Professional Documents

Culture Documents

Cable Reel With Automated Layering - Mahdi Designs

Cable Reel With Automated Layering - Mahdi Designs

Uploaded by

Matthews Andrea MachilaCopyright:

Available Formats

You might also like

- TM 5-3805-262-10 Case MW24C Scoop LoaderDocument200 pagesTM 5-3805-262-10 Case MW24C Scoop LoaderAdvocate100% (2)

- Busbar Manual CCA (Copper Clad Aluminium)Document5 pagesBusbar Manual CCA (Copper Clad Aluminium)Affid bin Abi ThalibNo ratings yet

- MOperador SY215C Serie HO6898 - Crawler Hydraulic ExcavatorDocument435 pagesMOperador SY215C Serie HO6898 - Crawler Hydraulic ExcavatorRojasDura.100% (5)

- Conduit & Trunking Capacity ChartDocument20 pagesConduit & Trunking Capacity ChartvelisbarNo ratings yet

- Cek 3Document210 pagesCek 3Fachri RamadhanNo ratings yet

- Overhead Conveyor Products PDFDocument16 pagesOverhead Conveyor Products PDFPierre Hopkins100% (1)

- Flexible Road Overlay Design by FWDDocument9 pagesFlexible Road Overlay Design by FWDafifa kausar100% (1)

- Core 1 1 KV Aluminium Copper PVC Insulated Armoured Power CaDocument2 pagesCore 1 1 KV Aluminium Copper PVC Insulated Armoured Power Carnd.ptcwiNo ratings yet

- P I CABS 2 10TN MOD v2 ENDocument5 pagesP I CABS 2 10TN MOD v2 ENDiana AlexandraNo ratings yet

- Aerial Bundle Conductor Abc CableDocument1 pageAerial Bundle Conductor Abc CableBrianNo ratings yet

- Be Summer 2015Document4 pagesBe Summer 2015babaf79912No ratings yet

- 2018 - CATALOG - Maxbrio RipperDocument6 pages2018 - CATALOG - Maxbrio RipperJuanPabloCruzNo ratings yet

- Wire Rope Specifications 18000: Manitowoc Cranes, IncDocument2 pagesWire Rope Specifications 18000: Manitowoc Cranes, IncDavid FlemmingNo ratings yet

- Singly Reinforced Beam: Design For ShearDocument16 pagesSingly Reinforced Beam: Design For ShearArbaz AhmedNo ratings yet

- Eurotruss HD34Document2 pagesEurotruss HD34Lässäri On läskiNo ratings yet

- Steel Wire Rope: Factors Affecting Rope Life Tensile GradeDocument1 pageSteel Wire Rope: Factors Affecting Rope Life Tensile GradeHUNG NIKKONo ratings yet

- Tabular Presentation of Basic Technical Data RMC ConductorsDocument2 pagesTabular Presentation of Basic Technical Data RMC ConductorsBuyme1 CNC BIZNo ratings yet

- Sas Micropile Manual With Grade 97Document16 pagesSas Micropile Manual With Grade 97JR GEOCONSULTORES INGENIEROSNo ratings yet

- Bbs For Test Pile A1 & A2: Name of WorkDocument33 pagesBbs For Test Pile A1 & A2: Name of WorkSaraswati ChandraNo ratings yet

- Catalog - Maxbrio Ripper Seires - Ver.1504 - Eng (1M)Document6 pagesCatalog - Maxbrio Ripper Seires - Ver.1504 - Eng (1M)henry vegaNo ratings yet

- Standard Belt Cross SectionsDocument26 pagesStandard Belt Cross Sectionsagung badoNo ratings yet

- Maxbrio RippersDocument6 pagesMaxbrio Ripperssbhade1993No ratings yet

- ID - No./Seat No.: ATTEMPT ALL QUESTIONS. Assume Any Missing DataDocument2 pagesID - No./Seat No.: ATTEMPT ALL QUESTIONS. Assume Any Missing DataMuhammad Sharif JamaliNo ratings yet

- Be Winter 2016Document3 pagesBe Winter 2016babaf79912No ratings yet

- Kinematic Wave Routing - ExampleDocument33 pagesKinematic Wave Routing - ExamplethewodrosNo ratings yet

- Diepa B50 - High Performance Rotation Resistant Steel Wire RopeDocument1 pageDiepa B50 - High Performance Rotation Resistant Steel Wire RopeKonstantinos SynodinosNo ratings yet

- WallcalcDocument31 pagesWallcalcSubhekshya ShresthaNo ratings yet

- NHA Hydraulic Tubing Anchor Data SheetDocument1 pageNHA Hydraulic Tubing Anchor Data Sheet朱向斌No ratings yet

- Rubber Conveyor Belts Steel CordsDocument4 pagesRubber Conveyor Belts Steel CordsnicolasNo ratings yet

- EPR Insulated AC Medium-Voltage Submarine CableDocument3 pagesEPR Insulated AC Medium-Voltage Submarine CableGcNo ratings yet

- 3 V Belt DriveDocument29 pages3 V Belt DriveMurugesan RameshNo ratings yet

- Bearing DesignDocument5 pagesBearing DesignVenkat RaoNo ratings yet

- Design Girder: 1. Data - Data PerencanaanDocument6 pagesDesign Girder: 1. Data - Data PerencanaanMuhammad Rizki AnwarNo ratings yet

- Cable Current RatingDocument3 pagesCable Current RatingAnuj BhardwajNo ratings yet

- Technical Information of 150kV HVAC Submarine CableDocument2 pagesTechnical Information of 150kV HVAC Submarine Cablebagja wigunaNo ratings yet

- Exp. No: - 01 Date:09/08/2021 Cam AnalysisDocument8 pagesExp. No: - 01 Date:09/08/2021 Cam AnalysisAnantha ReddyNo ratings yet

- Parallel Flange Channels PFC Eurocode Data Sheet PDFDocument2 pagesParallel Flange Channels PFC Eurocode Data Sheet PDFviswanathanNo ratings yet

- Parallel Flange Channels PFC Eurocode Data SheetDocument2 pagesParallel Flange Channels PFC Eurocode Data SheetviswanathanNo ratings yet

- Post TensionDocument8 pagesPost Tensionedc1312No ratings yet

- N2XBYDocument5 pagesN2XBYbonadupangNo ratings yet

- Eurotruss XDDocument2 pagesEurotruss XDjoshNo ratings yet

- Interspan PT DesignDocument21 pagesInterspan PT DesignDương TrầnNo ratings yet

- N2XRYDocument5 pagesN2XRYicalcalNo ratings yet

- Extra Item AnalysisDocument6 pagesExtra Item Analysissri projectssNo ratings yet

- N2XSRYDocument1 pageN2XSRYYulian Dea ZollaNo ratings yet

- N2XSRYDocument1 pageN2XSRYKrisnandha RahardianNo ratings yet

- 8 Foundations CombinedDocument32 pages8 Foundations Combinedhamadamjad047No ratings yet

- TaperedRollerBearings TS (TaperedSingle) ImperialDocument5 pagesTaperedRollerBearings TS (TaperedSingle) ImperialRonald esquivelNo ratings yet

- N2XYDocument5 pagesN2XYSamuel SantosNo ratings yet

- Birla Institute of Technology and Science, PilaniDocument3 pagesBirla Institute of Technology and Science, PilaniSharad ShrivastavaNo ratings yet

- SWG To MM - Standard Gauge To MM ConversionDocument3 pagesSWG To MM - Standard Gauge To MM ConversionMRSUPERCOOLNo ratings yet

- ANCHORAGE AND LAP LENGTHS (According To BS 5400 Part 4 Clause 5.8.6.)Document22 pagesANCHORAGE AND LAP LENGTHS (According To BS 5400 Part 4 Clause 5.8.6.)Brook KingNo ratings yet

- Technical News: Engineering Information For The Professional EngineerDocument2 pagesTechnical News: Engineering Information For The Professional EngineerFelipe GustavoNo ratings yet

- Es en Isolated Footing - XLSMDocument8 pagesEs en Isolated Footing - XLSMBeka TayeNo ratings yet

- N2xy PDFDocument5 pagesN2xy PDFArnold StevenNo ratings yet

- Inch Conduit FillDocument2 pagesInch Conduit FillAhrariMustafaNo ratings yet

- Report#3 Testingthetensilestrengthofmetalsusingtheuniversaltestingmachine Chem1103l Group26Document8 pagesReport#3 Testingthetensilestrengthofmetalsusingtheuniversaltestingmachine Chem1103l Group26MarielleCaindecNo ratings yet

- FD34 Square Truss: FactsDocument2 pagesFD34 Square Truss: FactsJakob PaulinNo ratings yet

- Catálogo - Acoplamento L - MetricDocument8 pagesCatálogo - Acoplamento L - MetricMarcos Marcandali de JesusNo ratings yet

- Conductores Copperweld PDFDocument4 pagesConductores Copperweld PDFMiguel Ángel Díaz SepúlvedaNo ratings yet

- Datasheet LiYCY Cable PDFDocument1 pageDatasheet LiYCY Cable PDFResaKandhy100% (1)

- User Manual: Earthfault Compensation Controller EFC50Document122 pagesUser Manual: Earthfault Compensation Controller EFC50Ichim NasuiNo ratings yet

- FMB120 Quick Manual v1.4Document16 pagesFMB120 Quick Manual v1.4yoyovohNo ratings yet

- MOS and BiCMOS Circuit Design ProcessDocument17 pagesMOS and BiCMOS Circuit Design ProcessNarasimha Murthy YayavaramNo ratings yet

- Application Guide For Power Factor Testing of Cables and PotheadsDocument2 pagesApplication Guide For Power Factor Testing of Cables and PotheadsPardeep SindhuNo ratings yet

- Final Project Report PDFDocument105 pagesFinal Project Report PDFSushila DhimanNo ratings yet

- KZCO AllcatalogDocument76 pagesKZCO AllcatalogJaime SuaNo ratings yet

- 1192384864insulators 2010 DriwisaDocument2 pages1192384864insulators 2010 DriwisaAna LucíaNo ratings yet

- HR2470Document4 pagesHR2470Cata100% (1)

- Instructions PDFDocument1 pageInstructions PDFNikola UroševićNo ratings yet

- Parts CatalogDocument73 pagesParts CatalogBernardoNo ratings yet

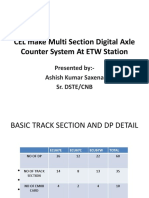

- 1630481949539-Msdac Etw NewDocument52 pages1630481949539-Msdac Etw NewAshim ChakrabortyNo ratings yet

- Windsor Chariot I CapsolDocument112 pagesWindsor Chariot I CapsolNestor Marquez-DiazNo ratings yet

- Hydraulics - SteeringDocument3 pagesHydraulics - SteeringSilvio RomanNo ratings yet

- GIGABYTE 8VM800M Schematics: Sheet Title Sheet TitleDocument32 pagesGIGABYTE 8VM800M Schematics: Sheet Title Sheet TitleSjf NetNo ratings yet

- cdd161033-LG MS119MLDocument36 pagescdd161033-LG MS119MLfranklin antonio RodriguezNo ratings yet

- Mike Holt's Illustrated Guide Onal Electrical Code, 2020 NEC 355Document1 pageMike Holt's Illustrated Guide Onal Electrical Code, 2020 NEC 355Tito BustamanteNo ratings yet

- Product Sheet IR 2011: Intended UseDocument1 pageProduct Sheet IR 2011: Intended UseMarcelo Silva100% (2)

- KM-2810 DP-110: Parts ListDocument47 pagesKM-2810 DP-110: Parts ListDuplicar Soluções GráficasNo ratings yet

- SolidWorks Routing Piping and TubingDocument2 pagesSolidWorks Routing Piping and Tubingbadmus babatundeNo ratings yet

- Dirana Anp 11002 EnuDocument24 pagesDirana Anp 11002 Enubcqbao100% (2)

- IntroductionDocument34 pagesIntroductionDiego Alfredo Aguilera AlmadaNo ratings yet

- Mcs 012 PDFDocument397 pagesMcs 012 PDFIshan TiwariNo ratings yet

- 3GAA201410 AEG M3aa 200mla 2 PDFDocument2 pages3GAA201410 AEG M3aa 200mla 2 PDFrafaelliscano20No ratings yet

- 0901b80380959cc7 PDFDocument2 pages0901b80380959cc7 PDFRonaldo ArlandNo ratings yet

- Industrial Diesel Generator Set - 60 HZ: General Specifications KOHLER SDMO Premium QualityDocument7 pagesIndustrial Diesel Generator Set - 60 HZ: General Specifications KOHLER SDMO Premium Qualitythaisg01No ratings yet

- KBPC35005/W - KBPC3510/W: 35A Bridge RectifierDocument2 pagesKBPC35005/W - KBPC3510/W: 35A Bridge RectifierWagdy MohamedNo ratings yet

- SOR For Procurement of Bulk Materials For Sapele CEGX-02 and Sapele W-7T Flowline ConstructionDocument4 pagesSOR For Procurement of Bulk Materials For Sapele CEGX-02 and Sapele W-7T Flowline ConstructionKasarachi AmadiNo ratings yet

- 1.5 1.75 Ton at 500mm Load Center: SH1F1-0 / 31 Aug. '07Document21 pages1.5 1.75 Ton at 500mm Load Center: SH1F1-0 / 31 Aug. '07JulianoNo ratings yet

Cable Reel With Automated Layering - Mahdi Designs

Cable Reel With Automated Layering - Mahdi Designs

Uploaded by

Matthews Andrea MachilaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cable Reel With Automated Layering - Mahdi Designs

Cable Reel With Automated Layering - Mahdi Designs

Uploaded by

Matthews Andrea MachilaCopyright:

Available Formats

Mahdi Designs 0

Cable reel with

automated layering

This cable reel design evenly spools up a

500m length of a 5mm diameter cable.

This automated system ensures the cables

wraps up evenly and neatly around the

entire width of the cable drum. This allows

for a compact system and prevents the

cable from becoming bunched up and

messy.

CAD Model

Manufactured

System components

The major aspects of this cable reel are:

• A motor, drive train and cable drum

• Timing pulleys & a self reversing

screw to guide the cable wrapping

• An encoder wheel to measure how

much cable is spooled out

• Electronics

These points are discussed further below

CAD Files

Motor drive and drum

sizing

A motor mounted on the outer side of the

reel links to a pair of spur gears. In this

design a gear ratio of 1:2 was chose to give

an increase in torque. The force applied on

the cable as well as the speed it can be

pulled back at should be considered for

the specific application. Note that the force

on the cable as well as its speed will

depend on how much of the cable is

spooled up. If most of the cable is spooled

up and the effective diameter of the drum

is large then the cable will be pulled back

faster but with less force and vice versa.

The force and speed of the cable are

proportional to the effective diameter of

the cable drum - force is torque divided by

perpendicular distance.

The gear pair also allow for a slip ring to be

mounted concentric to (inside of) the

driven gear. This allows electrical signals

and/or power to pass from the electronics

on the outside through to the cable. In this

design a series of rods form the inner

diameter of the drum, it is important to

note the inner diameter should conform to

the minimum bend radius of the cable

being used (generally 6-8 x cable

diameter).

In order to calculate the required

size/dimensions of the cable drum the

below formula can be used. In this design,

the length of cable was already

determined and the width between

flanges, ‘C’, was chosen to match the

working length of the self reversing screw.

The winding depth, ‘A’, was found using the

formula below with help from an online

quadratic solver.

Thefollowingformulahasbeendevelopedtodeterminedrumcapacityundernormaltensionanduniform

windingconditions.

Formula L=Lengthofrope(metres)

A=Desireddepthofwinding(mm)

L=(A+B)xAxC Thedepthoftheflangeisnormallyreducedby40

to50mmtoalloygroundclearancefortherope

K B=Diameterofbarrel(mm)

C=Widthbetweenflanges(mm)

K=Aconstantdevelopedaccordingtothediameterof

therope.

Tablesbelowshowthevalueofconstantsfrom2to

38mmropediameter

Ropediameter Ropediameter

с mm

2 1274 16 91490

3 2865 18 103100

4 5093 19 114900

7958 20 127400

6 11470 22 154100

7 1.5600 24 183300

20370 26 215200

9 25780 28 249600

11 38520 32 326000

13 53800 35 389900

14 62400 38 459700

WorkedExample:

DrumDimensions:A=330mm,B=330mm,C=455mm

Rope22mmdiameter

LengthofRope 660×330×455

=643m

ondrum 154100

Self reversing lead

screw

Also known as a level wind screw or

diamond screw, this component is crucial

to this design:

• Two sets of spiral cuts which link into

to each other allow the nut to reverse

directions once it reaches the end of

the screw. This facilitates back and

forth motion without the need to

change the rotational direction of the

screw

• The nut on the screw should move

over one width of the cable per

revolution of the cable drum. This

guides the cable in such a way that it

wraps up in a tight layered manner

around the drum. The working length

of the screw should match the width

between the drum flanges such that

the nuts direction reverses once the

cable reaches the edges of the drum

• The cable drum and the screw can be

linked together with pulleys and a

timing belt, however we must alter the

effective pitch of the screw to match

the thickness of the cable. In this

design the pitch of the screw was

25mm so a pulley ratio of 1:5 was

used. This meant that one rotation of

the cable drum would cause the

screw to rotate 1/5th of a rotation and

the nut would move 5mm.

Encoder wheel & cable

guide

A rotary encoder measures angular

position

• In this design this is an effective way

to measure how much cable has

been spooled out. A knurled wheel of

a known diameter was mounted to

the encoder. Keeping track of the

number of rotations can be

converted to a distance

measurement of how much cable

has been spooled out. Distance =

wheel circumference multiplied by

number of revolutions

• In the case of a land or pipe crawling

robot this is a useful way to know how

far the robot has travelled

• A cable guide ensures the cable

comes out at some controlled angle.

In this design Teflon guider blocks

minimise friction, alternatively

rollers/bearings could also be used

• A cable was sourced which was rated

for the required pulling force and a

wire mesh grip was used for the cable

strain relief (not shown in CAD but

visible in photo of manufactured unit)

Manufacturing

This system was a one off prototype not

optimised for manufacturing

• In this design off the shelf

components where possible

• Several custom parts where made

mostly using CNC machining - STEP

files and detailed drawings where

sent to a supplier

• Some 3D printed parts where used for

basic electronics covers

6x©3.30THRUALL

M4x0.7-6HTHRUALL

10.90

14.10

20°0+

20°0-210

IZO

CAD Files

Compact Slewing

Bionic Bearing

Hand

Mahdi Designs

Sydney Australia

YouTube

support@mdesigns.space

You might also like

- TM 5-3805-262-10 Case MW24C Scoop LoaderDocument200 pagesTM 5-3805-262-10 Case MW24C Scoop LoaderAdvocate100% (2)

- Busbar Manual CCA (Copper Clad Aluminium)Document5 pagesBusbar Manual CCA (Copper Clad Aluminium)Affid bin Abi ThalibNo ratings yet

- MOperador SY215C Serie HO6898 - Crawler Hydraulic ExcavatorDocument435 pagesMOperador SY215C Serie HO6898 - Crawler Hydraulic ExcavatorRojasDura.100% (5)

- Conduit & Trunking Capacity ChartDocument20 pagesConduit & Trunking Capacity ChartvelisbarNo ratings yet

- Cek 3Document210 pagesCek 3Fachri RamadhanNo ratings yet

- Overhead Conveyor Products PDFDocument16 pagesOverhead Conveyor Products PDFPierre Hopkins100% (1)

- Flexible Road Overlay Design by FWDDocument9 pagesFlexible Road Overlay Design by FWDafifa kausar100% (1)

- Core 1 1 KV Aluminium Copper PVC Insulated Armoured Power CaDocument2 pagesCore 1 1 KV Aluminium Copper PVC Insulated Armoured Power Carnd.ptcwiNo ratings yet

- P I CABS 2 10TN MOD v2 ENDocument5 pagesP I CABS 2 10TN MOD v2 ENDiana AlexandraNo ratings yet

- Aerial Bundle Conductor Abc CableDocument1 pageAerial Bundle Conductor Abc CableBrianNo ratings yet

- Be Summer 2015Document4 pagesBe Summer 2015babaf79912No ratings yet

- 2018 - CATALOG - Maxbrio RipperDocument6 pages2018 - CATALOG - Maxbrio RipperJuanPabloCruzNo ratings yet

- Wire Rope Specifications 18000: Manitowoc Cranes, IncDocument2 pagesWire Rope Specifications 18000: Manitowoc Cranes, IncDavid FlemmingNo ratings yet

- Singly Reinforced Beam: Design For ShearDocument16 pagesSingly Reinforced Beam: Design For ShearArbaz AhmedNo ratings yet

- Eurotruss HD34Document2 pagesEurotruss HD34Lässäri On läskiNo ratings yet

- Steel Wire Rope: Factors Affecting Rope Life Tensile GradeDocument1 pageSteel Wire Rope: Factors Affecting Rope Life Tensile GradeHUNG NIKKONo ratings yet

- Tabular Presentation of Basic Technical Data RMC ConductorsDocument2 pagesTabular Presentation of Basic Technical Data RMC ConductorsBuyme1 CNC BIZNo ratings yet

- Sas Micropile Manual With Grade 97Document16 pagesSas Micropile Manual With Grade 97JR GEOCONSULTORES INGENIEROSNo ratings yet

- Bbs For Test Pile A1 & A2: Name of WorkDocument33 pagesBbs For Test Pile A1 & A2: Name of WorkSaraswati ChandraNo ratings yet

- Catalog - Maxbrio Ripper Seires - Ver.1504 - Eng (1M)Document6 pagesCatalog - Maxbrio Ripper Seires - Ver.1504 - Eng (1M)henry vegaNo ratings yet

- Standard Belt Cross SectionsDocument26 pagesStandard Belt Cross Sectionsagung badoNo ratings yet

- Maxbrio RippersDocument6 pagesMaxbrio Ripperssbhade1993No ratings yet

- ID - No./Seat No.: ATTEMPT ALL QUESTIONS. Assume Any Missing DataDocument2 pagesID - No./Seat No.: ATTEMPT ALL QUESTIONS. Assume Any Missing DataMuhammad Sharif JamaliNo ratings yet

- Be Winter 2016Document3 pagesBe Winter 2016babaf79912No ratings yet

- Kinematic Wave Routing - ExampleDocument33 pagesKinematic Wave Routing - ExamplethewodrosNo ratings yet

- Diepa B50 - High Performance Rotation Resistant Steel Wire RopeDocument1 pageDiepa B50 - High Performance Rotation Resistant Steel Wire RopeKonstantinos SynodinosNo ratings yet

- WallcalcDocument31 pagesWallcalcSubhekshya ShresthaNo ratings yet

- NHA Hydraulic Tubing Anchor Data SheetDocument1 pageNHA Hydraulic Tubing Anchor Data Sheet朱向斌No ratings yet

- Rubber Conveyor Belts Steel CordsDocument4 pagesRubber Conveyor Belts Steel CordsnicolasNo ratings yet

- EPR Insulated AC Medium-Voltage Submarine CableDocument3 pagesEPR Insulated AC Medium-Voltage Submarine CableGcNo ratings yet

- 3 V Belt DriveDocument29 pages3 V Belt DriveMurugesan RameshNo ratings yet

- Bearing DesignDocument5 pagesBearing DesignVenkat RaoNo ratings yet

- Design Girder: 1. Data - Data PerencanaanDocument6 pagesDesign Girder: 1. Data - Data PerencanaanMuhammad Rizki AnwarNo ratings yet

- Cable Current RatingDocument3 pagesCable Current RatingAnuj BhardwajNo ratings yet

- Technical Information of 150kV HVAC Submarine CableDocument2 pagesTechnical Information of 150kV HVAC Submarine Cablebagja wigunaNo ratings yet

- Exp. No: - 01 Date:09/08/2021 Cam AnalysisDocument8 pagesExp. No: - 01 Date:09/08/2021 Cam AnalysisAnantha ReddyNo ratings yet

- Parallel Flange Channels PFC Eurocode Data Sheet PDFDocument2 pagesParallel Flange Channels PFC Eurocode Data Sheet PDFviswanathanNo ratings yet

- Parallel Flange Channels PFC Eurocode Data SheetDocument2 pagesParallel Flange Channels PFC Eurocode Data SheetviswanathanNo ratings yet

- Post TensionDocument8 pagesPost Tensionedc1312No ratings yet

- N2XBYDocument5 pagesN2XBYbonadupangNo ratings yet

- Eurotruss XDDocument2 pagesEurotruss XDjoshNo ratings yet

- Interspan PT DesignDocument21 pagesInterspan PT DesignDương TrầnNo ratings yet

- N2XRYDocument5 pagesN2XRYicalcalNo ratings yet

- Extra Item AnalysisDocument6 pagesExtra Item Analysissri projectssNo ratings yet

- N2XSRYDocument1 pageN2XSRYYulian Dea ZollaNo ratings yet

- N2XSRYDocument1 pageN2XSRYKrisnandha RahardianNo ratings yet

- 8 Foundations CombinedDocument32 pages8 Foundations Combinedhamadamjad047No ratings yet

- TaperedRollerBearings TS (TaperedSingle) ImperialDocument5 pagesTaperedRollerBearings TS (TaperedSingle) ImperialRonald esquivelNo ratings yet

- N2XYDocument5 pagesN2XYSamuel SantosNo ratings yet

- Birla Institute of Technology and Science, PilaniDocument3 pagesBirla Institute of Technology and Science, PilaniSharad ShrivastavaNo ratings yet

- SWG To MM - Standard Gauge To MM ConversionDocument3 pagesSWG To MM - Standard Gauge To MM ConversionMRSUPERCOOLNo ratings yet

- ANCHORAGE AND LAP LENGTHS (According To BS 5400 Part 4 Clause 5.8.6.)Document22 pagesANCHORAGE AND LAP LENGTHS (According To BS 5400 Part 4 Clause 5.8.6.)Brook KingNo ratings yet

- Technical News: Engineering Information For The Professional EngineerDocument2 pagesTechnical News: Engineering Information For The Professional EngineerFelipe GustavoNo ratings yet

- Es en Isolated Footing - XLSMDocument8 pagesEs en Isolated Footing - XLSMBeka TayeNo ratings yet

- N2xy PDFDocument5 pagesN2xy PDFArnold StevenNo ratings yet

- Inch Conduit FillDocument2 pagesInch Conduit FillAhrariMustafaNo ratings yet

- Report#3 Testingthetensilestrengthofmetalsusingtheuniversaltestingmachine Chem1103l Group26Document8 pagesReport#3 Testingthetensilestrengthofmetalsusingtheuniversaltestingmachine Chem1103l Group26MarielleCaindecNo ratings yet

- FD34 Square Truss: FactsDocument2 pagesFD34 Square Truss: FactsJakob PaulinNo ratings yet

- Catálogo - Acoplamento L - MetricDocument8 pagesCatálogo - Acoplamento L - MetricMarcos Marcandali de JesusNo ratings yet

- Conductores Copperweld PDFDocument4 pagesConductores Copperweld PDFMiguel Ángel Díaz SepúlvedaNo ratings yet

- Datasheet LiYCY Cable PDFDocument1 pageDatasheet LiYCY Cable PDFResaKandhy100% (1)

- User Manual: Earthfault Compensation Controller EFC50Document122 pagesUser Manual: Earthfault Compensation Controller EFC50Ichim NasuiNo ratings yet

- FMB120 Quick Manual v1.4Document16 pagesFMB120 Quick Manual v1.4yoyovohNo ratings yet

- MOS and BiCMOS Circuit Design ProcessDocument17 pagesMOS and BiCMOS Circuit Design ProcessNarasimha Murthy YayavaramNo ratings yet

- Application Guide For Power Factor Testing of Cables and PotheadsDocument2 pagesApplication Guide For Power Factor Testing of Cables and PotheadsPardeep SindhuNo ratings yet

- Final Project Report PDFDocument105 pagesFinal Project Report PDFSushila DhimanNo ratings yet

- KZCO AllcatalogDocument76 pagesKZCO AllcatalogJaime SuaNo ratings yet

- 1192384864insulators 2010 DriwisaDocument2 pages1192384864insulators 2010 DriwisaAna LucíaNo ratings yet

- HR2470Document4 pagesHR2470Cata100% (1)

- Instructions PDFDocument1 pageInstructions PDFNikola UroševićNo ratings yet

- Parts CatalogDocument73 pagesParts CatalogBernardoNo ratings yet

- 1630481949539-Msdac Etw NewDocument52 pages1630481949539-Msdac Etw NewAshim ChakrabortyNo ratings yet

- Windsor Chariot I CapsolDocument112 pagesWindsor Chariot I CapsolNestor Marquez-DiazNo ratings yet

- Hydraulics - SteeringDocument3 pagesHydraulics - SteeringSilvio RomanNo ratings yet

- GIGABYTE 8VM800M Schematics: Sheet Title Sheet TitleDocument32 pagesGIGABYTE 8VM800M Schematics: Sheet Title Sheet TitleSjf NetNo ratings yet

- cdd161033-LG MS119MLDocument36 pagescdd161033-LG MS119MLfranklin antonio RodriguezNo ratings yet

- Mike Holt's Illustrated Guide Onal Electrical Code, 2020 NEC 355Document1 pageMike Holt's Illustrated Guide Onal Electrical Code, 2020 NEC 355Tito BustamanteNo ratings yet

- Product Sheet IR 2011: Intended UseDocument1 pageProduct Sheet IR 2011: Intended UseMarcelo Silva100% (2)

- KM-2810 DP-110: Parts ListDocument47 pagesKM-2810 DP-110: Parts ListDuplicar Soluções GráficasNo ratings yet

- SolidWorks Routing Piping and TubingDocument2 pagesSolidWorks Routing Piping and Tubingbadmus babatundeNo ratings yet

- Dirana Anp 11002 EnuDocument24 pagesDirana Anp 11002 Enubcqbao100% (2)

- IntroductionDocument34 pagesIntroductionDiego Alfredo Aguilera AlmadaNo ratings yet

- Mcs 012 PDFDocument397 pagesMcs 012 PDFIshan TiwariNo ratings yet

- 3GAA201410 AEG M3aa 200mla 2 PDFDocument2 pages3GAA201410 AEG M3aa 200mla 2 PDFrafaelliscano20No ratings yet

- 0901b80380959cc7 PDFDocument2 pages0901b80380959cc7 PDFRonaldo ArlandNo ratings yet

- Industrial Diesel Generator Set - 60 HZ: General Specifications KOHLER SDMO Premium QualityDocument7 pagesIndustrial Diesel Generator Set - 60 HZ: General Specifications KOHLER SDMO Premium Qualitythaisg01No ratings yet

- KBPC35005/W - KBPC3510/W: 35A Bridge RectifierDocument2 pagesKBPC35005/W - KBPC3510/W: 35A Bridge RectifierWagdy MohamedNo ratings yet

- SOR For Procurement of Bulk Materials For Sapele CEGX-02 and Sapele W-7T Flowline ConstructionDocument4 pagesSOR For Procurement of Bulk Materials For Sapele CEGX-02 and Sapele W-7T Flowline ConstructionKasarachi AmadiNo ratings yet

- 1.5 1.75 Ton at 500mm Load Center: SH1F1-0 / 31 Aug. '07Document21 pages1.5 1.75 Ton at 500mm Load Center: SH1F1-0 / 31 Aug. '07JulianoNo ratings yet