Professional Documents

Culture Documents

Sandvik CM 1208i Mobile Jaw Brochure

Sandvik CM 1208i Mobile Jaw Brochure

Uploaded by

Benjamin MurphyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sandvik CM 1208i Mobile Jaw Brochure

Sandvik CM 1208i Mobile Jaw Brochure

Uploaded by

Benjamin MurphyCopyright:

Available Formats

Specification Summary

Sandvik Crawlmaster 1208i

General information

•3 basic types:

Comfort –feeder with grizzly, by-pass chute and as an option Natural Fine removal conveyor.

Classic – feeder with grizzly, by-pass chute, NF screen and optional NF conveyor.

Trend – separate feeder, separate screen with stepped grizzly on top. Optional NF conveyor.

•NF conveyor made by Sandvik Roxon. Width=500mm (20”), discharge height=3m (9’10”)

SANDVIK CRAWLMASTER 1208i

•Crawlmaster CM 1208i is transported in one piece. Everything stays on-board.

•The feed hopper sides are hydraulically foldable for easy transport and fast set-up/close down.

•Sandvik Rubber in feeder pan, absorbing impact and noise.

•Step less speed regulation of the feeder.

•A by-pass chute directs undersize through the grizzly to the discharge conveyor.

•Sandvik Roxon discharge conveyor with belt scraper, steering rolls and impact bars under the

crusher. Width 1400mm (52”), discharge height 3.3 – 3.8m (10’10” – 12’5”).

•Ground clearance below discharge conveyor approx. 350mm (14”) when crawling.

•Clearance between moving jaw in crusher and discharge conveyor, approx. 420mm (16 1/2”).

•Wide range of jaw plates for different applications is available.

•Automatic closes Side Setting in crusher.

•Platforms on top of crusher and around power pack provide access for inspection and

maintenance.

•Four 24V flood lights are fitted for illumination at night.

•Flash lights and a siren provide visual and aural warning of movement and stand-by.

•The Crawlmaster is maneuvered by remote control

•Emergency stop buttons are provided at appropriate places.

•A level monitor system above the crusher stops the feeder if the crusher is blocked.

•A number of sensors at different key locations ensure a trouble free operation and safe guard

against costly breakdowns.

•Advanced process automation by interlocking.

•The process is continuously and automatically monitored by the ”intelligence”.

•No spillage of hydraulic oil during filter changes due to vacuumized system.

•Pump for refilling diesel.

•The design and manufacture of the Sandvik CM 1208i complies with ISO 9001 and all the

directives required for CE marking. The diesel engine complies with EU Emission Regulation

97/68/EC step II and US norms EPA II.

Sandvik Rock Processing 05-12

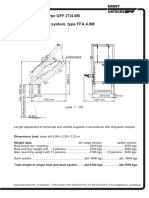

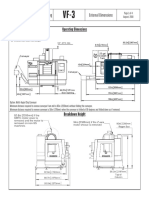

Specification Summary COMFORT Dimension Comfort & Classic Trend

Operation

Height 4.25m / 167” 4.90m / 193”

Width 3.13m / 123” 3.58m / 141”

Lenght 16.37m / 54’ 17.90m / 59’

Transport

Height 3.80m / 150” 4.09m / 161”

Width 3.00m / 118” 3.39m / 141”

Lenght 16.43m / 54’ 18.00m / 59’

CLASSIC Weight1 Comfort Classic Trend

tons 58 59 70

short tons 64 65 77

1 excluding options

Feed station Comfort Classic Trend

Feeder type GF 1246 GF 1246 F 1235

Grizzly length 1.2m / 4’ 1.2m / 4’ -

TREND Hopper 6 m3 / 6 m3 / 10 m3 /

210 ft3 210 ft3 350 ft3

Screen type - FF 1012 S 1220

Decks - 2 2 (stepped

grizzly on top)

Crusher

SANDVIK CRAWLMASTER 1208i

Type Sandvik JawmasterTM 1208

Options Feed opening 1200x800mm / 48x32”

Drive From diesel engine via V-belts

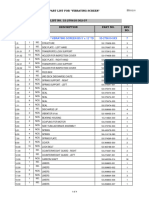

CM1 Over band magnet and hydraulic coupling.

CM4 Dust filter. Discharge conveyor

CM5A NF conveyor incl. Support (7,2m x 500mm)

Belt width 1400mm / 52”

CM6 Automatic lubrication system for the jaw crusher.

Drive Fixed speed hydraulic motors.

CM7 Hydraulic hammer set. Complete with hammer Approx. Discharge

and boom. (Rammer) height under drum 3.3-3.8m 10’10” +/- 10”

CM8 Water spray system. (Spray nozzles both on On-board power pack

crusher and discharge conveyor)

CM9 Belt scale on discharge conveyor. Diesel engine Deutz BF6M 1015 C turbo-

charged intercooled V6

CM11 Radio Remote control. Rated output 256kW / 350hp at 1500rpm

CM12 King pin for dolly. (2 pcs.) Fuel tank volume 938dm3 / 250 US gallons

CM13 3-axle dolly.

Hydraulic system

CM14 Flood lights for the crawler tracks.

CM16 Synthetic environmental oil. (Hydra Way Bio Power source Pumps mounted on power pack.

Oil tank volume 350dm3 / 250 US Gallons

SE 32-68)

CM18 Diesel driven heater for the engine. Crawler tracks

CM20 Adoption Mines and quarries for UK.

Type D6C

CM29 Complete manometer & O-ring set.

Length c/c 3715mm / 145”

CM29A Complete Filter set (80h service.) Track shoe width 500mm / 20”

CM30 Level indicator for stock pile at discharge end.

CM31 Lifting arrangement for shipping. Performance

CM33 Scalping screen 1500x3000 1D Max.feed size 760mm / 30”

incl. 2 prod. conveyors. Capacity (up to) 600mtph

Approx.fuel consumption

at75% continuous load 25-35l/h / 7-9 US Gallons/h

Traveling speed 1.2 km/h

Max.slope-climbing

capability Approx. 20°

05-12

You might also like

- If Poem Worksheet PDFDocument12 pagesIf Poem Worksheet PDFRaniaGF100% (2)

- GT205 Multi-Frequency: Track-Mounted ScreenDocument2 pagesGT205 Multi-Frequency: Track-Mounted Screenosvaldo arcos0% (1)

- Test Unit 4Document4 pagesTest Unit 4PepiLopez100% (2)

- Holiness by Micah Stampley (Chords)Document1 pageHoliness by Micah Stampley (Chords)Jesse Wilson100% (3)

- 770 Trommel Tracked: SpecificationDocument4 pages770 Trommel Tracked: SpecificationVishwdeep VaidNo ratings yet

- Techspec QJ240 PDFDocument2 pagesTechspec QJ240 PDFNazeeh Abdulrhman AlbokaryNo ratings yet

- Uj440I Jaw Crusher Pioneering Solutions For You: Technical SpecificationDocument2 pagesUj440I Jaw Crusher Pioneering Solutions For You: Technical SpecificationMeth MalimouNo ratings yet

- Impact Crushers: I-110 I-110RS I-130 I-130RSDocument12 pagesImpact Crushers: I-110 I-110RS I-130 I-130RSGabriel InfanteNo ratings yet

- Cone Orange GBDocument8 pagesCone Orange GBr mcleodNo ratings yet

- Tree Types & Installation MethodsDocument68 pagesTree Types & Installation Methodsgfabela100% (13)

- (Plattner 2016) - Design Thinking Research Making Design Thinking FoundationalDocument288 pages(Plattner 2016) - Design Thinking Research Making Design Thinking Foundationalc_labra100% (2)

- Sandvik CM1211 Mobile Jaw BrochureDocument2 pagesSandvik CM1211 Mobile Jaw BrochureBenjamin MurphyNo ratings yet

- Techspec - QA330 - Fintec 542Document2 pagesTechspec - QA330 - Fintec 542Benjamin MurphyNo ratings yet

- US440i Cone Crusher Unit: in ActionDocument2 pagesUS440i Cone Crusher Unit: in Actioneaglego00No ratings yet

- Powerscreen Trakpactor 320 Brochure EN2018Document1 pagePowerscreen Trakpactor 320 Brochure EN2018DCNo ratings yet

- Techspec QJ340Document2 pagesTechspec QJ340Antonio SoaresNo ratings yet

- Sandvik UJ300 Wheeled Jaw BrochureDocument2 pagesSandvik UJ300 Wheeled Jaw BrochureBenjamin MurphyNo ratings yet

- Technical Specification Impact Crusher I 120Document8 pagesTechnical Specification Impact Crusher I 120Eric EricssonNo ratings yet

- Techspec Qh440 2013 Rev1 LRDocument2 pagesTechspec Qh440 2013 Rev1 LRPrach ThongsomNo ratings yet

- UH440i Tech Spec 2015 (Rev 01)Document2 pagesUH440i Tech Spec 2015 (Rev 01)Frank Higuera100% (1)

- MR 6Document1 pageMR 6Omar AymanNo ratings yet

- Equipment Sheet: Oceangoing TugDocument2 pagesEquipment Sheet: Oceangoing TugKingsley UkohaNo ratings yet

- Powerscreen Premiertrak 400 R400 Brochure JAW CRUSHERDocument1 pagePowerscreen Premiertrak 400 R400 Brochure JAW CRUSHERFatema KhatunNo ratings yet

- Precast Concrete Panels Loading Tables BBLDocument11 pagesPrecast Concrete Panels Loading Tables BBLMicron Macron100% (1)

- MT 5Document1 pageMT 5Omar AymanNo ratings yet

- Powerscreen Crushing Brochure 2017 enDocument25 pagesPowerscreen Crushing Brochure 2017 enSivavishalNo ratings yet

- qh441 Specification Sheet EnglishDocument2 pagesqh441 Specification Sheet EnglishSadqain AliNo ratings yet

- Sv06Cnl Sv08Cnl: Aichi Global Series Scissors ModelDocument2 pagesSv06Cnl Sv08Cnl: Aichi Global Series Scissors ModelAlin Ziyanti PanjaitanNo ratings yet

- 1000SR Brochure 2017 EN PDFDocument1 page1000SR Brochure 2017 EN PDFmarceloaav1No ratings yet

- 1000SR Brochure 2017 EN PDFDocument1 page1000SR Brochure 2017 EN PDFmarceloaav1100% (1)

- Powerscreen Screening Brochure 2015 enDocument21 pagesPowerscreen Screening Brochure 2015 ensindy garzonNo ratings yet

- Freefall-Lifeboat, Type GFF .9M With Sliding Ramp / Davit System, Type FFA 4.9M - (T) 4Document1 pageFreefall-Lifeboat, Type GFF .9M With Sliding Ramp / Davit System, Type FFA 4.9M - (T) 4Lilik KhoiriyahNo ratings yet

- Pneumatic TransportersDocument4 pagesPneumatic Transportersks2000n1No ratings yet

- Sandvik QJ341 Spec SheetDocument2 pagesSandvik QJ341 Spec SheetDodom BirdNo ratings yet

- Techspec QA140Document2 pagesTechspec QA140Dyego GarciaNo ratings yet

- Ideal For Big Jobs 5 Sections Z-R Fold, 5 Inch Line, 180 Cubic Meters Per HourDocument16 pagesIdeal For Big Jobs 5 Sections Z-R Fold, 5 Inch Line, 180 Cubic Meters Per HourJonathan Guzmán MendozaNo ratings yet

- Innovative Reliable EconomicalDocument2 pagesInnovative Reliable EconomicaliVAN čOLAKNo ratings yet

- Sandvik QS331 Mobile Cone BrochureDocument2 pagesSandvik QS331 Mobile Cone BrochureBenjamin MurphyNo ratings yet

- Model GT205S Mobile Screening Plant Model 205S Spec Sheet: Operational ModeDocument2 pagesModel GT205S Mobile Screening Plant Model 205S Spec Sheet: Operational ModeVladimir Illich Pinzon BallenNo ratings yet

- TL 2392 SPDocument1 pageTL 2392 SPJun DetalNo ratings yet

- Powerscreen 1300 Maxtrak Brochure (3e5)Document1 pagePowerscreen 1300 Maxtrak Brochure (3e5)Jhona SuárezNo ratings yet

- S1930e FichaDocument2 pagesS1930e FichaMario EscamillaNo ratings yet

- S190 Feature Sheet Feb 2022 DigitalDocument2 pagesS190 Feature Sheet Feb 2022 Digitalvictor porrasNo ratings yet

- SR3390DDocument2 pagesSR3390DJean-Michel LeclercNo ratings yet

- Powerscreen India Crushing Screening Conveyor Brochure 2023 (WEB)Document36 pagesPowerscreen India Crushing Screening Conveyor Brochure 2023 (WEB)Sabitavo MandalNo ratings yet

- UH320 ClassicDocument2 pagesUH320 ClassicRicardo E Andrea RachelNo ratings yet

- Terex Finlay I-110RS Impact Crusher PDFDocument4 pagesTerex Finlay I-110RS Impact Crusher PDFeaglego00No ratings yet

- Component PricesDocument5 pagesComponent PricesBharath KumarNo ratings yet

- Dimenzije Mašine VF-3Document4 pagesDimenzije Mašine VF-3AleksandarMilenkovicNo ratings yet

- Spec I Fi Ca Tions: Critical DimensionsDocument1 pageSpec I Fi Ca Tions: Critical DimensionsMaxWittNo ratings yet

- STS 4 Inch Piranha Dredger Spec Sheet 2023Document1 pageSTS 4 Inch Piranha Dredger Spec Sheet 2023felipejesus.emaildecontasNo ratings yet

- Hoja Tecnica QJ341Document2 pagesHoja Tecnica QJ341Guillermo PaisNo ratings yet

- SANY Roller SSR120C-8 Specs NEWDocument2 pagesSANY Roller SSR120C-8 Specs NEWGuillermo HerreraNo ratings yet

- 2019 CP Range Guide LR - PDDocument16 pages2019 CP Range Guide LR - PDmoisesNo ratings yet

- Seaeye Tiger Equipment FlyerDocument2 pagesSeaeye Tiger Equipment FlyerParaZzzitNo ratings yet

- Equipos de PerforaciónDocument55 pagesEquipos de PerforaciónManuel ValdesNo ratings yet

- PCR DTHDocument2 pagesPCR DTHHernánNo ratings yet

- 1140523021191Document110 pages1140523021191Irimia Matei Alex100% (3)

- Machine Layout Drawing Installation Dimensions: ST-10Y/15YDocument9 pagesMachine Layout Drawing Installation Dimensions: ST-10Y/15YlpreiravazuimmNo ratings yet

- Qe341 Scalping Screen Pioneering Solutions For You: Technical SpecificationDocument2 pagesQe341 Scalping Screen Pioneering Solutions For You: Technical SpecificationJesusFloresRodriguezNo ratings yet

- Understanding Your Boats Systems and Choices.From EverandUnderstanding Your Boats Systems and Choices.Rating: 3 out of 5 stars3/5 (1)

- DF410 - JCB PowerunitDocument2 pagesDF410 - JCB PowerunitBenjamin MurphyNo ratings yet

- Maintenance Manual CJ408-01 - MM - S222.158.en-02Document60 pagesMaintenance Manual CJ408-01 - MM - S222.158.en-02Benjamin MurphyNo ratings yet

- IM01.06.en-Tightening TorqueDocument2 pagesIM01.06.en-Tightening TorqueBenjamin MurphyNo ratings yet

- Operators Manual CH420-01 - OM - S223.498.en-01Document118 pagesOperators Manual CH420-01 - OM - S223.498.en-01Benjamin MurphyNo ratings yet

- 0 1 NO. Ga. of Vibrating Screen Bs 5' X 12' TD 53-270610-5XX 7Document4 pages0 1 NO. Ga. of Vibrating Screen Bs 5' X 12' TD 53-270610-5XX 7Benjamin MurphyNo ratings yet

- MB231 enDocument23 pagesMB231 enBenjamin MurphyNo ratings yet

- Lokotrack LT120 S N 77565Document629 pagesLokotrack LT120 S N 77565Benjamin Murphy100% (1)

- Maintenance Manual CH420-01 - MM - S223.516.en-03Document196 pagesMaintenance Manual CH420-01 - MM - S223.516.en-03Benjamin MurphyNo ratings yet

- Front Page - Manual CH420.enDocument1 pageFront Page - Manual CH420.enBenjamin MurphyNo ratings yet

- Finlay Apron FeederDocument4 pagesFinlay Apron FeederBenjamin MurphyNo ratings yet

- 900 X 600 Metrotrak Feeder Control BoxDocument1 page900 X 600 Metrotrak Feeder Control BoxBenjamin MurphyNo ratings yet

- Warrior 1400X - Collection ConveyorDocument4 pagesWarrior 1400X - Collection ConveyorBenjamin MurphyNo ratings yet

- HQR1112 Main Conv - Impact Bars & Impact PlateDocument2 pagesHQR1112 Main Conv - Impact Bars & Impact PlateBenjamin MurphyNo ratings yet

- 1107 Oil RecomendationDocument2 pages1107 Oil RecomendationBenjamin MurphyNo ratings yet

- Finlay 883+ Roller MountingsDocument1 pageFinlay 883+ Roller MountingsBenjamin MurphyNo ratings yet

- CH430 LinersDocument1 pageCH430 LinersBenjamin MurphyNo ratings yet

- 900x600 STD HADocument3,002 pages900x600 STD HABenjamin Murphy100% (1)

- Fintec 1107 ManualDocument40 pagesFintec 1107 ManualBenjamin MurphyNo ratings yet

- Sandvik Stationary Crusher BorchureDocument1 pageSandvik Stationary Crusher BorchureBenjamin MurphyNo ratings yet

- HQR1112 Discharge HopperDocument14 pagesHQR1112 Discharge HopperBenjamin MurphyNo ratings yet

- 900 X 600 Metrotrak Schematic HydDocument1 page900 X 600 Metrotrak Schematic HydBenjamin MurphyNo ratings yet

- Sandvik UH311 Wheeled Cone BrochureDocument2 pagesSandvik UH311 Wheeled Cone BrochureBenjamin MurphyNo ratings yet

- Complete Track RangeDocument17 pagesComplete Track RangeBenjamin MurphyNo ratings yet

- RSV1400 Au 23072012Document2 pagesRSV1400 Au 23072012Benjamin Murphy100% (1)

- Striker SQR2062 20x6 Mobile Scalping ScreenDocument2 pagesStriker SQR2062 20x6 Mobile Scalping ScreenBenjamin MurphyNo ratings yet

- Ims Hazemag Ap-Kvh 1010RDocument5 pagesIms Hazemag Ap-Kvh 1010RBenjamin MurphyNo ratings yet

- Sandvik Stationary Crushers BrochureDocument2 pagesSandvik Stationary Crushers BrochureBenjamin MurphyNo ratings yet

- BurquipDocument38 pagesBurquipBenjamin MurphyNo ratings yet

- S7 ManualDocument308 pagesS7 ManualBenjamin MurphyNo ratings yet

- Kpto 176 - GB - LQDocument4 pagesKpto 176 - GB - LQBenjamin MurphyNo ratings yet

- Tang v. CaDocument2 pagesTang v. CaDominique Pobe100% (1)

- MIP 2021 (Budget Proposal)Document215 pagesMIP 2021 (Budget Proposal)Yanny ManggugubatNo ratings yet

- Bolt FEADocument149 pagesBolt FEATarek AbulailNo ratings yet

- Printable Company Profile SampleDocument10 pagesPrintable Company Profile SampleanskhanNo ratings yet

- Kelly: © 2019, Jo Kelly, To Be or Not To ActDocument5 pagesKelly: © 2019, Jo Kelly, To Be or Not To ActSebastián Baeza100% (1)

- DESIGN OF TIE BEAM or PLINTH BEAMDocument2 pagesDESIGN OF TIE BEAM or PLINTH BEAMJadrien Mark ImperialNo ratings yet

- Mustafa Barakat CV 2 - 2020Document6 pagesMustafa Barakat CV 2 - 2020Musa BaraNo ratings yet

- South Dakota State Treasurer Unclaimed Property: Claim FormDocument2 pagesSouth Dakota State Treasurer Unclaimed Property: Claim FormMiguel Paz100% (1)

- DBMS - Lecture 7 FunctionsDocument47 pagesDBMS - Lecture 7 FunctionsHafiz Al Asad ManikNo ratings yet

- Ranc Pengajaran PET225 DR Jafre 2015Document6 pagesRanc Pengajaran PET225 DR Jafre 2015MonsterNo ratings yet

- Managing Stress at WorkplaceDocument11 pagesManaging Stress at WorkplacePranav ShreeNo ratings yet

- Research Paper Topics About DogsDocument7 pagesResearch Paper Topics About Dogscafjhhaj100% (1)

- JavascriptDocument15 pagesJavascriptRajashekar PrasadNo ratings yet

- Mixed Tense 3 RéponsesDocument3 pagesMixed Tense 3 RéponsesLFolNo ratings yet

- Biography Recount Text: Xi-Toi 2Document7 pagesBiography Recount Text: Xi-Toi 2Adinda GaluhNo ratings yet

- Design and Development of Koch Fractal AntennaDocument5 pagesDesign and Development of Koch Fractal AntennaHAPURNo ratings yet

- 112 HSE Interview Questions With Answers PDFDocument138 pages112 HSE Interview Questions With Answers PDFaman anandNo ratings yet

- G25 Liban V GordonDocument3 pagesG25 Liban V GordonJohn Lester TanNo ratings yet

- Y8 Autumn B2 Support EoB Assessment Version ADocument4 pagesY8 Autumn B2 Support EoB Assessment Version Af.igrejaNo ratings yet

- Igo Primo Exe DownloadDocument4 pagesIgo Primo Exe DownloadMark V BeekNo ratings yet

- Letter of Request Service Credits Brigada 2022Document2 pagesLetter of Request Service Credits Brigada 2022KEICHIE QUIMCONo ratings yet

- Symptomatology Close 1Document41 pagesSymptomatology Close 1Sk Saklin MustakNo ratings yet

- MPKDocument15 pagesMPKghaliyahalmiraNo ratings yet

- Redeeming Time: Heidegger, Woolf, Eliot and The Search For An Authentic TemporalityDocument10 pagesRedeeming Time: Heidegger, Woolf, Eliot and The Search For An Authentic TemporalityazraNo ratings yet

- Prepare A Report On Smart City 'Document12 pagesPrepare A Report On Smart City 'Ringtones WorldsNo ratings yet

- Aecs Class 5 Practice Test Term1evs17Document13 pagesAecs Class 5 Practice Test Term1evs17spanja_barcNo ratings yet