Professional Documents

Culture Documents

Flyer Unit Rulmeca EN

Flyer Unit Rulmeca EN

Uploaded by

Bruno Alberto de SouzaCopyright:

Available Formats

You might also like

- TR 25-1-2022 PreviewDocument9 pagesTR 25-1-2022 Previewkanarendran50% (2)

- Epl 8TDocument6 pagesEpl 8Tapi-3777439No ratings yet

- Layout Borpile Trap 2 MAIN ROAD STA.21+237.5 - 21+675 (1 / 2)Document4 pagesLayout Borpile Trap 2 MAIN ROAD STA.21+237.5 - 21+675 (1 / 2)Bogeiman SyahNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- 1159 Diagrama Sistema Eje Levante Con y Sin Abs Diagrama Sistema Eje Levante Con y Sin ABSDocument5 pages1159 Diagrama Sistema Eje Levante Con y Sin Abs Diagrama Sistema Eje Levante Con y Sin ABSBernardo OlivaNo ratings yet

- D49986GC20 sg2 PDFDocument450 pagesD49986GC20 sg2 PDFmanacerNo ratings yet

- RS 485 Still The Most Robust CommunicationDocument12 pagesRS 485 Still The Most Robust Communicationelengineer100% (1)

- Philips+FWC 505Document78 pagesPhilips+FWC 505Franklin DownsNo ratings yet

- DECAL, WIRING SCHEMATIC (Xe), VFD, SD, AIR COOLEDDocument4 pagesDECAL, WIRING SCHEMATIC (Xe), VFD, SD, AIR COOLEDMarcos LunaNo ratings yet

- D/S Dokmoka LoringthepiDocument1 pageD/S Dokmoka LoringthepiManupriya KapleshNo ratings yet

- FW C700 PDFDocument74 pagesFW C700 PDFFreddy FerrerNo ratings yet

- Slewing: SolutionsDocument15 pagesSlewing: SolutionsJoão Márcio de MirandaNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- Industry DriveDocument10 pagesIndustry DriveEric ParkerNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- Philips FW C390 Service ID4010Document80 pagesPhilips FW C390 Service ID4010José Ramón MoránNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- 9120 Pi ENDocument2 pages9120 Pi ENAli AlsaidiNo ratings yet

- EW2025R ECCO 8.5x11Document1 pageEW2025R ECCO 8.5x11Steven Quintero saldarriagaNo ratings yet

- Foremaster Brochure by Manuli HydraulicsDocument12 pagesForemaster Brochure by Manuli HydraulicsEdwar Giovanny GrajalesNo ratings yet

- WPL Lamella Separator Data SheetDocument2 pagesWPL Lamella Separator Data SheetSuhas JadhavNo ratings yet

- DUL and DUS (2014) PDFDocument18 pagesDUL and DUS (2014) PDFАлексей РепехаNo ratings yet

- Plano Sistema de LevanteDocument1 pagePlano Sistema de LevanteRodolfoNo ratings yet

- Roller Technical DescriptionDocument6 pagesRoller Technical DescriptionMarcial Jr. MilitanteNo ratings yet

- RD10V Catalogue EnglishDocument2 pagesRD10V Catalogue Englishhenry vegaNo ratings yet

- Wh6 - Electronics May 26 2019Document11 pagesWh6 - Electronics May 26 2019Marlon Ferrer AfanNo ratings yet

- U/S Dokmoka LoringthepiDocument1 pageU/S Dokmoka LoringthepiManupriya KapleshNo ratings yet

- Kubota GR2020G - GR2120 - GR2120AU Lawn and Garden Tractor Operators ManualDocument100 pagesKubota GR2020G - GR2120 - GR2120AU Lawn and Garden Tractor Operators ManualСвятослав ВороновNo ratings yet

- CLG ISODEWAXING Paper - IDW - NPRA - PaperDocument11 pagesCLG ISODEWAXING Paper - IDW - NPRA - Paperkumar.arunk6784No ratings yet

- Nightstick XPR 5568 IntrantDocument2 pagesNightstick XPR 5568 IntrantProject Sales CorpNo ratings yet

- Philips fwm399-21 22 25 30 Ver1.0Document82 pagesPhilips fwm399-21 22 25 30 Ver1.0JeovannyAlexanderMatamorosSanchezNo ratings yet

- Power TransmissionDocument718 pagesPower Transmissionv8wfm8d8r7No ratings yet

- Pure Precision Sure Performance: Precision-Made Hydraulic SealsDocument3 pagesPure Precision Sure Performance: Precision-Made Hydraulic SealshufuentsNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- Power Circuit For D.O.L. Starting For Motor Rotation Refer To Installation Layout Sn-100462-D001Document1 pagePower Circuit For D.O.L. Starting For Motor Rotation Refer To Installation Layout Sn-100462-D001jhonNo ratings yet

- 423-8756-23 - Cab Wiring Diagram (50-Series)Document5 pages423-8756-23 - Cab Wiring Diagram (50-Series)jNo ratings yet

- sc069674-01 (1) - 220810 - 112715Document2 pagessc069674-01 (1) - 220810 - 112715David Aquino GallegosNo ratings yet

- Steering Unit Lagu: Data SheetDocument12 pagesSteering Unit Lagu: Data SheetsuperNo ratings yet

- P-205-05 Current Transformers For Special ApplicationDocument16 pagesP-205-05 Current Transformers For Special ApplicationSarmad HussainNo ratings yet

- D3 - Engineering PlansDocument24 pagesD3 - Engineering PlansSashi KumarNo ratings yet

- DECAL, WIRING SCHEMATIC (Xe), WFAN STR, VFD, SD, AIR COOLEDDocument4 pagesDECAL, WIRING SCHEMATIC (Xe), WFAN STR, VFD, SD, AIR COOLEDMarcos LunaNo ratings yet

- Mud King Butterfly ValveDocument6 pagesMud King Butterfly ValveArie SafariNo ratings yet

- How We Work With Suppliers: Upholding Apple's Values in Our Supply ChainDocument18 pagesHow We Work With Suppliers: Upholding Apple's Values in Our Supply ChainNguyễn Văn NghĩaNo ratings yet

- 02-311 Range Tramming Panel - 77016430 - JDocument12 pages02-311 Range Tramming Panel - 77016430 - JmauriciogroglezNo ratings yet

- Cat Dcs Sis ControllerDocument16 pagesCat Dcs Sis ControllerLucas Pereira0% (1)

- Solid Alliance Multi-Operator DasDocument3 pagesSolid Alliance Multi-Operator DasDiego ZABALANo ratings yet

- 4-77016430 2 Drawing G PDFDocument11 pages4-77016430 2 Drawing G PDFJose RuizNo ratings yet

- Carver Px1450 Px-Series Rev.c AmplifierDocument9 pagesCarver Px1450 Px-Series Rev.c Amplifieradrianvelazquezjarv15No ratings yet

- Rockmaster BrochureDocument8 pagesRockmaster BrochureEdwar Giovanny GrajalesNo ratings yet

- D/S Dokmoka Loringthepi: NotesDocument1 pageD/S Dokmoka Loringthepi: NotesManupriya KapleshNo ratings yet

- FWM390Document82 pagesFWM390GMS ELECTRONICANo ratings yet

- Cut To Length LineDocument1 pageCut To Length LinesadanandaNo ratings yet

- Filtration BrochureDocument3 pagesFiltration BrochureMahmudul HasanNo ratings yet

- DECAL, WIRING SCHEMATIC (Xe), VFD, SD, WATER COOLEDDocument4 pagesDECAL, WIRING SCHEMATIC (Xe), VFD, SD, WATER COOLEDMarcos LunaNo ratings yet

- Nitor, Narro Flat Sop/DprDocument3 pagesNitor, Narro Flat Sop/DprAmarK90No ratings yet

- Operator'S Manual: Read and Save This ManualDocument166 pagesOperator'S Manual: Read and Save This ManualMac KrisNo ratings yet

- Indo German Ind.: 2012 Volume V CatalogDocument10 pagesIndo German Ind.: 2012 Volume V CatalogNikhil TiwaryNo ratings yet

- FL4025 QD Para-FlexDocument4 pagesFL4025 QD Para-FlexIsaac MonteroNo ratings yet

- Kim Jong Un: Supreme Leader of North KoreaFrom EverandKim Jong Un: Supreme Leader of North KoreaRating: 3.5 out of 5 stars3.5/5 (2)

- 2023 02 15 - REACH - IRB Signed NSDocument2 pages2023 02 15 - REACH - IRB Signed NSBruno Alberto de SouzaNo ratings yet

- 3HAC081954 PS IRB 460 On OmniCore-enDocument50 pages3HAC081954 PS IRB 460 On OmniCore-enBruno Alberto de SouzaNo ratings yet

- Hidraulica - ProtecDocument80 pagesHidraulica - ProtecBruno Alberto de Souza100% (1)

- Catalog Bulk Handling Motorized Pulleys ENDocument96 pagesCatalog Bulk Handling Motorized Pulleys ENBruno Alberto de SouzaNo ratings yet

- Catalog Drum Motors ENDocument120 pagesCatalog Drum Motors ENBruno Alberto de SouzaNo ratings yet

- Ou 142 enDocument1 pageOu 142 enBruno Alberto de SouzaNo ratings yet

- Catalog Drive Roller ENDocument56 pagesCatalog Drive Roller ENBruno Alberto de SouzaNo ratings yet

- 115 enDocument1 page115 enBruno Alberto de SouzaNo ratings yet

- Ou 247 enDocument1 pageOu 247 enBruno Alberto de SouzaNo ratings yet

- Ou 266 enDocument1 pageOu 266 enBruno Alberto de SouzaNo ratings yet

- Ou 324 enDocument1 pageOu 324 enBruno Alberto de SouzaNo ratings yet

- Ou 339 enDocument1 pageOu 339 enBruno Alberto de SouzaNo ratings yet

- This Document Is Compiled From The Articles of The .: Talia Cad Software LTDDocument10 pagesThis Document Is Compiled From The Articles of The .: Talia Cad Software LTDBruno Alberto de SouzaNo ratings yet

- 1554 enDocument1 page1554 enBruno Alberto de SouzaNo ratings yet

- 19 enDocument60 pages19 enBruno Alberto de SouzaNo ratings yet

- Small Business ProjectDocument2 pagesSmall Business ProjectYousef ManasraNo ratings yet

- A Pilot Cancer-Phenome Biobanking System in A Low-Resource Southeast Asian Setting: The Philippine General Hospital Biobank ExperienceDocument9 pagesA Pilot Cancer-Phenome Biobanking System in A Low-Resource Southeast Asian Setting: The Philippine General Hospital Biobank ExperienceSteven IStudy SmithNo ratings yet

- MDR PDFDocument16 pagesMDR PDFBandameedi RamuNo ratings yet

- Display and Data Logger S330 / S331Document6 pagesDisplay and Data Logger S330 / S331titodeviscarNo ratings yet

- ChevyDocument3 pagesChevysecretNo ratings yet

- Games For Training Educationn Health and SportDocument212 pagesGames For Training Educationn Health and SportBlatme BlatNo ratings yet

- CHAPTER - 7 Structural DesignDocument32 pagesCHAPTER - 7 Structural Designzakaria100% (2)

- NEDAL Busbars Technical SpecificationsDocument6 pagesNEDAL Busbars Technical Specificationssanjeev banerjee100% (1)

- Kashmir Moeed PirzadaDocument13 pagesKashmir Moeed Pirzadamanojkp33No ratings yet

- Energy Recovery Council: 2016 Directory of Waste-To-Energy FacilitiesDocument72 pagesEnergy Recovery Council: 2016 Directory of Waste-To-Energy FacilitiesJorge Martinez100% (1)

- BRM v3-1 Taxonomy 20130615Document52 pagesBRM v3-1 Taxonomy 20130615kevinzhang2022No ratings yet

- Wood Supply and Demand Analysis in Pakistan - Key IssuesDocument12 pagesWood Supply and Demand Analysis in Pakistan - Key IssuesMAk KhanNo ratings yet

- Travclan - Business Development Associate: About UsDocument3 pagesTravclan - Business Development Associate: About Uscharu bishtNo ratings yet

- L-4rr-lI/CSE Date: 27/0312023: Section-ADocument35 pagesL-4rr-lI/CSE Date: 27/0312023: Section-AQuazi Hasnat IrfanNo ratings yet

- Winker Motion On CarolloDocument3 pagesWinker Motion On Carolloal_crespoNo ratings yet

- REVIEWERDocument3 pagesREVIEWERRuvy Jean Codilla-FerrerNo ratings yet

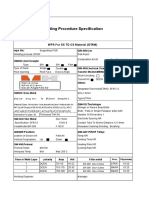

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Document1 pageWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNo ratings yet

- Wrtitten Assignment Unit 1Document6 pagesWrtitten Assignment Unit 1Francis Desoliviers Winner-BluheartNo ratings yet

- Changes To WebsiteDocument4 pagesChanges To Websitegacha sad lordNo ratings yet

- 2 - Introduction To CompilationDocument13 pages2 - Introduction To CompilationShaddyNo ratings yet

- EVALUATING OTHERS DRAFT PowerPoint PresentationDocument16 pagesEVALUATING OTHERS DRAFT PowerPoint PresentationtrixiaagelzNo ratings yet

- Kontron - 886LCD-M User ManualDocument78 pagesKontron - 886LCD-M User ManualDamiano ZitoNo ratings yet

- Tinkerpreneur 2024 - BrochureDocument6 pagesTinkerpreneur 2024 - BrochurejiyacolabworkNo ratings yet

- Halton Design Guide enDocument54 pagesHalton Design Guide enimtiyaz94No ratings yet

- National Environment (Management of Ozone Depleting Substances & Products) Regulations S.I. No. 48 of 2020Document68 pagesNational Environment (Management of Ozone Depleting Substances & Products) Regulations S.I. No. 48 of 2020John Paul NuwagabaNo ratings yet

- Case Digests in Statutory Construction Philippine Law StudentDocument58 pagesCase Digests in Statutory Construction Philippine Law StudentJoshua Emmanuel100% (5)

- T-6700 Series Four Channel IP Network Audio Adapter (Rack Mount) T-6704Document1 pageT-6700 Series Four Channel IP Network Audio Adapter (Rack Mount) T-6704fahim_bdNo ratings yet

- ELS - Q1 - Week 4aDocument3 pagesELS - Q1 - Week 4apeterjo raveloNo ratings yet

- Tandberg En8040-UserGuideDocument38 pagesTandberg En8040-UserGuideMikhil0% (1)

Flyer Unit Rulmeca EN

Flyer Unit Rulmeca EN

Uploaded by

Bruno Alberto de SouzaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flyer Unit Rulmeca EN

Flyer Unit Rulmeca EN

Uploaded by

Bruno Alberto de SouzaCopyright:

Available Formats

DRIVE ROLLERS GLOBAL PRESENCE AND LOCAL SERVICE

UNIT

Rulmeca 24VDC Drive Rollers (RDR) are designed to play a key role in industrial applications

in which roller transportation is an important part of the production process. Drive Roller is a

8° ed. UN EN 02/24

1O

MA

motor integrated Ø 50 mm roller for unit handling conveyors able to transmit motion to the

R

ST

CH

GR IN

2

OO BE AN ED LT

VED TU DARD FOR BE adjacent rollers by belts.

HAND

Thanks to the wide possible configurations and selected finishing, this product is easily

placed into a large variety of unit handling applications.

M

OT The RDR (Rulmeca Drive Rollers), can be connected to slave driven rollers by round belts,

OR SIDE

Poly V belts, chains or can be executed crowned to drive light belts.

D OU

PI

BL

O E O

NI

P

N GR D LY

2C

R O W NS O O VE D HE A -V H

EAD

LING

IDEAL IN APPLICATIONS:

Manufacturing, Sales, Service ABOUT RULMECA

Sales, Service Founded in 1962, the Rulmeca Group has

BRUSHLESS MOTOR

WIDE RANGE

TECHNOLOGY WITH grown to be a leading partner to the global

SPEEDS SET Australia Indonesia

CONSTANT TORQUE Canada Italy materials handling industry. Rulmeca Group

China Poland is the world’s largest supplier of rollers, idlers,

Denmark / Sweden South Africa

pulleys and motorized pulleys for heavy

Finland Spain / Portugal

HIGH EFFICIENCY LOW LEVELS France Thailand duty belt conveyors for quarries and mining

ENERGY SAVING OF SYSTEM NOISE Germany United Kingdom applications and of Rollers, Drum Motors and

India USA

24V Drive Rollers for Intralogistics.

FREQUENT SAFETY FOR LINE

START/STOP CYCLES OPERATORS UNIT HANDLING

ROLLERS, DRUM MOTORS

24V DRIVE ROLLERS

AND COMPONENTS

CONTROL MODULES

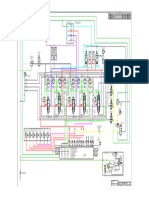

RDR BL3 can be driven by: Group Headquarters: Rulmeca Holding S.p.A.

Via A. Toscanini, 1 - I-24011 Almè (Bergamo) Italy

- PLC directly thanks to all needed electronics and protections integrated in the roller. Tel +39 035 4300 111 - export-it@rulmeca.com

- Rulmeca Motion Control (RMC-BL3) card simplifies the BL3 Drive Roller interface to systems.

- Zero Pressure Accumulation (ZPA) card prevents products from touching in-transit in

rulmeca.com

order to ensure a safe accumulation without pressure of the units.

DRUM MOTORS

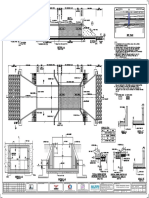

EASE OF INSTALLATION: A Rulmeca Drum Motor is the ideal method of driving conveyor belts. A totally anclosed

unit, with the motor, gearbox and all working parts hermetically sealed within the outer shell.

Rulmeca drum motors are much faster and easier to install because

they are just one component with all included, instead of the

traditional multiple components motor transmission systems.

SPACE-SAVING DESIGN:

With the electrical drive, bearings and gearbox enclosed inside the

shell, Rulmeca drum motors are very compact and therefore require

less space and reduced footprint. The more centred weight balance

increases the conveyor stability and therefore safety.

DESIGNED FOR THE TOUGHEST CONDITIONS:

The Rulmeca drum motors are designed to operate perfectly even in

UNIT HANDLING

the most aggressive environmental conditions, such as in presence SOLUTIONS FOR ANY INDUSTRY Rulmeca Group, headquartered in OEMs, engineering companies and end

of water, dust, grit, chemicals, grease, oil and even during high Bergamo (Almé), Italy, has grown users confirms us as one of the most

pressure wash-down procedures.

to become the world’s leading trusted brands in the industry. Rulmeca

AIRPORT, SECURITY DISTRIBUTION CENTRES manufacturer of conveyor rollers, 24V products improve the performance,

AND X-RAY SCREENING AND WAREHOUSING

drive rollers and other components for safety and reliability of systems,

GUARANTEED FOR FOOD:

the unit handling industry. equipment and machines.

Thanks to their flat smooth surfaces, food compliant polymers,

stainless steel finish and totally enclosed, hermetically sealed design, Rulmeca Group products are developed Rulmeca is strongly committed to the

Rulmeca drum motors are easy to clean, thus reducing contamination and produced to meet the most continuous improvement and develop-

risk in food processing environments. POSTAL, PARCEL FOOD AND FISH

demanding challenges of all major unit ment of its product range.

AND E-COMMERCE PROCESSING

STANDARD DRUM MOTOR RANGE handling applications. Rulmeca rollers Rulmeca Group offers a portfolio of

80LP 113LP 138LP 80LS 113LS 138LS 165LS 220M 220H are light, sturdy, self-lubrificated, shock state-of-the-art components for a vast

Diameter [mm] 85.5 113.6 135 81.5 113.5 138.5 165 216 216

MAINTENANCE-FREE: resistent and can be constructed using array of industries and application

from 0.06 0.06 0.06 0.02 0.035 0.1 0.11 0.37 0.37

The fully sealed design ensures that internal parts are not exposed to Power [kW] aluminium, mild steel, stainless steel handling.

to 0.12 0.55 0.55 0.12 0.55 1.00 2.20 4.00 5.50 MANUFACTURING, PACKAGING BEVERAGE

external environmental conditions or tampering. A completely self- AND AUTOMATION PROCESSING and high resistance technopolymers. We have the expertise, the experience and

Roller Length RL from 253 240 275 200 250 300 350 400 450

contained unit, requiring no maintenance throughout its service lifetime.

[mm] to 912 1212 1212 1000 1200 1800 1800 2000 2000 The close partnership with our customers, the products you need, so contact us.

RULMECA ROLLERS GL-GM SERIES 111 SERIES

WIDE RANGE OF PRODUCTS Idler or gravity rollers handling

light and medium loads are

completely in zinc-plated steel with

Idler or gravity rollers for light loads

are in technopolymer, bearing balls

in stainless steel, lightweight, quiet,

Rulmeca offers a broad range of conveyor rollers that cover all process for the handling and product manufactured to give a long service life, even under extremely severe conditions. prelubricated full complement ball smooth running and consequently

transport of unit loads. Our products provide customised solutions to meet all handling needs with gravity and driven bearings, making them smooth reduce gravity conveyor slopes.

The use of strict quality control procedures during all stages of manufacture guarantees a conveyors. running and quiet. Food certified materials on request.

ADVANTAGES ROLLER SIZE GUIDE

RULMECA ROLLERS HAVE DIFFERENT BENEFITS

ACCORDING TO SERIES AND MATERIAL SHAFT Ø

16 18 20 24 30 32 38 40 50 51 60 63 76 80 89 102 108 133 159 194

/ TUBE

_

MINIMUM STARTING RESISTANCE GL 6

8

117 SERIES

Made in PVC, zinc plated steel or Aisi

119 SERIES

With technopolymer end-caps

RULMECA rollers run very smoothly and allow the 10 304 tubes, with radial precision bearings, and radial precision bearings and

handling of very light packages with a minimum slope.

12

endcaps in technopolymer and are zinc-plated steel tube are ideal

ch11

_

extremely quiet and smooth running. for pallet handling.

111 5

MAXIMUM SHOCK RESISTANCE

6

RULMECA rollers are highly shock resistant, 8

maintaining roller concentricity. 10

12

MPS-PS SERIES 135 SERIES

_

117 8

SAFETY OF HANDLED MATERIALS 10 Driven rollers made in zinc-plated mild

Idler rollers for the handling of

12

medium and heavy loads with steel, Aisi 304 or shock resistant PVC

Delicate materials can be safely handled without 14

being damaged by scratches. radial precision bearings for use in tubes. With options of Polyamide and

17

internal, external, dusty, humid or steel pinion sprockets, with Poly-V /

ch11

_ GM 12 normal environments. round belt head and version 135/VA

EASY CLEANING

15 with fixed head.

RULMECA rollers can be easily cleaned with any 135 14 Available with 1 crown or 2 crowns.

detergent in use and can be water sprayed. 138 14

FDN/FDR 15

_

MPS 15

LIGHTNESS 119 20 138 SERIES KRF-KRO SERIES

XPS 20

Reduces considerably the weight of the handling 139 20 Friction rollers for light and medium Tapered rollers made by conical

system. loads have the same features and sectors in technopolymers are

PS 20

25 options as the 135 series. The pinions used for gravity curves and driven

_

NOISE REDUCTION 30

40

are interchangeable and easily replaced

by the ones of 135 series.

curves with chain loops, round

belt and Poly-V belt.

Silent use in internal applications. Available with 1 crown or 2 crowns.

ROLLER LOAD

ATMOSPHERIC FACTORS

_

RESISTANCE Light load

(< 50 daN)

Medium load

(50 ÷ 250 daN)

Heavy load

(250 ÷ 500 daN)

Very heavy load

(500 ÷ 2200 daN)

KRM SERIES XPS SERIES

Can be exposed to all atmospheric factors including GL

frost, ultraviolet rays. 111

Tapered rollers made completely Driven rollers with steel pinion

117

in steel with zinc-plated shell sprockets welded on the tube for chain

_

GM

CORROSION RESISTANCE 135

designed for driven curves driven conveyors.

138 trasporting heavy loads, including They have perfect application in pallet

Plastic materials do not RUST! Rollers can be pallets. and heavy load handling.

FDN/FDR

equipped with ball bearings and shafts in stainless

MPS

steel.

119

XPS

_

CHEMICAL AGENTS RESISTANCE 139

PS

RULMECA rollers with stainless steel components Application must be evaluated taking into consideration application, loads and environmental conditions. 139 SERIES FDN-FDR SERIES

are highly resistant to chemical agents. Shaft and tube ø are shown above, other dimensions are available on request.

Driven rollers similar to the 119 series Friction and adjustable friction

ELECTRICAL PALLET ROLLERS

but with steel pinion welded to the tube. rollers, complete steel construction

They have perfect application in pallet used for heavy load handling and

and heavy load handling. accumulation.

The EPS-AS1 roller is a completely enclosed 400 V electrical drive Ø89 roller, with

the gear box, asynchronous electric motor and bearings located inside the drive

drum.This drive roller can be installed in conveyors that are part of complex logistic

PINION OR CROWN COMPONENTS

systems and logics. The EPS-AS1 has perfect application in pallet and heavy load

handling and it can be connected by chains to slave driven rollers (like XPS or 139 SPROCKET

Rulmeca product range includes polymeric

series rollers). An optional integrated 24 VDC electromagnetic stationary brake acts

Driven rollers with pinion or crown and steel wheels for material handling industry,

as holding device.

sprockets welded on the tube for chain as well as omnidirectional wheels and ball

FEATURES: driven conveyors. transfer units. Products used worldwide,

• Space-saving design;

as single components or pre-assembled in

• Ease of installation;

• All internal components protected against external factors; special zinc-plated profiles: Minirail, Medirail

• Maintenance-free. and Heavyrail.

You might also like

- TR 25-1-2022 PreviewDocument9 pagesTR 25-1-2022 Previewkanarendran50% (2)

- Epl 8TDocument6 pagesEpl 8Tapi-3777439No ratings yet

- Layout Borpile Trap 2 MAIN ROAD STA.21+237.5 - 21+675 (1 / 2)Document4 pagesLayout Borpile Trap 2 MAIN ROAD STA.21+237.5 - 21+675 (1 / 2)Bogeiman SyahNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- 1159 Diagrama Sistema Eje Levante Con y Sin Abs Diagrama Sistema Eje Levante Con y Sin ABSDocument5 pages1159 Diagrama Sistema Eje Levante Con y Sin Abs Diagrama Sistema Eje Levante Con y Sin ABSBernardo OlivaNo ratings yet

- D49986GC20 sg2 PDFDocument450 pagesD49986GC20 sg2 PDFmanacerNo ratings yet

- RS 485 Still The Most Robust CommunicationDocument12 pagesRS 485 Still The Most Robust Communicationelengineer100% (1)

- Philips+FWC 505Document78 pagesPhilips+FWC 505Franklin DownsNo ratings yet

- DECAL, WIRING SCHEMATIC (Xe), VFD, SD, AIR COOLEDDocument4 pagesDECAL, WIRING SCHEMATIC (Xe), VFD, SD, AIR COOLEDMarcos LunaNo ratings yet

- D/S Dokmoka LoringthepiDocument1 pageD/S Dokmoka LoringthepiManupriya KapleshNo ratings yet

- FW C700 PDFDocument74 pagesFW C700 PDFFreddy FerrerNo ratings yet

- Slewing: SolutionsDocument15 pagesSlewing: SolutionsJoão Márcio de MirandaNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- Industry DriveDocument10 pagesIndustry DriveEric ParkerNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- Philips FW C390 Service ID4010Document80 pagesPhilips FW C390 Service ID4010José Ramón MoránNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- 9120 Pi ENDocument2 pages9120 Pi ENAli AlsaidiNo ratings yet

- EW2025R ECCO 8.5x11Document1 pageEW2025R ECCO 8.5x11Steven Quintero saldarriagaNo ratings yet

- Foremaster Brochure by Manuli HydraulicsDocument12 pagesForemaster Brochure by Manuli HydraulicsEdwar Giovanny GrajalesNo ratings yet

- WPL Lamella Separator Data SheetDocument2 pagesWPL Lamella Separator Data SheetSuhas JadhavNo ratings yet

- DUL and DUS (2014) PDFDocument18 pagesDUL and DUS (2014) PDFАлексей РепехаNo ratings yet

- Plano Sistema de LevanteDocument1 pagePlano Sistema de LevanteRodolfoNo ratings yet

- Roller Technical DescriptionDocument6 pagesRoller Technical DescriptionMarcial Jr. MilitanteNo ratings yet

- RD10V Catalogue EnglishDocument2 pagesRD10V Catalogue Englishhenry vegaNo ratings yet

- Wh6 - Electronics May 26 2019Document11 pagesWh6 - Electronics May 26 2019Marlon Ferrer AfanNo ratings yet

- U/S Dokmoka LoringthepiDocument1 pageU/S Dokmoka LoringthepiManupriya KapleshNo ratings yet

- Kubota GR2020G - GR2120 - GR2120AU Lawn and Garden Tractor Operators ManualDocument100 pagesKubota GR2020G - GR2120 - GR2120AU Lawn and Garden Tractor Operators ManualСвятослав ВороновNo ratings yet

- CLG ISODEWAXING Paper - IDW - NPRA - PaperDocument11 pagesCLG ISODEWAXING Paper - IDW - NPRA - Paperkumar.arunk6784No ratings yet

- Nightstick XPR 5568 IntrantDocument2 pagesNightstick XPR 5568 IntrantProject Sales CorpNo ratings yet

- Philips fwm399-21 22 25 30 Ver1.0Document82 pagesPhilips fwm399-21 22 25 30 Ver1.0JeovannyAlexanderMatamorosSanchezNo ratings yet

- Power TransmissionDocument718 pagesPower Transmissionv8wfm8d8r7No ratings yet

- Pure Precision Sure Performance: Precision-Made Hydraulic SealsDocument3 pagesPure Precision Sure Performance: Precision-Made Hydraulic SealshufuentsNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- Power Circuit For D.O.L. Starting For Motor Rotation Refer To Installation Layout Sn-100462-D001Document1 pagePower Circuit For D.O.L. Starting For Motor Rotation Refer To Installation Layout Sn-100462-D001jhonNo ratings yet

- 423-8756-23 - Cab Wiring Diagram (50-Series)Document5 pages423-8756-23 - Cab Wiring Diagram (50-Series)jNo ratings yet

- sc069674-01 (1) - 220810 - 112715Document2 pagessc069674-01 (1) - 220810 - 112715David Aquino GallegosNo ratings yet

- Steering Unit Lagu: Data SheetDocument12 pagesSteering Unit Lagu: Data SheetsuperNo ratings yet

- P-205-05 Current Transformers For Special ApplicationDocument16 pagesP-205-05 Current Transformers For Special ApplicationSarmad HussainNo ratings yet

- D3 - Engineering PlansDocument24 pagesD3 - Engineering PlansSashi KumarNo ratings yet

- DECAL, WIRING SCHEMATIC (Xe), WFAN STR, VFD, SD, AIR COOLEDDocument4 pagesDECAL, WIRING SCHEMATIC (Xe), WFAN STR, VFD, SD, AIR COOLEDMarcos LunaNo ratings yet

- Mud King Butterfly ValveDocument6 pagesMud King Butterfly ValveArie SafariNo ratings yet

- How We Work With Suppliers: Upholding Apple's Values in Our Supply ChainDocument18 pagesHow We Work With Suppliers: Upholding Apple's Values in Our Supply ChainNguyễn Văn NghĩaNo ratings yet

- 02-311 Range Tramming Panel - 77016430 - JDocument12 pages02-311 Range Tramming Panel - 77016430 - JmauriciogroglezNo ratings yet

- Cat Dcs Sis ControllerDocument16 pagesCat Dcs Sis ControllerLucas Pereira0% (1)

- Solid Alliance Multi-Operator DasDocument3 pagesSolid Alliance Multi-Operator DasDiego ZABALANo ratings yet

- 4-77016430 2 Drawing G PDFDocument11 pages4-77016430 2 Drawing G PDFJose RuizNo ratings yet

- Carver Px1450 Px-Series Rev.c AmplifierDocument9 pagesCarver Px1450 Px-Series Rev.c Amplifieradrianvelazquezjarv15No ratings yet

- Rockmaster BrochureDocument8 pagesRockmaster BrochureEdwar Giovanny GrajalesNo ratings yet

- D/S Dokmoka Loringthepi: NotesDocument1 pageD/S Dokmoka Loringthepi: NotesManupriya KapleshNo ratings yet

- FWM390Document82 pagesFWM390GMS ELECTRONICANo ratings yet

- Cut To Length LineDocument1 pageCut To Length LinesadanandaNo ratings yet

- Filtration BrochureDocument3 pagesFiltration BrochureMahmudul HasanNo ratings yet

- DECAL, WIRING SCHEMATIC (Xe), VFD, SD, WATER COOLEDDocument4 pagesDECAL, WIRING SCHEMATIC (Xe), VFD, SD, WATER COOLEDMarcos LunaNo ratings yet

- Nitor, Narro Flat Sop/DprDocument3 pagesNitor, Narro Flat Sop/DprAmarK90No ratings yet

- Operator'S Manual: Read and Save This ManualDocument166 pagesOperator'S Manual: Read and Save This ManualMac KrisNo ratings yet

- Indo German Ind.: 2012 Volume V CatalogDocument10 pagesIndo German Ind.: 2012 Volume V CatalogNikhil TiwaryNo ratings yet

- FL4025 QD Para-FlexDocument4 pagesFL4025 QD Para-FlexIsaac MonteroNo ratings yet

- Kim Jong Un: Supreme Leader of North KoreaFrom EverandKim Jong Un: Supreme Leader of North KoreaRating: 3.5 out of 5 stars3.5/5 (2)

- 2023 02 15 - REACH - IRB Signed NSDocument2 pages2023 02 15 - REACH - IRB Signed NSBruno Alberto de SouzaNo ratings yet

- 3HAC081954 PS IRB 460 On OmniCore-enDocument50 pages3HAC081954 PS IRB 460 On OmniCore-enBruno Alberto de SouzaNo ratings yet

- Hidraulica - ProtecDocument80 pagesHidraulica - ProtecBruno Alberto de Souza100% (1)

- Catalog Bulk Handling Motorized Pulleys ENDocument96 pagesCatalog Bulk Handling Motorized Pulleys ENBruno Alberto de SouzaNo ratings yet

- Catalog Drum Motors ENDocument120 pagesCatalog Drum Motors ENBruno Alberto de SouzaNo ratings yet

- Ou 142 enDocument1 pageOu 142 enBruno Alberto de SouzaNo ratings yet

- Catalog Drive Roller ENDocument56 pagesCatalog Drive Roller ENBruno Alberto de SouzaNo ratings yet

- 115 enDocument1 page115 enBruno Alberto de SouzaNo ratings yet

- Ou 247 enDocument1 pageOu 247 enBruno Alberto de SouzaNo ratings yet

- Ou 266 enDocument1 pageOu 266 enBruno Alberto de SouzaNo ratings yet

- Ou 324 enDocument1 pageOu 324 enBruno Alberto de SouzaNo ratings yet

- Ou 339 enDocument1 pageOu 339 enBruno Alberto de SouzaNo ratings yet

- This Document Is Compiled From The Articles of The .: Talia Cad Software LTDDocument10 pagesThis Document Is Compiled From The Articles of The .: Talia Cad Software LTDBruno Alberto de SouzaNo ratings yet

- 1554 enDocument1 page1554 enBruno Alberto de SouzaNo ratings yet

- 19 enDocument60 pages19 enBruno Alberto de SouzaNo ratings yet

- Small Business ProjectDocument2 pagesSmall Business ProjectYousef ManasraNo ratings yet

- A Pilot Cancer-Phenome Biobanking System in A Low-Resource Southeast Asian Setting: The Philippine General Hospital Biobank ExperienceDocument9 pagesA Pilot Cancer-Phenome Biobanking System in A Low-Resource Southeast Asian Setting: The Philippine General Hospital Biobank ExperienceSteven IStudy SmithNo ratings yet

- MDR PDFDocument16 pagesMDR PDFBandameedi RamuNo ratings yet

- Display and Data Logger S330 / S331Document6 pagesDisplay and Data Logger S330 / S331titodeviscarNo ratings yet

- ChevyDocument3 pagesChevysecretNo ratings yet

- Games For Training Educationn Health and SportDocument212 pagesGames For Training Educationn Health and SportBlatme BlatNo ratings yet

- CHAPTER - 7 Structural DesignDocument32 pagesCHAPTER - 7 Structural Designzakaria100% (2)

- NEDAL Busbars Technical SpecificationsDocument6 pagesNEDAL Busbars Technical Specificationssanjeev banerjee100% (1)

- Kashmir Moeed PirzadaDocument13 pagesKashmir Moeed Pirzadamanojkp33No ratings yet

- Energy Recovery Council: 2016 Directory of Waste-To-Energy FacilitiesDocument72 pagesEnergy Recovery Council: 2016 Directory of Waste-To-Energy FacilitiesJorge Martinez100% (1)

- BRM v3-1 Taxonomy 20130615Document52 pagesBRM v3-1 Taxonomy 20130615kevinzhang2022No ratings yet

- Wood Supply and Demand Analysis in Pakistan - Key IssuesDocument12 pagesWood Supply and Demand Analysis in Pakistan - Key IssuesMAk KhanNo ratings yet

- Travclan - Business Development Associate: About UsDocument3 pagesTravclan - Business Development Associate: About Uscharu bishtNo ratings yet

- L-4rr-lI/CSE Date: 27/0312023: Section-ADocument35 pagesL-4rr-lI/CSE Date: 27/0312023: Section-AQuazi Hasnat IrfanNo ratings yet

- Winker Motion On CarolloDocument3 pagesWinker Motion On Carolloal_crespoNo ratings yet

- REVIEWERDocument3 pagesREVIEWERRuvy Jean Codilla-FerrerNo ratings yet

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Document1 pageWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNo ratings yet

- Wrtitten Assignment Unit 1Document6 pagesWrtitten Assignment Unit 1Francis Desoliviers Winner-BluheartNo ratings yet

- Changes To WebsiteDocument4 pagesChanges To Websitegacha sad lordNo ratings yet

- 2 - Introduction To CompilationDocument13 pages2 - Introduction To CompilationShaddyNo ratings yet

- EVALUATING OTHERS DRAFT PowerPoint PresentationDocument16 pagesEVALUATING OTHERS DRAFT PowerPoint PresentationtrixiaagelzNo ratings yet

- Kontron - 886LCD-M User ManualDocument78 pagesKontron - 886LCD-M User ManualDamiano ZitoNo ratings yet

- Tinkerpreneur 2024 - BrochureDocument6 pagesTinkerpreneur 2024 - BrochurejiyacolabworkNo ratings yet

- Halton Design Guide enDocument54 pagesHalton Design Guide enimtiyaz94No ratings yet

- National Environment (Management of Ozone Depleting Substances & Products) Regulations S.I. No. 48 of 2020Document68 pagesNational Environment (Management of Ozone Depleting Substances & Products) Regulations S.I. No. 48 of 2020John Paul NuwagabaNo ratings yet

- Case Digests in Statutory Construction Philippine Law StudentDocument58 pagesCase Digests in Statutory Construction Philippine Law StudentJoshua Emmanuel100% (5)

- T-6700 Series Four Channel IP Network Audio Adapter (Rack Mount) T-6704Document1 pageT-6700 Series Four Channel IP Network Audio Adapter (Rack Mount) T-6704fahim_bdNo ratings yet

- ELS - Q1 - Week 4aDocument3 pagesELS - Q1 - Week 4apeterjo raveloNo ratings yet

- Tandberg En8040-UserGuideDocument38 pagesTandberg En8040-UserGuideMikhil0% (1)