Professional Documents

Culture Documents

Bar Bending and Cutting Work

Bar Bending and Cutting Work

Uploaded by

AKBAR ALICopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bar Bending and Cutting Work

Bar Bending and Cutting Work

Uploaded by

AKBAR ALICopyright:

Available Formats

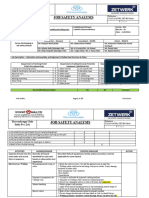

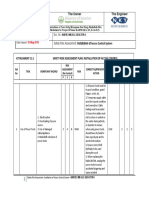

Jubliant Infrastructure Limited-Bharuch

Annexure-6

JOB SAFETY ANALYSIS

JSA NO. Department /

Job Title: Routine/ Non Routine New/ Revised

Activity/ No…

Reference work Permit

JOB SAFETY ANALYSIS no: Supervisor:

Prepared By:

Department: Project Plant location: Niacinamie

Reviewed By:

Job Description: Bar bending and cutting work

Approved By:

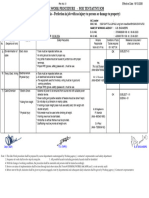

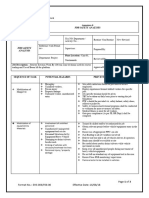

SEQUENCE OF TASK POTENIAL HAZARDS PREVENTIVE MEASURES

Bar bending and cutting Improper placement of rod Secure and align rod before operation the machine.

work Damage the electrical Use mandatory PPEs like safety shoes, hand gloves, goggles, helmet etc.

cable, No earthing Proper rating of electrical cable & connections shall be used. Replace

Rotating parts/unguarded damaged electrical cable.

machine Connection through 30mA ELCB.

Caught in between Machine shall be provided for emergency stoppage, other than ON/OFF

machine & bending switch.

roller/blade, hit or struck Ensure proper routing of cable.

sharp object may cause All the rotating parts shall be guarded.

injury Do not permit loose clothing.

Electrical shock Hold bar firmly.

Bar bending/cutting machine operation area should be isolated &

barricaded.

Machine shall be only operated by operator.

Training to the bar bending and cutting.

Day-1 Day-2 Day-3

Permit issuer

Permit acceptor

Prepared by- Permit Issuer and Permit Acceptor Reviewed by-Plant Manager/ Safety officer

Approved By HOD

Page 1 of 1

Format No.: EHS-006/F06-00 Effective Date:

You might also like

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- JSA InsulationDocument8 pagesJSA InsulationOlavilam Prakash100% (4)

- A.C Motor ReplacementDocument1 pageA.C Motor Replacementmadjid bobNo ratings yet

- A.C Motor ReplacementDocument1 pageA.C Motor ReplacementReda BoualiNo ratings yet

- CNC Milling Machine ProcedureDocument1 pageCNC Milling Machine ProcedureAmaliaAprina100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Steel Cutting, Bending, Welding and Grinding Work JsaDocument2 pagesSteel Cutting, Bending, Welding and Grinding Work JsaAKBAR ALINo ratings yet

- JHA InstrumentationDocument8 pagesJHA Instrumentationசேகர் வேதாரண்யம்No ratings yet

- JSA CABLE TaggingDocument5 pagesJSA CABLE TaggingthennarasuNo ratings yet

- Welding Work JsaDocument2 pagesWelding Work JsaAKBAR ALINo ratings yet

- Grinding Work JsaDocument2 pagesGrinding Work JsaAKBAR ALINo ratings yet

- Reinforcement Cutting Bending JSA HSE ProfessionalsDocument1 pageReinforcement Cutting Bending JSA HSE ProfessionalsNoval FebriNo ratings yet

- Grinding Operation JSA HSE ProfessionalsDocument1 pageGrinding Operation JSA HSE ProfessionalsSamadov 13No ratings yet

- Concrete Breakina Jsa by Breaker MachineDocument2 pagesConcrete Breakina Jsa by Breaker MachineAKBAR ALINo ratings yet

- JSA No - 08 - Grounding System Installation and Testing - Biju - (Revised - 17 July 2016)Document6 pagesJSA No - 08 - Grounding System Installation and Testing - Biju - (Revised - 17 July 2016)babjihanumanthuNo ratings yet

- Job Safety Analysis For: Hcu & Lobs Revamp ProjectDocument6 pagesJob Safety Analysis For: Hcu & Lobs Revamp ProjectShilpiengg SafetyNo ratings yet

- Grinding Operation JSA HSE ProfessionalsDocument4 pagesGrinding Operation JSA HSE ProfessionalsYogisopian HadiNo ratings yet

- JSA For Rebar Works Includes Working in ScaffoldingDocument4 pagesJSA For Rebar Works Includes Working in ScaffoldingMohammed Minhaj100% (1)

- A.C Motor Replacement Template)Document1 pageA.C Motor Replacement Template)DQE040 HSSENo ratings yet

- JSA Welding & Cutting WorksDocument1 pageJSA Welding & Cutting WorksCherry BetonioNo ratings yet

- JSA-Fabrication, AssemblyDocument19 pagesJSA-Fabrication, AssemblyAshfaq Husain AnsariNo ratings yet

- Instruction Manual: Rishabh Instruments Pvt. LTDDocument3 pagesInstruction Manual: Rishabh Instruments Pvt. LTDShiaTVfanNo ratings yet

- Job Safety & Environmental Analysis WorksheetDocument2 pagesJob Safety & Environmental Analysis WorksheetCherry BetonioNo ratings yet

- SOP Fabrication and Erection and Repairing - PS ..Document28 pagesSOP Fabrication and Erection and Repairing - PS ..Hari NairNo ratings yet

- 36 - Footing WorkDocument1 page36 - Footing WorkRafee PieNo ratings yet

- Setting Up Air Compressor & Power Tools Components (NEW KNJTC)Document6 pagesSetting Up Air Compressor & Power Tools Components (NEW KNJTC)mohdhidzwanNo ratings yet

- Cutting & Welding Job JSADocument1 pageCutting & Welding Job JSADeepak PatelNo ratings yet

- Replce Rmu With Summ ProjectDocument8 pagesReplce Rmu With Summ Projectshaibaz chafekarNo ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- SOP For Lighting JobDocument3 pagesSOP For Lighting Jobgulam safi100% (1)

- Brick Work JsaDocument1 pageBrick Work JsaAKBAR ALINo ratings yet

- Centrifuge JSADocument2 pagesCentrifuge JSAandriNo ratings yet

- 2 - JSA Hot WorkDocument9 pages2 - JSA Hot WorkAijaz AhmedNo ratings yet

- Elltec Animec AM-2S Blood-Infusion Warmer Service ManualDocument29 pagesElltec Animec AM-2S Blood-Infusion Warmer Service Manualpiotr.lompartNo ratings yet

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocument2 pagesJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemNo ratings yet

- Job Safety and Environmental Analysis WorksheetDocument2 pagesJob Safety and Environmental Analysis WorksheetCherry Betonio100% (1)

- JSA For Rebar Works Includes Working in ScaffoldingDocument4 pagesJSA For Rebar Works Includes Working in Scaffoldingyc safetyNo ratings yet

- 621-CC#09 Idler and Frame ChangingDocument4 pages621-CC#09 Idler and Frame ChangingBuddy Hart100% (1)

- JSA Mechanical Plant and Machinery SafetyDocument8 pagesJSA Mechanical Plant and Machinery SafetyMazlan Ashaari100% (1)

- Hoist Limit Switch Stopper of Crawler Crane (P&H) Fell Down: Incident Details: RecommendationsDocument2 pagesHoist Limit Switch Stopper of Crawler Crane (P&H) Fell Down: Incident Details: RecommendationsSamuel GeorgeNo ratings yet

- Monitor Signage: Service ManualDocument36 pagesMonitor Signage: Service ManualOSCAR IVAN AGUDELO GILNo ratings yet

- Handtool Safety Training Electric Hand Drill 1. Training Safety PrerequisitesDocument3 pagesHandtool Safety Training Electric Hand Drill 1. Training Safety Prerequisitesretheep0% (1)

- Jsa Hot Work-Fabrication of Assembly BedDocument4 pagesJsa Hot Work-Fabrication of Assembly BedAbhi SandiNo ratings yet

- IR Tower Light 70762158 Light SourceDocument78 pagesIR Tower Light 70762158 Light SourceveereshNo ratings yet

- SOP-Coil Winding MachinesDocument4 pagesSOP-Coil Winding MachinesRadhaKrishnan RNo ratings yet

- Attachment 13.1 Safety Risk Assessment Plan: Installation of M.V SwitchgearDocument5 pagesAttachment 13.1 Safety Risk Assessment Plan: Installation of M.V SwitchgearehteshamNo ratings yet

- RMP - PV-351 - 009 - Feed Cable Tensioning and InspectionDocument14 pagesRMP - PV-351 - 009 - Feed Cable Tensioning and InspectionMagdiel PaezNo ratings yet

- Access Control System: Safety Risk Assessment: Installation ofDocument5 pagesAccess Control System: Safety Risk Assessment: Installation ofehteshamNo ratings yet

- Taladro Magnetico Manual HB350 - Im - HB350Document44 pagesTaladro Magnetico Manual HB350 - Im - HB350capacitacion1689No ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- 007 Oper. Control - Injection Molding MachineDocument6 pages007 Oper. Control - Injection Molding MachineRobert UlatanNo ratings yet

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- Chain Pulley Block JsaDocument2 pagesChain Pulley Block JsaAKBAR ALINo ratings yet

- JSA Machinal PipingDocument7 pagesJSA Machinal PipingNaitik Desai48100% (1)

- Jsa For Cable PullingDocument9 pagesJsa For Cable Pullingshaibaz chafekarNo ratings yet

- Performance Criteria - Perfection in Job With No Injury To Persons or Damage To PropertyDocument1 pagePerformance Criteria - Perfection in Job With No Injury To Persons or Damage To PropertySouvik BanerjeeNo ratings yet

- JSA PRE-TEST Upload ContohDocument2 pagesJSA PRE-TEST Upload ContohDenny Kurniawan PrawiraNo ratings yet

- Sequence of Basic Job Steps Potential Hazards Safeguard/Controls To Be Put in Place ResponsibilityDocument6 pagesSequence of Basic Job Steps Potential Hazards Safeguard/Controls To Be Put in Place ResponsibilityAli AshfaqueNo ratings yet

- Lock Out Tag OutDocument2 pagesLock Out Tag OutPablo Arreola RomeroNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Rope Pulley JsaDocument1 pageRope Pulley JsaAKBAR ALINo ratings yet

- Material Lifting Shifting by Farana/craneDocument1 pageMaterial Lifting Shifting by Farana/craneAKBAR ALINo ratings yet

- Gas Cutting Work JsaDocument2 pagesGas Cutting Work JsaAKBAR ALINo ratings yet

- Chain Pulley Block JsaDocument2 pagesChain Pulley Block JsaAKBAR ALINo ratings yet

- Nut Bolt Tighten by Hammering Spanner and Torque Machine JsaDocument4 pagesNut Bolt Tighten by Hammering Spanner and Torque Machine JsaAKBAR ALINo ratings yet

- Equipment/reactor Erection Work JsaDocument3 pagesEquipment/reactor Erection Work JsaAKBAR ALINo ratings yet

- JSA For Materia/equipment Loading Unloading & Shifting Work JsaDocument3 pagesJSA For Materia/equipment Loading Unloading & Shifting Work JsaAKBAR ALINo ratings yet

- Gritting, Railling and Stair Case Erection Work JsaDocument5 pagesGritting, Railling and Stair Case Erection Work JsaAKBAR ALINo ratings yet

- Equipment Erection by Crane JsaDocument1 pageEquipment Erection by Crane JsaAKBAR ALINo ratings yet

- Shuttring & Deshuttring Work JsaDocument4 pagesShuttring & Deshuttring Work JsaAKBAR ALINo ratings yet

- Rebaring Work JsaDocument1 pageRebaring Work JsaAKBAR ALINo ratings yet

- Shuttring, Deshuttering, Steel Fixing, P.C.C and R.C.C Work JsaDocument5 pagesShuttring, Deshuttering, Steel Fixing, P.C.C and R.C.C Work JsaAKBAR ALINo ratings yet

- Plastering Work JsaDocument1 pagePlastering Work JsaAKBAR ALINo ratings yet

- Deck Sheet Method StatementDocument7 pagesDeck Sheet Method StatementAKBAR ALINo ratings yet

- Steel Cutting, Bending, Welding and Grinding Work JsaDocument2 pagesSteel Cutting, Bending, Welding and Grinding Work JsaAKBAR ALINo ratings yet

- Concrete Breakina Jsa by Breaker MachineDocument2 pagesConcrete Breakina Jsa by Breaker MachineAKBAR ALINo ratings yet

- Confined Space Jsa/excavation JsaDocument2 pagesConfined Space Jsa/excavation JsaAKBAR ALINo ratings yet

- .Inspection Checklist For Safety BeltDocument1 page.Inspection Checklist For Safety BeltAKBAR ALINo ratings yet