Professional Documents

Culture Documents

ABC Catalog Part3 DXC in Line

ABC Catalog Part3 DXC in Line

Uploaded by

Yves DelandmeterCopyright:

Available Formats

You might also like

- Service Manual 900 OG Factory 16V M85-M93Document572 pagesService Manual 900 OG Factory 16V M85-M93Sting Eyes100% (1)

- RS425 TerexDocument2 pagesRS425 TerexMAQUINARIA 2022No ratings yet

- Engine Mechanical : Group 11CDocument36 pagesEngine Mechanical : Group 11CRomaNo ratings yet

- BMW N73 EngineDocument45 pagesBMW N73 EngineSalisbur100% (2)

- STP 1212Document22 pagesSTP 1212waleedyehiaNo ratings yet

- Swe Info Mk1Document57 pagesSwe Info Mk1শফিউল আলমNo ratings yet

- Eaton Airflex CS BrochureDocument14 pagesEaton Airflex CS BrochureluisedonossaNo ratings yet

- QuickServe+Online+ + (4310591) N14+Base+Engine+ (STC,+Celect™,+Celect+Plus™) +Service+ManualDocument16 pagesQuickServe+Online+ + (4310591) N14+Base+Engine+ (STC,+Celect™,+Celect+Plus™) +Service+ManualZakNo ratings yet

- Ac Solenoid & Solenoid BrakesDocument6 pagesAc Solenoid & Solenoid BrakesPrajapati AtulkumarNo ratings yet

- Rotary Screw Compressors Models XJS/XJF 95 Through 151: E70-510 SPC/JAN 97Document4 pagesRotary Screw Compressors Models XJS/XJF 95 Through 151: E70-510 SPC/JAN 97dfmolinaNo ratings yet

- STP 1010Document26 pagesSTP 1010waleedyehiaNo ratings yet

- Kta38 G5Document2 pagesKta38 G5Patricio Andres Ibañez ConchaNo ratings yet

- Drum BrakesDocument7 pagesDrum BrakesZahir KhiraNo ratings yet

- Z1300 Kawasaki Service Manual NewDocument372 pagesZ1300 Kawasaki Service Manual NewdNo ratings yet

- Cummins Generator Set KTA-3067-GS: Specifications Available EquipmentDocument2 pagesCummins Generator Set KTA-3067-GS: Specifications Available EquipmentSyam Nair100% (1)

- Motor - 1NZ Manual en InglesDocument170 pagesMotor - 1NZ Manual en InglesAbdelG100% (1)

- ZRS320E SpecificationDocument7 pagesZRS320E SpecificationSabahNo ratings yet

- CDA - Elecon Flexible CouplingDocument5 pagesCDA - Elecon Flexible CouplingMohit GuptaNo ratings yet

- Worldwide Parts Source LLC Source For Hard To Find Engine Gasket Sets Engine Rering Kits Engine Overhaul Kits With Pistons Phone: 269 673 2313Document125 pagesWorldwide Parts Source LLC Source For Hard To Find Engine Gasket Sets Engine Rering Kits Engine Overhaul Kits With Pistons Phone: 269 673 2313Ed MenēndezNo ratings yet

- Drive System Bearings: June 1, 2018Document24 pagesDrive System Bearings: June 1, 2018Anonymous YggO6T6GzNo ratings yet

- 02 Technical Description DGS 62 NDocument14 pages02 Technical Description DGS 62 NAlexis Jimenez GarciaNo ratings yet

- Presentation On Oil Rig Electrics - ModifiedDocument42 pagesPresentation On Oil Rig Electrics - Modifiedjagdish choudharyNo ratings yet

- Subaru EX40 EFI Gas Engine - Service ManualDocument64 pagesSubaru EX40 EFI Gas Engine - Service ManualHanselPerezAguirreNo ratings yet

- Instruction Manual Cable Reel Type: 10.1 R612-250 K450/1/Fci/Mck 10.1 R612-250 K450/2/Fci/MckDocument27 pagesInstruction Manual Cable Reel Type: 10.1 R612-250 K450/1/Fci/Mck 10.1 R612-250 K450/2/Fci/MckcristianNo ratings yet

- Sandvik 311 SoloDocument29 pagesSandvik 311 Solomarco antonio resendiz meloNo ratings yet

- Millennium Variable Speed Drive: Operating InstructionsDocument20 pagesMillennium Variable Speed Drive: Operating Instructionsmarianogalli80No ratings yet

- XRCP 500 50Hz TDSDocument1 pageXRCP 500 50Hz TDSLucasNo ratings yet

- Pompa LowaraDocument48 pagesPompa LowaraDragan AdrianNo ratings yet

- Ctu - 800injector - Hydraulic Circuit PDFDocument56 pagesCtu - 800injector - Hydraulic Circuit PDFDhruba Jyoti Buragohain100% (1)

- KG 367,000 LB: Maximum GVWDocument4 pagesKG 367,000 LB: Maximum GVWBoySetiadyNo ratings yet

- 6520-3902004РТ ENGL. (ЕВРО -2, 3, 4)Document1,445 pages6520-3902004РТ ENGL. (ЕВРО -2, 3, 4)kiên HoangNo ratings yet

- Starters AzjDocument2 pagesStarters AzjosobaxNo ratings yet

- Electrical Machines Block 2Document23 pagesElectrical Machines Block 2Aravind PadhiNo ratings yet

- ConServ Rig 6Document2 pagesConServ Rig 6mohammedNo ratings yet

- VSD PDFDocument20 pagesVSD PDFJovanny MarquezNo ratings yet

- 2JZ Eng-IgnDocument5 pages2JZ Eng-IgnHaris KhanNo ratings yet

- Eksitasi Generator ACDocument8 pagesEksitasi Generator ACUmmi Ulan Dari0% (1)

- Brochure Mesin Yanmar 6EY17WDocument4 pagesBrochure Mesin Yanmar 6EY17WVirgus UmbaiNo ratings yet

- BCH AC Brake Motor Write UpDocument2 pagesBCH AC Brake Motor Write UpNaveen Gupta100% (1)

- Electric Submersible PumpingDocument12 pagesElectric Submersible Pumpinglvargas3767No ratings yet

- Lexus 2000 GS300 Gs400 Engine Owner's ManualDocument24 pagesLexus 2000 GS300 Gs400 Engine Owner's ManualItThAchArT SaekrungNo ratings yet

- 04 N73+Engine+WorkbookDocument23 pages04 N73+Engine+Workbookabdull rehmanNo ratings yet

- XJF-XJS E70-510 SPC-Jan 05Document4 pagesXJF-XJS E70-510 SPC-Jan 05Alex MoralesNo ratings yet

- XCA160L8_2全地面起重机技术规格书Technical specifications(英文)Document41 pagesXCA160L8_2全地面起重机技术规格书Technical specifications(英文)RizkiRamadhanNo ratings yet

- Brushless Exciters For Turbine GeneratorsDocument8 pagesBrushless Exciters For Turbine GeneratorsEM wing, D&E, NEEPCO, GuwahatiNo ratings yet

- ABC Catalog Part5 DZC in VDocument4 pagesABC Catalog Part5 DZC in VYves DelandmeterNo ratings yet

- UC Tech ManualDocument21 pagesUC Tech ManualJose EspinozaNo ratings yet

- Hci 734 HDocument8 pagesHci 734 HCarlos Henrique Vargas Dos Santos100% (1)

- 913 Datenblatt Bau EnglischDocument6 pages913 Datenblatt Bau Englischyveshouthoofdthotmail.comNo ratings yet

- Deutz 913 SpecsDocument6 pagesDeutz 913 SpecsIrwin JoseNo ratings yet

- GeneradorDocument8 pagesGeneradorNANDORG27No ratings yet

- Series CR: ApplicationsDocument6 pagesSeries CR: ApplicationsRaymond LimNo ratings yet

- Hci634y 312Document9 pagesHci634y 312Nos GoteNo ratings yet

- PI044GDocument10 pagesPI044GracsoNo ratings yet

- Tamd 74 LDocument2 pagesTamd 74 LNaresh SookdeoNo ratings yet

- Doosan Engine Brochure PDFDocument7 pagesDoosan Engine Brochure PDFHawdang BabanNo ratings yet

- 2KJ3514-7KN38-9AR1-Z B33+C46+D11+K01+K06+L02+L75+M10+M59+N1S+P92 Datasheet enDocument2 pages2KJ3514-7KN38-9AR1-Z B33+C46+D11+K01+K06+L02+L75+M10+M59+N1S+P92 Datasheet encaukhoeoNo ratings yet

- Miller Big Blue 600xDocument8 pagesMiller Big Blue 600xmathi vijayNo ratings yet

- ABB BrakeMotorsDocument32 pagesABB BrakeMotorsDuy Anh TrầnNo ratings yet

- Three-Phase Induction MotorsDocument36 pagesThree-Phase Induction MotorsCARMEN DIMITRIUNo ratings yet

- STC TRS Conventional 02Document419 pagesSTC TRS Conventional 02battery sectionNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- TDC Nº1 Cyl. Motor 3054c - 416eDocument3 pagesTDC Nº1 Cyl. Motor 3054c - 416eJosé GonzalezNo ratings yet

- JP Sauer Sohn Catalogues - CompressorsDocument12 pagesJP Sauer Sohn Catalogues - Compressorsengkos koswaraNo ratings yet

- Alpha Lubricator System OperationDocument190 pagesAlpha Lubricator System Operationlalinda67% (3)

- McQuay IT - Daikin Conversion v20160108Document50 pagesMcQuay IT - Daikin Conversion v20160108Jose CuevasNo ratings yet

- Westerbeake 7.6 BTD Parts List Edition 1Document52 pagesWesterbeake 7.6 BTD Parts List Edition 1darrylloach100% (1)

- UBa18E0093-MOUOTCHOUO PUWA CALVIN - MECE 400Document34 pagesUBa18E0093-MOUOTCHOUO PUWA CALVIN - MECE 400Puwa CalvinNo ratings yet

- Engine Detroit S-60Document76 pagesEngine Detroit S-60josue100% (3)

- COMPOSITE Cylinder Head Pt3Document21 pagesCOMPOSITE Cylinder Head Pt3stojanoski89No ratings yet

- Petrol, Diesel, Rotary, Reciprocatry, Ic, Ec, Parts of EnginesDocument12 pagesPetrol, Diesel, Rotary, Reciprocatry, Ic, Ec, Parts of Enginesnishant010No ratings yet

- 20V4000C23 Operating InstructionsDocument176 pages20V4000C23 Operating InstructionsJorge Enrique Fuentes MarinNo ratings yet

- Pautas de Reutilizacion y Recuperacion Del Cigueñal C13Document17 pagesPautas de Reutilizacion y Recuperacion Del Cigueñal C13Dany NavarroNo ratings yet

- Piston, Connecting Rod and Cylinder Liner L28/32H: DescriptionDocument57 pagesPiston, Connecting Rod and Cylinder Liner L28/32H: DescriptionERepublikPolskaNo ratings yet

- G1800 RevisedDocument193 pagesG1800 RevisedYC CarieloNo ratings yet

- Engine Maintenance Manual (Document296 pagesEngine Maintenance Manual (Jenadir Martins100% (1)

- 02.engine Mechanical SystemDocument158 pages02.engine Mechanical SystemJulian MoralesNo ratings yet

- CASE Трактор MX285 PDFDocument689 pagesCASE Трактор MX285 PDFnachev dimitarNo ratings yet

- Lec 3 - Engine ParametersDocument26 pagesLec 3 - Engine ParametersGODNo ratings yet

- MazdaDocument30 pagesMazdagerber damianNo ratings yet

- Suzuki DF9,9 & DF15Document202 pagesSuzuki DF9,9 & DF15Anonymous yjK3peI7No ratings yet

- Speccifications 1Document236 pagesSpeccifications 1garage ô tô CarmaxNo ratings yet

- PR6412 Computer Aided Machine Drawing Lab ManualDocument99 pagesPR6412 Computer Aided Machine Drawing Lab Manualvigneshkannaganesan75% (4)

- CHP 19 Overview Fuel Inj.Document29 pagesCHP 19 Overview Fuel Inj.Foresight MisrNo ratings yet

- 06 - Tfheo We 0431Document486 pages06 - Tfheo We 0431jrrodrigueza2100% (1)

- Selected Failures of Internal Combustion Engine PistonsDocument8 pagesSelected Failures of Internal Combustion Engine PistonsDarmawan PutrantoNo ratings yet

- Solidworks Student Edition. For Academic Use Only.: 1911 Simplex EngineDocument30 pagesSolidworks Student Edition. For Academic Use Only.: 1911 Simplex Engineapi-273572571No ratings yet

- 449 Engine: A Intake Valve E Exhaust Valve X Flywheel Side of EngineDocument2 pages449 Engine: A Intake Valve E Exhaust Valve X Flywheel Side of EngineLUKASNo ratings yet

- EgeDocument15 pagesEgeMithoon ChakrabortyNo ratings yet

ABC Catalog Part3 DXC in Line

ABC Catalog Part3 DXC in Line

Uploaded by

Yves DelandmeterOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABC Catalog Part3 DXC in Line

ABC Catalog Part3 DXC in Line

Uploaded by

Yves DelandmeterCopyright:

Available Formats

ANGLO BELGIAN

CORPORATION N.V.

ENGINE TYPE DXN – DXS - DXC.

MAKE THE COMPARASION AND FIND OUT

WHAT IS THE BEST ON LONG TERM.

DXN-DXS-DXC ENGINE COMPONENTS.

CRANKSHAFT PISTON FUEL INJECTION

CRANKCASE CYLINDER LINER EQUIPMENTCYLINDER LINER

The alloy steel (42CrMo) one-piece The pistons are of light aluminium alloy The engine is equipped with an

forged crankshaft is placed in a and reinforced at the level of the two individual injection pump per cylinder

monobloc perlitic cast iron crankcase. first ring grooves by Ni-Resist inserts. and its rack is positioned by a hydraulic

The crankcase has a rigid box structure The piston is equipped with 5 thin rings: speed governor. The fuel injection

with an additional bearing on the fly- 1 chromed fire ring, 3 compression rings pipes are short, double-walled and

wheel side to limit crankshaft deflexion and 1 oil scraper ring, all located above interchangeable and resistant to high

and bearing wear. Water circulation the floating piston pin. The cylinder liner injection pressures.

pumps and luboil pumps are built on the is produced from a wear resistant

front-side of the pump-casing and are centrifugal cast iron slightly alloyed with

directly driven from the crankshaft chromium, Based on experience a

through intermediate precision gears. judicious choice of piston, piston rings

Large inspection doors permit easy and cylinder liner, achieved a good

access and easy maintenance. Thin running characteristic at low rates of

bearing shells are used. The camshaft wear, and a very low luboil

and speed governor are driven from the consumption.

flywheel side of the crankshaft.

SECURITY AND

CONTROLS

The control and security system is built

according to the rules of the

international classification cocieties.

CONNECTING RODS

The connecting rods are forged from BEARINGS

high quality steel (42CrMo) and The main and connecting rods bearings

controlled by magna-flux. The large end are produced from thin steel shells

is horizontally split in order to limit covered by a cupperlead layer, nickel

deformations by thigthening the conrod dam and an overlay plating with

bolts. Disassembling through cilnder corrosion resistant flash with extreme

liner is possible. good running-in conditions.

CYLINDER HEAD

Each perlitic cast iron cylinderhead is

fastened on the cylinderbloc by means

fo 6 tie bolts. The dismantling does not

require the removal of the peripheric

accessories. The cylinderhead is

CAMSHAFT equipped with valve seats, one inlet-

and one stellited exhaust valve, a start-

COMPRESSED AIR

The camshaft is composed of individual air valve, a decompression valve and an STARTING

and separate cams per function and per overpressure (safety) valve.

cylinder. The induction hardened cams 30 bar, directly on the cylinders.

are assembled on a steel alloyed shaft Electric starting only on special

(composed in 2 parts). demand.

POWER – TAKE - OFF

100% on flywheel side. On front-

side a viscous torsional vibration is

standard. Pulley and secondary

power-take-off on demand.

DXN/DXS/DXC – TECHNICAL CHARACTERISTICS.

DEFINITION FUEL CONSUMPTION AIR & EXHAUST GAS

3

The DX-Type of engine is a 4- g/kWh (g/HPh) Inlet air flow: (m /s)

stroke direct injection, single rpm 600 720 750 rpm cyl DXN DXS DXC

3DXN204(150)208(153)210(155) 3 0.21 0.35 0.45

acting diesel engine, built with 3DXS202(149)202(149)204(150) 600 6 0.42 0.80 1.00

all cylinder is line and 3 3DXC202(149)201(148)203(149) 8 0.56 --- 1.39

6DXN205(151)208(153)209(154)

versions available: 6DXS200(147)200(147)202(149) 3 0.25 0.45 0.58

DXN: Naturale Aspirated Engine 6DXC199(147)199(147)201(148) 720 6 0.50 0.96 1.20

DXS: Turbocharged engine 8DXN205(151)208(153)209(154)

8DXC199(147)199(147)201(148) 8 0.67 --- 1.60

DXC: Turbocharged and inter-

cooled engine. For fuel oil: 3 0.26 0.47 0.61

All engines standard Anti-clock; on - net heat value of 42700 750 6 0.52 0.96 1.25

demand Clock rotation. kJ/kg, 8 0.70 --- 1.66

- without engine-driven

BASIC DATA pumps, Exhaust gas flow: (m3/s)

- tolerance: + 5%.rpm cyl DXN DXS DXC

Cycle: 4 stroke, single acting. 3 0.50 0.75 1.00

Cylinders: 3-6-8 in line. 600 6 1.00 1.75 2.22

Bore: 242 mm. OIL CONSUMPTION 8 1.33 --- 3.05

Stroke: 320 mm. DXN: 1.0g/kWh =

Cylinder: 14.72 liter 3 0.60 0.99 1.30

0.75g/Hph 720 6 1.20 2.13 2.68

Swept 6 cylinders: 88.3 liters. DXS-DXC: 0.8 g/kWh =

volume: 8 cylinders: 117.8 liters. 8 1.60 --- 3.60

0.60g/Hph

Compression ratio: 3 0.62 1.03 1.36

DX: 12.45: 1 750 6 1.25 2.22 2.80

DXS-DXC: 12.06:1 HEAT REMOVAL 8 1.66 --- 3.75

Injection: Direct, mechanical.

One pump per cylinder. (kWth / kWeng) DXN DXS DXC

Jacket cooling 0.68 0.52 0.44 Exhaust gas temperatures –

PRESSURES Charge air cooling 0 0 0.126 cylinderhead outlet: (ºC)

Lubricating oil 0.03 0.03 0.03 rpm cy DXN DXS DXC

Brake mean effective pressure (bar)

3 460 440 470

Rpm 600 720 750

600 6 460 430 465

DXN 6.25 6.12 5.99 FLOW OF FLUIDS 8 460 --- 440

DXS 8.99 8.81 8.66 High Temperature circuit: (m3/h) 3 480 430 460

DXC 12.50 12.24 12.00 rpm 600 720 750 720 6 480 430 460

3DX N/S/C 28 33.5 35 8 480 --- 460

Maximum combustion pressure 6DX N/S/C 28 33.5 35

(bar) 3 480 430 460

8DX 28 33.5 35 750 6 480 430 460

DXN DXS DXC 8DXC 38 46 48 8 480 --- 460

60 70 85

Low Temperature circuit: (m3/h)

rpm 600 720 750

Lubricating oil pressure (bar)

(SAE 30 - 3DX N/S/C 19 23 24 Exhaust gas temperatures –

75ºC) 6DX N/S/C 19 23 24 cylinderhead outlet: (ºC)

8DX 19 23 24

Rpm Idle speed– 600 750 8DXC 29 34.5 36 DXS DXS DXC DXC

1.50 3.25 3.25 rpm cyl Bef After Bef After

turbo turbo turbo Turbo

1.75 3.75 3.75 Lubricating oil: (m3/h)(SAE 30 -

75ºC) 3 500 340 560 380

ROTATION SPEED rpm 600 720 750 600 6 480 380 530 420

Pump 7.4 8.2 8.75 8 --- --- 510 400

Piston speed (m/s)

capacity 490 430 548 385

Rpm 600 720 750 3

3DX N/S/C 720 6 480 430 520 400

6.4 7.6 8.0 6DX N/S/C 4.8 5.3 5.45 --- --- 520 420

8

8DX / 8DXC 6.1 6.6 6.75

Fire speed: 120 rpm. 3 490 430 548 385

750 6 480 430 520 400

WORKING TEMPERATURES (ºC) 8 --- --- 520 420

MASS MOMENT OF INERTIA

Normal Alarm Stop

3DXC including flywheel: 280 kgm2

6DXC including flywheel: 120 kgm2

HT-cooling 75-80 85 90

8XZC including flywheel: 131 kgm

2 Luboil (LT) 75-80 85 90

Data based on standard version.

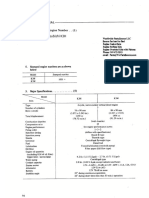

DXN/DXS/DXC – POWER & MAIN DIMENSIONS.

POWER OF THE 14000

TYPE OF ENGINE rpm ENGINE (ISO 3046 – I)

Nm

TORQUE-CHARACTERISTIC

kW HP

DXC-engines

12000

3DXN-600-000 600 138 187

3DXS-600-045 600 199 270

3DXC-600-080 600 249 337

10000

3DXC-600-100 600 276 375

3DXN-720-000 720 163 220

3DXS-720-045 720 236 320 8000

3DXC-720-080 720 292 397

3DXC-720-100 720 325 441

6000

3DXN-750-000 750 166 225

3DXS-750-045 750 239 325

3DXC-750-080 750 298 406

4000

3DXC-750-100 750 331 450

8DXC 6DXC

2000 6DXS 6DXN

POWER OF THE 3DXC 3DXS

TYPE OF ENGINE rpm ENGINE (ISO 3046 – I) 3DXN

0

kW HP 225 300 375 450 525 600 675

rpm

750

6DXN-600-000 600 276 375

6DXS-600-045 600 398 541

POWER OF THE

6DXC-600-080 600 497 675

TYPE OF ENGINE Rpm ENGINE (ISO 3046 – I)

6DXC-600-100 600 552 750

kW HP

6DXN-720-000 720 325 441

6DXS-720-045 720 470 639 8DXN-600-000 600 368 500

6DXC-720-080 720 585 794 8DXC-600-080 600 662 900

6DXC-720-100 720 649 882 8DXC-600-100 600 736 1000

6DXN-750-000 750 331 450 8DXN-720-000 720 432 587

6DXS-750-045 750 478 650 8DXC-720-080 720 777 1056

6DXC-750-080 750 596 810 8DXC-720-100 720 864 1174

6DXC-750-100 750 662 900 8DXN-750-000 750 442 600

8DXC-750-080 750 795 1080

Flywheel, vibration damper and coolers are included 8DXC-750-100 750 883 1200

D (mm)

TYPE Mass (kg)* A (mm) B (mm) C (mm) E (mm) F (mm) G (mm) H (mm) I (mm)

Shallow Deep

3DX 6900 2530 1152 1712 458 870 780 760 200 1930

6DX 8860 3640 1035 1990 458 870 835 760 200 1930

8DX 11500 4430 1035 1820 458 870 900 760 200 1930

You might also like

- Service Manual 900 OG Factory 16V M85-M93Document572 pagesService Manual 900 OG Factory 16V M85-M93Sting Eyes100% (1)

- RS425 TerexDocument2 pagesRS425 TerexMAQUINARIA 2022No ratings yet

- Engine Mechanical : Group 11CDocument36 pagesEngine Mechanical : Group 11CRomaNo ratings yet

- BMW N73 EngineDocument45 pagesBMW N73 EngineSalisbur100% (2)

- STP 1212Document22 pagesSTP 1212waleedyehiaNo ratings yet

- Swe Info Mk1Document57 pagesSwe Info Mk1শফিউল আলমNo ratings yet

- Eaton Airflex CS BrochureDocument14 pagesEaton Airflex CS BrochureluisedonossaNo ratings yet

- QuickServe+Online+ + (4310591) N14+Base+Engine+ (STC,+Celect™,+Celect+Plus™) +Service+ManualDocument16 pagesQuickServe+Online+ + (4310591) N14+Base+Engine+ (STC,+Celect™,+Celect+Plus™) +Service+ManualZakNo ratings yet

- Ac Solenoid & Solenoid BrakesDocument6 pagesAc Solenoid & Solenoid BrakesPrajapati AtulkumarNo ratings yet

- Rotary Screw Compressors Models XJS/XJF 95 Through 151: E70-510 SPC/JAN 97Document4 pagesRotary Screw Compressors Models XJS/XJF 95 Through 151: E70-510 SPC/JAN 97dfmolinaNo ratings yet

- STP 1010Document26 pagesSTP 1010waleedyehiaNo ratings yet

- Kta38 G5Document2 pagesKta38 G5Patricio Andres Ibañez ConchaNo ratings yet

- Drum BrakesDocument7 pagesDrum BrakesZahir KhiraNo ratings yet

- Z1300 Kawasaki Service Manual NewDocument372 pagesZ1300 Kawasaki Service Manual NewdNo ratings yet

- Cummins Generator Set KTA-3067-GS: Specifications Available EquipmentDocument2 pagesCummins Generator Set KTA-3067-GS: Specifications Available EquipmentSyam Nair100% (1)

- Motor - 1NZ Manual en InglesDocument170 pagesMotor - 1NZ Manual en InglesAbdelG100% (1)

- ZRS320E SpecificationDocument7 pagesZRS320E SpecificationSabahNo ratings yet

- CDA - Elecon Flexible CouplingDocument5 pagesCDA - Elecon Flexible CouplingMohit GuptaNo ratings yet

- Worldwide Parts Source LLC Source For Hard To Find Engine Gasket Sets Engine Rering Kits Engine Overhaul Kits With Pistons Phone: 269 673 2313Document125 pagesWorldwide Parts Source LLC Source For Hard To Find Engine Gasket Sets Engine Rering Kits Engine Overhaul Kits With Pistons Phone: 269 673 2313Ed MenēndezNo ratings yet

- Drive System Bearings: June 1, 2018Document24 pagesDrive System Bearings: June 1, 2018Anonymous YggO6T6GzNo ratings yet

- 02 Technical Description DGS 62 NDocument14 pages02 Technical Description DGS 62 NAlexis Jimenez GarciaNo ratings yet

- Presentation On Oil Rig Electrics - ModifiedDocument42 pagesPresentation On Oil Rig Electrics - Modifiedjagdish choudharyNo ratings yet

- Subaru EX40 EFI Gas Engine - Service ManualDocument64 pagesSubaru EX40 EFI Gas Engine - Service ManualHanselPerezAguirreNo ratings yet

- Instruction Manual Cable Reel Type: 10.1 R612-250 K450/1/Fci/Mck 10.1 R612-250 K450/2/Fci/MckDocument27 pagesInstruction Manual Cable Reel Type: 10.1 R612-250 K450/1/Fci/Mck 10.1 R612-250 K450/2/Fci/MckcristianNo ratings yet

- Sandvik 311 SoloDocument29 pagesSandvik 311 Solomarco antonio resendiz meloNo ratings yet

- Millennium Variable Speed Drive: Operating InstructionsDocument20 pagesMillennium Variable Speed Drive: Operating Instructionsmarianogalli80No ratings yet

- XRCP 500 50Hz TDSDocument1 pageXRCP 500 50Hz TDSLucasNo ratings yet

- Pompa LowaraDocument48 pagesPompa LowaraDragan AdrianNo ratings yet

- Ctu - 800injector - Hydraulic Circuit PDFDocument56 pagesCtu - 800injector - Hydraulic Circuit PDFDhruba Jyoti Buragohain100% (1)

- KG 367,000 LB: Maximum GVWDocument4 pagesKG 367,000 LB: Maximum GVWBoySetiadyNo ratings yet

- 6520-3902004РТ ENGL. (ЕВРО -2, 3, 4)Document1,445 pages6520-3902004РТ ENGL. (ЕВРО -2, 3, 4)kiên HoangNo ratings yet

- Starters AzjDocument2 pagesStarters AzjosobaxNo ratings yet

- Electrical Machines Block 2Document23 pagesElectrical Machines Block 2Aravind PadhiNo ratings yet

- ConServ Rig 6Document2 pagesConServ Rig 6mohammedNo ratings yet

- VSD PDFDocument20 pagesVSD PDFJovanny MarquezNo ratings yet

- 2JZ Eng-IgnDocument5 pages2JZ Eng-IgnHaris KhanNo ratings yet

- Eksitasi Generator ACDocument8 pagesEksitasi Generator ACUmmi Ulan Dari0% (1)

- Brochure Mesin Yanmar 6EY17WDocument4 pagesBrochure Mesin Yanmar 6EY17WVirgus UmbaiNo ratings yet

- BCH AC Brake Motor Write UpDocument2 pagesBCH AC Brake Motor Write UpNaveen Gupta100% (1)

- Electric Submersible PumpingDocument12 pagesElectric Submersible Pumpinglvargas3767No ratings yet

- Lexus 2000 GS300 Gs400 Engine Owner's ManualDocument24 pagesLexus 2000 GS300 Gs400 Engine Owner's ManualItThAchArT SaekrungNo ratings yet

- 04 N73+Engine+WorkbookDocument23 pages04 N73+Engine+Workbookabdull rehmanNo ratings yet

- XJF-XJS E70-510 SPC-Jan 05Document4 pagesXJF-XJS E70-510 SPC-Jan 05Alex MoralesNo ratings yet

- XCA160L8_2全地面起重机技术规格书Technical specifications(英文)Document41 pagesXCA160L8_2全地面起重机技术规格书Technical specifications(英文)RizkiRamadhanNo ratings yet

- Brushless Exciters For Turbine GeneratorsDocument8 pagesBrushless Exciters For Turbine GeneratorsEM wing, D&E, NEEPCO, GuwahatiNo ratings yet

- ABC Catalog Part5 DZC in VDocument4 pagesABC Catalog Part5 DZC in VYves DelandmeterNo ratings yet

- UC Tech ManualDocument21 pagesUC Tech ManualJose EspinozaNo ratings yet

- Hci 734 HDocument8 pagesHci 734 HCarlos Henrique Vargas Dos Santos100% (1)

- 913 Datenblatt Bau EnglischDocument6 pages913 Datenblatt Bau Englischyveshouthoofdthotmail.comNo ratings yet

- Deutz 913 SpecsDocument6 pagesDeutz 913 SpecsIrwin JoseNo ratings yet

- GeneradorDocument8 pagesGeneradorNANDORG27No ratings yet

- Series CR: ApplicationsDocument6 pagesSeries CR: ApplicationsRaymond LimNo ratings yet

- Hci634y 312Document9 pagesHci634y 312Nos GoteNo ratings yet

- PI044GDocument10 pagesPI044GracsoNo ratings yet

- Tamd 74 LDocument2 pagesTamd 74 LNaresh SookdeoNo ratings yet

- Doosan Engine Brochure PDFDocument7 pagesDoosan Engine Brochure PDFHawdang BabanNo ratings yet

- 2KJ3514-7KN38-9AR1-Z B33+C46+D11+K01+K06+L02+L75+M10+M59+N1S+P92 Datasheet enDocument2 pages2KJ3514-7KN38-9AR1-Z B33+C46+D11+K01+K06+L02+L75+M10+M59+N1S+P92 Datasheet encaukhoeoNo ratings yet

- Miller Big Blue 600xDocument8 pagesMiller Big Blue 600xmathi vijayNo ratings yet

- ABB BrakeMotorsDocument32 pagesABB BrakeMotorsDuy Anh TrầnNo ratings yet

- Three-Phase Induction MotorsDocument36 pagesThree-Phase Induction MotorsCARMEN DIMITRIUNo ratings yet

- STC TRS Conventional 02Document419 pagesSTC TRS Conventional 02battery sectionNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- TDC Nº1 Cyl. Motor 3054c - 416eDocument3 pagesTDC Nº1 Cyl. Motor 3054c - 416eJosé GonzalezNo ratings yet

- JP Sauer Sohn Catalogues - CompressorsDocument12 pagesJP Sauer Sohn Catalogues - Compressorsengkos koswaraNo ratings yet

- Alpha Lubricator System OperationDocument190 pagesAlpha Lubricator System Operationlalinda67% (3)

- McQuay IT - Daikin Conversion v20160108Document50 pagesMcQuay IT - Daikin Conversion v20160108Jose CuevasNo ratings yet

- Westerbeake 7.6 BTD Parts List Edition 1Document52 pagesWesterbeake 7.6 BTD Parts List Edition 1darrylloach100% (1)

- UBa18E0093-MOUOTCHOUO PUWA CALVIN - MECE 400Document34 pagesUBa18E0093-MOUOTCHOUO PUWA CALVIN - MECE 400Puwa CalvinNo ratings yet

- Engine Detroit S-60Document76 pagesEngine Detroit S-60josue100% (3)

- COMPOSITE Cylinder Head Pt3Document21 pagesCOMPOSITE Cylinder Head Pt3stojanoski89No ratings yet

- Petrol, Diesel, Rotary, Reciprocatry, Ic, Ec, Parts of EnginesDocument12 pagesPetrol, Diesel, Rotary, Reciprocatry, Ic, Ec, Parts of Enginesnishant010No ratings yet

- 20V4000C23 Operating InstructionsDocument176 pages20V4000C23 Operating InstructionsJorge Enrique Fuentes MarinNo ratings yet

- Pautas de Reutilizacion y Recuperacion Del Cigueñal C13Document17 pagesPautas de Reutilizacion y Recuperacion Del Cigueñal C13Dany NavarroNo ratings yet

- Piston, Connecting Rod and Cylinder Liner L28/32H: DescriptionDocument57 pagesPiston, Connecting Rod and Cylinder Liner L28/32H: DescriptionERepublikPolskaNo ratings yet

- G1800 RevisedDocument193 pagesG1800 RevisedYC CarieloNo ratings yet

- Engine Maintenance Manual (Document296 pagesEngine Maintenance Manual (Jenadir Martins100% (1)

- 02.engine Mechanical SystemDocument158 pages02.engine Mechanical SystemJulian MoralesNo ratings yet

- CASE Трактор MX285 PDFDocument689 pagesCASE Трактор MX285 PDFnachev dimitarNo ratings yet

- Lec 3 - Engine ParametersDocument26 pagesLec 3 - Engine ParametersGODNo ratings yet

- MazdaDocument30 pagesMazdagerber damianNo ratings yet

- Suzuki DF9,9 & DF15Document202 pagesSuzuki DF9,9 & DF15Anonymous yjK3peI7No ratings yet

- Speccifications 1Document236 pagesSpeccifications 1garage ô tô CarmaxNo ratings yet

- PR6412 Computer Aided Machine Drawing Lab ManualDocument99 pagesPR6412 Computer Aided Machine Drawing Lab Manualvigneshkannaganesan75% (4)

- CHP 19 Overview Fuel Inj.Document29 pagesCHP 19 Overview Fuel Inj.Foresight MisrNo ratings yet

- 06 - Tfheo We 0431Document486 pages06 - Tfheo We 0431jrrodrigueza2100% (1)

- Selected Failures of Internal Combustion Engine PistonsDocument8 pagesSelected Failures of Internal Combustion Engine PistonsDarmawan PutrantoNo ratings yet

- Solidworks Student Edition. For Academic Use Only.: 1911 Simplex EngineDocument30 pagesSolidworks Student Edition. For Academic Use Only.: 1911 Simplex Engineapi-273572571No ratings yet

- 449 Engine: A Intake Valve E Exhaust Valve X Flywheel Side of EngineDocument2 pages449 Engine: A Intake Valve E Exhaust Valve X Flywheel Side of EngineLUKASNo ratings yet

- EgeDocument15 pagesEgeMithoon ChakrabortyNo ratings yet