Professional Documents

Culture Documents

8548G, 8549L, 8550M Bulletin RE

8548G, 8549L, 8550M Bulletin RE

Uploaded by

Christian DeleonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8548G, 8549L, 8550M Bulletin RE

8548G, 8549L, 8550M Bulletin RE

Uploaded by

Christian DeleonCopyright:

Available Formats

3M™ Envision™ Wrap Overlaminates ProductProduct

Bulletin Bulletin

8548G,8548G, 8549L,

8549L, 8550M

8550M

Revision E, July 2020

L2 Product Name (variable) Revision E, July 2020

8548G Gloss Wrap Overlaminate Quick Links

3M Graphics Warranties

8549L Luster Wrap Overlaminate Technical Information Selector

8550M Matte Wrap Overlaminate Safety Data Sheets (SDS)

Flammability (ASTM E84 Reports)

Product Description Videos

• Suitable for application surfaces that are flat, flat with rivets, corrugated, Some of these links lead to web-based

simple curves, compound curves, or deep channels and concave surfaces. resources that are not product-specific.

• Gloss, Luster and Matte high performance non-PVC

• Excellent conformability and lifting resistance

• 8550M provides a UL 410 slip resistant surface for floor graphics

• Good scratch resistance

• Excellent UV protection

• Long-term vertical durability

• Horizontal warranty

• Expected performance life of 9 years (unwarranted period applied to a flat, vertical, outdoor surface)

Recommended Types of Graphics and End Uses

• 8548G/8549L/8550M: For inkjet printed films

- 3M™ Controltac™ Graphic Film with Comply™ v3 Adhesive IJ180Cv3

- 3M™ Controltac™ Graphic Film with Comply™ Adhesive IJ180C

- 3M™ Controltac™ Graphic Film IJ180-10

- 3M™ Print Wrap Film IJ180mC-10/IJ180mC-114/IJ180mC-120

- 3M™ Envision™ Print Wrap Film LX480mC

- 3M™ Envision™ Print Wrap Film SV480mC

- 3M™ Controltac™ Wrap Film with Comply™ v3 Adhesive IJ380Cv3

- 3M™ Scotchcal™ Graphic Film with Comply™ v3 Adhesive IJ170Cv3

- 3M™ Print Wrap Film IJ175Cv3

- 3M™ Scotchlite™ Print Wrap Film 780mC-10R

• Fleet

• Vehicle Wraps

• Watercraft

• Transit

• Labels

• Thermoformable

• Signage

• Awning

• Smooth Walls/Textured Walls and Surfaces

- 8550M is an excellent rough wall material that helps reduce gloss banding that can form when using other rough wall films.

• Windows and Glass

• Floor graphics (8550M only)

NOTE: 8550M has been tested according to the UL 410 standard, and has been certified as slip-resistant for use on floor graphics.

3M™ Envision™ Wrap Overlaminates

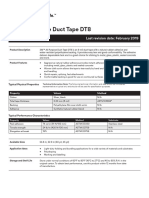

Characteristics

These are typical values for unprocessed product. Processing may change the values.

Performance Characteristics

Characteristic Value

Material Non-PVC

Thickness 2 mils

8548G: Gloss

Gloss 8549L: Luster

8550M: Matte

8548G: Polyester

Liner

8549L/8550M: Kraft paper

Lamination Temperature 50 to 100 F (10 to +38 C)

In Use Temperature -65 to +200 F (-54 to +93C) (not for extended periods of time

Range at the extremes)

• Resists mild alkalis, mild acids, and salt

• Excellent resistance to water (does not include immersion)

Chemical Resistance

• Resists occasional fuel spills

• Does not resist isopropyl alcohol

ASTM E84 reports: 8548G, 8550M or go to the On-line

Flammability Product Catalog at 3M.com/graphics

All other test reports: call 1-800-328-3908

Warranty Information

All 3M graphic protection products are covered by the 3M Basic Product Warranty.

A warranty period may be offered based on the graphic construction and application details. Always refer to the 3M Product Bulletin for the

3M base film or flexible substrate you are using to determine if the graphic protection product you want to use is recommended and what,

if any warranty period is offered.

i IMPORTANT NOTE

Warranty information including limitations and exceptions and warranty periods for this product can be found at

3MGraphics.com/warranties.

Warranty Coverage Overview

The warranty coverage for eligible graphics is based on the user both reading and following all applicable and current 3M Graphics Product

and Instruction Bulletins. The warranty period for eligible graphics is as stated in the 3M Graphics Warranties Matrices at the time that the

film was purchased. Information found at 3M.com/graphicswarranties includes:

• 3M Graphics Warranties Bulletin

- This bulletin contains information on limitations and exceptions, and warranty period reductions for 3M Graphics Warranties. The war-

ranty period may be reduced and stipulations may apply for certain constructions, applications, and graphic exposures as covered in

this Bulletin.

• 3M Graphics Warranties Selector

- Use this selector to search for your vertical warranty period by product type, ink type, film name, and/or ink/printer platform.

• U.S. Desert Southwest Region Map

- Use this map of hot, arid desert areas to determine if you are subject to reduced warranted durabilities.

The warranties set forth in this Bulletin are made in lieu of all other express or implied warranties, including any implied warranty of

merchantability, fitness for a particular purpose, or arising out of a course of dealing, custom, or usage of trade.

2 Product Bulletin 8548G, 8549L, 8550M - Revision E,

July 2020

3M™ Envision™ Wrap Overlaminates

3M Basic Product Warranty

3M Graphics Products are warranted to be free of defects in materials and manufacture at the time of shipment and to meet the

specifications stated in its applicable 3M Graphics Product Bulletin and as further set forth in the 3M Graphics Warranties Bulletin.

Limited Remedy

The limited remedy applicable to each warranty is addressed in the 3M Graphics Warranties Bulletin found at 3M.com/graphicswarranties.

Limitation of Liability

Except to the extent prohibited by law, 3M SHALL NOT UNDER ANY CIRCUMSTANCES BE LIABLE TO PURCHASER OR USER FOR ANY

DIRECT (EXCEPT FOR THE LIMITED REMEDY PROVIDED HEREIN), INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES (INCLUDING, BUT NOT LIMITED TO, LABOR, NON-3M MATERIAL CHARGES, LOSS OF PROFITS, REVENUE, BUSINESS,

OPPORTUNITY, OR GOODWILL) RESULTING FROM OR IN ANY WAY RELATED TO 3M'S GRAPHICS PRODUCTS, SERVICES, OR THIS

BULLETIN. This limitation of liability applies regardless of the legal or equitable theory under which such losses or damages are sought.

Warranty Period Matrices

See the 3M Graphics Warranties Matrices at 3M.com/graphicswarranties, for vertical warranty period information specific to your film.

Additional Limitations

See the 3M Graphics Warranties Bulletin at 3MGraphics.com/warranties, for terms, additional limitations of your warranty, if any,

information on reduced warranties for different exposures, and limitations of liability.

Health and Safety

! CAUTION

When handling any chemical products, read the manufacturers’ container labels and the Safety Data Sheets (SDS) for important

health, safety and environmental information. To obtain SDS sheets for 3M products go to 3M.com/SDS, or by mail or in case of an

emergency, call 1-800-364-3577 or 1-651-737-6501.

When using any equipment, always follow the manufacturer’s instructions for safe operation.

Factors that Affect Graphic Performance Life

The actual performance life of a graphic is affected by:

• the combinations of graphics materials used.

• complete ink drying or curing.

• selection, condition and preparation of the substrate.

• surface texture.

• application methods.

• angle and direction of sun exposure.

• environmental conditions.

• cleaning or maintenance methods.

Product Bulletin 8548G, 8549L, 8550M - Revision E, July 2020 3

3M™ Envision™ Wrap Overlaminates

Graphics Manufacturing

! CAUTION

Before using any equipment, always read the manufacturer’s instructions for safe operation.

Completely Dry Graphics

i IMPORTANT NOTE

Incomplete drying or curing can result in graphic failure including curling, increased shrinkage and adhesion failure, which are not

covered under any 3M Graphic Warranty.

See the specific ink’s 3M Product and Instruction Bulletin for more details.

Application Tapes

There are two types of application tapes. See 3M Instruction Bulletin AT-1 to determine what application tape is recommended for the film

or finished graphic.

Premasking Tape

Increases stiffness during application while preventing stretching and damage. Use when little or no liner is exposed. See 3M Instruction

Bulletin 4.3 for complete details.

Prespacing Tape

Holds cut and weeded letters or graphics in place during application and after removing the film liner, while preventing stretching and

damage. Use when large amounts of liner are exposed. See 3M Instruction Bulletin 4.3 for complete details.

Application and Installation

In addition to other 3M Bulletins specified in this document, the following Bulletins provide details that the user may need to properly

manufacture a graphic.

• 3M Instruction Bulletin 4.22 Lamination Basics for Inkjet Printed Graphics

Slip Resistance for Floor or Sidewalk Sign Graphics

The UL 410 Slip Resistance of Floor Surface Materials covers the testing of floor and finishing materials to determine if their minimum

average and minimum individual static coefficients of friction (COF) meet or exceed the specified requirements with respect to slip

resistance only. The floor surface materials covered by this standard include floor coverings (FCM), floor treatment materials (FTM) and

walkway construction materials (WCM). The average static coefficient of friction for FTM, FCM, and WCM products shall be at least 0.50

and individual static coefficients of friction shall be at least 0.45 when tested in accordance with the requirements of this standard

Method: The floor samples were tested dry only. The slip resistance characteristics of the materials were measured in accordance with the

established and standardized practice of Underwriters Laboratories Inc. and in accordance with the latest Standard of Slip Resistance of

Floor Surface Materials, UL 410.

Results: An average slip resistance characteristic greater than 0.50 was recorded for each of the materials tested.

4 Product Bulletin 8548G, 8549L, 8550M - Revision E,

July 2020

3M™ Envision™ Wrap Overlaminates

Maintenance and Cleaning

Use a cleaner designed for high-quality painted surfaces. The cleaner must be wet, non-abrasive, without solvents, and have a pH value

between 3 and 11 (neither strongly acidic nor strongly alkaline). See 3M Instruction Bulletin 6.5 for details.

i IMPORTANT NOTE

It is not recommended to use Isopropyl alcohol on the Products specified in this document. Use a detergent, such as Simple

Green™, and water to clean.

Shelf Life, Storage and Shipping

Shelf Life

The shelf life is never more than 3 years from the date of manufacture on the original box.

If you process the film, the shelf life is changed to 1 year from the processing date, but not later than the 3 year maximum from the

manufacturing date.

Storage Conditions

• 40 to 100 F (4 to 38 C)

• Out of sunlight

• Clean, dry area

• Original container

• Bring the film to room temperature before use

Shipping Finished Graphics

Flat, or rolled printed side out on 6 inch (15 cm) or larger core. This helps prevent the application tape, if used, from popping off.

Commercial Solutions © 3M 2020. All rights reserved.

3M Center, Building 220-12E-04 3M, Controltac, Comply, and MCS are trademarks of 3M. Used

St. Paul, MN 55144 under license in Canada.

All other trademarks are property of their respective owners.

1-800-328-3908 Revision E, July 2020 Please recycle.

3M.com/Graphics

You might also like

- The Nalco Water Handbook Fourth Edition Nalco Company Full ChapterDocument67 pagesThe Nalco Water Handbook Fourth Edition Nalco Company Full Chaptermonica.chaney628100% (14)

- Cell Homeostasis Virtual LabDocument2 pagesCell Homeostasis Virtual LabNicolai MendozaNo ratings yet

- 8508 8509 8510 Bulletin REDocument4 pages8508 8509 8510 Bulletin REChristian DeleonNo ratings yet

- Product Bulletin 8048GDocument6 pagesProduct Bulletin 8048GChristian DeleonNo ratings yet

- MultimediaDocument10 pagesMultimediaGanjaNo ratings yet

- Electroplating/Anodizing Tape: Technical Data December, 2006Document2 pagesElectroplating/Anodizing Tape: Technical Data December, 2006sanjay ukalkarNo ratings yet

- PB 2080Document5 pagesPB 2080Sergio MarinNo ratings yet

- Plating Masking TapDocument2 pagesPlating Masking TapkkphadnisNo ratings yet

- 3M Venture Tape 1599B TDS v12-2017Document2 pages3M Venture Tape 1599B TDS v12-2017Hernan Romero RomeroNo ratings yet

- Glass Cloth Tape: Technical DataDocument2 pagesGlass Cloth Tape: Technical DataАндрей МошкинNo ratings yet

- Spec 3m 375Document2 pagesSpec 3m 375Thích Rong ChơiNo ratings yet

- Ficha Tecnica - Lamina 8519 3mDocument2 pagesFicha Tecnica - Lamina 8519 3mJuan Sebastian Martinez FloresNo ratings yet

- 3M Preservation Sealing Tape 481Document6 pages3M Preservation Sealing Tape 481Mait YNo ratings yet

- General Purpose Polyester/ Silicone Tape: 8952 8952L (Linered)Document2 pagesGeneral Purpose Polyester/ Silicone Tape: 8952 8952L (Linered)Hardware 02No ratings yet

- 3M Glass Cloth Tape 361Document5 pages3M Glass Cloth Tape 361edwardNo ratings yet

- 481 Preservation Sealing TapeDocument2 pages481 Preservation Sealing TapeSixmonNo ratings yet

- 425 427 DS Eng BNL 08 2015Document3 pages425 427 DS Eng BNL 08 2015Mostafa AlakhliNo ratings yet

- Ficha 218Document2 pagesFicha 218Victor Javier Reyes NavarroNo ratings yet

- Cinta 365 ElectricaDocument2 pagesCinta 365 ElectricamiguelNo ratings yet

- 3M_ Polyurethane Protective Tape 8657DL - TDS - FINALDocument2 pages3M_ Polyurethane Protective Tape 8657DL - TDS - FINALRinti ArnoNo ratings yet

- 3M 8979 TDSDocument2 pages3M 8979 TDSmaimonides76No ratings yet

- Flame Retardant Label Materials 7203 and 7204Document2 pagesFlame Retardant Label Materials 7203 and 7204FAH MANNo ratings yet

- Ventureshield™ Paint Protection Film 7510Cc/Cs-Ld: Technical Data Sheet April 2011Document2 pagesVentureshield™ Paint Protection Film 7510Cc/Cs-Ld: Technical Data Sheet April 2011Димитър ПетровNo ratings yet

- 850 - Clear & Colored - TDS 2013Document2 pages850 - Clear & Colored - TDS 2013KarinaNo ratings yet

- 3M Laser Markable Label Material 7847Document6 pages3M Laser Markable Label Material 7847Haresh KapadiyaNo ratings yet

- 3M Scotch Transparent Film Tape 600 2Document6 pages3M Scotch Transparent Film Tape 600 2Deepak LoganathanNo ratings yet

- ACFInterconnect 6000575Document4 pagesACFInterconnect 6000575mazacotesNo ratings yet

- 3M Filament Tape 897Document2 pages3M Filament Tape 897German CalvoNo ratings yet

- 3M™ Scotch-Seal™ Mastic Tape and Pads 2229: Data Sheet May 2013Document2 pages3M™ Scotch-Seal™ Mastic Tape and Pads 2229: Data Sheet May 2013peloquin1349391No ratings yet

- 3m Safety Tape 5072Document2 pages3m Safety Tape 5072Erikas KulpinasNo ratings yet

- Ts en 3m Scotchcal Graphic Ij15 Ij16Document5 pagesTs en 3m Scotchcal Graphic Ij15 Ij16Umesh KirantNo ratings yet

- PTFE Glass Cloth Tape: Technical Data March, 2014Document2 pagesPTFE Glass Cloth Tape: Technical Data March, 2014Lord KrsnikNo ratings yet

- 3M-Polyurethane-Protective-Tape-8658DL-TDS-FINALDocument2 pages3M-Polyurethane-Protective-Tape-8658DL-TDS-FINALRinti ArnoNo ratings yet

- Scotch: Masking Tape 244Document2 pagesScotch: Masking Tape 244Frank CahuiNo ratings yet

- 3M Acrylic Foam Tape GT7108: Technical Data SheetDocument3 pages3M Acrylic Foam Tape GT7108: Technical Data SheetRajiv SharmaNo ratings yet

- Scotch-Weld: Medical Grade Instant Adhesive PrimersDocument3 pagesScotch-Weld: Medical Grade Instant Adhesive PrimerssendiruNo ratings yet

- 3M™ Acrylic Foam Tape 4222: Technical Data SheetDocument2 pages3M™ Acrylic Foam Tape 4222: Technical Data SheetDejChonlateeNo ratings yet

- 3M™ High Temperature Aluminum Foil Tape 433_20230111Document4 pages3M™ High Temperature Aluminum Foil Tape 433_20230111ryanpetters86No ratings yet

- 3M Duct Tape 8979Document2 pages3M Duct Tape 8979Jun Xian WaiNo ratings yet

- 3M FT-DT8DuctTapeDocument2 pages3M FT-DT8DuctTapeElviera MphieNo ratings yet

- 766 Safety TapeDocument2 pages766 Safety TapeAch Dja'far SNo ratings yet

- 3M 8067 LeedDocument2 pages3M 8067 LeedStefano CamillucciNo ratings yet

- ASTM E84 Technical BulletinDocument2 pagesASTM E84 Technical BulletinHauntingFire007No ratings yet

- Double Coated Splicing Tapes: Technical Data March, 2008Document3 pagesDouble Coated Splicing Tapes: Technical Data March, 2008douglas lopezNo ratings yet

- Scotch: Filament TapeDocument2 pagesScotch: Filament TapeGuillermo CorreaNo ratings yet

- 3M 950Document4 pages3M 950Le Tan HoaNo ratings yet

- Wepp Cas52gDocument1 pageWepp Cas52gArthur Sanda LayukNo ratings yet

- IJ180 Bulletin RUDocument9 pagesIJ180 Bulletin RUPartha SahaNo ratings yet

- 3M Scotch Weld Nylon Bonder Structural Adhesive DP8910NS FlyerDocument2 pages3M Scotch Weld Nylon Bonder Structural Adhesive DP8910NS FlyerThuy NguyenNo ratings yet

- 3m Ecdst 9750 TdsDocument4 pages3m Ecdst 9750 TdsGhost_suolNo ratings yet

- Bpxe B4c4vuDocument1 pageBpxe B4c4vurajeshpatnaikNo ratings yet

- 3M 101 Paper Masking Tape 1 X55m MI TAIWAN DatasheetDocument2 pages3M 101 Paper Masking Tape 1 X55m MI TAIWAN Datasheetfelixnord19No ratings yet

- Textran TDH Premium: Universal Tractor Transmission OilDocument3 pagesTextran TDH Premium: Universal Tractor Transmission OilRobert RobertsNo ratings yet

- 3M Aluminum Foil Tape 425Document5 pages3M Aluminum Foil Tape 425Yo ANo ratings yet

- Retaining Compound Anaerobic Adhesive TDSDocument4 pagesRetaining Compound Anaerobic Adhesive TDSPaul TushausNo ratings yet

- Technical Data Sheet: PermacolorDocument2 pagesTechnical Data Sheet: PermacolordjossNo ratings yet

- 3M™ Scotch® Transparent Film Tape 600 - 20230623Document4 pages3M™ Scotch® Transparent Film Tape 600 - 20230623Athit DathorngNo ratings yet

- 3m Polyurethane Seam Sealer 08684 08365 08694 08689 Technical Datasheet en Eu - 0820Document4 pages3m Polyurethane Seam Sealer 08684 08365 08694 08689 Technical Datasheet en Eu - 0820Marino Sánchez GuitianNo ratings yet

- Industrial SealsTechManualDocument60 pagesIndustrial SealsTechManualAlvaroNo ratings yet

- VHB Acrylic Foam Tape: Technical Data March, 2001Document2 pagesVHB Acrylic Foam Tape: Technical Data March, 2001daskhagoNo ratings yet

- 3M™ Polyester Tape 8911 - 20240614Document4 pages3M™ Polyester Tape 8911 - 20240614comprasbex1No ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Creatine Kinase: Store at 2-8ºCDocument4 pagesCreatine Kinase: Store at 2-8ºCLaboratorios HerliNo ratings yet

- Sarita Devi Et Al 2022Document9 pagesSarita Devi Et Al 2022camila.gbarbosaNo ratings yet

- Dinesh Dhumal Formatted CVDocument9 pagesDinesh Dhumal Formatted CVManoharNo ratings yet

- Calcium Versanate Buffer SolutionDocument8 pagesCalcium Versanate Buffer Solutionjesusruizbadra357No ratings yet

- Application Note - Using THGA and Zeeman Background Correction For Blood-Lead Determination in Customer-Validated ApplicationsDocument4 pagesApplication Note - Using THGA and Zeeman Background Correction For Blood-Lead Determination in Customer-Validated ApplicationsNguyễnHoàngDanhNo ratings yet

- Procedure of Flexural Strength TestDocument6 pagesProcedure of Flexural Strength TestEroll Morga VillanuevaNo ratings yet

- Chemical EORDocument50 pagesChemical EORAmmar Abdul HussainNo ratings yet

- HSSC I Send Up Key ChemistryDocument5 pagesHSSC I Send Up Key Chemistrymymegaacc111No ratings yet

- Laser Cladding Remanufacturing of Aircraft Landing Gear Based On 30CrMnSiNi2A SteelDocument13 pagesLaser Cladding Remanufacturing of Aircraft Landing Gear Based On 30CrMnSiNi2A Steelzixin chenNo ratings yet

- In Context: Subject Area: Organic Chemistry Level: 14-16 Years (Higher) Topic: Addition Polymers Source: RSC - Li/2GrwsijDocument5 pagesIn Context: Subject Area: Organic Chemistry Level: 14-16 Years (Higher) Topic: Addition Polymers Source: RSC - Li/2GrwsijRajlaxmi JainNo ratings yet

- ChemDocument2 pagesChemSussy BakaNo ratings yet

- GFOAM-9121C-02 - Technical Data SheetDocument1 pageGFOAM-9121C-02 - Technical Data SheetPierre-Olivier MouthuyNo ratings yet

- 01-Chep-11-Chemical Kinetics-Theory-Final-EDocument8 pages01-Chep-11-Chemical Kinetics-Theory-Final-EAbhishek RavirajNo ratings yet

- Kinetics For Benzene#ethylene Reaction in Near-Critical RegionsDocument8 pagesKinetics For Benzene#ethylene Reaction in Near-Critical RegionsDulce GradillaNo ratings yet

- Nickel Troubleshooting GuideDocument45 pagesNickel Troubleshooting GuideFrancisco BocanegraNo ratings yet

- Calibration of PHDocument4 pagesCalibration of PHPortier AkademikNo ratings yet

- 5.characterization of Petroleum FractionsDocument65 pages5.characterization of Petroleum FractionsNatalia AguilarNo ratings yet

- The Forensic Use of Chemiluminescence and LuminolDocument33 pagesThe Forensic Use of Chemiluminescence and Luminolmacvia.eu100% (6)

- Iso 5662 1978Document4 pagesIso 5662 1978muhammed hairieNo ratings yet

- Mil-Std-202-Method 103, Humidity (Steady State)Document5 pagesMil-Std-202-Method 103, Humidity (Steady State)Great StuffNo ratings yet

- Cambridge IGCSE: Chemistry 0620/63Document12 pagesCambridge IGCSE: Chemistry 0620/63Rishabh RaoNo ratings yet

- 11 Chemistry Module 2Document19 pages11 Chemistry Module 2SpongeBob SquarePants Fidget ToysNo ratings yet

- Diagnostic Test All Subjects - Docx Version 1Document22 pagesDiagnostic Test All Subjects - Docx Version 1Junelle Joy CatbaganNo ratings yet

- Activity Sheet-03 (Rutherford Gold Foil Experiment)Document2 pagesActivity Sheet-03 (Rutherford Gold Foil Experiment)Nkemzi Nzetengenle100% (1)

- Rohs PDFDocument21 pagesRohs PDFSameer KmNo ratings yet

- Manual Quadra Q4 PlatinumDocument48 pagesManual Quadra Q4 PlatinumDos PiNo ratings yet

- G30, G40, G60 and G90: Understanding Zinc-Based Coating WeightsDocument12 pagesG30, G40, G60 and G90: Understanding Zinc-Based Coating WeightsAhmad KhalifaNo ratings yet

- The Granulation Methods of Double Base PropellantDocument5 pagesThe Granulation Methods of Double Base PropellantSimbarashe NyotaNo ratings yet