Professional Documents

Culture Documents

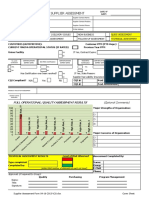

Comprehensive Supplier Audit - SafetyCulture

Comprehensive Supplier Audit - SafetyCulture

Uploaded by

reachtoramanCopyright:

Available Formats

You might also like

- Stravinsky Oedipus RexDocument131 pagesStravinsky Oedipus Rexkantee100% (16)

- ISO 9001 Quality Manual TemplateDocument43 pagesISO 9001 Quality Manual TemplateNC Rigor Luis93% (14)

- Entry of Apperance With Motion To Reset Preliminary ConferenceDocument4 pagesEntry of Apperance With Motion To Reset Preliminary ConferenceBalboa JapeNo ratings yet

- IMS Audit - Version 1Document11 pagesIMS Audit - Version 1arobNo ratings yet

- Supplier Assessment Form 04-16-2013 v20Document16 pagesSupplier Assessment Form 04-16-2013 v20Kovacs AndreeaNo ratings yet

- ISO 9001 Self Assessment ChecklistDocument2 pagesISO 9001 Self Assessment ChecklistJamal NasirNo ratings yet

- Questionario de Auditoria Check ListDocument4 pagesQuestionario de Auditoria Check ListGerardo Gómez SalasNo ratings yet

- Stalcop Llc. Supplier Audit Form: Page 1 of 12Document12 pagesStalcop Llc. Supplier Audit Form: Page 1 of 12ArdiFebriansyahNo ratings yet

- Preparation Checklist For ISO 22000 Audit IauditorDocument5 pagesPreparation Checklist For ISO 22000 Audit IauditorWalid RahmouniNo ratings yet

- Supplier Assessment ChecklistDocument2 pagesSupplier Assessment ChecklistCOLONEL ZIKRIA100% (1)

- ISO 9001 Quality Gap AnalysisDocument48 pagesISO 9001 Quality Gap Analysistracey.gartonNo ratings yet

- Quality IndicatorsDocument47 pagesQuality IndicatorsMaría Del Carmen Hernández CórdovaNo ratings yet

- BSI ISO 9001 Self Assessment Checklist PDFDocument2 pagesBSI ISO 9001 Self Assessment Checklist PDFHarshith Rao VadnalaNo ratings yet

- Abhishek Consultant ResumeDocument4 pagesAbhishek Consultant ResumeAbhishek SrivastvaNo ratings yet

- Job Description: QADocument3 pagesJob Description: QAhatackerNo ratings yet

- Quality ManagementDocument49 pagesQuality ManagementnnoumanNo ratings yet

- Supplier Quality Survey FormDocument4 pagesSupplier Quality Survey Formsutharitessh100% (1)

- Qms ManualDocument60 pagesQms ManualMayur RankNo ratings yet

- Iatf 16949:2016 Checklist - SafetycultureDocument84 pagesIatf 16949:2016 Checklist - Safetyculture88No1FanNo ratings yet

- Abhishek Consultant ResumeDocument4 pagesAbhishek Consultant ResumeAbhishek SrivastvaNo ratings yet

- 1 Check ListDocument60 pages1 Check ListRodrigo ArcilaNo ratings yet

- Chapter-V Om-2Document26 pagesChapter-V Om-2BerhanuTsarikuNo ratings yet

- QA QC-ManagerDocument2 pagesQA QC-ManagerMuhammad Abubakar SheikhNo ratings yet

- Quality Management 010Document70 pagesQuality Management 010Muhammad AsfarNo ratings yet

- Senior Warranty Engineer Generic JDDocument4 pagesSenior Warranty Engineer Generic JDAmr MohsenNo ratings yet

- ISO 9001 Awareness Program For CECDocument16 pagesISO 9001 Awareness Program For CECsuniljayaNo ratings yet

- Resume Sample For Quality Control InspectorDocument7 pagesResume Sample For Quality Control Inspectorc2yyr2c3100% (1)

- QADDocument12 pagesQADSrinivasan RadhaNo ratings yet

- 20 Jan 2022 Isaac MorokoDocument9 pages20 Jan 2022 Isaac MorokoIsaac MorokoNo ratings yet

- Fta Checklist Group NV 7-6-09Document7 pagesFta Checklist Group NV 7-6-09initiative1972No ratings yet

- SamplemanualDocument7 pagesSamplemanualisrael afolayan mayomiNo ratings yet

- IATF 16949 - 2016 Audit - SafetyCultureDocument97 pagesIATF 16949 - 2016 Audit - SafetyCultureShafiq KhanNo ratings yet

- Statistical Quality Control in LaboratoryDocument11 pagesStatistical Quality Control in Laboratoryabhijit612100% (2)

- 4 Quality Management System: Date: 29 October 2008 Location: AssessorDocument21 pages4 Quality Management System: Date: 29 October 2008 Location: AssessordkhondeNo ratings yet

- Supplier Quality QuestionnaireDocument4 pagesSupplier Quality QuestionnairesutharitesshNo ratings yet

- Unit I Quality Control and Reliability Engineering IP 33502Document4 pagesUnit I Quality Control and Reliability Engineering IP 33502Nishika chopraNo ratings yet

- Supplier Audit ChecklistDocument21 pagesSupplier Audit ChecklistAnonymous W2gdmMVhoM100% (2)

- Reliability Maturity Matrix: ©2015 Fred SchenkelbergDocument1 pageReliability Maturity Matrix: ©2015 Fred Schenkelbergmzai2003100% (1)

- Quality Checklist: Prepared By: DateDocument4 pagesQuality Checklist: Prepared By: DateIgnacio PerezNo ratings yet

- Supplier Qualification QuestionnaireDocument4 pagesSupplier Qualification QuestionnaireSeptian SuharyadiNo ratings yet

- Quality Control: This Approach Places An Emphasis On Three AspectsDocument12 pagesQuality Control: This Approach Places An Emphasis On Three AspectsJohn YohansNo ratings yet

- Gap Analysis ISO 9001 Checklist - SafetyCultureDocument9 pagesGap Analysis ISO 9001 Checklist - SafetyCultureZineb HAFIDINo ratings yet

- Pubh5107 Final Exam ReviewDocument419 pagesPubh5107 Final Exam Reviewkhanguraamanpreet55No ratings yet

- Amo Contractor Self-Audit ChecklistDocument6 pagesAmo Contractor Self-Audit ChecklistinternJGIPNo ratings yet

- 2006 CSTE CBOK Skill Category 1 (Part1)Document38 pages2006 CSTE CBOK Skill Category 1 (Part1)api-37337260% (1)

- Lesson 1 Applying Quality Standards AqsDocument289 pagesLesson 1 Applying Quality Standards Aqsjonathan labajoNo ratings yet

- Introduction To Quality ControlDocument22 pagesIntroduction To Quality ControlSakeena Naureen Ashraf100% (1)

- Supplier Assessment Form NewDocument49 pagesSupplier Assessment Form NewChinh Lê ĐìnhNo ratings yet

- FINAL - Audit Report - RAJEEV KUMARDocument4 pagesFINAL - Audit Report - RAJEEV KUMARRajeev KumarNo ratings yet

- Information: IATF 16949:2016 AuditDocument71 pagesInformation: IATF 16949:2016 AuditAshish SomaddarNo ratings yet

- Quality Checklist TemplateDocument4 pagesQuality Checklist TemplateSolange SaldíaNo ratings yet

- Quality Assurance and Quality Compliance Specialist: Arunkumar VenkatesanDocument3 pagesQuality Assurance and Quality Compliance Specialist: Arunkumar VenkatesangunneshNo ratings yet

- ISO 9001 - 2015 Audit Checklist - SafetyCultureDocument47 pagesISO 9001 - 2015 Audit Checklist - SafetyCultureengjaildaNo ratings yet

- QA Manager YogeshDocument4 pagesQA Manager YogeshParag WadekarNo ratings yet

- Maximizing Efficiency and Compliance: Essential Tips For Conducting An Effective Annual Product Quality Review (APQR)Document10 pagesMaximizing Efficiency and Compliance: Essential Tips For Conducting An Effective Annual Product Quality Review (APQR)aniaaa220No ratings yet

- Supplier Quality Survey Form2Document4 pagesSupplier Quality Survey Form2Sutha Tamil NambeNo ratings yet

- ISO 9001-2015 Transition Checklist C 01 Rev ADocument4 pagesISO 9001-2015 Transition Checklist C 01 Rev Avikkasverma.in100% (1)

- SQA Paper Solution Nov19Document16 pagesSQA Paper Solution Nov19satyamshingade2No ratings yet

- Quality Control DepartmentDocument5 pagesQuality Control DepartmentRonnel MatampaleNo ratings yet

- Criminal Procedure (Investigative) OutlineDocument22 pagesCriminal Procedure (Investigative) OutlineJohnny EmmNo ratings yet

- Constitutional InterpretationDocument13 pagesConstitutional InterpretationAndrew SekayiriNo ratings yet

- (Me 15) Bosh - Lecture 02Document36 pages(Me 15) Bosh - Lecture 02Strong Boy OgkoNo ratings yet

- Danika Tynes ResumeDocument6 pagesDanika Tynes ResumeDanika Tynes100% (1)

- Solo 1-MathDocument3 pagesSolo 1-Mathapi-168501117No ratings yet

- SBU 105 Introduction To ComputersDocument2 pagesSBU 105 Introduction To ComputersSaviourNo ratings yet

- Grade 9 Character EssayDocument9 pagesGrade 9 Character EssayAliceCameronRussellNo ratings yet

- Corpas Pastor, G. & Gaber, M. Noviembre, 2020 Remote Interpreting in Public Service Settings Technology, Perceptions and PracticeDocument22 pagesCorpas Pastor, G. & Gaber, M. Noviembre, 2020 Remote Interpreting in Public Service Settings Technology, Perceptions and PracticeLuis TraductorNo ratings yet

- Designer Profile For Jonathan IveDocument6 pagesDesigner Profile For Jonathan IveJaneNo ratings yet

- Law & Corporate FinanceDocument238 pagesLaw & Corporate FinanceRajesh Shantaram Shinde100% (1)

- COVID-19 and Pregnancy: A Review of Clinical Characteristics, Obstetric Outcomes and Vertical TransmissionDocument20 pagesCOVID-19 and Pregnancy: A Review of Clinical Characteristics, Obstetric Outcomes and Vertical TransmissionDra Sandra VèlezNo ratings yet

- Cfa Level II ErrataDocument11 pagesCfa Level II ErrataWasita PiamwareeNo ratings yet

- Republic of The Philippines Department of Education Ugong Pasig National High SchoolDocument12 pagesRepublic of The Philippines Department of Education Ugong Pasig National High SchoolJOEL MONTERDENo ratings yet

- Volvo B5TL: When All You Need Is Everything in A Double Deck BusDocument13 pagesVolvo B5TL: When All You Need Is Everything in A Double Deck BusКонстантин КосаревNo ratings yet

- (Environmental Pollution 16) Kai Bester, Christa S. McArdell, Cajsa Wahlberg, Thomas D. Bucheli (Auth.), Despo Fatta-Kassinos, Kai Bester, Klaus Kümmerer (Eds.) - Xenobiotics in The Urban WaterDocument521 pages(Environmental Pollution 16) Kai Bester, Christa S. McArdell, Cajsa Wahlberg, Thomas D. Bucheli (Auth.), Despo Fatta-Kassinos, Kai Bester, Klaus Kümmerer (Eds.) - Xenobiotics in The Urban WaterKarlysson JorddanNo ratings yet

- Section Viii Div 1 Div 2 Div ComparisonDocument2 pagesSection Viii Div 1 Div 2 Div Comparisonapparaokr100% (5)

- What Is WifiDocument7 pagesWhat Is WifiHemant ThakkarNo ratings yet

- People v. RiveraDocument17 pagesPeople v. RiveraYori AvilaNo ratings yet

- Administralia: Instagram Captions / Questions + Answers From The Comments 2019 - 2020 byDocument45 pagesAdministralia: Instagram Captions / Questions + Answers From The Comments 2019 - 2020 byIina SivulaNo ratings yet

- Cuttack Chapter 2Document38 pagesCuttack Chapter 2jagadeeshnayakNo ratings yet

- TCW Modules MidtermsDocument11 pagesTCW Modules MidtermsSTEM-PERALTA RYZA M.No ratings yet

- United States Court of Appeals, Third CircuitDocument7 pagesUnited States Court of Appeals, Third CircuitScribd Government DocsNo ratings yet

- Tiểu luận TemplateDocument7 pagesTiểu luận TemplateThảo NguyênNo ratings yet

- Schem SPI Symbol Editor Users GuideDocument78 pagesSchem SPI Symbol Editor Users GuideRamasubramanian SNo ratings yet

- Role of It in Banking ReportDocument27 pagesRole of It in Banking ReportPrathmesh JambhulkarNo ratings yet

- Module. Major Foundations and Philosophies of CurriculumDocument7 pagesModule. Major Foundations and Philosophies of CurriculumJohn Dave MabántaNo ratings yet

- 16 Legacy B1 - P1 Quiz 8BDocument2 pages16 Legacy B1 - P1 Quiz 8BKremena Mihova100% (2)

- Mtz28je5ave MTZ28 5viDocument6 pagesMtz28je5ave MTZ28 5viIRAN FREONNo ratings yet

Comprehensive Supplier Audit - SafetyCulture

Comprehensive Supplier Audit - SafetyCulture

Uploaded by

reachtoramanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comprehensive Supplier Audit - SafetyCulture

Comprehensive Supplier Audit - SafetyCulture

Uploaded by

reachtoramanCopyright:

Available Formats

Go digital today!

Convert your paper checklists into digital forms

Scan this QR code to use this paper checklist on your smartphone or tablet or visit

https://safetyculture.com/

Title Page

Client / Site

Location Address

Conducted on Date

Prepared by

Quality Management

Is the quality system documented, controlled and maintained to clearly describe current practice?

Compliant Partial Compliant Non Compliant N/A

Do quality reports, trend charts and data analysis identify areas of opportunity and are used by

management on a routine

Compliant Partial Compliant Non Compliant N/A

Are quality-performance targets clearly defined, included in the business plan and monitored for

improvements?

Compliant Partial Compliant Non Compliant N/A

Does executive management participate in periodic quality system reviews that address quality-

related feedback from customers and internal quality metrics?

Compliant Partial Compliant Non Compliant N/A

Continuous Improvement

Are preventive actions taken based on the analysis of significant business trends, design reviews,

customer satisfaction surveys or other meaningful inputs?

Compliant Partial Compliant Non Compliant N/A

Is there a formal approach used to actively pursue cost containment and other continual

improvement activities throughout the organization?

Compliant Partial Compliant Non Compliant N/A

Is a corrective action system in place that provides root cause analysis and takes timely and effective

action to prevent recurrence?

Compliant Partial Compliant Non Compliant N/A

Does the corrective action system cover customer, internal and supplier issues?

Compliant Partial Compliant Non Compliant N/A

Education & Training

Is the skill and education level required for each job documented and appropriate training provided?

Compliant Partial Compliant Non Compliant N/A

Is employee qualification/certification maintained where the quality outcome of the process cannot

be verified and is strongly dependent upon operator skill?

Compliant Partial Compliant Non Compliant N/A

Are suitable methods used to verify training effectiveness?

Compliant Partial Compliant Non Compliant N/A

Are suitable records of maintained?

Compliant Partial Compliant Non Compliant N/A

Occupational Health & Safety

Does the health and safety management system address the safety of personnel without comprising

the achievement of product quality requirements?

Compliant Partial Compliant Non Compliant N/A

Does the health and safety management system address the requirement for emergency planning?

Compliant Partial Compliant Non Compliant N/A

Does the health and safety policy state the organization’s health and safety objectives and

management's commitment to continual improvement of H&S metrics?

Compliant Partial Compliant Non Compliant N/A

Are procedures used for the on-going identification of hazards, the assessment of risks, and the

implementation of necessary control measures?

Compliant Partial Compliant Non Compliant N/A

Design & Development Support

Are customer needs and requirements incorporated into product designs and/or manufacturing

processes?

Compliant Partial Compliant Non Compliant N/A

Are Critical-to-Quality (CTQ) characteristics are identified, understood and records retained?

Compliant Partial Compliant Non Compliant N/A

Are product specifications and drawings generated, controlled and maintained for new or changed

product designs?

Compliant Partial Compliant Non Compliant N/A

Is design validation is an integral part of the design process and occurs prior to production release?

Compliant Partial Compliant Non Compliant N/A

Are human and technical resources are adequate to meet the requirements for design collaboration,

tooling design, and electronic drawing and data exchange?

Compliant Partial Compliant Non Compliant N/A

Quality Planning

Are production samples inspected and provided to customers upon request?

Compliant Partial Compliant Non Compliant N/A

Are customer production requirements and quality specifications are reviewed to ensure they can be

met on a consistent basis?

Compliant Partial Compliant Non Compliant N/A

Are reliability test plans developed and routinely followed?

Compliant Partial Compliant Non Compliant N/A

Is testing used to verify the design specifications, drive design improvements and provide an on-

going check of materials and workmanship?

Compliant Partial Compliant Non Compliant N/A

Is product reliability test data is available upon request and historical test performance data shows a

highly stable process and product design?

Compliant Partial Compliant Non Compliant N/A

Customer Documentation

Are new and revised customer specifications reviewed and implemented in a timely manner?

Compliant Partial Compliant Non Compliant N/A

Are current process control documents in place and used for production start-up and continuing

production?

Compliant Partial Compliant Non Compliant N/A

Does customer notification/approval occur for changes to control plans, manufacturing site, product

transfers, raw material or product obsolescence?

Compliant Partial Compliant Non Compliant N/A

Is there a record control system is in place for the identification, storage, protection, retrieval,

retention time, and disposition of quality records?

Compliant Partial Compliant Non Compliant N/A

Are quality records maintained?

Compliant Partial Compliant Non Compliant N/A

Procurement

Is there a formal process used for the selection, qualification and re-qualification of suppliers?

Compliant Partial Compliant Non Compliant N/A

Are purchases from unapproved suppliers prevented by a properly controlled and available approved

supplier list?

Compliant Partial Compliant Non Compliant N/A

Are purchases from unapproved suppliers prevented by a properly controlled and available approved

supplier list?

Compliant Partial Compliant Non Compliant N/A

Are preventive actions taken to continuously improve performance of the supplier base?

Compliant Partial Compliant Non Compliant N/A

Does the supplier assurance system ensure that all purchased product or material conforms to

defined specifications and applicable regulatory or customer requirements?

Compliant Partial Compliant Non Compliant N/A

Does a system exist for the identification, verification and protection of customer supplied product

that includes notifying the customer if product is damaged or lost?

Compliant Partial Compliant Non Compliant N/A

Incoming Material

Is receiving inspection performed per documented procedures and detailed work instructions?

Compliant Partial Compliant Non Compliant N/A

Is inspected material adequately identified as to acceptance or rejection and traceable to receiving

inspection report?

Compliant Partial Compliant Non Compliant N/A

Do supplier corrective action requests requiring root cause investigation show responses are

analyzed?

Compliant Partial Compliant Non Compliant N/A

Manufacturing Quality

Is there a formal method used to qualify new or rebuilt production equipment prior to production

use?

Compliant Partial Compliant Non Compliant N/A

Are control plans used to plan and deploy inspection and test functions throughout the production

process?

Compliant Partial Compliant Non Compliant N/A

Are appropriate work instructions are available where needed that accurately describe all work

methods including inspections and tests to be done during production?

Compliant Partial Compliant Non Compliant N/A

Are appropriate inspections, tests and process adjustments made per applicable work instructions to

verify conformance at key points throughout the process and prior to shipment?

Compliant Partial Compliant Non Compliant N/A

Is the inspection and process status of the product identified and maintained throughout the

production process?

Compliant Partial Compliant Non Compliant N/A

Are customers notified of low yield production lots or issues that affect product reliability?

Compliant Partial Compliant Non Compliant N/A

Process Control

Are key part characteristics and process parameters are reviewed and statistically based controls

and/or problem solving tools are used to control variation?

Compliant Partial Compliant Non Compliant N/A

Are written improvement plans are implemented to reduce sources of variation?

Compliant Partial Compliant Non Compliant N/A

Is process capability is measured and actions are taken to maintain established minimum Cpk/Ppk

targets?

Compliant Partial Compliant Non Compliant N/A

Are out of control conditions are noted on charts and documented corrective action is taken to bring

the process back into control?

Compliant Partial Compliant Non Compliant N/A

Nonconforming Material

Are nonconforming materials, parts and assemblies are segregated (where practical) and identified

to prevent unapproved use?

Compliant Partial Compliant Non Compliant N/A

Are control plans used to plan and deploy inspection and test functions throughout the production

process?

Compliant Partial Compliant Non Compliant N/A

Are appropriate work instructions are available where needed that accurately describe all work

methods including inspections and tests to be done during production?

Compliant Partial Compliant Non Compliant N/A

Are appropriate inspections, tests and process adjustments made per applicable work instructions to

verify conformance at key points throughout the process and prior to shipment?

Compliant Partial Compliant Non Compliant N/A

Is the inspection and process status of the product identified and maintained throughout the

production process?

Compliant Partial Compliant Non Compliant N/A

Are customers notified of low yield production lots or issues that affect product reliability?

Compliant Partial Compliant Non Compliant N/A

Are key part characteristics and process parameters are reviewed and statistically based controls

and/or problem solving tools are used to control variation?

Compliant Partial Compliant Non Compliant N/A

Are written improvement plans are implemented to reduce sources of variation?

Compliant Partial Compliant Non Compliant N/A

Is process capability is measured and actions are taken to maintain established minimum Cpk/Ppk

targets?

Compliant Partial Compliant Non Compliant N/A

Are out of control conditions are noted on charts and documented corrective action is taken to bring

the process back into control?

Compliant Partial Compliant Non Compliant N/A

Are nonconforming materials, parts and assemblies are segregated (where practical) and identified

to prevent unapproved use?

Compliant Partial Compliant Non Compliant N/A

Is reworked material, parts and assemblies are re-inspected or re-tested to confirm compliance to

requirements?

Compliant Partial Compliant Non Compliant N/A

Is the use of nonconforming material is documented under a formal waiver or concession system?

Compliant Partial Compliant Non Compliant N/A

Is product traceability maintained to facilitate problem evaluation and corrective action?

Compliant Partial Compliant Non Compliant N/A

Is there a positive recall system to notify customers of nonconforming product that has already been

shipped?

Compliant Partial Compliant Non Compliant N/A

Monitoring & Measurement

Are gauge repeatability and reproducibility studies conducted to verify suitability of measuring

devices for their use in checking product quality or control of processes?

Compliant Partial Compliant Non Compliant N/A

Are measuring devices and gauges and test equipment are routinely calibrated and controlled per

documented procedures?

Compliant Partial Compliant Non Compliant N/A

Are gauges and test equipment calibrated against standards traceable to a recognized regulatory

body or agency?

Compliant Partial Compliant Non Compliant N/A

Are assessments made to check the validity of previous measurements done on products where out-

of-calibration measuring devices were used?

Compliant Partial Compliant Non Compliant N/A

Are appropriate controls are in place to verify the suitability and accuracy of computer software prior

to initial use in checking product quality or control of processes?

Compliant Partial Compliant Non Compliant N/A

Maintenance

Are tools stored in an appropriate, clearly defined area, with systematic tracking that provides

traceability, particularly of customer-owned tools and equipment?

Compliant Partial Compliant Non Compliant N/A

Does a formal preventive maintenance system (PM) exist for production equipment, tools and

fixtures?

Compliant Partial Compliant Non Compliant N/A

Is the preventive maintenance schedule is followed since product cannot be made with tools that are

outside of maintenance period?

Compliant Partial Compliant Non Compliant N/A

Environment

Does a documented environmental policy exist that includes a commitment to comply with relevant

environmental legislation and regulations and to continual improvement and pollution prevention?

Compliant Partial Compliant Non Compliant N/A

Is there is an environmental management system that ensures compliance to all applicable

government regulations and there are no outstanding, unresolved violations of these regulations?

Compliant Partial Compliant Non Compliant N/A

Is there a system is in place to minimize the use, disposal and emissions of hazardous chemicals are

not used in the manufacturing process?

Compliant Partial Compliant Non Compliant N/A

Is there an on-going emphasis is placed on using materials that are; compliant with applicable

regulations like WEEE, biodegradable, recyclable, re-usable, reduces pollutant emissions at the point

of use?

Compliant Partial Compliant Non Compliant N/A

Storage & Packing

Are areas around the facility clean and orderly and are tools and equipment properly stored and

readily available for use and is lighting and air quality are adequate?

Compliant Partial Compliant Non Compliant N/A

Is proper equipment and methods used to prevent product damage or loss in all phases of the

material handling process?

Compliant Partial Compliant Non Compliant N/A

Are documented procedures followed to ensure proper control and preservation of handling, storage

(FIFO), packaging, and delivery of product?

Compliant Partial Compliant Non Compliant N/A

Is the suitability of product packaging reviewed and concerns communicated to the customer prior to

initial production shipment?

Compliant Partial Compliant Non Compliant N/A

Is stored product/material periodically inspected, and where applicable, actions are taken to prevent

deterioration per documented procedures?

Compliant Partial Compliant Non Compliant N/A

Have contingency plans been developed that describe actions to be taken in the event of a major

interruption of the manufacturing process?

Compliant Partial Compliant Non Compliant N/A

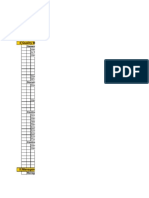

Completion

Full Name and Signature of Inspector Sign

The templates available in our Public Library have been created by our customers and employees to help get you started using SafetyCulture's solutions. The templates are intended to be used as

hypothetical examples only and should not be used as a substitute for professional advice. You should seek your own professional advice to determine if the use of a template is permissible in your

workplace or jurisdiction. You should independently determine whether the template is suitable for your circumstances.

You might also like

- Stravinsky Oedipus RexDocument131 pagesStravinsky Oedipus Rexkantee100% (16)

- ISO 9001 Quality Manual TemplateDocument43 pagesISO 9001 Quality Manual TemplateNC Rigor Luis93% (14)

- Entry of Apperance With Motion To Reset Preliminary ConferenceDocument4 pagesEntry of Apperance With Motion To Reset Preliminary ConferenceBalboa JapeNo ratings yet

- IMS Audit - Version 1Document11 pagesIMS Audit - Version 1arobNo ratings yet

- Supplier Assessment Form 04-16-2013 v20Document16 pagesSupplier Assessment Form 04-16-2013 v20Kovacs AndreeaNo ratings yet

- ISO 9001 Self Assessment ChecklistDocument2 pagesISO 9001 Self Assessment ChecklistJamal NasirNo ratings yet

- Questionario de Auditoria Check ListDocument4 pagesQuestionario de Auditoria Check ListGerardo Gómez SalasNo ratings yet

- Stalcop Llc. Supplier Audit Form: Page 1 of 12Document12 pagesStalcop Llc. Supplier Audit Form: Page 1 of 12ArdiFebriansyahNo ratings yet

- Preparation Checklist For ISO 22000 Audit IauditorDocument5 pagesPreparation Checklist For ISO 22000 Audit IauditorWalid RahmouniNo ratings yet

- Supplier Assessment ChecklistDocument2 pagesSupplier Assessment ChecklistCOLONEL ZIKRIA100% (1)

- ISO 9001 Quality Gap AnalysisDocument48 pagesISO 9001 Quality Gap Analysistracey.gartonNo ratings yet

- Quality IndicatorsDocument47 pagesQuality IndicatorsMaría Del Carmen Hernández CórdovaNo ratings yet

- BSI ISO 9001 Self Assessment Checklist PDFDocument2 pagesBSI ISO 9001 Self Assessment Checklist PDFHarshith Rao VadnalaNo ratings yet

- Abhishek Consultant ResumeDocument4 pagesAbhishek Consultant ResumeAbhishek SrivastvaNo ratings yet

- Job Description: QADocument3 pagesJob Description: QAhatackerNo ratings yet

- Quality ManagementDocument49 pagesQuality ManagementnnoumanNo ratings yet

- Supplier Quality Survey FormDocument4 pagesSupplier Quality Survey Formsutharitessh100% (1)

- Qms ManualDocument60 pagesQms ManualMayur RankNo ratings yet

- Iatf 16949:2016 Checklist - SafetycultureDocument84 pagesIatf 16949:2016 Checklist - Safetyculture88No1FanNo ratings yet

- Abhishek Consultant ResumeDocument4 pagesAbhishek Consultant ResumeAbhishek SrivastvaNo ratings yet

- 1 Check ListDocument60 pages1 Check ListRodrigo ArcilaNo ratings yet

- Chapter-V Om-2Document26 pagesChapter-V Om-2BerhanuTsarikuNo ratings yet

- QA QC-ManagerDocument2 pagesQA QC-ManagerMuhammad Abubakar SheikhNo ratings yet

- Quality Management 010Document70 pagesQuality Management 010Muhammad AsfarNo ratings yet

- Senior Warranty Engineer Generic JDDocument4 pagesSenior Warranty Engineer Generic JDAmr MohsenNo ratings yet

- ISO 9001 Awareness Program For CECDocument16 pagesISO 9001 Awareness Program For CECsuniljayaNo ratings yet

- Resume Sample For Quality Control InspectorDocument7 pagesResume Sample For Quality Control Inspectorc2yyr2c3100% (1)

- QADDocument12 pagesQADSrinivasan RadhaNo ratings yet

- 20 Jan 2022 Isaac MorokoDocument9 pages20 Jan 2022 Isaac MorokoIsaac MorokoNo ratings yet

- Fta Checklist Group NV 7-6-09Document7 pagesFta Checklist Group NV 7-6-09initiative1972No ratings yet

- SamplemanualDocument7 pagesSamplemanualisrael afolayan mayomiNo ratings yet

- IATF 16949 - 2016 Audit - SafetyCultureDocument97 pagesIATF 16949 - 2016 Audit - SafetyCultureShafiq KhanNo ratings yet

- Statistical Quality Control in LaboratoryDocument11 pagesStatistical Quality Control in Laboratoryabhijit612100% (2)

- 4 Quality Management System: Date: 29 October 2008 Location: AssessorDocument21 pages4 Quality Management System: Date: 29 October 2008 Location: AssessordkhondeNo ratings yet

- Supplier Quality QuestionnaireDocument4 pagesSupplier Quality QuestionnairesutharitesshNo ratings yet

- Unit I Quality Control and Reliability Engineering IP 33502Document4 pagesUnit I Quality Control and Reliability Engineering IP 33502Nishika chopraNo ratings yet

- Supplier Audit ChecklistDocument21 pagesSupplier Audit ChecklistAnonymous W2gdmMVhoM100% (2)

- Reliability Maturity Matrix: ©2015 Fred SchenkelbergDocument1 pageReliability Maturity Matrix: ©2015 Fred Schenkelbergmzai2003100% (1)

- Quality Checklist: Prepared By: DateDocument4 pagesQuality Checklist: Prepared By: DateIgnacio PerezNo ratings yet

- Supplier Qualification QuestionnaireDocument4 pagesSupplier Qualification QuestionnaireSeptian SuharyadiNo ratings yet

- Quality Control: This Approach Places An Emphasis On Three AspectsDocument12 pagesQuality Control: This Approach Places An Emphasis On Three AspectsJohn YohansNo ratings yet

- Gap Analysis ISO 9001 Checklist - SafetyCultureDocument9 pagesGap Analysis ISO 9001 Checklist - SafetyCultureZineb HAFIDINo ratings yet

- Pubh5107 Final Exam ReviewDocument419 pagesPubh5107 Final Exam Reviewkhanguraamanpreet55No ratings yet

- Amo Contractor Self-Audit ChecklistDocument6 pagesAmo Contractor Self-Audit ChecklistinternJGIPNo ratings yet

- 2006 CSTE CBOK Skill Category 1 (Part1)Document38 pages2006 CSTE CBOK Skill Category 1 (Part1)api-37337260% (1)

- Lesson 1 Applying Quality Standards AqsDocument289 pagesLesson 1 Applying Quality Standards Aqsjonathan labajoNo ratings yet

- Introduction To Quality ControlDocument22 pagesIntroduction To Quality ControlSakeena Naureen Ashraf100% (1)

- Supplier Assessment Form NewDocument49 pagesSupplier Assessment Form NewChinh Lê ĐìnhNo ratings yet

- FINAL - Audit Report - RAJEEV KUMARDocument4 pagesFINAL - Audit Report - RAJEEV KUMARRajeev KumarNo ratings yet

- Information: IATF 16949:2016 AuditDocument71 pagesInformation: IATF 16949:2016 AuditAshish SomaddarNo ratings yet

- Quality Checklist TemplateDocument4 pagesQuality Checklist TemplateSolange SaldíaNo ratings yet

- Quality Assurance and Quality Compliance Specialist: Arunkumar VenkatesanDocument3 pagesQuality Assurance and Quality Compliance Specialist: Arunkumar VenkatesangunneshNo ratings yet

- ISO 9001 - 2015 Audit Checklist - SafetyCultureDocument47 pagesISO 9001 - 2015 Audit Checklist - SafetyCultureengjaildaNo ratings yet

- QA Manager YogeshDocument4 pagesQA Manager YogeshParag WadekarNo ratings yet

- Maximizing Efficiency and Compliance: Essential Tips For Conducting An Effective Annual Product Quality Review (APQR)Document10 pagesMaximizing Efficiency and Compliance: Essential Tips For Conducting An Effective Annual Product Quality Review (APQR)aniaaa220No ratings yet

- Supplier Quality Survey Form2Document4 pagesSupplier Quality Survey Form2Sutha Tamil NambeNo ratings yet

- ISO 9001-2015 Transition Checklist C 01 Rev ADocument4 pagesISO 9001-2015 Transition Checklist C 01 Rev Avikkasverma.in100% (1)

- SQA Paper Solution Nov19Document16 pagesSQA Paper Solution Nov19satyamshingade2No ratings yet

- Quality Control DepartmentDocument5 pagesQuality Control DepartmentRonnel MatampaleNo ratings yet

- Criminal Procedure (Investigative) OutlineDocument22 pagesCriminal Procedure (Investigative) OutlineJohnny EmmNo ratings yet

- Constitutional InterpretationDocument13 pagesConstitutional InterpretationAndrew SekayiriNo ratings yet

- (Me 15) Bosh - Lecture 02Document36 pages(Me 15) Bosh - Lecture 02Strong Boy OgkoNo ratings yet

- Danika Tynes ResumeDocument6 pagesDanika Tynes ResumeDanika Tynes100% (1)

- Solo 1-MathDocument3 pagesSolo 1-Mathapi-168501117No ratings yet

- SBU 105 Introduction To ComputersDocument2 pagesSBU 105 Introduction To ComputersSaviourNo ratings yet

- Grade 9 Character EssayDocument9 pagesGrade 9 Character EssayAliceCameronRussellNo ratings yet

- Corpas Pastor, G. & Gaber, M. Noviembre, 2020 Remote Interpreting in Public Service Settings Technology, Perceptions and PracticeDocument22 pagesCorpas Pastor, G. & Gaber, M. Noviembre, 2020 Remote Interpreting in Public Service Settings Technology, Perceptions and PracticeLuis TraductorNo ratings yet

- Designer Profile For Jonathan IveDocument6 pagesDesigner Profile For Jonathan IveJaneNo ratings yet

- Law & Corporate FinanceDocument238 pagesLaw & Corporate FinanceRajesh Shantaram Shinde100% (1)

- COVID-19 and Pregnancy: A Review of Clinical Characteristics, Obstetric Outcomes and Vertical TransmissionDocument20 pagesCOVID-19 and Pregnancy: A Review of Clinical Characteristics, Obstetric Outcomes and Vertical TransmissionDra Sandra VèlezNo ratings yet

- Cfa Level II ErrataDocument11 pagesCfa Level II ErrataWasita PiamwareeNo ratings yet

- Republic of The Philippines Department of Education Ugong Pasig National High SchoolDocument12 pagesRepublic of The Philippines Department of Education Ugong Pasig National High SchoolJOEL MONTERDENo ratings yet

- Volvo B5TL: When All You Need Is Everything in A Double Deck BusDocument13 pagesVolvo B5TL: When All You Need Is Everything in A Double Deck BusКонстантин КосаревNo ratings yet

- (Environmental Pollution 16) Kai Bester, Christa S. McArdell, Cajsa Wahlberg, Thomas D. Bucheli (Auth.), Despo Fatta-Kassinos, Kai Bester, Klaus Kümmerer (Eds.) - Xenobiotics in The Urban WaterDocument521 pages(Environmental Pollution 16) Kai Bester, Christa S. McArdell, Cajsa Wahlberg, Thomas D. Bucheli (Auth.), Despo Fatta-Kassinos, Kai Bester, Klaus Kümmerer (Eds.) - Xenobiotics in The Urban WaterKarlysson JorddanNo ratings yet

- Section Viii Div 1 Div 2 Div ComparisonDocument2 pagesSection Viii Div 1 Div 2 Div Comparisonapparaokr100% (5)

- What Is WifiDocument7 pagesWhat Is WifiHemant ThakkarNo ratings yet

- People v. RiveraDocument17 pagesPeople v. RiveraYori AvilaNo ratings yet

- Administralia: Instagram Captions / Questions + Answers From The Comments 2019 - 2020 byDocument45 pagesAdministralia: Instagram Captions / Questions + Answers From The Comments 2019 - 2020 byIina SivulaNo ratings yet

- Cuttack Chapter 2Document38 pagesCuttack Chapter 2jagadeeshnayakNo ratings yet

- TCW Modules MidtermsDocument11 pagesTCW Modules MidtermsSTEM-PERALTA RYZA M.No ratings yet

- United States Court of Appeals, Third CircuitDocument7 pagesUnited States Court of Appeals, Third CircuitScribd Government DocsNo ratings yet

- Tiểu luận TemplateDocument7 pagesTiểu luận TemplateThảo NguyênNo ratings yet

- Schem SPI Symbol Editor Users GuideDocument78 pagesSchem SPI Symbol Editor Users GuideRamasubramanian SNo ratings yet

- Role of It in Banking ReportDocument27 pagesRole of It in Banking ReportPrathmesh JambhulkarNo ratings yet

- Module. Major Foundations and Philosophies of CurriculumDocument7 pagesModule. Major Foundations and Philosophies of CurriculumJohn Dave MabántaNo ratings yet

- 16 Legacy B1 - P1 Quiz 8BDocument2 pages16 Legacy B1 - P1 Quiz 8BKremena Mihova100% (2)

- Mtz28je5ave MTZ28 5viDocument6 pagesMtz28je5ave MTZ28 5viIRAN FREONNo ratings yet