Professional Documents

Culture Documents

3 of 8 Construction Tolerance

3 of 8 Construction Tolerance

Uploaded by

Bernard Reynoso0 ratings0% found this document useful (0 votes)

6 views8 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

6 views8 pages3 of 8 Construction Tolerance

3 of 8 Construction Tolerance

Uploaded by

Bernard ReynosoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 8

ONE FILINVEST CONSTRUCTION TOLERANCE

ORTIGAS, MANILA, PHILIPPINES SECTION 01 71 00

PART 1 - GENERAL

12

18

RELATED DOCUMENTS

The drawings and general provisions of the Contract, including General

and Supplementary Conditions, and Division 1 Specification Sections,

apply to this Section.

‘SUMMARY

This Section includes tolerances for the structural frame and

construction surveying requirements:

Gerieral contyactor’s monitoring plan for the structural frame.

Vertical alignment tolerance

Horizontal alignment tolerance.

Tolerance for embedded items

‘tolerance for cross-sectional dimensions of concrete ‘elements.

Related Sections:

01 45 00 - structural Testing, Inspection, and Quality Assurance

(03 10 00 ~ Concrete Forming and Accessories

03 20 00 - Conerete Reinforcing

03 30 00 - Cast-in-Place Concrete

05 12 00 - Structural Steel Framing

05 31 00 ~ Steel Decking

REFERENCE STANDARDS

The latest versions of the publications listed below form a part of

this specification; comply with provisions of these publications except

as otherwise shown or specified.

1. American Concrete Institute: ACI 117 - standard specification

for Tolerances for Concrete

2. American Institute of Steel Construction: Code of Standard

Practice for Steel Buildings and Bridges

SUBMITTALS

General Contractor's Methods Description Narrative detailing the plan

for surveying and monitoring of the structure during construction.

1, Narrative shall address all of the items described in Article 1.5

of this Section.

2. Narrative shall be submitted before steel or concre

preconstruction meeting and at least two weeks prior to the

beginning of fabrication of the primary structural frame.

3321.00 01 71 00 - 4 2017-01-25

ONE FILINVEST CONSTRUCTION TOLERANCE

ORTIGAS, MANILA, PHILIPPINES SECTION 01 71 00

1.5 “CONSTRUCTION TOLERANCE REQUIREMENTS

The General Contractor is responsible for constructing the building

within tolerance. The tolerance of the structural frame ‘shall be in

accordance with the following industry standards, except where more

stringent. requirements are specifically noted in this section:

1. american Concrete Institute: ACI 117 ~ Standard Specification

for Tolerances for Conerete

2. American Institute 6f Steel Construction: Code of Standard

Practice for Steel Buildings and Bridges

B. Methods Description Narrative: The General Contractor shall prepare a

Methods bescription Narrative that shall addzess the following topics:

1, Survey procedures to moniter column and core wall shortening

a, The splice elevations of the steel columns shall be

surveyed at every tier. The steel columns shall be

fabricated 1/16 inches over-length per floor to account for

expected shortening unlese directed otherwise by the

Structural Engineer, This amount is based on experience

with similar sized projects and may be further refined once

the General Contractor has created a construction schedule.

Refer to Structural General Notes

Concrete columns shall be placed to the reference

elevations at each level tinless otherwise noted in the

structural drawings. Concrete columns shall be surveyed

every four floors.

c. The core wall elevations shall be surveyed at each wall

intersection every eight floors. The core walls shall be

placed to the reference elevation at each level unless

noted otherwise in the structural drawings.

All survey data shall be submitted within 24 hours. The

data will be reviewed by the Architect and Structural

Engineer.” Recommendations for corrective measures will. be

provided where appropriate. the contractor shall

immediately employ corrective measures or provide alternate

suggestions for corrective measures. Contractor shall

include the cost of any corrective measures in the base

bid.

2. Survey procedures to monitor the drift and alignneat of the

structural frame.

3. Survey procedures to monitor deflection of composite fleors. the

General Contractor shall survey the deflection of the first

instance of each typical level at a minimum to moniter the

deflection of the floor. Survey elevations shall be taken of the

bottom flange of every beam and girder at each efid and at

quarter-points along the span. Survey shall be performed twice;

once after steel is erected and again within 24 hours after the

concrete slab is placed.

3321.00 01 71 00 - 2 2017-01-25

ONE FILINVEST CONSTRUCTION TOLERANCE

ORTIGAS, MANILA, PHILIPPINES SECTION 01 71 00

4, Survey procedures to monitor deflection of concrete floors. The

General Contractor’ shall survey the deflection of the first

instance of each typical level at a minimum to monitor the

deflection of the floor. Survey elevations shall be taken at

approximately 12 locations on these floors. survey shall be

performed of the top of formwork elevations prior to concrete

placement, and of the top of slab elevations within 24 hours

after the fornwork is removed. Locations shall be mutually

agreed upon by the Contractor and the Structural Engineer.

5. Shop fabrication methedology for adjustment of column length to

account for column shortening, if necessary.

6. Executive sunmary of steel erection and fabrication quality

control plans as related to construction tolerance

7. Executive summary of concrete column and core wall quality

control plan as related to construction tolerance and

expected/historical concrete mix shrinkage properties. for the

mixes proposed to be used. The Contractor shall also coordinate

' with any required concrete mix shrinkage properties that are

indicated on the drawings or in the specifications.

8. Description of fabrication and installation procedures for steel

deck edge forms.

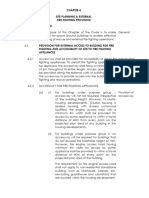

¢. Vertical Alignment.’ The following tolerance limits shall apply to all

vertical members such as walls and columns.

1.’ Pigure 1 illustrates the tolerance for vertical alignment of

columns and walls.

2. For vertical elements next to elevator openings: In addition to

the tolerance limits shown in Figure. 1, the reduction in the

clear elevator hoistway dimension shall be limited to 2 inches

total. See Figure 2,

D. Horizontal Alignment. The following tolerance Limits shall apply to

horizontal alignment (i.e., plan location) of horizontal elements of

the structural frane such as elab edges, beams, and girders.

1. ‘The variation in the horizontal alignment of thé work points of a

steel beam shall be acceptable if caused solely by variations in

steel Columa or concrete core wall alignment that are within the

Limits of Paragraph 1.5C, See Figure 3 - section at Slab Edge.

2. Edge forms for composite slabs shall be field installed to 2

tolerance of +/- 1 inch from the established building work lines.

See Figure 3 - Section at Slab Edce

3. Slab edge position tolerance of formed concrete slabs shall be in

accordance with ACI 117.

4. The maximum offset in slab edge location between adjacent floors

shall be 4/- 3/8 inches. See Figure 3 - offset Between Floors

B, Steel Elements Embedded in Concrete. The following tolerance limits

shall apply to the placement of steel elements of the structure

‘embedded into concrete

3321.00 01 71 00 - 3 2017-01-25

ONE FILINVEST CONSTRUCTION TOLERANCE

ORTIGAS, MANILA, PHILIPPINES SECTION 01 71 00

Weld plates or angles embedded into the concrete may be oversized

at contractor's option. Placement tolerance of embedded items

shall be of +/- 1 inch for both vertical and horizontal

alignment.

2, In-and-out tolerance for enbedded plates shall be 1/8 inch out of

the concrete and 1/4 inch into the concrete (recess)

F, Steel Framing supporting Precast Seating Risere/fascia:

1. | Fabricated Precast Support Seats shall be installed on raker

beams within 1/8" in plan location and elevation.

2. Maximum permissible fabrication tolerances in raker heam and.

truss framing are as follows:

a. . Bean/truss Height: +/- 1/8”

b. Camber: _+1/2" and -0" from specified canber

3. Maximum permissible erection tolerances for elevation in raker

beam and truss framing are +3/16” and -5/16”.

G. Teusse:

1. Permissible variation of length of fabricated portion of trusses

between supports shall not exceed +/-1/8”

2. Permissible variation of height of fabricated trusses shall not

exceed +/-1/8".

3, Camber: Permissible variation shall not exceed +1/2" or -0” from

specified camber.

4. Sweep for fabricated portions of trusses between supports,

measured relative to a straight line between supports, shall not

exceed 0.10 percent of the truss length. Sweep for fabricated

cantilevered sections of trusses, measured relative to a straight

Line between the support and the tip of the cantilever, shall not

exceed 0.10 percent of the length of the cantilever.

5. Straightness: Permissible variation not to exceed 0.20 percent

of the length

6. Twist of fabricated portions shall not exceed 0.10 degrees in 40

feet.

H, Cross-Sectional Dimensions of Concrete Elements. The following

tolerance limits shall apply to the thickness of concrete elements such

a5 walls, beams, and slabs.

1

3321.00

‘The tolerance for slab thickness, including thickness of concrete

on steel deck, shall be +3/8 inches and -1/4 inches

‘The tolerance for cross-sectional dimension of concrete walle and

beans shall be +1/2 inches and -3/8 inches.

01 71 00 - 4 2017-01-25

ONE FILINVEST CONSTRUCTION TOLERANCE

ORTIGAS, MANILA, PHILIPPINES SECTION 01 71 00

PART 2 ~ PRODUCTS - NOT APPLICABLE

PART 3 - EXECUTION - NOT APPLICAB!

END OF SECTION

3321.00 01 71 00-5 2017-01-25

ONE FILINVEST CONSTRUCTION TOLERANCE

ORTIGAS, MANILA, PHILTPPINES SECTION 01 71 00

2° MAX 2" MAX

KA LOCATION OF CONCRETE

j-——__ WALL OR STEELICONCRETE

AA) ~~ COLUMN AS SHOWN ON

" FRAMING PLAN

1" MAK

SLOPE NOT TO

EXCEED 1:500 |

HEIGHT = 100 FEET OR LESS

1/4" MAX 114" MAX

VERTICAL ALIGNMENT

Figure 1: Vertical Alignment of Columns and Walls

3321.00 01 71 00 - 6 2017-01-25

ONE FILINVEST CONSTRUCTION TOLERANCE

ORTIGAS, MANILA, PHILIPPINES SECTION 01 71 00

Ay

4 LOCATION OF VERTICAL

LEMENT THAT DEFINES

ae | eo EDGE OF ELEVATOR

HOISTWAY

TOLERANCE LIMIT FOR DRIFT

TOWARD HOISTWAY OF ADJACENT:

VERTICAL ELEMENTS TOWARD

<¥ HOISTWAY SHALL BE 1” OVER

THE RUN OF THE ELEVATOR ON

EACH SIDE, 2” TOTAL

ELEVATOR

HOISTWAY

VERTICAL ALIGNMENT

Figure 2: Vertical Elements at Elevator openings

3321.00 0171 00-7 2017-01-25

ONE FILINVEST CONSTRUCTION TOLERANCE

ORTIGAS, MANILA, PHILIPPINES SECTION 01 71 00

| !

| | VARIATION IN ALIGNMENT

SHALL BE ACCEPTABLE

IF CAUSED SOLELY BY

[1 VARIATIONS IN COLUMN

i 1” OR WALL ALIGNMENT

| THAT ARE WITHIN LIMITS:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chapter 2Document2 pagesChapter 2Bernard ReynosoNo ratings yet

- Chap 2Document56 pagesChap 2Bernard ReynosoNo ratings yet

- Application For Acceptance of Household/Storey Shelter Architectural PlansDocument2 pagesApplication For Acceptance of Household/Storey Shelter Architectural PlansBernard ReynosoNo ratings yet

- Chap 5Document4 pagesChap 5Bernard ReynosoNo ratings yet

- GFA CircularsDocument1 pageGFA CircularsBernard ReynosoNo ratings yet

- Case Study 1Document9 pagesCase Study 1Bernard ReynosoNo ratings yet

- Project BrochureDocument22 pagesProject BrochureBernard ReynosoNo ratings yet

- Chap 1Document41 pagesChap 1Bernard ReynosoNo ratings yet

- Chap 4Document13 pagesChap 4Bernard ReynosoNo ratings yet

- Appendix GDocument2 pagesAppendix GBernard ReynosoNo ratings yet

- The Wonders For Future Dubai.Document47 pagesThe Wonders For Future Dubai.Bernard ReynosoNo ratings yet

- Appendix IDocument13 pagesAppendix IBernard ReynosoNo ratings yet

- Beca M & E Plantroom SizeDocument3 pagesBeca M & E Plantroom SizeBernard ReynosoNo ratings yet

- Dawson Estate 20081029Document51 pagesDawson Estate 20081029Bernard ReynosoNo ratings yet

- Appendix CDocument5 pagesAppendix CBernard ReynosoNo ratings yet

- Appendix ADocument8 pagesAppendix ABernard ReynosoNo ratings yet

- Revise of DA FeesDocument7 pagesRevise of DA FeesBernard ReynosoNo ratings yet

- HDB Estate - ISODocument33 pagesHDB Estate - ISOBernard ReynosoNo ratings yet

- Chapter 2 MUNTINLUPA OKDocument7 pagesChapter 2 MUNTINLUPA OKBernard ReynosoNo ratings yet

- Revise Balconies GuidelineDocument9 pagesRevise Balconies GuidelineBernard ReynosoNo ratings yet

- JPT Lecture Prof Prac UAP DOCSDocument5 pagesJPT Lecture Prof Prac UAP DOCSBernard ReynosoNo ratings yet

- FP-2 - BF Sprinkler LayoutDocument1 pageFP-2 - BF Sprinkler LayoutBernard ReynosoNo ratings yet

- A-2.0r Revised Basement Floor Plan-SignedDocument1 pageA-2.0r Revised Basement Floor Plan-SignedBernard ReynosoNo ratings yet

- FP-5 - 3F Sprinkler LayoutDocument1 pageFP-5 - 3F Sprinkler LayoutBernard ReynosoNo ratings yet

- A-2.0r Revised Basement Floor PlanDocument1 pageA-2.0r Revised Basement Floor PlanBernard ReynosoNo ratings yet

- Partial Section C at Stair No.2 - Ground Floor LevelDocument1 pagePartial Section C at Stair No.2 - Ground Floor LevelBernard ReynosoNo ratings yet

- Chapter 1 Muntilupa OkDocument61 pagesChapter 1 Muntilupa OkBernard ReynosoNo ratings yet

- 4 of 8 Concrete Forming and AccessoriesDocument7 pages4 of 8 Concrete Forming and AccessoriesBernard ReynosoNo ratings yet

- 2 of 8 Structural Testing, Inspection and Quality AssuranceDocument14 pages2 of 8 Structural Testing, Inspection and Quality AssuranceBernard ReynosoNo ratings yet

- 1 of 8 G.E. Origenes General SpecsDocument7 pages1 of 8 G.E. Origenes General SpecsBernard ReynosoNo ratings yet