Professional Documents

Culture Documents

Fike Fiber LHD Cables

Fike Fiber LHD Cables

Uploaded by

brandon.carrasco.cmchOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fike Fiber LHD Cables

Fike Fiber LHD Cables

Uploaded by

brandon.carrasco.cmchCopyright:

Available Formats

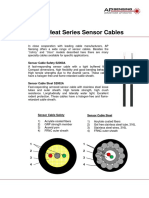

S200XA Linear Heat Series Sensor Cables

Multimode, Flame‐Retardant, Non‐Corrosive (FRNC)

Two types of multi‐mode, fiber‐optic sensor cables are available

for use with the N43 and N45 Series Distributed Temperature

Sensor (DTS) controllers – Sensor Cable Safety and Sensor Cable

Steel. Both cables have two fiber cores covered by polyacrylate,

with an outer cable sheath made of a halogen‐free, flame

retardant, non‐corrosive polyethylene‐based compound. Sensor Cable Safety S2000A

The Sensor Cable Safety (S2000A) is a fast‐responding sensor

cable with a tight‐buffered fiber, compact dimensions, high

flexibility, and good bending behavior. The Aramid yarn

surrounding the fibers offers good rodent protection and Sensor Cable Steel

withstands high tensile loads. S2002A and S2002A‐RED

The Sensor Cable Steel (S2002A and S2002A‐RED) are fast‐

responding sensor cables with stainless steel loose tubes and

outer sheath. This design offers high tensile strength, high crush

resistance, good rodent protection, and is longitudinally and

laterally watertight.

ORDERING

PART NUMBER DESCRIPTION

S2000A Sensor Safety Cable

S2002A Sensor Cable Steel

S2002A‐RED Sensor Cable Steel, red outer sheath, for use with DTS system

Sensor Safety Cable with 2 x pigtail with E2000 8° APC connectors[1] pre‐assembled on one cable

S2000A‐001

end. Provides splice protection and strain relief.

Sensor Cable Steel with 2 x pigtail with E2000 8° APC connectors[1] pre‐assembled on one cable

S2002A‐001

end. Provides splice protection and strain relief.

Pigtail with E2000 8° APC Connector for splicing to the sensor fiber, 5 m length. Used for

S2008A

connection to DTS or termination.

Pigtail with E2000 8° APC Connector for splicing to the sensor fiber, 3 m length. Used for

S2006A

connection to DTS or termination.

S2011A E2000 APC Adapter for connecting two E2000 APC connectors

Sensor (fiber) cutting tool. Used to cut the stainless steel tube, cable sheath removal, and

S2010A

splicing the pigtail to the sensor fiber.

[1] Pre‐assembled sensor cable connectors are optionally available to reduce deployment cost and time. The connectors are covered with a flexible protective

tube when shipped for safe transport.

P10324, July, 2022

SPECIFICATIONS

Fiber Cables

Cable Type S2000A S2002A S2002A‐RED

Cable Version Safety Steel armored

Outer Sheath Material Flame retardant, non‐corrosive (FRNC)

Swellable aramid yarns Stainless steel AISI 316L tube

Armoring

(metal free) Stainless steel AISI 316L wires

GRP strength member, fiber Gel‐free, fiber loose in FIMT

Cable Design

tight‐buffered in aramid yarn (fiber in a metal tube)

Standard Fiber Count / Cable 2 MM

UV‐Resistance Yes

Longitudinal Water Resistant No Yes

Approximate Weight[1] 17 kg/km (11.4 lb/ft) 29 kg/km (19.5 lb/ft)

Outer Diameter[1] 4 mm (0.16 in) 3.8 mm (0.15 in)

Crush Resistance[2] 1,000 N/10 cm 9,600 N/10 cm[4]

Tensile Strength (installation)[2] 1,000 N 800 N

Tensile Strength (operation)[2] 800 N

Operating Temperature ‐40°C to +85°C (‐40°F to +185°F)

Short Term Temperature ‐40°C to +150°C (‐40°F to +302°F)

Functional Integrity[3] up to +750°C (+1,382°F)

Optical Details

MM Attenuation OM2

850 nm Wavelength Maximum 2.7 dB/km / Average 2.5 dB/km

1300 nm Wavelength Maximum 0.8 kB/km / Average 0.7 kB/km

Installation Details

Outer Diameter[1] 4 mm (0.16 in) 3.8 mm (0.15 in)

Static Bending Radius[2] 15 x D (outer Ø)

Repeated Bending[2] 20 x D (outer Ø)

Installation Temperature ‐5°C to +50°C (23°F to +122°F)

Certifications and Approvals

IEC 60331‐25 [2]

IEC 60332‐1/‐2/‐3‐24

IEC 60754‐1/‐2

IEC

IEC 60793

IEC 60794‐1‐2

IEC 61034‐2

EN EN 187000

VDS EN 54‐5 / A1

UL UL 521

ULC/CAN ULC S530

FM FM 3210

[1] Tolerance of ‐5% / +10%

[2] Crush resistance IEC 60794‐1‐2, method E3A; Tensile strength short term (installation) IEC 60794‐1‐2, method E1 A/B; Tensile strength long term (operation)

IEC 60794‐1‐2, method E1 A/B; Static bend radius IEC 60794‐1‐2, method E11; Repeated bending IEC 60794‐1‐2, method E6.

[3] The functional integrity of the sensor cable was tested for 2 hours with min. flame temperature of 750°C as per IEC 60331‐25. The functional integrity of the

cable was maintained for several minutes in tunnel fire testing with temperatures exceeding 1000°C.

[4] 600 N/cm in operation / max. 960 N/cm during installation.

P10324, July, 2022

You might also like

- Sharjah Regulations of Construction Condition and Specification Complete - New FormatDocument191 pagesSharjah Regulations of Construction Condition and Specification Complete - New FormatAbdullah Abdel-MaksoudNo ratings yet

- Water Reticulation Report 20072016 - 150254Document5 pagesWater Reticulation Report 20072016 - 150254laikienfui100% (3)

- 2.3 Cable de Guardia - OPGW SPEC (15-53931)Document9 pages2.3 Cable de Guardia - OPGW SPEC (15-53931)xcazor morayNo ratings yet

- Linear Heat Series Sensor Cables - 2016-01-22 PDFDocument3 pagesLinear Heat Series Sensor Cables - 2016-01-22 PDFmohamedNo ratings yet

- Linear Heat Series Sensor Cables 2019-03-29Document3 pagesLinear Heat Series Sensor Cables 2019-03-29Yossi ShlomoNo ratings yet

- Lifeline® Specialty: Fire Resistant QFCI Cable: Fire Resistant, Flame Retardant Halogen-Free Loose Tube - QFCI/O/RM-JMDocument2 pagesLifeline® Specialty: Fire Resistant QFCI Cable: Fire Resistant, Flame Retardant Halogen-Free Loose Tube - QFCI/O/RM-JMkevinwz1989No ratings yet

- Central Loose Tube Armoured External Cable: ComplianceDocument2 pagesCentral Loose Tube Armoured External Cable: CompliancenajiruddinshaikNo ratings yet

- FastLink 12F (GYXTW) Double ArmouredDocument1 pageFastLink 12F (GYXTW) Double ArmouredHaiderNo ratings yet

- UniWay 6F (GYXTW) Double ArmouredDocument1 pageUniWay 6F (GYXTW) Double ArmouredHaiderNo ratings yet

- Fisa Tehnica Pentur Cablu Anti Incendiu JHSTH-2x2x0.8x500MDocument2 pagesFisa Tehnica Pentur Cablu Anti Incendiu JHSTH-2x2x0.8x500MSava SergiuNo ratings yet

- ZTT OPGW 21-116750 DatasheetDocument9 pagesZTT OPGW 21-116750 DatasheetMalik Shoaib khalidNo ratings yet

- Qup 11348 H42jfy TechnicalDocument4 pagesQup 11348 H42jfy TechnicalSteveihNo ratings yet

- Southern Cable CatalogueDocument46 pagesSouthern Cable CatalogueRaja Mohd AriffNo ratings yet

- Hoja Tecnica Ei12025Document3 pagesHoja Tecnica Ei12025Jose Luis TopeteNo ratings yet

- Rfoui-250v 2014Document5 pagesRfoui-250v 2014VENITHA KNo ratings yet

- Draka RFOUI-250V - 2014 Instrument CableDocument5 pagesDraka RFOUI-250V - 2014 Instrument CablePelin RoxanaNo ratings yet

- Specifications Sheet Ez1000 8mm Eddy Current Sensor Ams en 1723544Document9 pagesSpecifications Sheet Ez1000 8mm Eddy Current Sensor Ams en 1723544heartsseven36No ratings yet

- Corrigendum2 PDFDocument197 pagesCorrigendum2 PDFBhuvan BajajNo ratings yet

- 9007MS03S0300Document3 pages9007MS03S0300Mattia BelliniNo ratings yet

- Brosur CcsiDocument38 pagesBrosur CcsiTyrion LannisterNo ratings yet

- Increased Safety Stator Winding Temperature Sensors: Specification and Order OptionsDocument2 pagesIncreased Safety Stator Winding Temperature Sensors: Specification and Order Optionsswapneel_kulkarniNo ratings yet

- OsiSense XC Special Format - XCKMR44D1H29Document5 pagesOsiSense XC Special Format - XCKMR44D1H29IlyesDerouicheNo ratings yet

- Opgw-12b1-48 (62.7 12.7)Document9 pagesOpgw-12b1-48 (62.7 12.7)Palle YulianNo ratings yet

- ZTT OPGW 18-96689-56 Hilos Con 2 Capas - Ver.CDocument9 pagesZTT OPGW 18-96689-56 Hilos Con 2 Capas - Ver.CGiancarlos OliveraNo ratings yet

- Wire Spec 44 PDFDocument5 pagesWire Spec 44 PDFAdnan khanNo ratings yet

- Technical Specification: Optical Ground WireDocument9 pagesTechnical Specification: Optical Ground WireMiftahul KhairNo ratings yet

- OPGWDocument18 pagesOPGWGuilhermeNo ratings yet

- Preventa XCS - XCSDMP5902Document2 pagesPreventa XCS - XCSDMP5902Magda DiazNo ratings yet

- UniWay 2F (GYXTY) ArmouredDocument1 pageUniWay 2F (GYXTY) ArmouredHaiderNo ratings yet

- GTMETRPSOD XX X X - 2018v2Document4 pagesGTMETRPSOD XX X X - 2018v2Stone123456789No ratings yet

- Datasheet HSEKP423HADocument4 pagesDatasheet HSEKP423HAAshot GevorgyanNo ratings yet

- TECHNICAL SPECIFICATION - POWER FRC CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022Document6 pagesTECHNICAL SPECIFICATION - POWER FRC CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022nnNo ratings yet

- Opgw - 24g652-Ast-177 (69.8 - 256.7)Document9 pagesOpgw - 24g652-Ast-177 (69.8 - 256.7)pedro torresNo ratings yet

- Ofc CatalogueDocument18 pagesOfc CatalogueProject OfficeNo ratings yet

- 24 Fiber OPGW ANDES PDFDocument7 pages24 Fiber OPGW ANDES PDFMAN TNo ratings yet

- ZTT Opgw 19 95588 72FDocument10 pagesZTT Opgw 19 95588 72FmiperNo ratings yet

- All-Dielectric Self Supporting (ADSS) Aerial Loose Tube Fiber Optic CableDocument3 pagesAll-Dielectric Self Supporting (ADSS) Aerial Loose Tube Fiber Optic CableAhmad TaheriNo ratings yet

- Tesys DF Ls1-Gk1 Df101Document2 pagesTesys DF Ls1-Gk1 Df101Zoran NesicNo ratings yet

- ZTT Opgw 23-XJ25012Document8 pagesZTT Opgw 23-XJ25012miperNo ratings yet

- Technor Evde-Pr-Led enDocument2 pagesTechnor Evde-Pr-Led enHamza AHMED SAADINo ratings yet

- Technical Specification: DescriptionDocument2 pagesTechnical Specification: DescriptionAnonymous RcxX0FcNo ratings yet

- TeSys Giga - LC1G2254KUENDocument4 pagesTeSys Giga - LC1G2254KUENeloycaroyale22No ratings yet

- 9842LS TechdataDocument2 pages9842LS TechdatajavierraazNo ratings yet

- OS1LTSTA12UBKDocument2 pagesOS1LTSTA12UBKShimahNo ratings yet

- Cable Drop Huawei b.5.11 HW Gjyxfch-1,2b6aDocument6 pagesCable Drop Huawei b.5.11 HW Gjyxfch-1,2b6aEvelyn TorrezNo ratings yet

- Preventa Safety Detection XCSDMP7002 DocumentDocument2 pagesPreventa Safety Detection XCSDMP7002 DocumentAkmalIshakNo ratings yet

- Ficha Técnica Cable FUTP Categoría 6A Siemon Ref. 9A6L4-A5Document2 pagesFicha Técnica Cable FUTP Categoría 6A Siemon Ref. 9A6L4-A5Sergio VargasNo ratings yet

- SC - Low Voltage Catalogue - Aluminium - 2020Document18 pagesSC - Low Voltage Catalogue - Aluminium - 2020ooi.impacNo ratings yet

- NW4000-1000 Pre-Installation Package V2.1 PDFDocument8 pagesNW4000-1000 Pre-Installation Package V2.1 PDFAdi PrasetyoNo ratings yet

- Westlock 316 Silver BulletDocument3 pagesWestlock 316 Silver BulletSunil RajNo ratings yet

- BCC 12103150Document1 pageBCC 12103150sashtiNo ratings yet

- Spe For Opgw 48F IndiaDocument9 pagesSpe For Opgw 48F IndiaMahesh GKNo ratings yet

- GUCN804 TechdataDocument2 pagesGUCN804 TechdatacatalinnnspinuuuNo ratings yet

- Stopper PlugDocument4 pagesStopper PlugChanchai PrugpadeeNo ratings yet

- 29552C - Techdata CablesDocument2 pages29552C - Techdata CablesAbastecimiento KANGURNo ratings yet

- Ficha Tecnica Cable Solar Multicontac Staubli FLEX-SOL-EVO-MCDocument2 pagesFicha Tecnica Cable Solar Multicontac Staubli FLEX-SOL-EVO-MCLuis OrtizNo ratings yet

- Technical Specification - LV Control Cable - WP4Document10 pagesTechnical Specification - LV Control Cable - WP4nnNo ratings yet

- Siemon-Category6a Futp Cable International Spec-SheetDocument2 pagesSiemon-Category6a Futp Cable International Spec-SheetNicanor BozaNo ratings yet

- CONTRINEX Series 600 Proximity Sensors PDFDocument38 pagesCONTRINEX Series 600 Proximity Sensors PDFMemik TylnNo ratings yet

- 2 - 7714-U0gy8-HaDocument1 page2 - 7714-U0gy8-HaMohd Sami UddinNo ratings yet

- Taisolar DMDocument8 pagesTaisolar DMJOE FUNGNo ratings yet

- EstimateDocument103 pagesEstimatesainath murthyNo ratings yet

- Chapter 38 Instrument Installation and Commissioning 2010 Instrumentation Reference Book Fourth EditionDocument6 pagesChapter 38 Instrument Installation and Commissioning 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Ultimate Load Capacity of Reinforced Concrete SlabDocument8 pagesUltimate Load Capacity of Reinforced Concrete SlabUmed ADA-ALSATAR100% (1)

- ARAMCO Test Questions-1Document13 pagesARAMCO Test Questions-1AHMAD YAGHI67% (6)

- Tables For Wood Post Design Based On NDS 2005: Post Axial Capacity For Douglas Fir-Larch # 1, (Kips)Document22 pagesTables For Wood Post Design Based On NDS 2005: Post Axial Capacity For Douglas Fir-Larch # 1, (Kips)leroytuscanoNo ratings yet

- Dongbao OCTG Products CatalogDocument31 pagesDongbao OCTG Products CatalogAF Dowell MirinNo ratings yet

- Fin Plate ConnectionDocument2 pagesFin Plate ConnectionSudhakar Krishnamurthy100% (2)

- Series Abo 300: DN 50 - DN 600 (2" - 24") PN 10Document12 pagesSeries Abo 300: DN 50 - DN 600 (2" - 24") PN 10Vignesh NadimuthuNo ratings yet

- Mimo BlankDocument5 pagesMimo BlankAlan ZhouNo ratings yet

- Manual Taladro RadialDocument39 pagesManual Taladro RadialMartin Rodriguez RamirezNo ratings yet

- Environmental Protection and ManagementDocument10 pagesEnvironmental Protection and ManagementparathasiNo ratings yet

- Poly (Vinyl Chloride) (PVC) Plastic Pipe Fittings, Schedule 40Document5 pagesPoly (Vinyl Chloride) (PVC) Plastic Pipe Fittings, Schedule 40Andres Camilo BenitezNo ratings yet

- IckDocument22 pagesIckshahidul islamNo ratings yet

- Piping Engineer B2 PDFDocument1 pagePiping Engineer B2 PDFAniz DonuTz100% (1)

- MCQ For BMCT-VII (Final Exam Dec2020)Document4 pagesMCQ For BMCT-VII (Final Exam Dec2020)Urvi KhatriNo ratings yet

- Model Element Table - LOD MATRIX INSTRUCTIONSDocument6 pagesModel Element Table - LOD MATRIX INSTRUCTIONSMark ChuoNo ratings yet

- Engineer Estimate ManualDocument24 pagesEngineer Estimate ManualNes-tValdezNo ratings yet

- New Revised Currriculum (Civil) 2Document81 pagesNew Revised Currriculum (Civil) 2Mesafint lisanu100% (1)

- Mod 80 UlDocument4 pagesMod 80 UlJUAN PABLO VELA GUIMACNo ratings yet

- A-E SOW FinalTucsonDocument68 pagesA-E SOW FinalTucsonmdtaahNo ratings yet

- Hatelit Asphalt Reinforcement Grid: Installation GuidelinesDocument6 pagesHatelit Asphalt Reinforcement Grid: Installation GuidelinesjasbojanotNo ratings yet

- Encl. As AboveDocument16 pagesEncl. As AboveSanjoy RoyNo ratings yet

- Application Form / ChecklistDocument34 pagesApplication Form / ChecklistMC EstimationNo ratings yet

- Propped Cantilever With UdlDocument5 pagesPropped Cantilever With UdlIqbal Hossain50% (4)

- Roofing Fixer 5 J-Bolt To Purlin & G.I Sheet Connection Detail 6Document1 pageRoofing Fixer 5 J-Bolt To Purlin & G.I Sheet Connection Detail 6Fritz Natividad100% (2)

- Applsci 12 03547Document26 pagesApplsci 12 03547Bahaa HussainNo ratings yet

- Relationships Between Fibre Distribution, Workability and The MechanicalDocument11 pagesRelationships Between Fibre Distribution, Workability and The Mechanicalyousef alghaleedNo ratings yet

- Solved Examples On High Pressure Vessel Thicknesses & Their Calculations PDFDocument11 pagesSolved Examples On High Pressure Vessel Thicknesses & Their Calculations PDFShriyash DeshpandeNo ratings yet