Professional Documents

Culture Documents

MOS-008 For Water Leaking Test

MOS-008 For Water Leaking Test

Uploaded by

slayerzzz22Copyright:

Available Formats

You might also like

- Cockney MonologuesDocument2 pagesCockney MonologuesLaReceHawkins86% (7)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Isimba - A Church Management System For STDocument22 pagesIsimba - A Church Management System For STAllan Credo100% (3)

- Method Statement - Sub-Base and Aggregate Base CourseDocument9 pagesMethod Statement - Sub-Base and Aggregate Base CourseTAHER AMMAR100% (6)

- CV-0013-002 - Method Statement For Soil Improvement WorkDocument14 pagesCV-0013-002 - Method Statement For Soil Improvement Work한상호No ratings yet

- Pumphouse ConstructionDocument10 pagesPumphouse Constructionsuryakantame100% (2)

- Method of Statement For Road Crossing WorkDocument7 pagesMethod of Statement For Road Crossing WorkAnonymous voA5Tb0No ratings yet

- The Ultimate Guide To Drum Programming - EDMProdDocument32 pagesThe Ultimate Guide To Drum Programming - EDMProdSteveJones100% (4)

- Field Book for Quality Control in Earthwork Operations: Project Construction Management BookFrom EverandField Book for Quality Control in Earthwork Operations: Project Construction Management BookNo ratings yet

- Introduction To Criminology (Review Materials For 2013 Criminology Board Examination)Document43 pagesIntroduction To Criminology (Review Materials For 2013 Criminology Board Examination)Clarito Lopez88% (33)

- Method Statement Shotcrete: Page 1 of 7Document7 pagesMethod Statement Shotcrete: Page 1 of 7J. Kumar Infraprojects Ltd100% (3)

- Method Statement Installation of Rock BoltDocument5 pagesMethod Statement Installation of Rock BoltJ. Kumar Infraprojects Ltd100% (2)

- 04 Method of Statment - Chilled Water Pipe Insulation - PSDocument12 pages04 Method of Statment - Chilled Water Pipe Insulation - PSUnique PlanningNo ratings yet

- MST For Below Ground UPVC Drainage PipesDocument13 pagesMST For Below Ground UPVC Drainage Pipesمقاول تكييف كهرباء وصحيNo ratings yet

- MS C 06 PlasterinDocument4 pagesMS C 06 PlasterinYENDRU LALITHAKUMARINo ratings yet

- Method Statement For DI PipingDocument16 pagesMethod Statement For DI Pipingtomj9104No ratings yet

- Uncontrolled Flow of Air From WellDocument4 pagesUncontrolled Flow of Air From WellMahesh GediyaNo ratings yet

- Pigging in Pipeline Pre-Commissioning PDFDocument8 pagesPigging in Pipeline Pre-Commissioning PDFhemn100% (2)

- 22.MS For HydrotestDocument9 pages22.MS For HydrotestASHWANINo ratings yet

- Installation of Pipeline by HDD For NGN Pipeline ProjectDocument48 pagesInstallation of Pipeline by HDD For NGN Pipeline ProjectDie HArd100% (1)

- Spe 114703 MSDocument11 pagesSpe 114703 MSBobby Rifki SaputraNo ratings yet

- MST Water Pipe RelocationDocument29 pagesMST Water Pipe Relocationslayerzzz22No ratings yet

- Method Statement For BACKFILLING WORKSDocument12 pagesMethod Statement For BACKFILLING WORKSYash Sharma50% (2)

- Spe-214579-Ms Rigless Solution in Replacement of Rig InterventionDocument8 pagesSpe-214579-Ms Rigless Solution in Replacement of Rig Interventionbagus918No ratings yet

- Pigging in Pipeline Pre-Commissioning PDFDocument8 pagesPigging in Pipeline Pre-Commissioning PDFAbhiyan Anala Arvind100% (1)

- Pre - Commissioning & Commissioning ProcedureDocument6 pagesPre - Commissioning & Commissioning Procedurepankaj.ovalNo ratings yet

- Leakage TestDocument5 pagesLeakage TestScribdTranslationsNo ratings yet

- METHOD STATEMENT - Sub-Base and Aggregate Base Course: June 2018Document10 pagesMETHOD STATEMENT - Sub-Base and Aggregate Base Course: June 2018Tajammal ArifeenNo ratings yet

- Determination of Temporary Ditch Check Performance in Protecting Earthen Channels From Stormwater-Induced ErosionDocument8 pagesDetermination of Temporary Ditch Check Performance in Protecting Earthen Channels From Stormwater-Induced ErosionmickyfelixNo ratings yet

- RWTP GB CNS MST 000067 00Document61 pagesRWTP GB CNS MST 000067 00slayerzzz22No ratings yet

- Method Statement Raub EditDocument10 pagesMethod Statement Raub EditMohd HafizNo ratings yet

- Method Statement For The Flushing of Firefighting Pipes.R7Document9 pagesMethod Statement For The Flushing of Firefighting Pipes.R7adel rihanaNo ratings yet

- Ed Well ControlDocument18 pagesEd Well ControlAmeer BabylonianNo ratings yet

- Quad Pipe Hydrotest Procedure Rev1Document16 pagesQuad Pipe Hydrotest Procedure Rev1Trust EmmaNo ratings yet

- Method of Statement For GRP WorkDocument17 pagesMethod of Statement For GRP WorkAhmed IbrahimNo ratings yet

- KDP Well Test Procedures ManualDocument77 pagesKDP Well Test Procedures ManualJacob Keemink100% (2)

- 2005 Aberdeen 2 RussellDocument8 pages2005 Aberdeen 2 RussellLiner MasterNo ratings yet

- Quad Pipe Hydrotest Procedure Rev2Document15 pagesQuad Pipe Hydrotest Procedure Rev2Trust EmmaNo ratings yet

- Method Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFDocument8 pagesMethod Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFFredie UnabiaNo ratings yet

- MSAE014-QC-PRE-035-Quality Procedure For Hydrostatic TestingDocument12 pagesMSAE014-QC-PRE-035-Quality Procedure For Hydrostatic Testingqamar qateebNo ratings yet

- METHOD STATEMENT FOR System Commissinig and Testing - Rev 0Document5 pagesMETHOD STATEMENT FOR System Commissinig and Testing - Rev 0Osama MZNo ratings yet

- MDPE Work ProcedureDocument18 pagesMDPE Work ProcedureANURAG YADAVNo ratings yet

- Method Statement and Risk Assessment For Basement Waterproofing WorksDocument30 pagesMethod Statement and Risk Assessment For Basement Waterproofing WorksVishaul RamanNo ratings yet

- New Austrian Tunneling MethodDocument31 pagesNew Austrian Tunneling MethodJudy Ann CacutNo ratings yet

- Honing Procedure: Doc. No.: - Job No.: 26071Document10 pagesHoning Procedure: Doc. No.: - Job No.: 26071Muhammad GaneshaNo ratings yet

- Larsen & Toubro Limited - Ecc Division: Page 1 of 4Document4 pagesLarsen & Toubro Limited - Ecc Division: Page 1 of 4Akhilesh DwivediNo ratings yet

- WT Training ManualDocument429 pagesWT Training Manualbilmard100% (4)

- MIP6-CV-0013-001 - Method Statement For Excavation and Fill WorkDocument12 pagesMIP6-CV-0013-001 - Method Statement For Excavation and Fill Work한상호No ratings yet

- Successful Placement CementDocument11 pagesSuccessful Placement CementOmerNo ratings yet

- Fatal Incident in Pipeline During Pigging Activity 1689382935Document4 pagesFatal Incident in Pipeline During Pigging Activity 1689382935harish14586100% (1)

- RTR Piping System PDFDocument8 pagesRTR Piping System PDFmohdNo ratings yet

- Master Thesis Technical Paper 2019Document9 pagesMaster Thesis Technical Paper 2019MogheshwarGokulRNo ratings yet

- 13 PiggingDocument14 pages13 PiggingDaniel DamboNo ratings yet

- Epic For Upgrade of Port Control Tower and Systems at RlicDocument8 pagesEpic For Upgrade of Port Control Tower and Systems at RlicsreeNo ratings yet

- On Plot HydrotestingDocument14 pagesOn Plot HydrotestingShambu S VtkNo ratings yet

- Methodology For REHABILITATION OF WATER DISTRIBUTION AND SERVICE LINE APPURTENANCES CWDDocument6 pagesMethodology For REHABILITATION OF WATER DISTRIBUTION AND SERVICE LINE APPURTENANCES CWDFritz NatividadNo ratings yet

- CV-0013-006 - Method Statement For Trial Test For Stone ColumnDocument8 pagesCV-0013-006 - Method Statement For Trial Test For Stone Column한상호No ratings yet

- Example WMS DecommDocument7 pagesExample WMS DecommKin HamzahNo ratings yet

- Method Statement For Installation of Chilled Water Pipe (21!4!2024)Document22 pagesMethod Statement For Installation of Chilled Water Pipe (21!4!2024)sheik.rasith.anvarNo ratings yet

- Method Statement of Routine Pile Load Test (Dynamic)Document3 pagesMethod Statement of Routine Pile Load Test (Dynamic)Akhilesh Dwivedi100% (2)

- Method Statement PLUS PipeDocument11 pagesMethod Statement PLUS PipeMohd HafizNo ratings yet

- SQF-RAMS-LIN-DR-02 - Installation of Condensate Drain Pipes.Document30 pagesSQF-RAMS-LIN-DR-02 - Installation of Condensate Drain Pipes.Akshay DeepNo ratings yet

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- RWTP GB Qaqc MPR 000006Document37 pagesRWTP GB Qaqc MPR 000006slayerzzz22No ratings yet

- Case Study StudentDocument24 pagesCase Study Studentslayerzzz22No ratings yet

- RWTP GB Mne Msa 000139 SignedDocument39 pagesRWTP GB Mne Msa 000139 Signedslayerzzz22No ratings yet

- RWTP GB MNE MST 000043 - AV - SystemDocument52 pagesRWTP GB MNE MST 000043 - AV - Systemslayerzzz22No ratings yet

- RWTP GB MNE MST 000046 - Underground - DuctDocument54 pagesRWTP GB MNE MST 000046 - Underground - Ductslayerzzz22No ratings yet

- RWTP GB Cns Msa 000173Document61 pagesRWTP GB Cns Msa 000173slayerzzz22No ratings yet

- RWTP GB MNE MST 000031 Telecommunication SystemDocument60 pagesRWTP GB MNE MST 000031 Telecommunication Systemslayerzzz22No ratings yet

- RWTP-GB-AMS-L-000668-2024 - Reply-Site ObservationCorrective Action Request No. P1-003Document2 pagesRWTP-GB-AMS-L-000668-2024 - Reply-Site ObservationCorrective Action Request No. P1-003slayerzzz22No ratings yet

- Case Study Student AnswerDocument7 pagesCase Study Student Answerslayerzzz22No ratings yet

- Checklist Genenral Concret RepairDocument6 pagesChecklist Genenral Concret Repairslayerzzz22No ratings yet

- Australia Iteanary 2024Document3 pagesAustralia Iteanary 2024slayerzzz22No ratings yet

- RWTP GB CNS Msa 000177Document38 pagesRWTP GB CNS Msa 000177slayerzzz22No ratings yet

- Jlgwvkyfc Gkpxmvbs7Kxdtdymvcrgc Vcvbilbkfcxvnraep: Bill StatementDocument5 pagesJlgwvkyfc Gkpxmvbs7Kxdtdymvcrgc Vcvbilbkfcxvnraep: Bill Statementslayerzzz22No ratings yet

- RWTP GB Mne Msa 000049Document44 pagesRWTP GB Mne Msa 000049slayerzzz22No ratings yet

- RWTP-GB-C&S-MST - 000063-00 - General Repair WorkDocument38 pagesRWTP-GB-C&S-MST - 000063-00 - General Repair Workslayerzzz22No ratings yet

- RWTP GB Mne MST 000034 Smatv SystemDocument57 pagesRWTP GB Mne MST 000034 Smatv Systemslayerzzz22No ratings yet

- AMS QAQC Observation Reply TemplatesDocument1 pageAMS QAQC Observation Reply Templatesslayerzzz22No ratings yet

- RWTP GB Mne Msa 000066Document82 pagesRWTP GB Mne Msa 000066slayerzzz22No ratings yet

- Maybank2u CCPMDocument1 pageMaybank2u CCPMslayerzzz22No ratings yet

- RWTP GB Mne MST 000033 CA SystemDocument45 pagesRWTP GB Mne MST 000033 CA Systemslayerzzz22No ratings yet

- KVMRT-AZSB-SBK-PKG6-BTHS-MST-CIVS-000113.00 - MS Launching of Precast T-BeamDocument39 pagesKVMRT-AZSB-SBK-PKG6-BTHS-MST-CIVS-000113.00 - MS Launching of Precast T-Beamslayerzzz22No ratings yet

- G2101080364-mETAL mUFFDocument2 pagesG2101080364-mETAL mUFFslayerzzz22No ratings yet

- G2102006549 BCRichDocument2 pagesG2102006549 BCRichslayerzzz22No ratings yet

- G2012406439-Washburn DimeDocument2 pagesG2012406439-Washburn Dimeslayerzzz22No ratings yet

- Breakdown of ExpensesDocument2 pagesBreakdown of Expensesslayerzzz22No ratings yet

- G2011240654-Takeuchi FRDocument2 pagesG2011240654-Takeuchi FRslayerzzz22No ratings yet

- G2011006977-ESP PhoenixDocument2 pagesG2011006977-ESP Phoenixslayerzzz22No ratings yet

- G2007906394-ESP Mirage DeluxeDocument2 pagesG2007906394-ESP Mirage Deluxeslayerzzz22No ratings yet

- G2007704588-Boss BCB 6Document2 pagesG2007704588-Boss BCB 6slayerzzz22No ratings yet

- G2008506364-Fernandes Ratt R.crosbyDocument2 pagesG2008506364-Fernandes Ratt R.crosbyslayerzzz22No ratings yet

- Nanda 1Document4 pagesNanda 1Ethel GeorgeNo ratings yet

- Punsalan, Jr. vs. Vda. de LacsamanaDocument11 pagesPunsalan, Jr. vs. Vda. de LacsamanaLoubert BartolomeNo ratings yet

- Final Artifact Management Theory IIDocument11 pagesFinal Artifact Management Theory IIapi-651643566No ratings yet

- English Test - Imterchange 1 - Unit 1-8Document5 pagesEnglish Test - Imterchange 1 - Unit 1-8GabrielaNo ratings yet

- ACP194Document32 pagesACP194Samar SamerNo ratings yet

- Curriculum OF Environmental Science BS/MS: (Revised 2013)Document120 pagesCurriculum OF Environmental Science BS/MS: (Revised 2013)Jamal Ud Din QureshiNo ratings yet

- Unit 2 AiDocument79 pagesUnit 2 AiShirly NNo ratings yet

- Writing Project: A. Write A 800 - 1,000 Words Essay or Monograph in A Word Processor in FormatDocument4 pagesWriting Project: A. Write A 800 - 1,000 Words Essay or Monograph in A Word Processor in FormatEbri OjeNo ratings yet

- Max WeberDocument11 pagesMax WeberPKBM AL MUTHINo ratings yet

- Assessment of Digestive and GI FunctionDocument23 pagesAssessment of Digestive and GI FunctionSandeepNo ratings yet

- Cooltech PPM (Final 3.8.17)Document54 pagesCooltech PPM (Final 3.8.17)Teri Buhl100% (1)

- Digital Image Processing - S. Jayaraman, S. Esakkirajan and T. VeerakumarDocument4 pagesDigital Image Processing - S. Jayaraman, S. Esakkirajan and T. VeerakumarBenedict IsaacNo ratings yet

- Perlengkapan Bayi Ellena and FamilyDocument9 pagesPerlengkapan Bayi Ellena and FamilyintanchairranyNo ratings yet

- Lucies Farm Data Protection ComplaintDocument186 pagesLucies Farm Data Protection ComplaintcraigwalshNo ratings yet

- Martin Luther King Jr. - A True Historical Examination. (N.D.) - Retrieved OctoberDocument5 pagesMartin Luther King Jr. - A True Historical Examination. (N.D.) - Retrieved Octoberapi-336574490No ratings yet

- Solved Examples: Axes-Zz and - YyDocument8 pagesSolved Examples: Axes-Zz and - YyDeepak SahNo ratings yet

- MAN0019215 - TaqPathCOVID-19 - CE-IVD - RT-PCR Kit - IFUDocument27 pagesMAN0019215 - TaqPathCOVID-19 - CE-IVD - RT-PCR Kit - IFUFe LipeNo ratings yet

- Hispanic Tradition in Philippine ArtsDocument14 pagesHispanic Tradition in Philippine ArtsRoger Pascual Cuaresma100% (1)

- Store Name: United Food Company Kaust: It Code DescriptionDocument20 pagesStore Name: United Food Company Kaust: It Code DescriptionFazlul RifazNo ratings yet

- 2 The Origin of LifeDocument39 pages2 The Origin of LifeRydel GreyNo ratings yet

- Basic Law 01Document33 pagesBasic Law 01MitchNo ratings yet

- Hemispheric Structure and FuctionDocument4 pagesHemispheric Structure and FuctionDebby RizkyNo ratings yet

- AC S08 Week 08Document3 pagesAC S08 Week 08ERICK BORJA DELGADONo ratings yet

- Atr Summary Assignment 1Document6 pagesAtr Summary Assignment 1Livingstone OlekanmaNo ratings yet

- Hemanth PHP Resume-1Document3 pagesHemanth PHP Resume-1hemanthjinnala777No ratings yet

- Broadwater Farm Estate - The Active CommunityDocument5 pagesBroadwater Farm Estate - The Active CommunitycvaggasNo ratings yet

MOS-008 For Water Leaking Test

MOS-008 For Water Leaking Test

Uploaded by

slayerzzz22Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MOS-008 For Water Leaking Test

MOS-008 For Water Leaking Test

Uploaded by

slayerzzz22Copyright:

Available Formats

RWTP

•· Air Selangor RASAU WATER TREATMENT PLANT

�GAMUDA

PENGURUSAN AIR SELANGOR

SON BHD

METHOD STATEMENT

1.0 SCOPE OF WORKS

1.1 General Description

This method of statement is prepared to outline the procedure and resources used for the

work commencement for water leaking test used in Rasau Water Treatment Plant. It

comprises the sequence of work and technical compliance throughout the entire usage of form

tie. The form tie system prevents breakage in the formwork, thus keeping concrete structures

in good shape without discolouration. Thus, this water leaking test main concern for form tie

performance in water tank construction.

1.2 Reference

The scope of work is carried out in accordance to following:

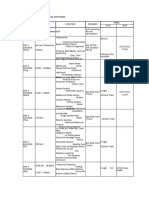

No Description Document Ref. No.

1. Job Safety Analysis RWTP-SPM-HSE-JSA-08

2. Shop Drawings RWTP- GB-H-WTP-CWT-CNS-TAN-CRS-000016

3. Quality Assurance/ Quality Control Plan RWTP-SPM-MOS-ITP-008-00

5. Environmental Impact & Aspect RWTP-SPM-HSE-EIA-08

1.3 Materials

Item Materials Usage

1. Water Pressure Gun Water leaking test purposes

2. Form tie Connect opposite faces of wall formwork to restrain the applied

concrete pressures

3. Corkjoint Swellable Waterstop

Superswell @47B

20x15mm

4. SIKA 215 Grout Repairs to concrete structures and grouting works

REF. NO: RWTP-SPM-MOS-008-00 Page 3

RWTP

.. · Air Selangor RASAU WATER TREATMENT PLANT

�GAMUDA

PENGURUSAN AIR SELANGOR

SON BHD

METHOD STATEMENT

1.4 Manpower

Item Designation Responsibilities

1. Construction manager - Responsible for monitoring the overall construction

activities, safety, and environmental issues

- Provide all necessary resources, safety and quality

measures to implement the earthwork activities

2. Site Engineer Planning, coordinating, supervising site activities

3. sss Conduct site toolbox meeting and ensure all the site

staffs obey the safety and health regulations

4. General Worker Helper

1.5 Work Procedure

1.5.1 Water Leaking Test

1) Prefabricated of 6" MS pipe with the following components (refer to figure 2)

• flange at one end with 6 to 8 nos. of 16mm dia. fasteners and end cap at the

other end

• pressure gauge and release valve

• Adaptor for pressure pump

• rubber gasket

2) The 6" dia. pipe with flange will be fixed to the pre-selected form-tie (refer to figure 1)

position with 6 to 8nos of 16mm dia. bolts fastener at 50mm to 65mm length tighten

into the wall and with a layer of rubber gasket to prevent loss of pressure.

3) Once installed, the pipe will be filled with water until completely filled up and air

bubble released.

4) Then pipe will be connected to compressor and pressure will be slowly increased to

require reading at 0.8 bar as per specification 2.14.18.

5) The test will be hold for 7 days to determine the said functionality of the swellable

water stop.

REF. NO: RWTP-SPM-MOS-008-00 Page 4

You might also like

- Cockney MonologuesDocument2 pagesCockney MonologuesLaReceHawkins86% (7)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Isimba - A Church Management System For STDocument22 pagesIsimba - A Church Management System For STAllan Credo100% (3)

- Method Statement - Sub-Base and Aggregate Base CourseDocument9 pagesMethod Statement - Sub-Base and Aggregate Base CourseTAHER AMMAR100% (6)

- CV-0013-002 - Method Statement For Soil Improvement WorkDocument14 pagesCV-0013-002 - Method Statement For Soil Improvement Work한상호No ratings yet

- Pumphouse ConstructionDocument10 pagesPumphouse Constructionsuryakantame100% (2)

- Method of Statement For Road Crossing WorkDocument7 pagesMethod of Statement For Road Crossing WorkAnonymous voA5Tb0No ratings yet

- The Ultimate Guide To Drum Programming - EDMProdDocument32 pagesThe Ultimate Guide To Drum Programming - EDMProdSteveJones100% (4)

- Field Book for Quality Control in Earthwork Operations: Project Construction Management BookFrom EverandField Book for Quality Control in Earthwork Operations: Project Construction Management BookNo ratings yet

- Introduction To Criminology (Review Materials For 2013 Criminology Board Examination)Document43 pagesIntroduction To Criminology (Review Materials For 2013 Criminology Board Examination)Clarito Lopez88% (33)

- Method Statement Shotcrete: Page 1 of 7Document7 pagesMethod Statement Shotcrete: Page 1 of 7J. Kumar Infraprojects Ltd100% (3)

- Method Statement Installation of Rock BoltDocument5 pagesMethod Statement Installation of Rock BoltJ. Kumar Infraprojects Ltd100% (2)

- 04 Method of Statment - Chilled Water Pipe Insulation - PSDocument12 pages04 Method of Statment - Chilled Water Pipe Insulation - PSUnique PlanningNo ratings yet

- MST For Below Ground UPVC Drainage PipesDocument13 pagesMST For Below Ground UPVC Drainage Pipesمقاول تكييف كهرباء وصحيNo ratings yet

- MS C 06 PlasterinDocument4 pagesMS C 06 PlasterinYENDRU LALITHAKUMARINo ratings yet

- Method Statement For DI PipingDocument16 pagesMethod Statement For DI Pipingtomj9104No ratings yet

- Uncontrolled Flow of Air From WellDocument4 pagesUncontrolled Flow of Air From WellMahesh GediyaNo ratings yet

- Pigging in Pipeline Pre-Commissioning PDFDocument8 pagesPigging in Pipeline Pre-Commissioning PDFhemn100% (2)

- 22.MS For HydrotestDocument9 pages22.MS For HydrotestASHWANINo ratings yet

- Installation of Pipeline by HDD For NGN Pipeline ProjectDocument48 pagesInstallation of Pipeline by HDD For NGN Pipeline ProjectDie HArd100% (1)

- Spe 114703 MSDocument11 pagesSpe 114703 MSBobby Rifki SaputraNo ratings yet

- MST Water Pipe RelocationDocument29 pagesMST Water Pipe Relocationslayerzzz22No ratings yet

- Method Statement For BACKFILLING WORKSDocument12 pagesMethod Statement For BACKFILLING WORKSYash Sharma50% (2)

- Spe-214579-Ms Rigless Solution in Replacement of Rig InterventionDocument8 pagesSpe-214579-Ms Rigless Solution in Replacement of Rig Interventionbagus918No ratings yet

- Pigging in Pipeline Pre-Commissioning PDFDocument8 pagesPigging in Pipeline Pre-Commissioning PDFAbhiyan Anala Arvind100% (1)

- Pre - Commissioning & Commissioning ProcedureDocument6 pagesPre - Commissioning & Commissioning Procedurepankaj.ovalNo ratings yet

- Leakage TestDocument5 pagesLeakage TestScribdTranslationsNo ratings yet

- METHOD STATEMENT - Sub-Base and Aggregate Base Course: June 2018Document10 pagesMETHOD STATEMENT - Sub-Base and Aggregate Base Course: June 2018Tajammal ArifeenNo ratings yet

- Determination of Temporary Ditch Check Performance in Protecting Earthen Channels From Stormwater-Induced ErosionDocument8 pagesDetermination of Temporary Ditch Check Performance in Protecting Earthen Channels From Stormwater-Induced ErosionmickyfelixNo ratings yet

- RWTP GB CNS MST 000067 00Document61 pagesRWTP GB CNS MST 000067 00slayerzzz22No ratings yet

- Method Statement Raub EditDocument10 pagesMethod Statement Raub EditMohd HafizNo ratings yet

- Method Statement For The Flushing of Firefighting Pipes.R7Document9 pagesMethod Statement For The Flushing of Firefighting Pipes.R7adel rihanaNo ratings yet

- Ed Well ControlDocument18 pagesEd Well ControlAmeer BabylonianNo ratings yet

- Quad Pipe Hydrotest Procedure Rev1Document16 pagesQuad Pipe Hydrotest Procedure Rev1Trust EmmaNo ratings yet

- Method of Statement For GRP WorkDocument17 pagesMethod of Statement For GRP WorkAhmed IbrahimNo ratings yet

- KDP Well Test Procedures ManualDocument77 pagesKDP Well Test Procedures ManualJacob Keemink100% (2)

- 2005 Aberdeen 2 RussellDocument8 pages2005 Aberdeen 2 RussellLiner MasterNo ratings yet

- Quad Pipe Hydrotest Procedure Rev2Document15 pagesQuad Pipe Hydrotest Procedure Rev2Trust EmmaNo ratings yet

- Method Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFDocument8 pagesMethod Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFFredie UnabiaNo ratings yet

- MSAE014-QC-PRE-035-Quality Procedure For Hydrostatic TestingDocument12 pagesMSAE014-QC-PRE-035-Quality Procedure For Hydrostatic Testingqamar qateebNo ratings yet

- METHOD STATEMENT FOR System Commissinig and Testing - Rev 0Document5 pagesMETHOD STATEMENT FOR System Commissinig and Testing - Rev 0Osama MZNo ratings yet

- MDPE Work ProcedureDocument18 pagesMDPE Work ProcedureANURAG YADAVNo ratings yet

- Method Statement and Risk Assessment For Basement Waterproofing WorksDocument30 pagesMethod Statement and Risk Assessment For Basement Waterproofing WorksVishaul RamanNo ratings yet

- New Austrian Tunneling MethodDocument31 pagesNew Austrian Tunneling MethodJudy Ann CacutNo ratings yet

- Honing Procedure: Doc. No.: - Job No.: 26071Document10 pagesHoning Procedure: Doc. No.: - Job No.: 26071Muhammad GaneshaNo ratings yet

- Larsen & Toubro Limited - Ecc Division: Page 1 of 4Document4 pagesLarsen & Toubro Limited - Ecc Division: Page 1 of 4Akhilesh DwivediNo ratings yet

- WT Training ManualDocument429 pagesWT Training Manualbilmard100% (4)

- MIP6-CV-0013-001 - Method Statement For Excavation and Fill WorkDocument12 pagesMIP6-CV-0013-001 - Method Statement For Excavation and Fill Work한상호No ratings yet

- Successful Placement CementDocument11 pagesSuccessful Placement CementOmerNo ratings yet

- Fatal Incident in Pipeline During Pigging Activity 1689382935Document4 pagesFatal Incident in Pipeline During Pigging Activity 1689382935harish14586100% (1)

- RTR Piping System PDFDocument8 pagesRTR Piping System PDFmohdNo ratings yet

- Master Thesis Technical Paper 2019Document9 pagesMaster Thesis Technical Paper 2019MogheshwarGokulRNo ratings yet

- 13 PiggingDocument14 pages13 PiggingDaniel DamboNo ratings yet

- Epic For Upgrade of Port Control Tower and Systems at RlicDocument8 pagesEpic For Upgrade of Port Control Tower and Systems at RlicsreeNo ratings yet

- On Plot HydrotestingDocument14 pagesOn Plot HydrotestingShambu S VtkNo ratings yet

- Methodology For REHABILITATION OF WATER DISTRIBUTION AND SERVICE LINE APPURTENANCES CWDDocument6 pagesMethodology For REHABILITATION OF WATER DISTRIBUTION AND SERVICE LINE APPURTENANCES CWDFritz NatividadNo ratings yet

- CV-0013-006 - Method Statement For Trial Test For Stone ColumnDocument8 pagesCV-0013-006 - Method Statement For Trial Test For Stone Column한상호No ratings yet

- Example WMS DecommDocument7 pagesExample WMS DecommKin HamzahNo ratings yet

- Method Statement For Installation of Chilled Water Pipe (21!4!2024)Document22 pagesMethod Statement For Installation of Chilled Water Pipe (21!4!2024)sheik.rasith.anvarNo ratings yet

- Method Statement of Routine Pile Load Test (Dynamic)Document3 pagesMethod Statement of Routine Pile Load Test (Dynamic)Akhilesh Dwivedi100% (2)

- Method Statement PLUS PipeDocument11 pagesMethod Statement PLUS PipeMohd HafizNo ratings yet

- SQF-RAMS-LIN-DR-02 - Installation of Condensate Drain Pipes.Document30 pagesSQF-RAMS-LIN-DR-02 - Installation of Condensate Drain Pipes.Akshay DeepNo ratings yet

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- RWTP GB Qaqc MPR 000006Document37 pagesRWTP GB Qaqc MPR 000006slayerzzz22No ratings yet

- Case Study StudentDocument24 pagesCase Study Studentslayerzzz22No ratings yet

- RWTP GB Mne Msa 000139 SignedDocument39 pagesRWTP GB Mne Msa 000139 Signedslayerzzz22No ratings yet

- RWTP GB MNE MST 000043 - AV - SystemDocument52 pagesRWTP GB MNE MST 000043 - AV - Systemslayerzzz22No ratings yet

- RWTP GB MNE MST 000046 - Underground - DuctDocument54 pagesRWTP GB MNE MST 000046 - Underground - Ductslayerzzz22No ratings yet

- RWTP GB Cns Msa 000173Document61 pagesRWTP GB Cns Msa 000173slayerzzz22No ratings yet

- RWTP GB MNE MST 000031 Telecommunication SystemDocument60 pagesRWTP GB MNE MST 000031 Telecommunication Systemslayerzzz22No ratings yet

- RWTP-GB-AMS-L-000668-2024 - Reply-Site ObservationCorrective Action Request No. P1-003Document2 pagesRWTP-GB-AMS-L-000668-2024 - Reply-Site ObservationCorrective Action Request No. P1-003slayerzzz22No ratings yet

- Case Study Student AnswerDocument7 pagesCase Study Student Answerslayerzzz22No ratings yet

- Checklist Genenral Concret RepairDocument6 pagesChecklist Genenral Concret Repairslayerzzz22No ratings yet

- Australia Iteanary 2024Document3 pagesAustralia Iteanary 2024slayerzzz22No ratings yet

- RWTP GB CNS Msa 000177Document38 pagesRWTP GB CNS Msa 000177slayerzzz22No ratings yet

- Jlgwvkyfc Gkpxmvbs7Kxdtdymvcrgc Vcvbilbkfcxvnraep: Bill StatementDocument5 pagesJlgwvkyfc Gkpxmvbs7Kxdtdymvcrgc Vcvbilbkfcxvnraep: Bill Statementslayerzzz22No ratings yet

- RWTP GB Mne Msa 000049Document44 pagesRWTP GB Mne Msa 000049slayerzzz22No ratings yet

- RWTP-GB-C&S-MST - 000063-00 - General Repair WorkDocument38 pagesRWTP-GB-C&S-MST - 000063-00 - General Repair Workslayerzzz22No ratings yet

- RWTP GB Mne MST 000034 Smatv SystemDocument57 pagesRWTP GB Mne MST 000034 Smatv Systemslayerzzz22No ratings yet

- AMS QAQC Observation Reply TemplatesDocument1 pageAMS QAQC Observation Reply Templatesslayerzzz22No ratings yet

- RWTP GB Mne Msa 000066Document82 pagesRWTP GB Mne Msa 000066slayerzzz22No ratings yet

- Maybank2u CCPMDocument1 pageMaybank2u CCPMslayerzzz22No ratings yet

- RWTP GB Mne MST 000033 CA SystemDocument45 pagesRWTP GB Mne MST 000033 CA Systemslayerzzz22No ratings yet

- KVMRT-AZSB-SBK-PKG6-BTHS-MST-CIVS-000113.00 - MS Launching of Precast T-BeamDocument39 pagesKVMRT-AZSB-SBK-PKG6-BTHS-MST-CIVS-000113.00 - MS Launching of Precast T-Beamslayerzzz22No ratings yet

- G2101080364-mETAL mUFFDocument2 pagesG2101080364-mETAL mUFFslayerzzz22No ratings yet

- G2102006549 BCRichDocument2 pagesG2102006549 BCRichslayerzzz22No ratings yet

- G2012406439-Washburn DimeDocument2 pagesG2012406439-Washburn Dimeslayerzzz22No ratings yet

- Breakdown of ExpensesDocument2 pagesBreakdown of Expensesslayerzzz22No ratings yet

- G2011240654-Takeuchi FRDocument2 pagesG2011240654-Takeuchi FRslayerzzz22No ratings yet

- G2011006977-ESP PhoenixDocument2 pagesG2011006977-ESP Phoenixslayerzzz22No ratings yet

- G2007906394-ESP Mirage DeluxeDocument2 pagesG2007906394-ESP Mirage Deluxeslayerzzz22No ratings yet

- G2007704588-Boss BCB 6Document2 pagesG2007704588-Boss BCB 6slayerzzz22No ratings yet

- G2008506364-Fernandes Ratt R.crosbyDocument2 pagesG2008506364-Fernandes Ratt R.crosbyslayerzzz22No ratings yet

- Nanda 1Document4 pagesNanda 1Ethel GeorgeNo ratings yet

- Punsalan, Jr. vs. Vda. de LacsamanaDocument11 pagesPunsalan, Jr. vs. Vda. de LacsamanaLoubert BartolomeNo ratings yet

- Final Artifact Management Theory IIDocument11 pagesFinal Artifact Management Theory IIapi-651643566No ratings yet

- English Test - Imterchange 1 - Unit 1-8Document5 pagesEnglish Test - Imterchange 1 - Unit 1-8GabrielaNo ratings yet

- ACP194Document32 pagesACP194Samar SamerNo ratings yet

- Curriculum OF Environmental Science BS/MS: (Revised 2013)Document120 pagesCurriculum OF Environmental Science BS/MS: (Revised 2013)Jamal Ud Din QureshiNo ratings yet

- Unit 2 AiDocument79 pagesUnit 2 AiShirly NNo ratings yet

- Writing Project: A. Write A 800 - 1,000 Words Essay or Monograph in A Word Processor in FormatDocument4 pagesWriting Project: A. Write A 800 - 1,000 Words Essay or Monograph in A Word Processor in FormatEbri OjeNo ratings yet

- Max WeberDocument11 pagesMax WeberPKBM AL MUTHINo ratings yet

- Assessment of Digestive and GI FunctionDocument23 pagesAssessment of Digestive and GI FunctionSandeepNo ratings yet

- Cooltech PPM (Final 3.8.17)Document54 pagesCooltech PPM (Final 3.8.17)Teri Buhl100% (1)

- Digital Image Processing - S. Jayaraman, S. Esakkirajan and T. VeerakumarDocument4 pagesDigital Image Processing - S. Jayaraman, S. Esakkirajan and T. VeerakumarBenedict IsaacNo ratings yet

- Perlengkapan Bayi Ellena and FamilyDocument9 pagesPerlengkapan Bayi Ellena and FamilyintanchairranyNo ratings yet

- Lucies Farm Data Protection ComplaintDocument186 pagesLucies Farm Data Protection ComplaintcraigwalshNo ratings yet

- Martin Luther King Jr. - A True Historical Examination. (N.D.) - Retrieved OctoberDocument5 pagesMartin Luther King Jr. - A True Historical Examination. (N.D.) - Retrieved Octoberapi-336574490No ratings yet

- Solved Examples: Axes-Zz and - YyDocument8 pagesSolved Examples: Axes-Zz and - YyDeepak SahNo ratings yet

- MAN0019215 - TaqPathCOVID-19 - CE-IVD - RT-PCR Kit - IFUDocument27 pagesMAN0019215 - TaqPathCOVID-19 - CE-IVD - RT-PCR Kit - IFUFe LipeNo ratings yet

- Hispanic Tradition in Philippine ArtsDocument14 pagesHispanic Tradition in Philippine ArtsRoger Pascual Cuaresma100% (1)

- Store Name: United Food Company Kaust: It Code DescriptionDocument20 pagesStore Name: United Food Company Kaust: It Code DescriptionFazlul RifazNo ratings yet

- 2 The Origin of LifeDocument39 pages2 The Origin of LifeRydel GreyNo ratings yet

- Basic Law 01Document33 pagesBasic Law 01MitchNo ratings yet

- Hemispheric Structure and FuctionDocument4 pagesHemispheric Structure and FuctionDebby RizkyNo ratings yet

- AC S08 Week 08Document3 pagesAC S08 Week 08ERICK BORJA DELGADONo ratings yet

- Atr Summary Assignment 1Document6 pagesAtr Summary Assignment 1Livingstone OlekanmaNo ratings yet

- Hemanth PHP Resume-1Document3 pagesHemanth PHP Resume-1hemanthjinnala777No ratings yet

- Broadwater Farm Estate - The Active CommunityDocument5 pagesBroadwater Farm Estate - The Active CommunitycvaggasNo ratings yet