Professional Documents

Culture Documents

PTO Control SheetV1

PTO Control SheetV1

Uploaded by

salomonbeleckCopyright:

Available Formats

You might also like

- SITXWHS001 SAB v3.0 PDFDocument49 pagesSITXWHS001 SAB v3.0 PDFgokarna shrestha50% (2)

- Hamza Muhammad - 00704965 - 1535-Qanmos College - IG1Document9 pagesHamza Muhammad - 00704965 - 1535-Qanmos College - IG1Rashid Jamil100% (2)

- Successful Instrumentation and Control Systems Design, Second EditionFrom EverandSuccessful Instrumentation and Control Systems Design, Second EditionRating: 4.5 out of 5 stars4.5/5 (10)

- Menon P Ravikeerthi 00761732 Tciq ProjectDocument19 pagesMenon P Ravikeerthi 00761732 Tciq ProjectNikhil Nixon100% (7)

- Risk Assesment of Workplace.Document17 pagesRisk Assesment of Workplace.Sufyan SufyanNo ratings yet

- Sufyan Muhammad, 00571515, Industrial Safety and Technical Training Institute (PVT) Ltd. (Istti), 1320Document9 pagesSufyan Muhammad, 00571515, Industrial Safety and Technical Training Institute (PVT) Ltd. (Istti), 1320Muhammad sufyan Muhammad sufyan100% (1)

- Planned Job Observations.Document3 pagesPlanned Job Observations.Tukachungurwa Byarugaba Alex67% (3)

- Swms-Fencing Work Revised-1Document10 pagesSwms-Fencing Work Revised-1JanakiramanNo ratings yet

- CHED Memorandum Order CMO Guidelines For Student Internship Abroad Program SIAP PDFDocument9 pagesCHED Memorandum Order CMO Guidelines For Student Internship Abroad Program SIAP PDFArnel Moreno Yurfo100% (1)

- PTO Control SheetDocument5 pagesPTO Control SheetsalomonbeleckNo ratings yet

- Time On This Job Notification Reason For Observation: 1. Suggested RemediesDocument1 pageTime On This Job Notification Reason For Observation: 1. Suggested Remediesgrant50% (4)

- 17.06 Planned Task ObservationsDocument1 page17.06 Planned Task Observationsgrant100% (1)

- SupervisorDocument2 pagesSupervisorgrantNo ratings yet

- PTO - Shuttering and de Shuttering Rev 2Document2 pagesPTO - Shuttering and de Shuttering Rev 2grantNo ratings yet

- PTO Project - Fire Line Pipe Fabrication at Magazine 10Document3 pagesPTO Project - Fire Line Pipe Fabrication at Magazine 10John NainggolanNo ratings yet

- Day 3 Job Hazard Analysis (Handout)Document6 pagesDay 3 Job Hazard Analysis (Handout)mike camsNo ratings yet

- PTO Project - Reposisi HDPE Di TSF Cell 2 Doc - Rev1Document3 pagesPTO Project - Reposisi HDPE Di TSF Cell 2 Doc - Rev1John NainggolanNo ratings yet

- B Report # EFI-MF-9-NP-2020Document3 pagesB Report # EFI-MF-9-NP-2020ghulamrasool726No ratings yet

- WSWP For Joint SealingDocument7 pagesWSWP For Joint SealingvictorNo ratings yet

- SheetingDocument2 pagesSheetinggrantNo ratings yet

- NEOM Pre Task Briefing Form - New FormatDocument2 pagesNEOM Pre Task Briefing Form - New FormatMohamed HafezNo ratings yet

- Operating Skill SawDocument2 pagesOperating Skill SawgrantNo ratings yet

- Operating Jig SawDocument2 pagesOperating Jig SawgrantNo ratings yet

- PTO - SteelfixingDocument2 pagesPTO - SteelfixinggrantNo ratings yet

- Assessment 2 Student Practical Demonstration of Tasks Job Card 1 AURETR131 V1Document11 pagesAssessment 2 Student Practical Demonstration of Tasks Job Card 1 AURETR131 V1bxdqsvr6wwNo ratings yet

- Control of Work ReviewDocument3 pagesControl of Work Reviewsidhanathsingh5No ratings yet

- PTO - Use of Hand ToolsDocument2 pagesPTO - Use of Hand ToolsgrantNo ratings yet

- NEBOSH International General Certificate in Occupational Health and SafetyDocument18 pagesNEBOSH International General Certificate in Occupational Health and SafetyAdnan ShaukatNo ratings yet

- 14 - Job Safety Analysis-loading and Offloading Materials装卸料Document5 pages14 - Job Safety Analysis-loading and Offloading Materials装卸料Jayvee Baradas Valdez100% (1)

- NEBOSH International General Certificate in Occupational Health and SafetyDocument28 pagesNEBOSH International General Certificate in Occupational Health and SafetyvenkateshNo ratings yet

- Safety Assessment in HM SymphonyDocument26 pagesSafety Assessment in HM Symphonyvilge rogesonNo ratings yet

- NEBOSH International General Certificate in Occupational Health and SafetyDocument18 pagesNEBOSH International General Certificate in Occupational Health and SafetyMayuresh MhatreNo ratings yet

- One Punggol - General Work Permit FormDocument3 pagesOne Punggol - General Work Permit FormSelvamNo ratings yet

- Hse-34 Staff Competency Assessment FormDocument3 pagesHse-34 Staff Competency Assessment Formqamer ashiqNo ratings yet

- Sample Igc3 ReportDocument25 pagesSample Igc3 Reportfarhanhussain852100% (1)

- RGP09006 - Workplace Observation (WPO) ProcedureDocument13 pagesRGP09006 - Workplace Observation (WPO) ProcedureMadhuNo ratings yet

- Safety OfficerDocument16 pagesSafety OfficerAzad pravesh khanNo ratings yet

- Gc3 - The Health and Assessor's Marking Sheet Safety Practical ApplicationDocument26 pagesGc3 - The Health and Assessor's Marking Sheet Safety Practical ApplicationpilakkadNo ratings yet

- Management - U0 3.2 - C04: Diploma in ME/EE/EP/EU/CH/PSDocument14 pagesManagement - U0 3.2 - C04: Diploma in ME/EE/EP/EU/CH/PSKunal AhiwaleNo ratings yet

- NEBOSH International General Certificate in Occupational Health and SafetyDocument20 pagesNEBOSH International General Certificate in Occupational Health and SafetysuleeshNo ratings yet

- PTO - BrickworkDocument2 pagesPTO - BrickworkgrantNo ratings yet

- Aea 1305 WC El MS 0002Document14 pagesAea 1305 WC El MS 0002Adil HasanovNo ratings yet

- NEBOSH International General Certificate - IGC3Document24 pagesNEBOSH International General Certificate - IGC3Ehsan MirzaNo ratings yet

- 1365 00824054 Ig2 06.03.24Document24 pages1365 00824054 Ig2 06.03.24kiranbabuambuNo ratings yet

- 101.08 Job Hazard AnalysisDocument5 pages101.08 Job Hazard AnalysisnihadNo ratings yet

- Nebosh GC3 ProjectDocument16 pagesNebosh GC3 ProjectNizar AhamedNo ratings yet

- Chandu Raveendran 00643493Document13 pagesChandu Raveendran 00643493rah uaeNo ratings yet

- NightDocument2 pagesNightnaalifeshow143No ratings yet

- GeneralDocument2 pagesGeneralnaalifeshow143No ratings yet

- Job Safety Analysis PSA-MailDocument50 pagesJob Safety Analysis PSA-MailechaNo ratings yet

- GC3 Report InspectionDocument23 pagesGC3 Report InspectionJigar PatelNo ratings yet

- MSA - March - 01Document7 pagesMSA - March - 01MUHAMMAD JUNAID PARACHANo ratings yet

- FMECG2SOP13 Rev3.04Document5 pagesFMECG2SOP13 Rev3.04deepaknaydu443No ratings yet

- SWMS 010 MLT Block Erection RKDocument28 pagesSWMS 010 MLT Block Erection RKrakeshkhanna78No ratings yet

- Anandhu M AVT Academy 1486Document17 pagesAnandhu M AVT Academy 1486anandmg41No ratings yet

- Power ToolDocument1 pagePower ToolR. Ayyanuperumal AyyanuperumalNo ratings yet

- Earthmoving ChecklistDocument8 pagesEarthmoving ChecklistramodNo ratings yet

- BP Permit-To-Work-Ptw-PolicyDocument22 pagesBP Permit-To-Work-Ptw-PolicyömerNo ratings yet

- PTO PaintingDocument2 pagesPTO Paintinggrant100% (1)

- Practical Project Management: Learning to Manage the Professional, Second EditionFrom EverandPractical Project Management: Learning to Manage the Professional, Second EditionRating: 2.5 out of 5 stars2.5/5 (2)

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- Material Safety Data Sheet: Chemical Name Class: Nonflammable Gas MixtureDocument4 pagesMaterial Safety Data Sheet: Chemical Name Class: Nonflammable Gas MixtureKaro toorNo ratings yet

- Risk Assessment Grandparents DayDocument5 pagesRisk Assessment Grandparents Dayapi-436147740No ratings yet

- MasterTile RSG 705 PART A Also MASTERTILE 550 BASE ONLYDocument12 pagesMasterTile RSG 705 PART A Also MASTERTILE 550 BASE ONLYSamseyla Hun0% (1)

- Baseline Risk Assessment: Phindile Kula (Project Coordinator)Document9 pagesBaseline Risk Assessment: Phindile Kula (Project Coordinator)EmilNo ratings yet

- Power2 340-H44: Operation ManualDocument166 pagesPower2 340-H44: Operation ManualDmitrii PustoshkinNo ratings yet

- Awareness Training Program ISO 45001: 2018Document99 pagesAwareness Training Program ISO 45001: 2018Nada HajriNo ratings yet

- Authorised Gas TestingDocument2 pagesAuthorised Gas Testingronachaif3191100% (1)

- Ncso Study GuideDocument38 pagesNcso Study GuideShubham SharmaNo ratings yet

- Health and Safety QuestionnaireDocument2 pagesHealth and Safety Questionnairesfo56830% (2)

- Decontamination Policy V8.0 December 2018Document52 pagesDecontamination Policy V8.0 December 2018Dave KlayNo ratings yet

- The Best - Deadly Poisons, Ingested or InhaledDocument1 pageThe Best - Deadly Poisons, Ingested or InhaledSyncOrSwim100% (1)

- Benzil PDFDocument5 pagesBenzil PDFAijaz NawazNo ratings yet

- Iso 45001:2018 Implementation: Ruth Wilkinson, BSC (Hons), MSC, Cmiosh Head of Health and SafetyDocument20 pagesIso 45001:2018 Implementation: Ruth Wilkinson, BSC (Hons), MSC, Cmiosh Head of Health and Safetyabdulrahman abduNo ratings yet

- Quinsyn Flex Us-SdsDocument10 pagesQuinsyn Flex Us-SdsMaria Guadalupe Cuellar RobledoNo ratings yet

- HSEPro Authorized Gas Tester TrainingDocument1 pageHSEPro Authorized Gas Tester TrainingAhmed BaderNo ratings yet

- Paraxylene Safety Data Sheet CPChemDocument14 pagesParaxylene Safety Data Sheet CPChemscribd405No ratings yet

- Simulated BusinessDocument20 pagesSimulated BusinessTatiana GMNo ratings yet

- Final TLE 7-8 Hairdressing Q1 M5 PDFDocument16 pagesFinal TLE 7-8 Hairdressing Q1 M5 PDFLorena Espedillon EscuadroNo ratings yet

- 10nkc 2012 20131Document8 pages10nkc 2012 20131trangngaNo ratings yet

- 1 Plan Training SessionDocument99 pages1 Plan Training Sessionjessalyn iladaNo ratings yet

- Tractor Transmission and Hydraulic Oil-GHS SDSDocument6 pagesTractor Transmission and Hydraulic Oil-GHS SDSRyan JX PakatangNo ratings yet

- WHS-LEG Ohsc p2Document34 pagesWHS-LEG Ohsc p2Leonardo RioNo ratings yet

- SDS Dodecane 2016 PDFDocument6 pagesSDS Dodecane 2016 PDFDireccion CalidadNo ratings yet

- Hse Poster PDFDocument4 pagesHse Poster PDFfani k3No ratings yet

- Neoprint Navy Blue LB ACDocument7 pagesNeoprint Navy Blue LB ACRosmerri Hj Md ZinNo ratings yet

- Jsa For Piping (FRP) WorkDocument10 pagesJsa For Piping (FRP) WorkYou1993100% (3)

- Unit IA1: Principles of Health and Safety ManagementDocument7 pagesUnit IA1: Principles of Health and Safety Managementw hiteNo ratings yet

- WedaBay EnvironmentalMonitoringPlan PDFDocument204 pagesWedaBay EnvironmentalMonitoringPlan PDFWahyu ArrNo ratings yet

PTO Control SheetV1

PTO Control SheetV1

Uploaded by

salomonbeleckOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTO Control SheetV1

PTO Control SheetV1

Uploaded by

salomonbeleckCopyright:

Available Formats

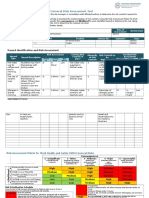

Loulo –Gounkoto Mine Complex

Z:\Health and Safety\Safety\OH&S MS-ISO 45001\21- Evaluation of Compliance\21_5 Planned Task Observations

Mine Site: Area:

Date: Time of Observation Start time: Finish time:

Employee’s Name: Observer’s Name:

Occupation: Occupation:

Time with Company Years: Months: Days: SOP reference number and Name:

Time in Present Position Years: Months: Days: Notification: Told in advance Not told in advance

Reason for Observation Experienced Worker Check Monthly Schedule Incapacitated Worker

Hazardous Task Incident Follow-up Substandard Performance

Training Follow Up Other (please specify)

Element 1: Observation only required

Sequence of Observation Compliance Comments Corrective Action Required

Steps of Procedure Yes No N/A

Ramming

The poles must first be distributed so that each one is positioned close to its marked

1. location. For correct alignment and to comply with the ramming tolerances, it is

recommended to install an N-S (North – South) and E-W (East – West) wire or to align

using laser equipment.

Predrilling and Ramming means due to hard soil ramming cannot be successful, the

2. drilling machine is use to drill with a drilling head diameter less than width of pole. The

drilling diameter can be found on the following table given in PVH Manual

3. The rectification and correction mean cutting, drilling, surface sanding, surface

cleaning, cutting area or impacted area galvanized. Proceed with cutting using a radial

grinder or similar, cut the pole to the designed length defined in assembly manual or

Health and Safety

Date created: 01/04/2013 Approved by: Dr. Mama Kanta Date of most recent review: 03

ONCE PRINTED, THIS DOCUMENT IS DEEMED “UNCONTROLLED COPY”

Loulo –Gounkoto Mine Complex

Z:\Health and Safety\Safety\OH&S MS-ISO 45001\21- Evaluation of Compliance\21_5 Planned Task Observations

site alignment

Surface sanding: after cutting, it must sand the surface to remove all minor possible

4.

rust areas Surface cleaning: It must be cleaned the area of oxide powder and rust

particles, as well as rest of dirt, mud and/or debris. It must use a soft brush, and a

cloth.

Galvanized repair: It must apply PVH “Galvanized repair procedure” to the areas

5.

damaged during the procedure of rectification or ramming

The post head assembly is installed on every support post of the jobsite. It is used to

6. cradle the bearing and allow rotation of the torque tube. Depending on the zone

defined in the project the following pieces must be used

Motor post is in the center of the row and in the powered row of the two linked rows of

the AxoneDuo tracker. Each foundation design is based on soil conditions, row width,

7.

and the model of PV module that is going to be installed. It is imperative for the safety

of the tracker that the motor base is installed, and

the motor attached to the torque tube prior to any modules being installed to the

AxoneDuo structure. The motor support installation is as follows:

TORQUE TUBES INSTALLATION

8.

After Post ramming, rectification and correction, post head installation and correction

the next step is to install the torque tubes following the types of trackers, layout

according to PVH assembly manual.

9.

10.

11.

12.

13.

Health and Safety Date created: 01/04/2013 Approved by: Dr. Mama Kanta Date of most recent review: 03

ONCE PRINTED, THIS DOCUMENT IS DEEMED “UNCONTROLLED COPY”

Loulo –Gounkoto Mine Complex

Z:\Health and Safety\Safety\OH&S MS-ISO 45001\21- Evaluation of Compliance\21_5 Planned Task Observations

14.

15.

Element 2: Interaction with the Observed person

Questions Answers Comments Corrective Action Required

1.

2.

3.

4.

5.

Element 3: Review

Could any of the practices or conditions observed result in Personal Injury or Property Damage? Yes No If Yes detail:

Were the methods and practices observed the most efficient and productive? Yes No If No detail:

Did the practices you observed comply with all of the applicable standards that exist for this

Yes No If No record corrective actions in Element 4:

task?

Can the worker be considered as competent to do assigned task as per existing safe work

Yes No If No record corrective actions in Element 4:

procedure?

Observer’s Comments:

Health and Safety Date created: 01/04/2013 Approved by: Dr. Mama Kanta Date of most recent review: 03

ONCE PRINTED, THIS DOCUMENT IS DEEMED “UNCONTROLLED COPY”

Loulo –Gounkoto Mine Complex

Z:\Health and Safety\Safety\OH&S MS-ISO 45001\21- Evaluation of Compliance\21_5 Planned Task Observations

Effectiveness

Element 4: Corrective Action Required By Whom Due Date Status

Yes or No

Employee Signature: Date: Observers Signature: Date:

Health and Safety Date created: 01/04/2013 Approved by: Dr. Mama Kanta Date of most recent review: 03

ONCE PRINTED, THIS DOCUMENT IS DEEMED “UNCONTROLLED COPY”

Loulo –Gounkoto Mine Complex

Z:\Health and Safety\Safety\OH&S MS-ISO 45001\21- Evaluation of Compliance\21_5 Planned Task Observations

Health and Safety Date created: 01/04/2013 Approved by: Dr. Mama Kanta Date of most recent review: 03

ONCE PRINTED, THIS DOCUMENT IS DEEMED “UNCONTROLLED COPY”

You might also like

- SITXWHS001 SAB v3.0 PDFDocument49 pagesSITXWHS001 SAB v3.0 PDFgokarna shrestha50% (2)

- Hamza Muhammad - 00704965 - 1535-Qanmos College - IG1Document9 pagesHamza Muhammad - 00704965 - 1535-Qanmos College - IG1Rashid Jamil100% (2)

- Successful Instrumentation and Control Systems Design, Second EditionFrom EverandSuccessful Instrumentation and Control Systems Design, Second EditionRating: 4.5 out of 5 stars4.5/5 (10)

- Menon P Ravikeerthi 00761732 Tciq ProjectDocument19 pagesMenon P Ravikeerthi 00761732 Tciq ProjectNikhil Nixon100% (7)

- Risk Assesment of Workplace.Document17 pagesRisk Assesment of Workplace.Sufyan SufyanNo ratings yet

- Sufyan Muhammad, 00571515, Industrial Safety and Technical Training Institute (PVT) Ltd. (Istti), 1320Document9 pagesSufyan Muhammad, 00571515, Industrial Safety and Technical Training Institute (PVT) Ltd. (Istti), 1320Muhammad sufyan Muhammad sufyan100% (1)

- Planned Job Observations.Document3 pagesPlanned Job Observations.Tukachungurwa Byarugaba Alex67% (3)

- Swms-Fencing Work Revised-1Document10 pagesSwms-Fencing Work Revised-1JanakiramanNo ratings yet

- CHED Memorandum Order CMO Guidelines For Student Internship Abroad Program SIAP PDFDocument9 pagesCHED Memorandum Order CMO Guidelines For Student Internship Abroad Program SIAP PDFArnel Moreno Yurfo100% (1)

- PTO Control SheetDocument5 pagesPTO Control SheetsalomonbeleckNo ratings yet

- Time On This Job Notification Reason For Observation: 1. Suggested RemediesDocument1 pageTime On This Job Notification Reason For Observation: 1. Suggested Remediesgrant50% (4)

- 17.06 Planned Task ObservationsDocument1 page17.06 Planned Task Observationsgrant100% (1)

- SupervisorDocument2 pagesSupervisorgrantNo ratings yet

- PTO - Shuttering and de Shuttering Rev 2Document2 pagesPTO - Shuttering and de Shuttering Rev 2grantNo ratings yet

- PTO Project - Fire Line Pipe Fabrication at Magazine 10Document3 pagesPTO Project - Fire Line Pipe Fabrication at Magazine 10John NainggolanNo ratings yet

- Day 3 Job Hazard Analysis (Handout)Document6 pagesDay 3 Job Hazard Analysis (Handout)mike camsNo ratings yet

- PTO Project - Reposisi HDPE Di TSF Cell 2 Doc - Rev1Document3 pagesPTO Project - Reposisi HDPE Di TSF Cell 2 Doc - Rev1John NainggolanNo ratings yet

- B Report # EFI-MF-9-NP-2020Document3 pagesB Report # EFI-MF-9-NP-2020ghulamrasool726No ratings yet

- WSWP For Joint SealingDocument7 pagesWSWP For Joint SealingvictorNo ratings yet

- SheetingDocument2 pagesSheetinggrantNo ratings yet

- NEOM Pre Task Briefing Form - New FormatDocument2 pagesNEOM Pre Task Briefing Form - New FormatMohamed HafezNo ratings yet

- Operating Skill SawDocument2 pagesOperating Skill SawgrantNo ratings yet

- Operating Jig SawDocument2 pagesOperating Jig SawgrantNo ratings yet

- PTO - SteelfixingDocument2 pagesPTO - SteelfixinggrantNo ratings yet

- Assessment 2 Student Practical Demonstration of Tasks Job Card 1 AURETR131 V1Document11 pagesAssessment 2 Student Practical Demonstration of Tasks Job Card 1 AURETR131 V1bxdqsvr6wwNo ratings yet

- Control of Work ReviewDocument3 pagesControl of Work Reviewsidhanathsingh5No ratings yet

- PTO - Use of Hand ToolsDocument2 pagesPTO - Use of Hand ToolsgrantNo ratings yet

- NEBOSH International General Certificate in Occupational Health and SafetyDocument18 pagesNEBOSH International General Certificate in Occupational Health and SafetyAdnan ShaukatNo ratings yet

- 14 - Job Safety Analysis-loading and Offloading Materials装卸料Document5 pages14 - Job Safety Analysis-loading and Offloading Materials装卸料Jayvee Baradas Valdez100% (1)

- NEBOSH International General Certificate in Occupational Health and SafetyDocument28 pagesNEBOSH International General Certificate in Occupational Health and SafetyvenkateshNo ratings yet

- Safety Assessment in HM SymphonyDocument26 pagesSafety Assessment in HM Symphonyvilge rogesonNo ratings yet

- NEBOSH International General Certificate in Occupational Health and SafetyDocument18 pagesNEBOSH International General Certificate in Occupational Health and SafetyMayuresh MhatreNo ratings yet

- One Punggol - General Work Permit FormDocument3 pagesOne Punggol - General Work Permit FormSelvamNo ratings yet

- Hse-34 Staff Competency Assessment FormDocument3 pagesHse-34 Staff Competency Assessment Formqamer ashiqNo ratings yet

- Sample Igc3 ReportDocument25 pagesSample Igc3 Reportfarhanhussain852100% (1)

- RGP09006 - Workplace Observation (WPO) ProcedureDocument13 pagesRGP09006 - Workplace Observation (WPO) ProcedureMadhuNo ratings yet

- Safety OfficerDocument16 pagesSafety OfficerAzad pravesh khanNo ratings yet

- Gc3 - The Health and Assessor's Marking Sheet Safety Practical ApplicationDocument26 pagesGc3 - The Health and Assessor's Marking Sheet Safety Practical ApplicationpilakkadNo ratings yet

- Management - U0 3.2 - C04: Diploma in ME/EE/EP/EU/CH/PSDocument14 pagesManagement - U0 3.2 - C04: Diploma in ME/EE/EP/EU/CH/PSKunal AhiwaleNo ratings yet

- NEBOSH International General Certificate in Occupational Health and SafetyDocument20 pagesNEBOSH International General Certificate in Occupational Health and SafetysuleeshNo ratings yet

- PTO - BrickworkDocument2 pagesPTO - BrickworkgrantNo ratings yet

- Aea 1305 WC El MS 0002Document14 pagesAea 1305 WC El MS 0002Adil HasanovNo ratings yet

- NEBOSH International General Certificate - IGC3Document24 pagesNEBOSH International General Certificate - IGC3Ehsan MirzaNo ratings yet

- 1365 00824054 Ig2 06.03.24Document24 pages1365 00824054 Ig2 06.03.24kiranbabuambuNo ratings yet

- 101.08 Job Hazard AnalysisDocument5 pages101.08 Job Hazard AnalysisnihadNo ratings yet

- Nebosh GC3 ProjectDocument16 pagesNebosh GC3 ProjectNizar AhamedNo ratings yet

- Chandu Raveendran 00643493Document13 pagesChandu Raveendran 00643493rah uaeNo ratings yet

- NightDocument2 pagesNightnaalifeshow143No ratings yet

- GeneralDocument2 pagesGeneralnaalifeshow143No ratings yet

- Job Safety Analysis PSA-MailDocument50 pagesJob Safety Analysis PSA-MailechaNo ratings yet

- GC3 Report InspectionDocument23 pagesGC3 Report InspectionJigar PatelNo ratings yet

- MSA - March - 01Document7 pagesMSA - March - 01MUHAMMAD JUNAID PARACHANo ratings yet

- FMECG2SOP13 Rev3.04Document5 pagesFMECG2SOP13 Rev3.04deepaknaydu443No ratings yet

- SWMS 010 MLT Block Erection RKDocument28 pagesSWMS 010 MLT Block Erection RKrakeshkhanna78No ratings yet

- Anandhu M AVT Academy 1486Document17 pagesAnandhu M AVT Academy 1486anandmg41No ratings yet

- Power ToolDocument1 pagePower ToolR. Ayyanuperumal AyyanuperumalNo ratings yet

- Earthmoving ChecklistDocument8 pagesEarthmoving ChecklistramodNo ratings yet

- BP Permit-To-Work-Ptw-PolicyDocument22 pagesBP Permit-To-Work-Ptw-PolicyömerNo ratings yet

- PTO PaintingDocument2 pagesPTO Paintinggrant100% (1)

- Practical Project Management: Learning to Manage the Professional, Second EditionFrom EverandPractical Project Management: Learning to Manage the Professional, Second EditionRating: 2.5 out of 5 stars2.5/5 (2)

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- Material Safety Data Sheet: Chemical Name Class: Nonflammable Gas MixtureDocument4 pagesMaterial Safety Data Sheet: Chemical Name Class: Nonflammable Gas MixtureKaro toorNo ratings yet

- Risk Assessment Grandparents DayDocument5 pagesRisk Assessment Grandparents Dayapi-436147740No ratings yet

- MasterTile RSG 705 PART A Also MASTERTILE 550 BASE ONLYDocument12 pagesMasterTile RSG 705 PART A Also MASTERTILE 550 BASE ONLYSamseyla Hun0% (1)

- Baseline Risk Assessment: Phindile Kula (Project Coordinator)Document9 pagesBaseline Risk Assessment: Phindile Kula (Project Coordinator)EmilNo ratings yet

- Power2 340-H44: Operation ManualDocument166 pagesPower2 340-H44: Operation ManualDmitrii PustoshkinNo ratings yet

- Awareness Training Program ISO 45001: 2018Document99 pagesAwareness Training Program ISO 45001: 2018Nada HajriNo ratings yet

- Authorised Gas TestingDocument2 pagesAuthorised Gas Testingronachaif3191100% (1)

- Ncso Study GuideDocument38 pagesNcso Study GuideShubham SharmaNo ratings yet

- Health and Safety QuestionnaireDocument2 pagesHealth and Safety Questionnairesfo56830% (2)

- Decontamination Policy V8.0 December 2018Document52 pagesDecontamination Policy V8.0 December 2018Dave KlayNo ratings yet

- The Best - Deadly Poisons, Ingested or InhaledDocument1 pageThe Best - Deadly Poisons, Ingested or InhaledSyncOrSwim100% (1)

- Benzil PDFDocument5 pagesBenzil PDFAijaz NawazNo ratings yet

- Iso 45001:2018 Implementation: Ruth Wilkinson, BSC (Hons), MSC, Cmiosh Head of Health and SafetyDocument20 pagesIso 45001:2018 Implementation: Ruth Wilkinson, BSC (Hons), MSC, Cmiosh Head of Health and Safetyabdulrahman abduNo ratings yet

- Quinsyn Flex Us-SdsDocument10 pagesQuinsyn Flex Us-SdsMaria Guadalupe Cuellar RobledoNo ratings yet

- HSEPro Authorized Gas Tester TrainingDocument1 pageHSEPro Authorized Gas Tester TrainingAhmed BaderNo ratings yet

- Paraxylene Safety Data Sheet CPChemDocument14 pagesParaxylene Safety Data Sheet CPChemscribd405No ratings yet

- Simulated BusinessDocument20 pagesSimulated BusinessTatiana GMNo ratings yet

- Final TLE 7-8 Hairdressing Q1 M5 PDFDocument16 pagesFinal TLE 7-8 Hairdressing Q1 M5 PDFLorena Espedillon EscuadroNo ratings yet

- 10nkc 2012 20131Document8 pages10nkc 2012 20131trangngaNo ratings yet

- 1 Plan Training SessionDocument99 pages1 Plan Training Sessionjessalyn iladaNo ratings yet

- Tractor Transmission and Hydraulic Oil-GHS SDSDocument6 pagesTractor Transmission and Hydraulic Oil-GHS SDSRyan JX PakatangNo ratings yet

- WHS-LEG Ohsc p2Document34 pagesWHS-LEG Ohsc p2Leonardo RioNo ratings yet

- SDS Dodecane 2016 PDFDocument6 pagesSDS Dodecane 2016 PDFDireccion CalidadNo ratings yet

- Hse Poster PDFDocument4 pagesHse Poster PDFfani k3No ratings yet

- Neoprint Navy Blue LB ACDocument7 pagesNeoprint Navy Blue LB ACRosmerri Hj Md ZinNo ratings yet

- Jsa For Piping (FRP) WorkDocument10 pagesJsa For Piping (FRP) WorkYou1993100% (3)

- Unit IA1: Principles of Health and Safety ManagementDocument7 pagesUnit IA1: Principles of Health and Safety Managementw hiteNo ratings yet

- WedaBay EnvironmentalMonitoringPlan PDFDocument204 pagesWedaBay EnvironmentalMonitoringPlan PDFWahyu ArrNo ratings yet