Professional Documents

Culture Documents

ACKNOWLEEDGEMENT

ACKNOWLEEDGEMENT

Uploaded by

Sridhar SriCopyright:

Available Formats

You might also like

- The Toyota Way, Second Edition: 14 Management Principles from the World's Greatest ManufacturerFrom EverandThe Toyota Way, Second Edition: 14 Management Principles from the World's Greatest ManufacturerRating: 4 out of 5 stars4/5 (103)

- FIRST 6.0: Flexographic Image Reproduction Specifications and TolerancesFrom EverandFIRST 6.0: Flexographic Image Reproduction Specifications and TolerancesNo ratings yet

- A Presentation On The Student Industrial Work Experience Scheme (Siwes) Undertaken at Armstrong Paints BY Ayodele Taiwo Ruth (CHM/2016/082)Document11 pagesA Presentation On The Student Industrial Work Experience Scheme (Siwes) Undertaken at Armstrong Paints BY Ayodele Taiwo Ruth (CHM/2016/082)Olushola Adebisi100% (2)

- CV59SH U32 Datasheet PDFDocument33 pagesCV59SH U32 Datasheet PDFlcd_vinay3480% (5)

- s4 Hana 1709 - EamDocument4 pagess4 Hana 1709 - EamrajeshNo ratings yet

- Konica Minolta Production Print Products For 2018Document22 pagesKonica Minolta Production Print Products For 201824x7first100% (1)

- pc4504-04 To Present Operation Parts and Service Manual 9-20-18Document153 pagespc4504-04 To Present Operation Parts and Service Manual 9-20-18Abdalla Mohammed SaeedNo ratings yet

- InternshipDocument60 pagesInternshipSanjay RayNo ratings yet

- Draft For Entrepre Assignment Final ReportDocument26 pagesDraft For Entrepre Assignment Final Reportvaraprasad333kvpNo ratings yet

- Company ProfileDocument6 pagesCompany ProfileFranklin Aleyamma JoseNo ratings yet

- Full ReportDocument20 pagesFull ReportSakshi Sidana100% (1)

- Operations Management XYZ Co. For Alkyd Resin Student # Module #Document40 pagesOperations Management XYZ Co. For Alkyd Resin Student # Module #mokbelNo ratings yet

- Dark Room ProcessDocument6 pagesDark Room ProcessllzjhcfrtdsNo ratings yet

- Induction Report PDFDocument38 pagesInduction Report PDFchetan bhatiaNo ratings yet

- Assignment On CSR ReportDocument28 pagesAssignment On CSR ReportRinkesh K MistryNo ratings yet

- Skin FlareDocument20 pagesSkin FlareDawood Yousaf M.YousafNo ratings yet

- Hindustan National LTD ProfileDocument14 pagesHindustan National LTD ProfilePranshuNo ratings yet

- Indian Rayon (Aditya Birla Nuvo)Document94 pagesIndian Rayon (Aditya Birla Nuvo)Chandresh ChavadaNo ratings yet

- CommerceDocument17 pagesCommerceKeira MariaNo ratings yet

- Production and Operation Management ReportDocument33 pagesProduction and Operation Management ReportSM0008100% (1)

- CCCCCCCCCCCCCCCCCCCCC C C CCCCCCCCCDocument14 pagesCCCCCCCCCCCCCCCCCCCCC C C CCCCCCCCCFazal Aleem KhanNo ratings yet

- Managerial EconomicsDocument13 pagesManagerial EconomicsAbhishek ModakNo ratings yet

- Asian PaintDocument34 pagesAsian PaintSantosh MirjeNo ratings yet

- Asian PaintsDocument47 pagesAsian Paintskhrn_himanshuNo ratings yet

- ACME Roy TempDocument30 pagesACME Roy TempPartha Sarathi RoyNo ratings yet

- Toaz - Info Roots Industries Report PRDocument31 pagesToaz - Info Roots Industries Report PR21BCO504 AbiramNo ratings yet

- Asian Paint PPT Presentation - PPTX Recovered)Document38 pagesAsian Paint PPT Presentation - PPTX Recovered)Akash SalveNo ratings yet

- "" Study On The Retailer of Cement Sheet of Everest Industries LTD"Document60 pages"" Study On The Retailer of Cement Sheet of Everest Industries LTD"Rohit AgarwalNo ratings yet

- Vikram Employee RetensionDocument61 pagesVikram Employee Retensionvishnu0751No ratings yet

- Service Industries LimitedDocument48 pagesService Industries Limitedmuhammadtaimoorkhan86% (7)

- Overall Marketing Activities of AFBLDocument30 pagesOverall Marketing Activities of AFBLNafis Hasan ShamitNo ratings yet

- History of Pidilite1Document13 pagesHistory of Pidilite1Shubhankar VaishNo ratings yet

- Dye Intermediates Manufacturers in India - Bodal ChemicalDocument2 pagesDye Intermediates Manufacturers in India - Bodal ChemicalbodalchemicalNo ratings yet

- Report Ibm 150Document12 pagesReport Ibm 150mohitNo ratings yet

- Role of Influencer & Dealers in Promoting Loyalty Program in Paint Industry A Study On Nerolac Paints, RanchiDocument64 pagesRole of Influencer & Dealers in Promoting Loyalty Program in Paint Industry A Study On Nerolac Paints, RanchiBibhuti Garnaik100% (1)

- Opti FloDocument11 pagesOpti FloAna QuintanaNo ratings yet

- Presented By:-Avinash V. More B.Tech. (Cosmetics) Guided By: - Prof. Dr. K. R. Biyani Sir M. Pharm., PH.D., D.P.P.MDocument19 pagesPresented By:-Avinash V. More B.Tech. (Cosmetics) Guided By: - Prof. Dr. K. R. Biyani Sir M. Pharm., PH.D., D.P.P.Mlab.kalibrasi BBPOM di SurabayaNo ratings yet

- RimalPatel 23 MBA BP AssignmentDocument11 pagesRimalPatel 23 MBA BP AssignmentKillol ShahNo ratings yet

- Stocks That Performing TodayDocument3 pagesStocks That Performing TodaySubham MazumdarNo ratings yet

- Multi Product Sulphonation PlantDocument3 pagesMulti Product Sulphonation PlantBhanu PathalaNo ratings yet

- 95-1176-01 HairCare Formulation GuideDocument24 pages95-1176-01 HairCare Formulation Guidetopguitar100% (1)

- Uniworth Textile Company MAIN PROJECTDocument36 pagesUniworth Textile Company MAIN PROJECTanki50% (2)

- TCP LimitedDocument3 pagesTCP LimitedAmit GargNo ratings yet

- (DARK ROOM PROCEDURE AND FILM PROCESSING) Forensic PhotographyDocument8 pages(DARK ROOM PROCEDURE AND FILM PROCESSING) Forensic PhotographyMardy Hoyohoy BarraquioNo ratings yet

- SWOT Analysis of Hindustan Unilever Ltd.Document21 pagesSWOT Analysis of Hindustan Unilever Ltd.Milan Kumar Pandey83% (12)

- 01 - Hair 101 - Shampoo Technology - Sept 2014 PDFDocument41 pages01 - Hair 101 - Shampoo Technology - Sept 2014 PDFOsamaAliMoussa100% (2)

- Operations Final ReportDocument12 pagesOperations Final ReportMustafa SethiNo ratings yet

- SIP ReportDocument24 pagesSIP Reportshubham21sssNo ratings yet

- Packages FinalDocument17 pagesPackages FinalAysha AhmedNo ratings yet

- Asian-Paints - Strategic ManagtDocument26 pagesAsian-Paints - Strategic Managtrahul_madhyaniNo ratings yet

- Clinpro Varnish TP EbuDocument8 pagesClinpro Varnish TP EbuКрасный НиндзяNo ratings yet

- Inventory Management in SRFDocument63 pagesInventory Management in SRFvishnu07510% (1)

- IT ReportDocument29 pagesIT ReportKingsley OgbavwuduNo ratings yet

- Profil EngDocument52 pagesProfil EngReza RhiNo ratings yet

- Overview of The CompanyDocument2 pagesOverview of The CompanyMohan ComputerNo ratings yet

- Fine Organic Industries LTD IPO Snapshot-201806191533423490461Document3 pagesFine Organic Industries LTD IPO Snapshot-201806191533423490461HDFC SecuritiesNo ratings yet

- Report of Ashapura Volclay LTDDocument33 pagesReport of Ashapura Volclay LTDNiraj Patel100% (2)

- Em A MiDocument20 pagesEm A MiPRAVEENRAMKRISHNANNo ratings yet

- Max Carporate ProfileDocument35 pagesMax Carporate ProfileSachin KothariNo ratings yet

- Wali Shah ThesisDocument45 pagesWali Shah ThesisSyed Wali ShahNo ratings yet

- The Definitive Guide to Journalism Media and Business AdministrationFrom EverandThe Definitive Guide to Journalism Media and Business AdministrationNo ratings yet

- A Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessNo ratings yet

- Formulas, Ingredients and Production of Cosmetics: Technology of Skin- and Hair-Care Products in JapanFrom EverandFormulas, Ingredients and Production of Cosmetics: Technology of Skin- and Hair-Care Products in JapanRating: 4 out of 5 stars4/5 (28)

- Underpinning Methods, Procedure and ApplicationsDocument10 pagesUnderpinning Methods, Procedure and ApplicationsAnonymous EPSHB9tXZNo ratings yet

- BE IT Syllabus Sem-III (BIT MESRA)Document3 pagesBE IT Syllabus Sem-III (BIT MESRA)Anudeex ShettyNo ratings yet

- Wheel Weight SizeDocument56 pagesWheel Weight SizeHerciu FlavianNo ratings yet

- CIV3703 Transport Engineering (USQ)Document34 pagesCIV3703 Transport Engineering (USQ)hao baiNo ratings yet

- NoteDocument264 pagesNoteBelayneh TadesseNo ratings yet

- 721007-620005-Computer Oriented Numerical MethodsDocument2 pages721007-620005-Computer Oriented Numerical MethodsTijo L PeterNo ratings yet

- Information Technology Services ControlsDocument12 pagesInformation Technology Services ControlsMohammed AliraqiNo ratings yet

- Porta Cabin Tech SpecDocument6 pagesPorta Cabin Tech SpecFARES BEN MESSAOUDNo ratings yet

- Informe DialuxDocument134 pagesInforme DialuxSFERNo ratings yet

- JSA ScaffoldingDocument10 pagesJSA ScaffoldingLo Roque100% (1)

- Stiffness ModifiersDocument5 pagesStiffness ModifiersA MumtazNo ratings yet

- Soal QafcoDocument3 pagesSoal QafcoRatu CeliaNo ratings yet

- Cicret BraceletDocument41 pagesCicret BraceletramrajNo ratings yet

- Artigo - Thermodynamics of Fluid-Phase Equilibria For Standard Chemical Engineering OperationsDocument24 pagesArtigo - Thermodynamics of Fluid-Phase Equilibria For Standard Chemical Engineering OperationsJoseCastilhoNo ratings yet

- Curriculum Vitae: PersonalDocument10 pagesCurriculum Vitae: PersonalAzhariArdyNo ratings yet

- Amoore - Life Beyond Big Data Governing With Little AnalyticsDocument27 pagesAmoore - Life Beyond Big Data Governing With Little Analyticsanton.de.rotaNo ratings yet

- Is:4926 RMCDocument21 pagesIs:4926 RMCRamesh100% (7)

- Aggregates DiscussionDocument90 pagesAggregates DiscussionJames PleñosNo ratings yet

- ANA Sales Enablement Plan PlaybookDocument39 pagesANA Sales Enablement Plan PlaybookDemand Metric100% (1)

- Ripex App SNMP enDocument64 pagesRipex App SNMP enhadiNo ratings yet

- Gin 2904Document12 pagesGin 2904Sen HuNo ratings yet

- Laboratory Manual 4: Discrete Time Fourier Transform & Discrete Fourier TransformDocument10 pagesLaboratory Manual 4: Discrete Time Fourier Transform & Discrete Fourier TransformHassanNo ratings yet

- ASTM D1119 - 00 - Percent Ash Content of Engine Coolants and AntirustsDocument2 pagesASTM D1119 - 00 - Percent Ash Content of Engine Coolants and Antirustsphamthuyha100% (2)

- Design and Fabrication of Screw Conveyor Report DownloadDocument3 pagesDesign and Fabrication of Screw Conveyor Report Downloadyohannes wendwesenNo ratings yet

- Lavallee & Ide - CatalogDocument36 pagesLavallee & Ide - CatalogCorey.DeGrandchamp6079No ratings yet

- Jackson 11.14 Homework Problem SolutionDocument4 pagesJackson 11.14 Homework Problem SolutionPero PericNo ratings yet

ACKNOWLEEDGEMENT

ACKNOWLEEDGEMENT

Uploaded by

Sridhar SriOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACKNOWLEEDGEMENT

ACKNOWLEEDGEMENT

Uploaded by

Sridhar SriCopyright:

Available Formats

ACKNOWLEEDGEMENT

We would like take this opportunity to express our heartfelt and profound thanks to Mr. Prudvi Raj, Hr Executive, Hindustan Photo Films Ltd for providing us with all the information about the company which is helpful for us to do the mini project. We would also like to extend our sincere gratitude to the management of Hindustan Photo Films Ltd for giving us permission to visit the company. A special thanks to Mr. Abdul Azeem, Assistant Professor, Department of Management Studies, MIC College of Technology, for accompanying us in visiting the company.

HINDUSTAN PHOTO FILMS LTD.

INTRODUCTION: Hindustan Photo Films Manufacturing Company Limited (HPF) is a Public Sector Undertaking, under the Department of Heavy Industry, incorporated in the year 1960, with a vision to make India self reliant in the field of photo sensitized goods. Hindustan Photo Films Manufacturing Company Limited engages in the manufacture and sale of photo sensitized goods in Southeast Asia. The company offers X-ray, cinematographic, and photographic films. Its products include medical diagnostic films, such as medical X-ray, medical imaging films, mammographic films, and scanner films. The company also provides industrial X-ray films, graphic arts films for the printing sector, bromide paper and roll films for the photographic sector, aerial film for the defense sector, and inkjet papers for the digital market. It offers its products under the brand name INDU. The company was incorporated in 1960 and is head quartered in Ootacamund, India. HPF is the only integrated manufacturer of photo sensitized goods in the whole of South East Asia. It is the only company with the technology for manufacture of medical X-ray, Graphic Arts and Black and White products of international standards. Hindustan Photo Films Manufacturing Company Limited (HPF) manufactures and markets its fleet of products under the brand name INDU, which means Silver. Mission: To become a major Player in the manufacture & marketing of photographic products in the country. Financial Details: Authorized share Capital: Rs. 210 Crore. Paid up share Capital: Rs. 205.87 Crore.

Listing with Stock Exchanges: Bombay Stock Exchange

Employee Details of HPF: Officers 90 Supervisors - 238 Workmen - 408 Total 736

Management Team of HPF: CEO Engineering / Production Research & Development HRD Finance Purchase Public Relations Marketing Quality Control &Assurance Company Secretary Shri.A.Gnanasekaran Shri. K.Selvaraj Dr.Palaniswamy Shri.E.Rajavelu Shri.S.B.Ravindra Smt.Saideepa Devesan Dr.Palaniswamy Shri.A.B.Kumar Shri.B.B.Choudhary Miss.M.Gita

Manufacturing Process Photographic film technically is a combination of silver halide emulsion and a flexible support. A normal photographic film consists of four layers. The top layer or super coat of gelatin protects the emulsion from scratches and abrasion marks. The next layer is the emulsion layer, silver halide suspended in gelatin. The third layer is the subbing layer which promotes the adhesion of the emulsion to the film base. There is the support, backed by anticurling layer of gelatin containing a light absorbing dye to prevent halation in the back.

The overall manufacturing process of photographic film consists of preparation of the emulsion of silver nitrate, alkyl halide and gelatin, precipitation of the emulsion, washing, chemical and spectral sensitization and finally coating on to a support. The emulsion is prepared by mixing silver nitrate in an alkaline silver bromide solution in the presence of a solution of gelatin. Double decomposition takes place and silver bromide which is insoluble, is precipitated. The silver bromide remains uniformly distributed throughout the gelatin. After the initial precipitation, the emulsion undergoes several after processes. The first is ripening, which involves maintaining the emulsion at an elevated temperature for several hours, wherein the larger halide crystals grow at the cost of the smaller ones. After ripening, the emulsion is chilled to set it and is then passed through a perforated stainless steel plate to shred it. It is then washed to remove undesirable soluble compounds, particularly excess bromide and nitrates. A further heat treatment, known as after-ripening is given and it is at this stage that the sensitivity specks of silver sulphide are formed.

IMPORTED POLYSTER BASE

COATING

EMULSION

CONVERSION

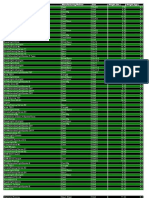

THE MANUFACTURING PROCESS OF HPF

Before coating the emulsion on the support, it is doctored by the additions of substances to improve its physical and sensitometric properties. These substances include the very small amounts of sensitizing dyes necessary to give orthochromatic or panchromatic activity. As important as the composition of the emulsion is its coating on to a base. The base is prepared by dissolving cellulose triacetate in a mixture of methylene chloride and alcohol, casting on a large heated chromium-faced drum which rotates, allowing the solvent to evaporate. The film becomes firm enough to be stripped off in a continuous sheet. The base is then passed through a series of heated chambers to remove the remaining solvent. The base is then wound into rolls. Another process of preparation of the base is melt extrusion of the polyester, polyethylene terephthalate through a slit dye and orientation of the film biaxially to improve the physical properties. The emulsion is coated on the base at a temperature high enough to keep the gelatin as a solution. The material is then chilled to set the gelatin and it then passes through a drying track where clean air at carefully controlled temperature and humidity remove virtually all of the large amounts of water contained in the gel. The conventional black and white photographic film consists of coating of emulsion on one side. The X-ray films are coated on both sides. Color films consist of simultaneous coating of several layers on one side. 4 PS OF MARKETING MIX: Product: The Hindustan Photo Film Manufacturing Co offers green sensitive medical x-ray film. This is a medium speed, high contrast, ortho sensitive film designed for use in all radiographic examination.

New Products: A new product Red Laser Scanner Film was launched recently. The following products were commercialized - Industrial x-ray with further low coating weight - Medical x-ray (Blue) on a large scale with low coating weight. Following products will soon be commercialized. - Graphic Arts Red Laser Scanner Film/Image Setter Film - Inkjet Paper - Polyester Subbed Base - Digital X-ray Film - Medical Imaging Film (Panchromatic) - Laser Printer Film Promotion: The promotional strategies used by HPF are as follows: Public Relations and Publicity: -Advertisement Polices/ Guide lines -Marketing and sales -Marketing Manual -Sales Manual.

Competitors of HPF: Company M/s Eastman Kodak CO. M /s Fuji Photo film Co. M/s Konica Corpn. M/s Mitsubishi M/s Agfa Gevaert. AG M/s 3 M M/s Polaroid Corporation Country USA Japan Japan Japan Germany Italy USA

You might also like

- The Toyota Way, Second Edition: 14 Management Principles from the World's Greatest ManufacturerFrom EverandThe Toyota Way, Second Edition: 14 Management Principles from the World's Greatest ManufacturerRating: 4 out of 5 stars4/5 (103)

- FIRST 6.0: Flexographic Image Reproduction Specifications and TolerancesFrom EverandFIRST 6.0: Flexographic Image Reproduction Specifications and TolerancesNo ratings yet

- A Presentation On The Student Industrial Work Experience Scheme (Siwes) Undertaken at Armstrong Paints BY Ayodele Taiwo Ruth (CHM/2016/082)Document11 pagesA Presentation On The Student Industrial Work Experience Scheme (Siwes) Undertaken at Armstrong Paints BY Ayodele Taiwo Ruth (CHM/2016/082)Olushola Adebisi100% (2)

- CV59SH U32 Datasheet PDFDocument33 pagesCV59SH U32 Datasheet PDFlcd_vinay3480% (5)

- s4 Hana 1709 - EamDocument4 pagess4 Hana 1709 - EamrajeshNo ratings yet

- Konica Minolta Production Print Products For 2018Document22 pagesKonica Minolta Production Print Products For 201824x7first100% (1)

- pc4504-04 To Present Operation Parts and Service Manual 9-20-18Document153 pagespc4504-04 To Present Operation Parts and Service Manual 9-20-18Abdalla Mohammed SaeedNo ratings yet

- InternshipDocument60 pagesInternshipSanjay RayNo ratings yet

- Draft For Entrepre Assignment Final ReportDocument26 pagesDraft For Entrepre Assignment Final Reportvaraprasad333kvpNo ratings yet

- Company ProfileDocument6 pagesCompany ProfileFranklin Aleyamma JoseNo ratings yet

- Full ReportDocument20 pagesFull ReportSakshi Sidana100% (1)

- Operations Management XYZ Co. For Alkyd Resin Student # Module #Document40 pagesOperations Management XYZ Co. For Alkyd Resin Student # Module #mokbelNo ratings yet

- Dark Room ProcessDocument6 pagesDark Room ProcessllzjhcfrtdsNo ratings yet

- Induction Report PDFDocument38 pagesInduction Report PDFchetan bhatiaNo ratings yet

- Assignment On CSR ReportDocument28 pagesAssignment On CSR ReportRinkesh K MistryNo ratings yet

- Skin FlareDocument20 pagesSkin FlareDawood Yousaf M.YousafNo ratings yet

- Hindustan National LTD ProfileDocument14 pagesHindustan National LTD ProfilePranshuNo ratings yet

- Indian Rayon (Aditya Birla Nuvo)Document94 pagesIndian Rayon (Aditya Birla Nuvo)Chandresh ChavadaNo ratings yet

- CommerceDocument17 pagesCommerceKeira MariaNo ratings yet

- Production and Operation Management ReportDocument33 pagesProduction and Operation Management ReportSM0008100% (1)

- CCCCCCCCCCCCCCCCCCCCC C C CCCCCCCCCDocument14 pagesCCCCCCCCCCCCCCCCCCCCC C C CCCCCCCCCFazal Aleem KhanNo ratings yet

- Managerial EconomicsDocument13 pagesManagerial EconomicsAbhishek ModakNo ratings yet

- Asian PaintDocument34 pagesAsian PaintSantosh MirjeNo ratings yet

- Asian PaintsDocument47 pagesAsian Paintskhrn_himanshuNo ratings yet

- ACME Roy TempDocument30 pagesACME Roy TempPartha Sarathi RoyNo ratings yet

- Toaz - Info Roots Industries Report PRDocument31 pagesToaz - Info Roots Industries Report PR21BCO504 AbiramNo ratings yet

- Asian Paint PPT Presentation - PPTX Recovered)Document38 pagesAsian Paint PPT Presentation - PPTX Recovered)Akash SalveNo ratings yet

- "" Study On The Retailer of Cement Sheet of Everest Industries LTD"Document60 pages"" Study On The Retailer of Cement Sheet of Everest Industries LTD"Rohit AgarwalNo ratings yet

- Vikram Employee RetensionDocument61 pagesVikram Employee Retensionvishnu0751No ratings yet

- Service Industries LimitedDocument48 pagesService Industries Limitedmuhammadtaimoorkhan86% (7)

- Overall Marketing Activities of AFBLDocument30 pagesOverall Marketing Activities of AFBLNafis Hasan ShamitNo ratings yet

- History of Pidilite1Document13 pagesHistory of Pidilite1Shubhankar VaishNo ratings yet

- Dye Intermediates Manufacturers in India - Bodal ChemicalDocument2 pagesDye Intermediates Manufacturers in India - Bodal ChemicalbodalchemicalNo ratings yet

- Report Ibm 150Document12 pagesReport Ibm 150mohitNo ratings yet

- Role of Influencer & Dealers in Promoting Loyalty Program in Paint Industry A Study On Nerolac Paints, RanchiDocument64 pagesRole of Influencer & Dealers in Promoting Loyalty Program in Paint Industry A Study On Nerolac Paints, RanchiBibhuti Garnaik100% (1)

- Opti FloDocument11 pagesOpti FloAna QuintanaNo ratings yet

- Presented By:-Avinash V. More B.Tech. (Cosmetics) Guided By: - Prof. Dr. K. R. Biyani Sir M. Pharm., PH.D., D.P.P.MDocument19 pagesPresented By:-Avinash V. More B.Tech. (Cosmetics) Guided By: - Prof. Dr. K. R. Biyani Sir M. Pharm., PH.D., D.P.P.Mlab.kalibrasi BBPOM di SurabayaNo ratings yet

- RimalPatel 23 MBA BP AssignmentDocument11 pagesRimalPatel 23 MBA BP AssignmentKillol ShahNo ratings yet

- Stocks That Performing TodayDocument3 pagesStocks That Performing TodaySubham MazumdarNo ratings yet

- Multi Product Sulphonation PlantDocument3 pagesMulti Product Sulphonation PlantBhanu PathalaNo ratings yet

- 95-1176-01 HairCare Formulation GuideDocument24 pages95-1176-01 HairCare Formulation Guidetopguitar100% (1)

- Uniworth Textile Company MAIN PROJECTDocument36 pagesUniworth Textile Company MAIN PROJECTanki50% (2)

- TCP LimitedDocument3 pagesTCP LimitedAmit GargNo ratings yet

- (DARK ROOM PROCEDURE AND FILM PROCESSING) Forensic PhotographyDocument8 pages(DARK ROOM PROCEDURE AND FILM PROCESSING) Forensic PhotographyMardy Hoyohoy BarraquioNo ratings yet

- SWOT Analysis of Hindustan Unilever Ltd.Document21 pagesSWOT Analysis of Hindustan Unilever Ltd.Milan Kumar Pandey83% (12)

- 01 - Hair 101 - Shampoo Technology - Sept 2014 PDFDocument41 pages01 - Hair 101 - Shampoo Technology - Sept 2014 PDFOsamaAliMoussa100% (2)

- Operations Final ReportDocument12 pagesOperations Final ReportMustafa SethiNo ratings yet

- SIP ReportDocument24 pagesSIP Reportshubham21sssNo ratings yet

- Packages FinalDocument17 pagesPackages FinalAysha AhmedNo ratings yet

- Asian-Paints - Strategic ManagtDocument26 pagesAsian-Paints - Strategic Managtrahul_madhyaniNo ratings yet

- Clinpro Varnish TP EbuDocument8 pagesClinpro Varnish TP EbuКрасный НиндзяNo ratings yet

- Inventory Management in SRFDocument63 pagesInventory Management in SRFvishnu07510% (1)

- IT ReportDocument29 pagesIT ReportKingsley OgbavwuduNo ratings yet

- Profil EngDocument52 pagesProfil EngReza RhiNo ratings yet

- Overview of The CompanyDocument2 pagesOverview of The CompanyMohan ComputerNo ratings yet

- Fine Organic Industries LTD IPO Snapshot-201806191533423490461Document3 pagesFine Organic Industries LTD IPO Snapshot-201806191533423490461HDFC SecuritiesNo ratings yet

- Report of Ashapura Volclay LTDDocument33 pagesReport of Ashapura Volclay LTDNiraj Patel100% (2)

- Em A MiDocument20 pagesEm A MiPRAVEENRAMKRISHNANNo ratings yet

- Max Carporate ProfileDocument35 pagesMax Carporate ProfileSachin KothariNo ratings yet

- Wali Shah ThesisDocument45 pagesWali Shah ThesisSyed Wali ShahNo ratings yet

- The Definitive Guide to Journalism Media and Business AdministrationFrom EverandThe Definitive Guide to Journalism Media and Business AdministrationNo ratings yet

- A Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessNo ratings yet

- Formulas, Ingredients and Production of Cosmetics: Technology of Skin- and Hair-Care Products in JapanFrom EverandFormulas, Ingredients and Production of Cosmetics: Technology of Skin- and Hair-Care Products in JapanRating: 4 out of 5 stars4/5 (28)

- Underpinning Methods, Procedure and ApplicationsDocument10 pagesUnderpinning Methods, Procedure and ApplicationsAnonymous EPSHB9tXZNo ratings yet

- BE IT Syllabus Sem-III (BIT MESRA)Document3 pagesBE IT Syllabus Sem-III (BIT MESRA)Anudeex ShettyNo ratings yet

- Wheel Weight SizeDocument56 pagesWheel Weight SizeHerciu FlavianNo ratings yet

- CIV3703 Transport Engineering (USQ)Document34 pagesCIV3703 Transport Engineering (USQ)hao baiNo ratings yet

- NoteDocument264 pagesNoteBelayneh TadesseNo ratings yet

- 721007-620005-Computer Oriented Numerical MethodsDocument2 pages721007-620005-Computer Oriented Numerical MethodsTijo L PeterNo ratings yet

- Information Technology Services ControlsDocument12 pagesInformation Technology Services ControlsMohammed AliraqiNo ratings yet

- Porta Cabin Tech SpecDocument6 pagesPorta Cabin Tech SpecFARES BEN MESSAOUDNo ratings yet

- Informe DialuxDocument134 pagesInforme DialuxSFERNo ratings yet

- JSA ScaffoldingDocument10 pagesJSA ScaffoldingLo Roque100% (1)

- Stiffness ModifiersDocument5 pagesStiffness ModifiersA MumtazNo ratings yet

- Soal QafcoDocument3 pagesSoal QafcoRatu CeliaNo ratings yet

- Cicret BraceletDocument41 pagesCicret BraceletramrajNo ratings yet

- Artigo - Thermodynamics of Fluid-Phase Equilibria For Standard Chemical Engineering OperationsDocument24 pagesArtigo - Thermodynamics of Fluid-Phase Equilibria For Standard Chemical Engineering OperationsJoseCastilhoNo ratings yet

- Curriculum Vitae: PersonalDocument10 pagesCurriculum Vitae: PersonalAzhariArdyNo ratings yet

- Amoore - Life Beyond Big Data Governing With Little AnalyticsDocument27 pagesAmoore - Life Beyond Big Data Governing With Little Analyticsanton.de.rotaNo ratings yet

- Is:4926 RMCDocument21 pagesIs:4926 RMCRamesh100% (7)

- Aggregates DiscussionDocument90 pagesAggregates DiscussionJames PleñosNo ratings yet

- ANA Sales Enablement Plan PlaybookDocument39 pagesANA Sales Enablement Plan PlaybookDemand Metric100% (1)

- Ripex App SNMP enDocument64 pagesRipex App SNMP enhadiNo ratings yet

- Gin 2904Document12 pagesGin 2904Sen HuNo ratings yet

- Laboratory Manual 4: Discrete Time Fourier Transform & Discrete Fourier TransformDocument10 pagesLaboratory Manual 4: Discrete Time Fourier Transform & Discrete Fourier TransformHassanNo ratings yet

- ASTM D1119 - 00 - Percent Ash Content of Engine Coolants and AntirustsDocument2 pagesASTM D1119 - 00 - Percent Ash Content of Engine Coolants and Antirustsphamthuyha100% (2)

- Design and Fabrication of Screw Conveyor Report DownloadDocument3 pagesDesign and Fabrication of Screw Conveyor Report Downloadyohannes wendwesenNo ratings yet

- Lavallee & Ide - CatalogDocument36 pagesLavallee & Ide - CatalogCorey.DeGrandchamp6079No ratings yet

- Jackson 11.14 Homework Problem SolutionDocument4 pagesJackson 11.14 Homework Problem SolutionPero PericNo ratings yet