopyright:

Available Formats

Keep this Product ID Number and use when contacting Customer Service:

OWNERS MANUAL

MODEL N 1479

OWNERS MANUAL

2

Save this owners manual for future reference and in the event that

the manufacturer has to be contacted.

**U.S. and Canada customers ONLY**

IF ASSISTANCE IS NEEDED,

DO NOT CONTACT THE STORE!

CALL OUR CUSTOMER SERVICE DEPARTMENT at

1 (800) 225-3865

HOURS: 7:00 a.m. to 5:00 p.m. Monday through Friday (Mountain Standard Time)

**Call or visit our Web site for Saturday hours**

Lifetime Products, Inc.

P0 Bot J00J0 |reeport 0erter, B|4g. 0-JJ 0|earf|e|4, Uta| &10J-00J0

**For customers outside the U.S. or Canada, please contact the store for assistance.**

REGISTER YOUR LIFETIME PRODUCT TODAY!

|I|E!IME'S PR0MISE !0 Y0U:

We invite you to read our privacy policy at www.lifetime.com

RE0IS!ER to4a!

!|ere are bere|ts to reg|ster|rg oar ||fet|e pro4act. d|t| oar rew or||re pro4act reg|strat|or for,

|t's fast ar4 eas! Reg|ster w|t| as at www.||fet|e.co ar4 erjo t|ese great bere|ts:

Receive exclusive money-saving oers rom BuyLietime.com, our online store, as well

as NEW product notications and special closeout promotions!

n the unlikely event o a product recall or saety modication, we will notiy you.

Registering your product guarantees you warranty service. you do not register your

product, your warranty rights will not be diminished. But you will need to provide a sales

receipt to verify your product purchase date before warranty service will be provided.

Maintaining your privacy is our long-standing policy at Lifetime. And you can rest as-

sured that Lifetime will not sell or provide your personal data to other third parties, or

allow them to use your personal data for their own purposes.

INSTRUCTION #1055302 B 4/19/2010

3

Most injuries are caused by misuse and/or not following instructions. Use caution when using this product.

To ensure safety, do not attempt to assemble this product without reading and

following all instructions carefully. Check the entire box and inside all packing

materials for parts and/or additional instruction material. Before beginning assembly,

identify and inventory all parts and hardware using the parts and hardware lists and

identiers in this document. Proper and complete assembly, use and supervision

are essential for proper orientation and to reduce the risk of accident or injury. A

high probability of serious injury exists if this product is not installed, maintained,

and/or operated properly. Failure to comply with any of the warnings in this

instruction manual may result in serious personal injuries such as cuts, broken

bones, nerve damage, paralysis, brain injury, or death. Failure to comply may also

result in property damage. Please heed all warnings and cautions.

|AI|URE !0 |0||0d !HESE dARNIN0S MAY RESU|! IN SERI0US INIURY 0R PR0PER!Y

0AMA0E AN0 dI|| \0I0 dARRAN!Y.

using a ladder during assembly, use extreme caution.

Two capable adults are recommended or this operation.

Check base daily or leakage. Leaks may cause product to all.

/ssemble the pole sections properly. Failure to do so could cause the pole

sections to separate during play or transport.

SAFETY INSTRUCTIONS

BEFORE BEGINNING ASSEMBLY

Keep the hardware bags and their contents separate. If any parts

are missing, call our Customer Service Department.

Identify and inventory all parts and hardware using the parts and

hardware lists and identiers in this document.

Test t all Bolts by inserting them into their respective holes. If

necessary, carefully scrape away any excess powder coating

buildup from inside the holes. Do not scrape away all of the

powder coating. Bare metal may rust. You may need to pound

some Bolts into place with a hammer or mallet.

4

TOOLS AND PARTS REQUIRED FOR THIS ASSEMBLY

*Two adults required to

complete assembly*

0r| a4a|ts s|oa|4 set ap t|e pro4act. 0o rot a||ow c|||4rer

|r t|e setap area art|| asseb| |s cop|ete.

Phillips Screwdriver

(1)

|arre|

(1)

!/J" drerc|

(2)

Scrap doo4

(1)

Sand

(362 lb)

(1)

Pliers

Rubber Mallet

(1)

J/Z" drerc|

(2)

dater Hose

(1)

9/J" drerc|

(2)

1/1" drerc|

(2)

1/J" A||er drerc|

(2, included)

5

This area is located at the top,

left-hand corner of the page

and indicates which tools

and hardware are needed to

cop|ete t|e asseb| steps

on a page.

Note:

!

Refer to the following areas throughout the instructions

to assist in the assembly process:

!||s area |s asaa|| |ocate4 |r t|e

bottom, left-hand corner of a step

and indicates that special attention

is needed to perform a particular

part of a step.

!|ese areas are asaa|| |ocate4 |r

the bottom, right-hand corner of a

step and indicate that damage to

t|e pro4act or ser|oas |rjar a

occur if the caution or warning is

not heeded.

dARNIN0

ASSEMBLY GUIDES

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

CAUTION

6

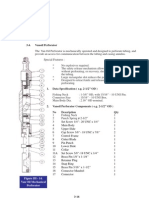

PARTS LIST

HARDWARE LIST

ID Item Description Qty

Pole Assembly Hardware (1066287)

ADS 1/4 x 3/4 Screw 2

AOF 3/8 Plug 2

ANS 1/2 Nylon Plug 2

CIH Domed Countersink Washer 2

Pole to Base Assembly Hardware (1066284)

AAO 5/16 Nylock Nut 2

ABD 5/16 Washer 4

AAE 5/16 x 1 Hex Bolt 2

ABN 1/2 x 1/8 Spacer 2

BTS 1/4 Barrel Nut 1

BZO 1/4 x 3 Shoulder Bolt 1

CCL 3/16 Allen Wrench (not illustrated) 2

Backboard to Rim Assembly Hardware (1046640)

AAS 1/4 x 2 3/4 Hex Bolt 2

ABS 1/2 x 2 5/16 Galvanized Spacer 2

AAB 1/4 Centerlock Nut 2

AAJ 5/16" Hex T-Nut 2

ABD 5/16 Washer 2

ABF 7/16 Rubber Washer 2

ABI 5/16 x 2 1/4 Tap Bolt 2

ADQ 5/16 x 1 Screw 2

ID Item Description Qty

/LH Top Pole 1

/LF Middle Pole 1

/LE Bottom Pole 1

AJK Right Backboard Bracket 1

AJJ Let Backboard Bracket 1

AJI Backboard 1

/L/ Rim 1

AKZ Net 1

AKC Extension Arm 4

BDL Dunk Latch 1

BDM Inner Guard 1

BDN Outer Guard 1

AJM Base 1

/L Pole Brace 2

AMU Wheel 2

AJC 1/2 x 15 3/4 Axle 1

AJE 1/2 x 7 Axle 1

AEF Base Plug 2

AMT Warning Sticker (Applied to Middle Pole) 1

7

HARDWARE LIST

ID Item Description Qty

Backboard to Rim Assembly Hardware (continued)

AOU 4 1/2" U-Bolt 1

ABK 5/16 Nylock Flange Nut 4

AJW Compression Spring 2

AOW Spring Retainer Plate 1

AAV 5/16 Jam Nut 2

Backboard to Pole Assembly Hardware (1046812)

ADG 1/2 x 6.625 Hex Bolt 4

/// 1/2 Centerlock Nut 4

/BL .69 x .59 Black Spacer 4

ABP 1/2 x 3/8 Clear Poly Spacer 4

ABA 3/8 x 6 1/2 Hex Bolt 1

ABB 3/8 Centerlock Nut 1

PARTS LIST

43

Parts shown at 10% of Actual Size

ALH (x1)

Top Pole

A|| (x1)

Middle Pole

ALE (x1)

Bottom Pole

ALI (x2)

Pole Brace

AKC (x4)

Extension Arm

30 1/2

*darr|rg St|cker app||e4 to s|4e rot s|owr

43

15 3/4

AI0 (x1)

1/2 x 15 3/4 Axle

15 3/4

7

AIE (x1)

1/2 x 7 Axle

AII (x1)

Let Backboard Bracket

AIK (x1)

Right Backboard Bracket

BDL (x1)

Dunk Latch

8

AKZ (x1)

Net

ALX (x1)

Rim

AII (x1)

Backboard

AIM (x1)

Base

Parts shown at 5% of Actual Size

Parts shown at 10% of Actual Size

PARTS IDENTIFIER

Parts shown at 25% of Actual Size

AMU (x2)

Wheel

BDM (x1)

Inner Guard

AE| (x2)

Base Plug

BDN (x1)

Outer Guard

9

HARDWARE IDENTIFIER

P0|E ASSEMB|Y HAR0dARE

Hardware shown at Actual Size

BA0KB0AR0 !0 RIM ASSEMB|Y HAR0dARE

Hardware shown at Actual Size

P0|E !0 BASE ASSEMB|Y HAR0dARE

Hardware shown at Actual Size

AAE (x2)

5/16 x 1 Hex Bolt

AAO (x2)

5/16 Nylock Nut

ABD (x4)

5/16 Washer

AAS (x2)

1/4 x 2 3/4 Hex Bolt

ADQ (x2)

5/16 x 1 Screw

ADS (x2)

1/4 x 3/4 Screw

ANS (x2)

1/2 Nylon Plug

A0| (x2)

3/8 Plug

ABN (x2)

1/2 x 1/8 Spacer

BTS (x1)

1/4 Barrel Nut

BZO (x1)

1/4 x 3 Shoulder Bolt

ABS (x2)

1/2 x 2 5/16 Galvanized Spacer

ABI (x2)

5/16 x 2 1/4 Tap Bolt

AAI (x2)

5/16" Hex T-Nut

ABD (x2)

5/16 Washer

CIH (x2)

Domed Counter-

sink Washer

10

HARDWARE IDENTIFIER

BA0KB0AR0 !0 RIM ASSEMB|Y HAR0dARE (00N!INUE0)

Hardware shown at Actual Size

Hardware shown at 25% of Actual Size

AId (x2)

Compression Spring

A0d (x1)

Spring Retainer Plate

6.625

(Not actual length)

BA0KB0AR0 !0 P0|E ASSEMB|Y HAR0dARE

Hardware shown at Actual Size

AAB (x2)

1/4 Centerlock Nut

AB| (x2)

7/16 Rubber Washer

ABK (x4)

5/16 Nylock

Flange Nut

AAV (x2)

5/16Jam Nut

AOU (x1)

4 1/2" U-Bolt

A00 (x4)

1/2 x 6.625 Hex Bolt

6 1/2

(Not actual length)

ABA (x1)

3/8 x 6 1/2 Hex Bolt

AAX (x4)

1/2 Centerlock Nut

ABL (x4)

.69 x .59 Black Spacer

ABP (x4)

1/2 x 3/8 Clear Poly Spacer

ABB (x1)

3/8 Centerlock Nut

11

POLE ASSEMBLY

HARDWARE REQUIRED

PARTS REQUIRED

TOOLS REQUIRED

S

E

C

1

Parts shown at 10% of Actual Size

Phillips Screwdriver

Hardware shown at Actual Size

Scrap doo4

ADS (x2)

1/4 x 3/4 Screw

ANS (x2)

1/2 Nylon Plug

A0| (x2)

3/8 Plug

ALH (x1)

Top Pole

A|| (x1)

Middle Pole

ALE (x1)

Bottom Pole

30 1/2

43

43

*darr|rg St|cker app||e4 to s|4e rot s|owr

CIH (x2)

Domed Countersink

Washer

12

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

ALH

A||

ADS

Align the hole in the Top Pole (ALH) with the slot in the M|44|e Po|e (A||) and

slide the Top Pole over the Middle Pole. Insert a 1/4 x 3/4 Screw (ADS)

through the small hole in the Top Pole and into the slot in the Middle Pole

as shown.

Note: The 1/4 x 3/4 Screw should be ush with the Pole, but

will spin freely once installed. Do not jam the Poles together

until instructed.

!

SEC

1.1

ADS (x1)

ALH

A||

darr|rg

St|cker

CIH

CIH (x1)

13

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

Align the hole in the M|44|e Po|e (A||) with the slot in the Bottom Pole (ALE) and

slide the Middle Pole over the Bottom Pole. Insert a 1/4 x 3/4 Screw (ADS)

through the small hole in the Middle Pole and into the slot in the Bottom

Pole as shown.

SEC

1.2

A||

ALE

Note: The 1/4 x 3/4 Screw should be ush with the Pole, but

will spin freely once installed. Do not jam the Poles together

until instructed.

!

CIH

A||

ALE

ADS (x1)

ADS

CIH (x1)

14

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

Insert the 1/&" P|ags (A0|) into the small holes on the M|44|e Po|e (A||).

Then insert the J/Z" N|or P|ags (ANS) into the large holes on the other

side of the Middle Pole as shown.

SEC

1.3

ANS (x2)

A0| (x2)

A||

A0|

ANS

N0 !00|S RE0UIRE0 |0R !HIS PA0E

Small Holes

Large Holes

15

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

WARNING

The Poles must be seated together! Even if the Poles cover

the slots before seating, they must be struck on a hard

surface ve to six times! Failure to seat the Poles correctly

could allow the Poles to separate during use, which could

lead to serious personal injuries or property damage.

Note: Do not hit your feet with the Pole sections,

as serious injury could occur.

!

Scrap doo4

If the !op ar4 M|44|e Po|es (A|H & A||) do not completely cover the slots on the

M|44|e ar4 Botto Po|es (A|| & A|E) after seating, DO NOT COMPLETE ASSEMBLY.

Call our Customer Service Department.

In order to seat the Poles, strike each end of the Pole very hard ve to six

times on a piece of scrap wood or cardboard. This must be done even if

the Poles cover the slots before seating has occurred.

SEC

1.4

ATTENTION: THIS STEP CANNOT BE REVERSED!

N0 HAR0dARE RE0UIRE0 |0R !HIS PA0E

ALH

A||

ALE

16

AIM (x1)

Base

ALI (x2)

Pole Brace

AI0 (x1)

1/2 x 15 3/4 Axle

AMU (x2)

Wheel

15 3/4

7

AIE (x1)

1/2 x 7 Axle

Parts shown at 10% of Actual Size

Part shown at 25% of Actual Size

POLE TO BASE ASSEMBLY

HARDWARE REQUIRED

PARTS REQUIRED

TOOLS REQUIRED

S

E

C

2

Part shown at 5% of Actual Size

Hardware shown at Actual Size

ABN (x2)

1/2 x 1/8 Spacer

AAE (x2)

5/16 x 1 Hex Bolt

AAO (x2)

5/16 Nylock Nut

BTS (x1)

1/4 Barrel Nut

ABD (x4)

5/16 Washer

Pliers

J/Z" drerc| (x2)

BZO (x1)

1/4 x 3 Shoulder Bolt

00|-1/J" A||er drerc|

(x2, included)

17

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

ALI

AAE

ABD

AIM

ABD

AAO

AAE (x2)

ABD (x4)

ABN (x2)

AAO (x2)

N0 !00|S RE0UIRE0 |0R !HIS PA0E

Attach the attened end of the Pole Brace (ALI) to the Base (AIM) with

the hardware shown. Only nger tighten the hardware.

SEC

2.1

Note: Repeat this step to install the other Pole Brace to

the other side of the Base.

!

Slide the J/Z" t J5 1/1" At|e (AI0) through the d|ee|s (AMU) and the holes

at the end of the Bottom Pole (ALE) as shown. Slide the J/Z" t !" At|e (AIE)

through the second set of holes at the end of the Bottom Pole as shown.

Then slide two 1/2 x 1/8 Spacers (ABN) onto the 1/2 x 15 3/4 Axle and

position them against the Wheels.

SEC

2.2

AI0

ABN

ABN

AMU

AMU

AI0

ALE

AIE

18

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

Place the Pole assembly on the ground with the darr|rg St|cker (AM!) on

the M|44|e Po|e (A||) facing down. Position the J/Z" t J5 1/1" At|e (AI0) under

the bottom slots of the Base (AIM) as shown, and step onto the Base so the

Axle snaps into the slots. Then rotate the Pole assembly upward so that

the J/Z" t !" At|e (AIE) snaps into the upper slots of the Base as shown.

SEC

2.3

AI0

AIM

BTS (x1)

1/2" (x2)

AIE

AIM

BZO (x1)

Attach the Pole Braces (ALI) to the Bottom Pole (ALE) with the hardware

shown, and t|g|ter a|| Po|e to Base asseb| |ar4ware.

SEC

2.4

BTS

BZO

ALE

ALI

Note: Tip the system forward so the Pole rests on the ground. Do not stand

the system up until it is lled with either sand or water later in the assembly.

!

ALI

3/16" (x2)

19

BACKBOARD TO RIM ASSEMBLY

S

E

C

3

Hardware shown at Actual Size

HARDWARE REQUIRED

AAS (x2)

1/4 x 2 3/4 Hex Bolt

ABS (x2)

1/2 x 2 5/16 Galvanized Spacer

ABD (x2)

5/16 Washer

ABK (x4)

5/16 Nylock

Flange Nut

AAB (x2)

1/4" Center-

lock Nut

Hardware shown at 25% of Actual Size

AOX (x1)

Rim Support Channel

AAC (x2)

5/16 x 1 3/4 Hex Bolt

ADQ (x2)

5/16 x 1 Screw

AOU (x1)

4 1/2" U-Bolt

ABI (x2)

5/16 x 2 1/4 Tap Bolt

AB| (x2)

7/16 Rubber Washer

AAI (x2)

5/16" Hex T-Nut

AId (x2)

Compression Spring

A0d (x1)

Spring Retainer Plate

AAV (x2)

5/16 Jam Nut

20

BACKBOARD TO RIM ASSEMBLY

S

E

C

3

PARTS REQUIRED

J/Z" drerc| (x2) !/J" drerc| (x2)

TOOLS REQUIRED

ALX (x1)

Rim

Parts shown at 10% of Actual Size

AII (x1)

Let Backboard Bracket

AIK (x1)

Right Backboard Bracket

AII (x1)

Backboard

Part shown at 25% of Actual Size

Part shown at 5% of Actual Size

BDM (x1)

Inner Guard

21

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

Note: Tighten all Nuts securely now.

!

Slide the 4 1/2 U-Bolt (AOU) through the |eft ar4 R|g|t Backboar4 Brackets (AII

& AIK). The U-Bolt must rest in the notches o the Backboard Brackets

as shown.

Fold up the sides of the Irrer 0aar4 (B0M) and place it between the

Backboard Brackets as shown. Secure the Backboard Brackets to

the Inner Guard using two 1/4 x 2 3/4 Hex Bolts (AAS), two 1/2 x

Z 5/J" 0a|ar|ze4 Spacers (ABS), and two J/1" 0erter|ock Nats (AAB).

SEC

3.1

SEC

3.2

AAS (x2)

ABS (x2)

AAB (x2)

7/16 (x2)

BDM

AAB

ABS

AAB

AAS

AAS

BDM

AOU

AII

AIK

Notch

AOU

AII

AIK

(Not to scale)

AOU (x1)

22

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

Place the Rim Support Channel (AOX) into the recess on the backside of

the Backboar4 (AII) so that the at side with holes is positioned against

the Backboard as shown. Then insert the 4 1/2 U-Bolt (AOU) through the

holes above the recess as shown.

SEC

3.3

AOU

AII

AOX

N0 !00|S RE0UIRE0 |0R !HIS PA0E

AOX (x1)

(Not to scale)

23

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

1/2 (x2)

SEC

3.4

ABD (x4)

AB| AB|

AAI

ABI

ABD

AB|

ALX

Insert two 5/16 x 2 1/4 Tap Bolts (ABI), two 5/J" das|ers (AB0), and two 7/16

Rabber das|ers (AB|) through the bottom holes in the back of the Rim (ALX)

as shown, and secure the hardware with two 5/J" Het !-Nats (AAI).

Correct Incorrect

AB0

AB0

AAI

AAI

ALX

Note: Do not overtighten the hardware so that the 7/16Rubber

Washers bulge outward as shown.

!

Note: Make sure that the 5/16 x 2 1/2 Tap Bolts are

positioned on the outside edge of the holes as shown.

!

ABI (x2)

AB| (x2) AAI (x2)

24

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

ABK

ABK

SEC

3.5

1/2 (x2)

Connect the Rim (ALX) to the Backboar4 (AII) with the hardware shown.

Thread the 5/J" Ia Nats (AA\) all the way down on the 4 1/2 U-Bolt (AOU).

On the underside of the Backboard, secure the 5/J" N|ock ||arge Nats

(ABK) onto the Tap Bolts.

AAV (x2)

AAV

ABK (x2)

Note: Tighten the 5/16 Nylock Flange Nuts (ABK) until they are ush with the ends of the Bolts.

!

25

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

Slide the 0opress|or Spr|rgs (AId) onto the 4 1/2 U-Bolt (AOU), and

place the Spr|rg Reta|rer P|ate (A0d) over the Compression Springs.

Tighten the 5/J" N|ock ||arge Nats (ABK) until the Rim (ALX) does not

wobble to complete this step.

Note: DO NOT COMPLETELY TIGHTEN THE 5/16 NYLOCK FLANGE NUTS IN

THIS STEP! Only tighten the Nuts until the Rim (ALX) does not wobble.

Tightening the Nuts will adjust the Rim tension.

!

SEC

3.6

A0d (x1)

AId (x2)

1/2 (x2)

ABK (x2)

AId

ABK

A0d

AId

26

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

Bend the |eft ar4 R|g|t Backboar4 Brackets (AII & AIK) outward by hand

and position the top holes in the Backboard Brackets over the holes

in the Backboar4 (AII). Then securely fasten the Backboard Brackets

to the Backboard with the hardware shown.

SEC

3.7

ADQ (x2)

1/2 (x2)

ADQ

ADQ

AII

27

BACKBOARD TO POLE ASSEMBLY

HARDWARE REQUIRED

PARTS REQUIRED

TOOLS REQUIRED

S

E

C

4

Parts shown at 10% of Actual Size

Hardware shown at Actual Size

AAX (x4)

1/2 Centerlock Nut

ABL (x4)

.69 x .59 Black Spacer

A00 (x4)

1/2 x 6 5/8 Hex Bolt

ABP (x4)

1/2 x 3/8 Clear Poly Spacer

ABA (x1)

3/8 x 6 1/2 Hex Bolt

ABB (x1)

3/8 Centerlock Nut

6 5/8

(Not actual length)

15 3/4

AKC (x4)

Extension Arm

BDL (x1)

Dunk Latch

BDN (x1)

Outer Guard

9/J" drerc| (x2)

Rubber Mallet

1/1" drerc| (x2)

6 1/2

(Not actual length)

28

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

3/4 (x2)

AAX (x1) ABL (x2)

6 5/8

(Not actual length)

A00 (x1)

Secure two of the Extension Arms (AKC) to the Backboard Brackets

in the location shown with the hardware indicated. Make sure to

attach the end of the Extension Arms with one hole to the Backboard

Brackets as shown.

SEC

4.1

AAX

ABL

A00

AKC

ABL

AKC

Note: Tighten the 1/2 Centerlock Nut (AAX) until it is ush with the end of the Bolt.

!

AKC

29

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

Place the 0ark |atc| (B0|) within the 0ater 0aar4 (B0N) and align the

holes at the end. Then position the Dunk Latch and 0uter 0uard

onto the Backboard Bracket /ssembly as shown. The Dunk Latch

ts within the Irrer 0aar4 (B0M) and the Outer Guard ts between the

Inner Guard and the Backboard Brackets.

SEC

4.2

BDN

BDL

BDN

BDL

BDM

AII AIK

N0 !00|S 0R HAR0dARE RE0UIRE0 |0R !HIS PA0E

30

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

3/4 (x2)

AAX (x1) ABL (x2)

6 5/8

(Not actual length)

A00 (x1)

SEC

4.3

AAX

ABL

A00

AKC

ABL

AKC

Secure the 0ark |atc| (B0|), 0ater 0aar4 (B0N), and the other two Extension

Arms (AKC) to the Backboard Brackets in the location shown with the

hardware indicated.

BDN

BDL

Note: Tighten the 1/2 Centerlock Nut (AAX) until it is ush with the end of the Bolt.

!

31

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

9/16 (x2)

ABB (x1)

dARNIN0

Do not operate the system without the Outer Guard in

place over the Dunk Latch. Doing so could increase

the risk of injuries described on Page Three. If the

Outer Guard becomes loose or detached, call our

Customer Service Department.

Lit the 0ark |atc| (B0|) and 0ater 0aar4 (B0N) so the slots line up with

the holes in the upper Extension Arms (AKC) that are closest to the

Backboar4 (AII). Then secure the Dunk Latch and 0uter 0uard to the

upper Extension Arms with the hardware shown.

SEC

4.4

ABB ABA

BDN

AKC AKC

AII

Note: Tighten the 3/8 Centerlock Nut (ABB) until it is ush with the end of the Bolt.

!

(Not actual length)

ABA (x1)

6 1/2

BDL

32

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

3/4 (x2)

AAX (x2) ABP (x4)

6 5/8

(Not actual length)

A00 (x2)

Lay the Backboard and Rim assembly next to the Pole assembly. Rest

the Rim on cardboard to prevent scratching. Then secure the Extension

Arms (AKC) to the Pole Assembly with the hardware shown.

SEC

4.5

AAX

AAX

ABP

ABP

ABP ABP

A00

A00

AKC

AKC

CAUTION: HAVE ONE ADULT HOLD THE BACKBOARD IN PLACE

UNTIL THIS STEP HAS BEEN COMPLETED!

Note: Tighten the 1/2 Centerlock Nuts (AAX) until they are ush with the end of the Bolts. Make

sure all hardware is securely tightened before moving to the next section.

!

33

|INA| ASSEMB|Y

HARDWARE REQUIRED

PARTS REQUIRED

TOOLS REQUIRED

S

E

C

5

Part shown at 10% of Actual Size

NO HARDWARE REQUIRED FOR THIS SECTION

AKZ (x1)

Net

AE| (x2)

Base Plug

|arre|

Sand

(362 lb)

dater Hose

Part shown at Actual Size

34

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

(362 lb)

N0 HAR0dARE RE0UIRE0 |0R !HIS PA0E

SEC

5.1

!wo a4a|ts are rea|re4 to cop|ete asseb|. !o preert ser|oas |rjar|es, t|e

Po|e s|oa|4 be |e|4 4owr b ore a4a|t at a|| t|es w|||e t|e Base |s be|rg |||e4.

0P!I0N A: |I||IN0 dI!H SAN0

(362 lb of sand required)

a. Insert a Base P|ag (AE|) into the Base (AIM) in the hole closest to the Pole.

b. Using a funnel, ll the Base with sand through the hole furthest from

the Pole until the sand is just below the hole.

c. Using two adults, stand the Base up on a at surface and nish lling

the Base with sand.

d. Insert the other Base Plug into the hole furthest from the Pole.

dARNIN0

For safety reasons, we recommend that sand be used

instead of water to ll the Base. If a leak develops, water

could run out unnoticed, allowing the system to fall over,

resulting in serious personal injuries, or property damage.

If using Water, check the Base carefully for leaks. If a

leak is found, lay the system down on the ground and

call Customer Service. Do not use, stand up, or play on

a leaking system.

AE|

AIM

35

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

N0 HAR0dARE RE0UIRE0 |0R !HIS PA0E

SEC

5.1

!wo a4a|ts are rea|re4 to cop|ete asseb|. !o preert ser|oas |rjar|es, t|e

Po|e s|oa|4 be |e|4 4owr b ore a4a|t at a|| t|es w|||e t|e Base |s be|rg |||e4.

0P!I0N B: |I||IN0 dI!H dA!ER

a. Insert a Base P|ag (AE|) into the Base (AIM) in the hole closest to the Pole.

b. Fill the Base with cold water through the hole furthest from the Pole

until the water is just below the hole.

c. Using two adults, stand the Base up on a at

surface and nish lling the Base with water.

d. Add one tablespoon of chlorine bleach to the

water to prevent algae formation.

e. Insert the other Base Plug into the

hole furthest from the Pole.

AE|

AIM

36

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

SEC

5.2

ALX

AKZ

Attach Net (AKZ) to the Rim (ALX).

Note: If a replacement Net is needed, please call our Customer Service Department.

Our Nets are shorter than average to reduce the risk of entanglement.

!

N0 !00|S 0R HAR0dARE RE0UIRE0 |0R !HIS PA0E

37

The basketball system may be adjusted from 8 feet to 10 feet.

0NL /DULTS SH0ULD /D1UST THE HE0HT 0F THE SSTEM.

To Raise the Hoop:

Place the end of a long object, such as a

broom handle, under the Rim and push upward.

To Lower the Hoop:

Place the broom handle behind the Backboard

and push upward into the release box. Carefully

support the weight as you lower the system.

OPERATION OF HEIGHT ADJUSTMENT SYSTEM

.

rd

Raise

Lower

dARNIN0: The system must only be moved by people capable of

handling its weight. Children should not be allowed to move the system.

CAUTION: The system must only be moved on its Wheels. Sliding the

Base may damage the Base which could result in leakage and the

system tipping over.

MOVING THE SYSTEM

a. Adjust the system to its lowest position, and use caution to prevent the height

mechanism from adjusting.

b. Stand in front of the system and pull on the Pole until the unit is balanced on

its Wheels.

c. Move the system to the desired location and carefully set the Base down.

38

The life of your basketball system depends on many variables. The climate, exposure

to corrosives such as salt, pesticides, or herbicides, and excessive use or misuse can

all contribute to Pole failure, which may cause property damage or personal injury.

Check your basketball system frequently for loose hardware, excessive wear, and

signs of corrosion. For safety reasons, and to prolong the life of your basketball

system, you must take the following preventive measures.

a. Check all Nuts and Bolts. If any are loose, tighten them.

b. Check all parts for excessive wear and tear. If necessary, replace any parts

that have been worn or damaged through usage. Contact our Customer Service

Department for replacement parts.

c. Inspect the Warning Sticker on the Pole. If it is ripped, faded, or illegible,

call our Customer Service Department to request a replacement Sticker.

d. Check all Pole sections for visible rust or chipped or cracked paint. If either

are present, do the following:

1. Use an emery cloth to completely remove any rust or chipped paint.

2. Clean the area with a damp cloth and allow it to dry.

3. Apply two coats of a rust preventative, high gloss enamel paint to the

area. Allow the paint to dry between coats.

I| RUS! HAS PENE!RA!E0 !HR0U0H !HE P0|E ANYdHERE, REP|A0E I! IMME0IA!E|Y!

POLE CARE AND SYSTEM MAINTENANCE

39

NOTES

40

NOTES

41

NOTES

42

ENHANCE YOUR LIFETIME

PURCHASE BY ADDING

ACCESSORIES OR OTHER GREAT PRODUCTS:

Or call: 1-800-424-3865

To purchase accessories or other Lifetime Products, visit us at:

www.lifetime.com

43

|AU!E 0E NE PAS SUI\RE 0ES A\ER!ISSEMEN!S, \0US RIS0UEZ 0E 0AUSER 0ES B|ESSU-

RES 0RA\ES E!/0U 0ES 00MMA0ES A |'E0UIPEMEN!.

SI N0 SE 0BE0E0EN ES!AS A0\ER!EN0IAS PUE0EN PR00U0IRSE 0RA\ES |ESI0NES Y/0

DAOS A LA PROPIEDAD.

Le proprietaire doit s'assurer que tous les joueurs connaissent et appliquent

les regles suivantes an d'utiliser l'equipement en toute securite.

El propietario del sistema debe asegurarse de que todos los jugadores

conozcan y respeten estas reglas para que el sistema se use en forma

segura.

|AI|URE !0 |0||0d !HESE dARNIN0S MAY RESU|! IN SERI0US INIURY AN0/0R

PR0PER!Y 0AMA0E.

Owners must ensure that all players know and follow these rules for safe

operation of the system.

0nly hang rom the rim brieNy to regain balance or avoid injuring others. Release

the rim as soon as safely possible.

During play, especially when perorming dunk type activities, keep player's ace

away from the backboard, rim, and net. Serious injury could occur if teeth/face

come in contact with the backboard, rim, or net. Player should wear a mouth

guard during play.

Do not slide, climb, or play on base or pole.

Completely ll base according to manuacturer's instructions. Never leave the

unit standing in an upright position without rst lling the base with weight or

the system will tip quickly causing serious personal injury.

when adjusting height or moving system, keep hands and ngers away rom

moving parts.

Do not allow children to move or adjust system.

Do not wear jewelry (rings, watches, necklaces, etc.) during play. 0bjects may

entangle in net.

Keep organic material away rom pole base. 0rass, litter, etc. could cause

corrosion and/or deterioration.

Surace beneath the base must be smooth and ree o gravel or other objects.

Cuelguese del aro solo en orma breve, para recuperar el equilibrio o evitar

lesionar a otros jugadores. Sueltese del aro lo mas pronto que pueda hacerlo

con seguridad.

Durante el juego, especialmente al embocar violentamente de alto, la cara

de los jugadores debe mantenerse alejada del tablero, el aro y la red. Pueden

producirse lesiones graves si los dientes o la cara entran en contacto con el

tablero, el aro o la red. Los jugadores deben usar un protector bucal durante

el juego.

No se deslice, no trepe ni juegue sobre la base o el poste.

Llene la base completamente siguiendo las instrucciones del abricante.

Nunca deje la unidad en posicion de uso sin haber llenado previamente la base

con material de contrapeso, pues el sistema podra tumbarse rapidamente y

causar graves lesiones personales.

Mantenga las manos y los dedos alejados de las piezas movibles cuando

regule la altura o desplace el sistema.

No deje que los nios regulen ni desplacen el sistema.

No use joyas (anillos, relojes, collares o gargantillas, etc.) durante el juego.

Estos objetos pueden engancharse en la red.

La supercie donde se coloque la base debe estar lisa y desprovista de

piedras, grava u otros objetos. Las peroraciones pueden originar perdidas, y

estas pueden hacer que el sistema se tumbe.

No permita que la base del poste entre en contacto con materiales

organicos. El pasto, los desechos animales, etc., pueden causar corrosion y/o

deterioros.

Controle el poste y todas las piezas metalicas una vez al mes en busca de

signos visibles de corrosion (oxidacion, picaduras, escamado). Elimine todo

rastro de oxido y vuelva a pintar con esmalte para exteriores. Si el oxido ha

penetrado cualquier pieza de acero, reemplace esa pieza de inmediato.

nspeccione el sistema antes de cada uso para vericar que este

adecuadamente contrapesado, que los elementos de jacion no esten Nojos,

que no haya desgaste excesivo, inestabilidad ni signos de corrosion. Si

encuentra irregularidades, reparelas antes de usar el sistema.

Nunca juegue con un equipo daado.

No use el sistema en presencia de vientos uertes o condiciones climaticas

adversas, ya que puede tumbarse. Coloque la unidad en su posicion de

almacenamiento y/o en una zona a resguardo del viento, lejos de propiedades

personales que puedan daarse si el sistema se cae, y de lneas de suministro

de energa.

No use el sistema para levantar ningun objeto. El mecanismo esta diseado

para elevar solamente el peso del tablero con el aro. No cuelgue nada de la

agarradera, el aro, el tablero ni los brazos de elevacion, ya que esto puede

daar el sistema y anular la garanta.

Ne vous suspendez pas a l'anneau plus que necessaire pour retrouver votre

equilibre ou eviter de blesser les autres joueurs. Relachez l'anneau aussitot que

possible.

Lors d'un match, particulierement dans le cas des smashs, le visage du joueur

ne doit pas aire ace au panneau, a l'anneau, ni au let. Le joueur risque de

graves blessures si ses dents ou son visage entrent en contact avec le panneau,

l'anneau, ou le let. Les joueurs doivent toujours porter un protege-dents

lorsqu'ils jouent.

Ne glissez pas, ne grimpez pas, et ne jouez pas sur la base ou le poteau.

Remplissez completement la base selon les instructions du abricant. Ne

laissez jamais l'unite debout de plein pied sans avoir d'abord rempli la base avec

un poids ou l'equipement pourrait basculer rapidement et causer de graves

blessures.

Lorsque vous ajustez la hauteur ou lorsque vous deplacez l'equipement,

gardez vos mains et doigts loin des pices mobiles.

Ne permettez pas aux enants de deplacer ou d'ajuster l'equipement.

Ne portez pas de bijoux (bagues, montres, colliers, etc.) lorsque vous jouez.

Ces objets pourraient s'accrocher au let.

La surace sur laquelle est posee la base doit etre lisse et sans gravier ou tout

autre objet qui pourrait trouer la base entranant ainsi une fuite ce qui pourrait

aire basculer l'equipement.

La base ne doit pas non plus etre posee sur aucun type de matiere organique.

L'herbe, les dechets, etc. peuvent entrainer la corrosion et la deterioration de

l'equipement.

Une ois par mois, veriez que le Poteau et toutes les pieces en metal ne

montrent pas de signes de corrosion (rouille, piqres, ecaillage). Enlevez toute la

rouille et repeignez completement avec une peinture pour exterieur. Si la rouille

a penetre une des pieces en acier, vous devrez remplacer immediatement la

pice en question.

/ chaque ois que vous allez utiliser l'equipement, veriez d'abord l'equilibre,

la possibilite de pieces desserrees ou usees, la stabilite de l'equipement et tout

signe de corrosion ou reparation necessaire avant utilisation.

Ne jouez jamais avec un equipement endommage.

N'utilisez pas l'equipement lors de ortes raales de vent ou de mauvais temps.

L'equipement pourrait basculer. Placez l'equipement dans un endroit abrite du

vent ou loin des structures qu'il pourrait endommager s'il basculait et loin des

ls electriques.

N'utilisez pas l'equipement pour lever ou soulever quoique ce soit. Son

mecanisme a ete conu uniquement pour soutenir le poids du panneau et de

l'anneau. N'accrochez rien au manche, a l'anneau, au panneau ni aux leviers

sous peine d'endommager l'equipement et d'annuler la garantie.

#FS16400 10/12/2004

www.lifetime.com

Punctures cause leakage and could cause system to tip over.

0nce a month check pole and all metal parts or signs o corrosion (rust, pitting,

chipping). Completely remove rust and repaint with exterior enamel. If rust has

penetrated any steel part, replace that part immediately.

Check system beore each use or proper ballast, loose hardware, excessive

wear, instability, and signs of corrosion and repair before use.

Never play on damaged equipment.

Do not use system during windy or severe weather. System may tip over. Place

system in an area protected from the wind or in an area away from property that

may be damaged if the system falls, and from overhead power lines.

Do not use the system to lit or hoist anything. The mechanism is designed

to lift only the weight of the backboard and rim. Do not hang anything from

the handle, rim backboard, or lifter arms as this will damage the system and

void the warranty.

WARNING

ADVERTENCIA AVERTISSEMENT

44

|I|E!IME BASKE!BA|| E0UIPMEN!

5-YEAR |IMI!E0 |A0!0RY dARRAN!Y

!HE MANU|A0!URER RESER\ES !HE RI0H! !0 MAKE SUBS!I!U!I0NS !0 dARRAN!Y 0|AIMS I| PAR!S ARE

UNAVAILABLE OR OBSOLETE.

1. Lietime basketball systems are warranted to the original purchaser to be ree rom deects in

material or workmanship for a period of ve years from the date of original retail purchase. The word

defects is dened as imperfections that impair the use of the product. Defects resulting from misuse,

abuse or negligence will void this warranty. This warranty does not cover defects due to improper

installation, alteration or accident. This warranty does not cover damage caused by vandalism, rusting,

acts of nature or any other event beyond the control of the manufacturer.

2. This warranty is nontransferable and is expressly limited to the repair or replacement of defective

basketball equipment. the equipment is deective within the terms o this warranty, Lietime Products,

Inc. will repair or replace defective parts at no cost to the purchaser. Shipping charges to and from

the actory are not covered and are the responsibility o the purchaser. Labor charges and related

expenses for removal, installation or replacement of the basketball system or its components are not

covered under this warranty.

3. This warranty does not cover scratching or scufng of the product that may result from normal

usage. In addition, defects resulting from intentional damage, negligence, unreasonable use or

hanging from the net or rim will void this warranty.

4. Liability or incidental or consequential damages is excluded to the extent permitted by law. while

every attempt is made to embody the highest degree of safety in all equipment, freedom from injury

cannot be guaranteed. The user assumes all risk of injury resulting from the use of this product. All

merchandise is sold on this condition, and no representative of the company may waive or change

this policy.

5. This product is not intended or institutional or commercial use, Lietime Products, nc. does not assume

any liability for such use. Institutional or commercial use will void the warranty.

6. This warranty is expressly in lieu of all other warranties, expressed or implied, including warranties

o merchantability or tness or use to the extent permitted by Federal and state law. Neither Lietime

Products, Inc., nor any representative assumes any other liability in connection with this product.

This warranty gives you specic legal rights, and you may also have other rights which vary from

state to state.

A|| dARRAN!Y 0|AIMS MUS! BE A000MPANIE0 BY A SA|ES RE0EIP!.

REP0R! PR00U0! 0E|E0!S IN dRI!IN0 !0:

Lietime Products, nc., P0 Box 160010 Cleareld, UT 84016-0010, or call (800) 225-3865

M-F 7 a.m. to 5 p.m. MST.

**Call or visit our Web site for Saturday hours**

Please include your dated sales receipt and photographs of damaged parts.

!o reg|ster t|e pro4act, |s|t oar deb s|te at www.||fet|e.co

WARRANTY INFORMATION

www.lifetime.com

You might also like

- Full ManualDocument13 pagesFull ManualSteve Dowell80% (5)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- Compact Metal Bender Manual PDFDocument64 pagesCompact Metal Bender Manual PDFarnoldodiel55% (11)

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (3)

- Small Block Chevrolet: Stock and High-Performance RebuildsFrom EverandSmall Block Chevrolet: Stock and High-Performance RebuildsRating: 4 out of 5 stars4/5 (14)

- Installation Guide: Roadrelay™ 4Document54 pagesInstallation Guide: Roadrelay™ 4ugruposandres100% (3)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WFrom EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WRating: 4.5 out of 5 stars4.5/5 (6)

- 2003 ATV Polaris Predator 500 Factory Service ManualDocument193 pages2003 ATV Polaris Predator 500 Factory Service Manualmarlonkp80% (5)

- Sharp Tool PolicyDocument3 pagesSharp Tool Policyvikkasverma.in100% (4)

- "Title of The Project": Veer Narmad South Gujarat University (Vnsgu)Document85 pages"Title of The Project": Veer Narmad South Gujarat University (Vnsgu)Safwan mansuriNo ratings yet

- (Filmmaking Technique) - CAMERA STABILIZER PLANS, STEADY, STEADI, STEADICAM, STEDYDocument81 pages(Filmmaking Technique) - CAMERA STABILIZER PLANS, STEADY, STEADI, STEADICAM, STEDYTaproot Photog100% (1)

- Power Team HNS150 ManualDocument5 pagesPower Team HNS150 ManualTitanplyNo ratings yet

- Horizontal "Flatbed" Router Table: MLCS Manual For #9767Document11 pagesHorizontal "Flatbed" Router Table: MLCS Manual For #9767teromandosNo ratings yet

- Cedarapids 6x20 - 54780Document40 pagesCedarapids 6x20 - 54780Blake Cooley Anderson100% (4)

- Craftsman 42" Snowblower ManualDocument28 pagesCraftsman 42" Snowblower ManualtekantNo ratings yet

- Keurig CaseDocument5 pagesKeurig CaseMatthewLiuNo ratings yet

- Lean Extended EnterpriseDocument16 pagesLean Extended Enterprisesaquib malik100% (2)

- ManipurDocument21 pagesManipurSneha Singh80% (5)

- 8 Ight 2 ManualDocument46 pages8 Ight 2 ManualrobyadNo ratings yet

- 51550Document24 pages51550jombibiNo ratings yet

- Bench Grinder Stand: Model 03184Document5 pagesBench Grinder Stand: Model 03184gilbertogatoNo ratings yet

- Parabody GS4 ManualDocument27 pagesParabody GS4 ManualmokuskaNo ratings yet

- JWTS-10JF Table Saw ManualDocument28 pagesJWTS-10JF Table Saw Manualjune1962100% (1)

- Jaguar IV User ManualDocument73 pagesJaguar IV User Manualtashi869No ratings yet

- PR3000 Home Gym: Assembly ManualDocument24 pagesPR3000 Home Gym: Assembly ManualBack TrackNo ratings yet

- Sig Lt40 ManualDocument49 pagesSig Lt40 ManualMarsala NistoNo ratings yet

- Interchangeable Spindle Users Guide 4C v0311 WebDocument21 pagesInterchangeable Spindle Users Guide 4C v0311 WebMynor SGNo ratings yet

- Sigrc 74 Kadetlt 25Document34 pagesSigrc 74 Kadetlt 25carlosulloa100% (1)

- SOLE E35 Installation GuideDocument32 pagesSOLE E35 Installation GuideRafi ChowdhuryNo ratings yet

- TM-78 GT Grooving ToolDocument12 pagesTM-78 GT Grooving ToolMiguel MotaNo ratings yet

- A3ce DF-701Document42 pagesA3ce DF-701Ivan IonutNo ratings yet

- Parts Catalog: First Edition October 1995Document77 pagesParts Catalog: First Edition October 1995Iftikhar MughalNo ratings yet

- 052876-005 Patio Awning Installation ManualDocument8 pages052876-005 Patio Awning Installation ManualStacy OneillNo ratings yet

- Me 708Document17 pagesMe 708Ana Victoria LeonNo ratings yet

- 8910 Treadmill Rev ADocument16 pages8910 Treadmill Rev AAnonymous ijZ3W6JxT9No ratings yet

- Ontrac Cable Tray: Installation InstructionsDocument10 pagesOntrac Cable Tray: Installation Instructionsgeriko182No ratings yet

- 2100d Installation GuideDocument20 pages2100d Installation GuideJazz TubaNo ratings yet

- Easy Jig Information - 80% ArmsDocument2 pagesEasy Jig Information - 80% ArmsVictor PaigeNo ratings yet

- Easy Jig Information - 80% ArmsDocument2 pagesEasy Jig Information - 80% Arms9fakeemailNo ratings yet

- Prototrak & Trak CNC: Service and Troubleshooting ManualDocument85 pagesPrototrak & Trak CNC: Service and Troubleshooting ManualDavid LucioNo ratings yet

- Reebok Rb3000Document9 pagesReebok Rb3000Diana0112No ratings yet

- HRR 505 Piperj 3 CubaDocument8 pagesHRR 505 Piperj 3 CubaYasty RinallNo ratings yet

- Owner's Manual & Safety InstructionsDocument24 pagesOwner's Manual & Safety InstructionsAndy CeslowNo ratings yet

- Uluru LP Gas Grill: Assembly and Use ManualDocument25 pagesUluru LP Gas Grill: Assembly and Use ManualRob NortmanNo ratings yet

- SD Slip ManualDocument9 pagesSD Slip ManualGregory StewartNo ratings yet

- Weslo Cadence 859 Treadmill ManualDocument16 pagesWeslo Cadence 859 Treadmill Manualazesiel100% (1)

- Installation Instructions Winch Mounting Kit: Part Number: 74180 Application: Honda Foreman 500 & Honda RubiconDocument14 pagesInstallation Instructions Winch Mounting Kit: Part Number: 74180 Application: Honda Foreman 500 & Honda RubiconManuel Castro EdiolaNo ratings yet

- Vanoil PerforatorDocument3 pagesVanoil PerforatorFrans TongaNo ratings yet

- TM 9 3416 235 14 and PDocument67 pagesTM 9 3416 235 14 and PMikeNo ratings yet

- Thunder Tiger TT Staudacher S-300 ManualDocument16 pagesThunder Tiger TT Staudacher S-300 ManualAscenderBSPNo ratings yet

- Wire Stripping Machine Instruction ManualDocument16 pagesWire Stripping Machine Instruction Manualkrushnasis pradhanNo ratings yet

- 2815.3 FR Power Cage Attachment 050519 WHDocument38 pages2815.3 FR Power Cage Attachment 050519 WHStephen ChanNo ratings yet

- Yx70 Viking Assembly ManualDocument0 pagesYx70 Viking Assembly ManualJulie LafranceNo ratings yet

- Tools Required:: Axis Travel: Movement Speed Tracing Structural KitDocument8 pagesTools Required:: Axis Travel: Movement Speed Tracing Structural KitMonark HunyNo ratings yet

- Direct Socket TFDocument157 pagesDirect Socket TFJoão Rafael CortezNo ratings yet

- Campey - Raycam Infield - Operators & Parts ManualDocument15 pagesCampey - Raycam Infield - Operators & Parts ManualCampey Turf Care SystemsNo ratings yet

- Pioneer DEH 2200UB 2250UB EptDocument76 pagesPioneer DEH 2200UB 2250UB EptB.r. ArturoNo ratings yet

- 2003 Polaris Predator Factory Service ManualDocument193 pages2003 Polaris Predator Factory Service Manualshindudevil50% (2)

- TLR 8ight 2.0 Manual PDFDocument46 pagesTLR 8ight 2.0 Manual PDFChefiaNo ratings yet

- FG3 Manual 2Document10 pagesFG3 Manual 2Sead KurtovićNo ratings yet

- Buell Ulysses Side+TopcaseDocument5 pagesBuell Ulysses Side+TopcaseAndré PereiraNo ratings yet

- Total Daily Points Allowance For Weight WatchersDocument5 pagesTotal Daily Points Allowance For Weight WatchersOum El Ghoul50% (2)

- 2 MeterialsDocument12 pages2 MeterialsthinkiitNo ratings yet

- Inventories Part 1 With AnswersDocument9 pagesInventories Part 1 With AnswersDyenNo ratings yet

- Neuro Provokers 8Document6 pagesNeuro Provokers 8victorgbsNo ratings yet

- Case Analysis: The Future of Same-Day Delivery: Same As The Past'Document5 pagesCase Analysis: The Future of Same-Day Delivery: Same As The Past'Anindya BasuNo ratings yet

- Diaperbizneil Price ListDocument4 pagesDiaperbizneil Price ListdiaperbizneilNo ratings yet

- Steve Jobs The Short BiographyDocument9 pagesSteve Jobs The Short BiographyimdadbaharNo ratings yet

- Food and Retail Market in Croatia 2Document47 pagesFood and Retail Market in Croatia 2Ujedinjeni Regioni Srbije BečejNo ratings yet

- PLC of PepsiDocument7 pagesPLC of Pepsidhaval2410No ratings yet

- AddonsDocument11 pagesAddonsShreyas Marulkar100% (1)

- Alexander Blouse OriginalDocument12 pagesAlexander Blouse Originalcatherlk3100% (1)

- Ewf12853 User Manual en SGDocument68 pagesEwf12853 User Manual en SGWhite TigerNo ratings yet

- VallakipokhappioDocument26 pagesVallakipokhappioChris BNo ratings yet

- Magic Pos PDFDocument3 pagesMagic Pos PDFPraveen ChoudharyNo ratings yet

- Exam QuestionsDocument3 pagesExam QuestionsTope YomiNo ratings yet

- SFCM Full NotesDocument38 pagesSFCM Full NotesRanjana KejariwalNo ratings yet

- Textile and GarmentsDocument10 pagesTextile and Garmentssameer7986No ratings yet

- Refrigerated Transportation Best Practices Guide WEBDocument41 pagesRefrigerated Transportation Best Practices Guide WEBznim04No ratings yet

- Visual MerchandisingDocument21 pagesVisual MerchandisingBathula MeghanaNo ratings yet

- Roadblock Advertising AssignmentDocument9 pagesRoadblock Advertising AssignmentluvgunmNo ratings yet

- Sourcing Ass 1 P.gayathri and PadmasriDocument48 pagesSourcing Ass 1 P.gayathri and PadmasriSatadeep DattaNo ratings yet

- Customer Preference Towards Branded and Assembled ComputersDocument85 pagesCustomer Preference Towards Branded and Assembled ComputersOM Kumar100% (2)

- Resume 1 15 19 WordDocument5 pagesResume 1 15 19 Wordapi-458952277No ratings yet

- Job Hazard AnalysisDocument2 pagesJob Hazard AnalysisMarc Dared CagaoanNo ratings yet

- Ariens, Snow Blower, 921018 - Deluxe 30 Platinum PDFDocument44 pagesAriens, Snow Blower, 921018 - Deluxe 30 Platinum PDFDerekNo ratings yet