Professional Documents

Culture Documents

Product Submittal Sheet: 600S350-54 (50ksi, CP60) P - Punched

Product Submittal Sheet: 600S350-54 (50ksi, CP60) P - Punched

Uploaded by

zrkamine17Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Submittal Sheet: 600S350-54 (50ksi, CP60) P - Punched

Product Submittal Sheet: 600S350-54 (50ksi, CP60) P - Punched

Uploaded by

zrkamine17Copyright:

Available Formats

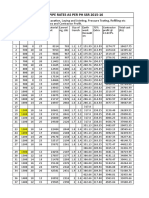

Product Submittal Sheet

Technical Services: 888-437-3244 Sales: 800-543-7140

Engineering Services: 877-832-3206 clarkdietrich.com

Product category: S350 (3-1/2" Flange Structural Stud) 05.40.00 (Cold-Formed Metal Framing)

Product name: 600S350-54 (50ksi, CP60) P - Punched

54mils (16ga) Coating: CP60 per AISI S240

Color coding: Green

Geometric Properties

Web depth 6.000 in

Flange width 3.500 in Punchout width 1.50 in

Stiffening lip 1.000 in Punchout length 4.00 in

Design thickness 0.0566 in Min. steel thickness 0.0538 in

Yield strength, Fy 50 ksi Fy with Cold-Work, Fya 50.0 ksi

Ultimate, Fu 65.0 ksi

Gross Section Properties of Full Section, Strong Axis

Cross sectional area (A) 0.825 in2

Member weight per foot of length 2.81 lb/ft

Moment of inertia (Ix) 5.023 in4

Section modulus (Sx) 1.674 in3

Radius of gyration (Rx) 2.467 in

Gross moment of inertia (Iy) 1.491 in4

Gross radius of gyration (Ry) 1.344 in

Used in framing applications:

Effective Section Properties, Strong Axis • Load-bearing walls

Effective Area (Ae) 0.440 in 2 • Curtain walls

Moment of inertia for deflection (Ix) 4.722 in4 • Tall interior walls

Section modulus (Sx) 1.335 in3 • Floor & ceiling joists

Allowable bending moment (Ma) 39.98 in-k • Trusses

Allowable moment based on distortion buckling (Mad) 35.80 in-k

Allowable shear force in web (solid section) 2823 lb

Allowable shear force in web (perforated section) 1947 lb

Unbraced length (Lu) 74.4 in

Torsional Properties

St. Venant torsion constant (J x 1000) 0.881 in4

Warping constant (Cw) 12.942 in6

Distance from shear center to neutral axis (Xo) -3.037 in

Distance between shear center and web centerline (m) 1.787 in

Radii of gyration (Ro) 4.137 in

Torsional flexural constant (Beta) 0.461

Code Approvals & Performance Standards

AISI S100-16 - North American Specification for the Design of CFS Structural Members

• Effective properties incorporate the strength increase from the cold work of forming

• Gross properties are based on the cross section away from the punchouts Structural

AISI S240-15 - North American Standard for Cold-Formed Steel Structural Framing Punchout

(Compliant to ASTM C955, but IBC replaced with AISI S200 in 2015, AISI S240 in 2018) East market punchout spacing:

• Section A3 - Material - Chemical & mechanical requirements (Referencing ASTM A1003/A1003M) 12" from lead end then 24" o.c.

• Section A4 - Corrosion Protection (Referencing ASTM A653/A653M)

• Section A5 - Products - Thickness, shapes, tolerances, identification West market punchout spacing:

• Section C - Installation - (Referencing ASTM C1007) 24" from lead end then 24" o.c.

AISI S202-15 - Code of Standard Practice for Cold-Formed Steel Structural Framing

• Section F3 - Delivery, Handling and Storage of Materials

Sustainability Credits For more details and LEED letters contact Technical Services at 888-437-3244 or visit clarkdietrich.com/LEED.

LEED v4.1 MR Credit: Environmental Product Declarations: EPD (1 point) - Sourcing of Raw Materials (up to 2 points) - Material Ingredients (1 point) - Construction and

Demolition Waste Management (up to 2 points)

LEED v4 MR Credit: Building Product Disclosure and Optimization: EPD (1 point) - Sourcing of Raw Materials (1 point) - Material Ingredients (1 point) - Construction and

Demolition Waste Management (up to 2 points) - Innovation Credit (up to 2 points).

CD-STRS © 08/21 ClarkDietrich

You might also like

- CBLM Rogh-In PDFDocument64 pagesCBLM Rogh-In PDFmyco saura80% (5)

- Load and Resistance Factor DesignDocument9 pagesLoad and Resistance Factor DesignYan Naung Ko100% (2)

- Product Submittal Sheet: 1400S200-68 (50ksi, CP60) P - PunchedDocument1 pageProduct Submittal Sheet: 1400S200-68 (50ksi, CP60) P - PunchedAdnan QuaziNo ratings yet

- 05a 1.25x5.5 Studs - Product Submittal Sheet - CD - 550PDS125-30-33ksiDocument2 pages05a 1.25x5.5 Studs - Product Submittal Sheet - CD - 550PDS125-30-33ksiGlenn PintorNo ratings yet

- StudDocument1 pageStudzaidg9876553No ratings yet

- Properties:: Product NameDocument1 pageProperties:: Product NamesumitNo ratings yet

- Crack Width Check Bottom Dome MxmaxDocument151 pagesCrack Width Check Bottom Dome MxmaxSaahil BaderNo ratings yet

- BT 01.01.00.iam Frame Analysis Report 20-11-2022 - SalinDocument47 pagesBT 01.01.00.iam Frame Analysis Report 20-11-2022 - SalinAbdianor Teknik mesinNo ratings yet

- Frame Analysis Penampang AtasDocument21 pagesFrame Analysis Penampang AtasMuhammad NaufalNo ratings yet

- FRAMECAD Steel SpecDocument3 pagesFRAMECAD Steel Specalberto5791No ratings yet

- Skid Prueba 4302Document53 pagesSkid Prueba 4302daniel augusto cubillos sarmientoNo ratings yet

- BT 01.01.00.iam Frame Analysis Report 20 - 11 - 2022-1-44Document44 pagesBT 01.01.00.iam Frame Analysis Report 20 - 11 - 2022-1-44turn on and playNo ratings yet

- Integriwise Assessment Report: Assessment To Api 579 Section 4. General Metal Loss. Thickness ProfilesDocument4 pagesIntegriwise Assessment Report: Assessment To Api 579 Section 4. General Metal Loss. Thickness ProfilesLazaro Irving Orozco CruzNo ratings yet

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilNo ratings yet

- Bolted Fin Plate Connection Title: Notes and AssumptionsDocument6 pagesBolted Fin Plate Connection Title: Notes and AssumptionsJonAthan LimNo ratings yet

- 2810 Bracket Design ReportDocument12 pages2810 Bracket Design ReportKar ConsultNo ratings yet

- Investigation On The Strength and Behavior of Cold-Formed Steel Angle ColumnsDocument8 pagesInvestigation On The Strength and Behavior of Cold-Formed Steel Angle ColumnsIJRASETPublicationsNo ratings yet

- Pile Cap DesignDocument13 pagesPile Cap Designmohammed samiNo ratings yet

- Timber Construction: Connection Design According To Nzs 3603 Using Spax ScrewsDocument12 pagesTimber Construction: Connection Design According To Nzs 3603 Using Spax Screwstimur sibaevNo ratings yet

- Pile Cap DesignDocument13 pagesPile Cap DesignShabbir OsmaniNo ratings yet

- Engineering Calculation Sheet Consulting EngineersDocument17 pagesEngineering Calculation Sheet Consulting EngineersParthiban ArivazhaganNo ratings yet

- Connection Design Steel Base Plate Bs5950 v2015 01Document4 pagesConnection Design Steel Base Plate Bs5950 v2015 01Anonymous j9PxwnoNo ratings yet

- ZBO Wireline ComplexDocument28 pagesZBO Wireline ComplexLUIS GUILLERMONo ratings yet

- Nu 2356 Ma - 20230103Document5 pagesNu 2356 Ma - 20230103Brion Bara IndonesiaNo ratings yet

- Corobore® 825: Fine Boring Tools With Silent Tools™ TechnologyDocument2 pagesCorobore® 825: Fine Boring Tools With Silent Tools™ TechnologyNILOHAYASHINo ratings yet

- WSD Connection MasterDocument5 pagesWSD Connection MasterSteelfab Structural AssociatesNo ratings yet

- H13 1.2344 SKD61 Flat BarDocument4 pagesH13 1.2344 SKD61 Flat BarMANJEET KUMARNo ratings yet

- Frame Kaki KakiDocument21 pagesFrame Kaki KakiMuhammad NaufalNo ratings yet

- Footing CalcutaionDocument15 pagesFooting Calcutaiong9bashNo ratings yet

- Bike Rack and Hitch Haul PartsDocument15 pagesBike Rack and Hitch Haul PartsJaNo ratings yet

- Machining Character Analysis of Coated and Uncoated End Mill On Heat Treated C45 SteelDocument8 pagesMachining Character Analysis of Coated and Uncoated End Mill On Heat Treated C45 SteelIJRASETPublicationsNo ratings yet

- Design Guide To AS1720Document12 pagesDesign Guide To AS1720Adam DawsonNo ratings yet

- Sika Anchorfix 2 PDFDocument7 pagesSika Anchorfix 2 PDFUnited Construction Est. TechnicalNo ratings yet

- IJTRD21945Document10 pagesIJTRD21945shashikant gaurNo ratings yet

- Low Hydrogen Mild Steel ElectrodesDocument6 pagesLow Hydrogen Mild Steel ElectrodesAdura OgunnuNo ratings yet

- Voith Hirth Couplings CatalogueDocument16 pagesVoith Hirth Couplings CataloguefedericoNo ratings yet

- 6C High Strength Reinforcement G HalstedDocument36 pages6C High Strength Reinforcement G HalstedRafid RabbaniNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Project Data: DesignDocument18 pagesProject Data: DesignMarco ZanellaNo ratings yet

- Experimental Analysis of Friction Welding For Dissimilar MetalsDocument45 pagesExperimental Analysis of Friction Welding For Dissimilar MetalsSumaiya BegamNo ratings yet

- Member Design Reinforced Concrete Corbel bs8110 v2015 01Document10 pagesMember Design Reinforced Concrete Corbel bs8110 v2015 01Aboalmaali100% (1)

- 240 - 950 BC - 20220722Document4 pages240 - 950 BC - 20220722Sabaresan :: PolymersNo ratings yet

- Lec 01 - Steel and Introduction To AISC Steel ManualDocument26 pagesLec 01 - Steel and Introduction To AISC Steel ManualbilalNo ratings yet

- Support Industrial Rack Catalogue PDFDocument12 pagesSupport Industrial Rack Catalogue PDFbelal545No ratings yet

- Specification: Si MN P S 0.08 0.56 1.02 0.013 0.010Document2 pagesSpecification: Si MN P S 0.08 0.56 1.02 0.013 0.010Jennylyn DañoNo ratings yet

- B231e VFR EnglishDocument32 pagesB231e VFR EnglishAlexandre SouzaNo ratings yet

- Link Belt CatalogoDocument24 pagesLink Belt Catalogodiegowrg2023No ratings yet

- SABIC Flat ProductDocument15 pagesSABIC Flat ProductAiman AliNo ratings yet

- 1.3 Design Data - SD 672 New Final - PDF 02-04-2018Document19 pages1.3 Design Data - SD 672 New Final - PDF 02-04-2018simon maaaklaNo ratings yet

- Foundation 1 Design ReportDocument6 pagesFoundation 1 Design ReportDinesh RajaNo ratings yet

- Pile Cap DesignDocument13 pagesPile Cap DesigngnanaNo ratings yet

- Frame Analysis Report: Project Info (Iproperties)Document45 pagesFrame Analysis Report: Project Info (Iproperties)Breno RossiNo ratings yet

- NASA - 60NiTi Superelastic Hybrid Angular Contact Ball Bearings - 2016Document18 pagesNASA - 60NiTi Superelastic Hybrid Angular Contact Ball Bearings - 2016akrobinsNo ratings yet

- Brands You Trust.: KROMBACH® Triple-Eccentric Valves (Tri-EX) AK110Document8 pagesBrands You Trust.: KROMBACH® Triple-Eccentric Valves (Tri-EX) AK110Luis Daniel ContrerasNo ratings yet

- Frame Analysis Report: Project Info (Iproperties)Document5 pagesFrame Analysis Report: Project Info (Iproperties)HIMANSHU SUTHARNo ratings yet

- Design For 4-Pile Group (Square Group)Document3 pagesDesign For 4-Pile Group (Square Group)Hemam Prasanta100% (1)

- 16 Bolt Pattern Fixed Base Plate Design - For 4.6 Grade Anchor BoltsDocument30 pages16 Bolt Pattern Fixed Base Plate Design - For 4.6 Grade Anchor Boltsafzal samaNo ratings yet

- Pile Cap DesignDocument13 pagesPile Cap DesignWahid wrbelNo ratings yet

- AAC LeichtBric 2020Document10 pagesAAC LeichtBric 2020Jared Josef GomezNo ratings yet

- Metal Tek ScrewDocument2 pagesMetal Tek ScrewAmin SalahNo ratings yet

- 4 Nov. 28 21 RA 9184Document233 pages4 Nov. 28 21 RA 9184GeloNo ratings yet

- Roman Architecture: RevisionDocument48 pagesRoman Architecture: Revisionaldemar reyes alvisNo ratings yet

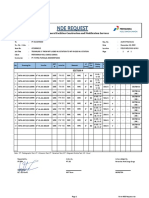

- STP XXXXXXX 15-Feb-19: Metro Engineering Works Sheet NoDocument1 pageSTP XXXXXXX 15-Feb-19: Metro Engineering Works Sheet NoNagender KumarNo ratings yet

- Request NDT Section 4 TGL 16-12-2022Document1 pageRequest NDT Section 4 TGL 16-12-2022Ferdie OSNo ratings yet

- Marshall Vs SuperpaveDocument72 pagesMarshall Vs SuperpaveSamarth Garg100% (1)

- Mos M&e Ot Acmv 010.00.RvwDocument39 pagesMos M&e Ot Acmv 010.00.RvwWan RollaNo ratings yet

- R 001 PDFDocument152 pagesR 001 PDFleekiangyenNo ratings yet

- The Use of Geomembranes in DamsDocument9 pagesThe Use of Geomembranes in DamsEngr. Muhammad Jamil Alam SandhuNo ratings yet

- Daewoo ERF-384Document67 pagesDaewoo ERF-384pepepeNo ratings yet

- Portfolio Nikolay NikolaevDocument120 pagesPortfolio Nikolay NikolaevJames HensleyNo ratings yet

- WB2553Document2 pagesWB2553Scott FullerNo ratings yet

- Recycled AggregatesDocument31 pagesRecycled Aggregatesshailesh goral56% (9)

- 62 038Document14 pages62 038inomadfmNo ratings yet

- OfonDocument3 pagesOfonMasomese Henry KikileNo ratings yet

- RFI-198 Embankment Fill Top Layer FDD Test and Level Check at Mawa End Approach (NA) Site (3!2!2021)Document1 pageRFI-198 Embankment Fill Top Layer FDD Test and Level Check at Mawa End Approach (NA) Site (3!2!2021)rownakNo ratings yet

- Scope of WorkDocument6 pagesScope of WorkArockia Rohan Vincent100% (2)

- BP2Document3 pagesBP2insane88No ratings yet

- High Skew Link Slab Bridge SystemDocument165 pagesHigh Skew Link Slab Bridge SystemRelu-Razvan TibreaNo ratings yet

- Ideal Home For Steel Fabrication: Gambia Groundnut Corporation - GambiaDocument12 pagesIdeal Home For Steel Fabrication: Gambia Groundnut Corporation - Gambiaomar mahmoudNo ratings yet

- Mobile Equipment Vibration Case Study From Operations To ISO StandardDocument12 pagesMobile Equipment Vibration Case Study From Operations To ISO Standardgk_kishoree81No ratings yet

- ModelDocument262 pagesModelMuhammad UsmanNo ratings yet

- McGuire Enterprises Launches Curb Ramp™ - An Eco-Friendly Driveway Ramp For Lowered CarsDocument2 pagesMcGuire Enterprises Launches Curb Ramp™ - An Eco-Friendly Driveway Ramp For Lowered CarsPR.comNo ratings yet

- TXMAS Honeywell ListDocument64 pagesTXMAS Honeywell ListLorena Yepes VareloNo ratings yet

- Method Statement For Air Leak For HVAC Duct System (Light Test)Document3 pagesMethod Statement For Air Leak For HVAC Duct System (Light Test)JAY ROD AWITNo ratings yet

- CRRI Presentation On GeosyntheticsDocument51 pagesCRRI Presentation On GeosyntheticsGautam RaiNo ratings yet

- QMS Manual ISO 9001:2015Document30 pagesQMS Manual ISO 9001:2015vivekcp8750% (2)

- (Guidelines) Bearings For BridgesDocument21 pages(Guidelines) Bearings For BridgesRAJENDRA PRASADNo ratings yet

- MS Data For Crossings Final Data PrasadDocument105 pagesMS Data For Crossings Final Data PrasadprasadunelapatiNo ratings yet