Professional Documents

Culture Documents

Table J2.1 & J2.2 - Effective Throat of PJP Groove Welds

Table J2.1 & J2.2 - Effective Throat of PJP Groove Welds

Uploaded by

Upadrasta HarishOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table J2.1 & J2.2 - Effective Throat of PJP Groove Welds

Table J2.1 & J2.2 - Effective Throat of PJP Groove Welds

Uploaded by

Upadrasta HarishCopyright:

Available Formats

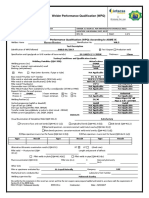

94 WELDS [Sect. J2.

TABLE J2.1

Effective Throat of

Partial-Joint-Penetration Groove Welds

Welding Position

F (flat), H (horiz.), Groove Type

V (vert.), (AWS D1.1,

Welding Process OH (overhead) Figure 3.3) Effective Throat

Shielded Metal Arc (SMAW) All J or U Groove

60◦ V

Gas Metal Arc (GMAW) All Depth of Groove

Flux Cored Arc (FCAW)

Submerged Arc (SAW) F J or U Groove

60◦ Bevel or V

Gas Metal Arc (GMAW) F, H 45◦ Bevel Depth of Groove

Flux Cored Arc (FCAW)

Shielded Metal Arc (SMAW) All 45◦ Bevel Depth of Groove

Minus 1/8 in. (3 mm)

Gas Metal Arc (GMAW) V, OH 45◦ Bevel Depth of Groove

Flux Cored Arc (FCAW) Minus 1/8 in. (3 mm)

The effective throat thickness of a partial-joint-penetration (PJP) groove weld

shall be as shown in Table J2.1.

User Note: The effective throat size of a partial-joint-penetration groove weld

is dependent on the process used and the weld position. The contract docu-

ments should either indicate the effective throat required or the weld strength

required, and the fabricator should detail the joint based on the weld process

and position to be used to weld the joint.

The effective weld size for flare groove welds, when filled flush to the surface

of a round bar, a 90◦ bend in a formed section, or rectangular HSS shall be as

shown in Table J2.2, unless other effective throats are demonstrated by tests. The

effective size of flare groove welds filled less than flush shall be as shown in

Table J2.2, less the greatest perpendicular dimension measured from a line flush

to the base metal surface to the weld surface.

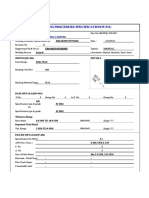

TABLE J2.2

Effective Weld Sizes of

Flare Groove Welds

Welding Process Flare Bevel Groove[a] Flare V Groove

GMAW and FCAW-G 5/8 R 3/4 R

SMAW and FCAW-S 5/16 R 5/8 R

SAW 5/16 R 1/2 R

For Flare Bevel Groove with R < 3/8 in. (10 mm) use only reinforcing fillet weld on filled flush joint.

[a]

General Note: R = radius of joint surface (can be assumed to be 2t for HSS), in. (mm)

Specification for Structural Steel Buildings, March 9, 2005

AMERICAN INSTITUTE OF STEEL CONSTRUCTION, INC.

You might also like

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- Polaris 380 Repair ManualDocument46 pagesPolaris 380 Repair ManualPool Supply Sales100% (5)

- Reference of WPS AWSDocument5 pagesReference of WPS AWSKent TanakNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Bolted Connections 1Document45 pagesBolted Connections 1Nicole ReyesNo ratings yet

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Welder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document18 pagesWelder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)mahendraNo ratings yet

- WPS14-1 A106 B SmawDocument4 pagesWPS14-1 A106 B SmawRahul MoottolikandyNo ratings yet

- OrificeMaster Single Chamber Orifice FittingDocument8 pagesOrificeMaster Single Chamber Orifice FittingPaul Wowor100% (1)

- HSS Radius 742c7a4e 5e10 4b0b 8ba8 A8516cdafd9fDocument14 pagesHSS Radius 742c7a4e 5e10 4b0b 8ba8 A8516cdafd9fTerraManNo ratings yet

- Flare Groove Welds To HSS CornersDocument6 pagesFlare Groove Welds To HSS CornersPO AsselinNo ratings yet

- AWS Guide To Abbreviations Certified WelderDocument1 pageAWS Guide To Abbreviations Certified Weldersigurdur hannessonNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- WPQ 006Document1 pageWPQ 006vinuNo ratings yet

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- Pre Qualified Weld DesginationDocument33 pagesPre Qualified Weld DesginationSumit patilNo ratings yet

- Effective Throat For Flare Bevel and Flare Groove WeldsDocument142 pagesEffective Throat For Flare Bevel and Flare Groove WeldsAnonymous pD2ymRUguNo ratings yet

- Welder Performance Qualification (WPQ) According To ASME IX Hassan HussienDocument1 pageWelder Performance Qualification (WPQ) According To ASME IX Hassan HussienMahmoud shawkyNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Projection Design & EquipmentDocument11 pagesProjection Design & EquipmentJoel BrasilBorgesNo ratings yet

- SampleDocument5 pagesSample이훈No ratings yet

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- W15 001S ASME Ahmad TermiziDocument1 pageW15 001S ASME Ahmad TermiziHoJienHauNo ratings yet

- Abdul Muhid WPQRDocument1 pageAbdul Muhid WPQRChandra Bintang W.PNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- Welding Procedure Specification (W.P.S) : Alstom India LimitedDocument2 pagesWelding Procedure Specification (W.P.S) : Alstom India LimitedAhmed saberNo ratings yet

- Aisc Tablas 8Document34 pagesAisc Tablas 8Juan Carlos Espinosa CoronaNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specification (WPS)Document2 pagesQw-482 Suggested Format For Welding Procedure Specification (WPS)ING HARRINSON FERREBUSNo ratings yet

- Welding Design, Welding Procedure and Performance QualificationDocument34 pagesWelding Design, Welding Procedure and Performance Qualificationkmas1612100% (3)

- Welding ProcDocument48 pagesWelding ProcJulioNo ratings yet

- 2 - WQT KPRDocument27 pages2 - WQT KPRSuryadev singhNo ratings yet

- WA-AEI-001 Some Comments AddressedDocument2 pagesWA-AEI-001 Some Comments AddressedMulPXNo ratings yet

- Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionDocument1 pagePt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionHaryanto RNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- Eslam Abdelhameed Asme Ix IdDocument1 pageEslam Abdelhameed Asme Ix Idel_sharkawy2011No ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- AbstractiiwDocument7 pagesAbstractiiwsk tripathiNo ratings yet

- WPQ Asme IxDocument1 pageWPQ Asme IxEDEN GONZALEZNo ratings yet

- 6gr Smaw WQTR - F. Edilo (Sn-189)Document1 page6gr Smaw WQTR - F. Edilo (Sn-189)hanz bermejoNo ratings yet

- 4.13 PJP Tubular T-, Y-, or K-Connections and Butt JointsDocument1 page4.13 PJP Tubular T-, Y-, or K-Connections and Butt JointsIbrahim shaikNo ratings yet

- Details of Fillet Welds D15M-D15-2002 - Section - 2.1Document40 pagesDetails of Fillet Welds D15M-D15-2002 - Section - 2.1drac_dracNo ratings yet

- Din 02353 (199812)Document10 pagesDin 02353 (199812)Robert SumińskiNo ratings yet

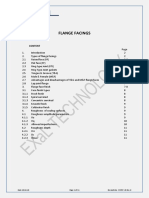

- Flange Facings: ContentDocument11 pagesFlange Facings: ContentcemalNo ratings yet

- Wps For Structure Mild Steel Fillet Weld - CompressDocument2 pagesWps For Structure Mild Steel Fillet Weld - CompressAhmed saberNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- WQT Form (AWS D1.1) 04-23Document1 pageWQT Form (AWS D1.1) 04-23hanz bermejoNo ratings yet

- Consumption Calculation PDFDocument1 pageConsumption Calculation PDFzniperxNo ratings yet

- WPQ Formats NEWDocument4 pagesWPQ Formats NEWMANABENDRA MAITRANo ratings yet

- PQWDocument3 pagesPQWcorey jacobsNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Asme Wps DemoDocument3 pagesAsme Wps Demoharis saleemNo ratings yet

- WPQRDocument1 pageWPQRJBStringerNo ratings yet

- 170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQDocument4 pages170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- A-Mtl-Pro-730-38931 Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- A-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- Collicutt Hanover: Ltd. 7550 Ednar Industrial Drive Red Deer, Alberta T4P 3R.2 BP Canada Chemical Comdany, P.O. BP JoifreDocument2 pagesCollicutt Hanover: Ltd. 7550 Ednar Industrial Drive Red Deer, Alberta T4P 3R.2 BP Canada Chemical Comdany, P.O. BP Joifrerajindo1No ratings yet

- Bolts FastenerDocument20 pagesBolts FastenerUpadrasta HarishNo ratings yet

- Table J2.3 - Minimum Effective Throat ThicknessDocument1 pageTable J2.3 - Minimum Effective Throat ThicknessUpadrasta HarishNo ratings yet

- Hollo Bolt CatlogDocument4 pagesHollo Bolt CatlogUpadrasta HarishNo ratings yet

- Table J3.5 - Values of Edge Distances IncrementDocument1 pageTable J3.5 - Values of Edge Distances IncrementUpadrasta HarishNo ratings yet

- Table J3.4 - Minimum Edge DistancesDocument1 pageTable J3.4 - Minimum Edge DistancesUpadrasta HarishNo ratings yet

- Table J3.3 - Nomial Hole DimensionsDocument1 pageTable J3.3 - Nomial Hole DimensionsUpadrasta HarishNo ratings yet

- Table 14-1 & 14-2 - Recommended Max Sizes For Anchor Rod Holes in Base PlateDocument1 pageTable 14-1 & 14-2 - Recommended Max Sizes For Anchor Rod Holes in Base PlateUpadrasta HarishNo ratings yet

- Table J2.5 - Available Strength of Welded JointsDocument1 pageTable J2.5 - Available Strength of Welded JointsUpadrasta HarishNo ratings yet

- Table C-J9.1 - Anchor Rod Hole DiametersDocument1 pageTable C-J9.1 - Anchor Rod Hole DiametersUpadrasta HarishNo ratings yet

- Table 15-3 - Dimensions and Weights of ClevisesDocument1 pageTable 15-3 - Dimensions and Weights of ClevisesUpadrasta HarishNo ratings yet

- Table 8.2 - WeldsDocument32 pagesTable 8.2 - WeldsUpadrasta HarishNo ratings yet

- Table 14.3 - Column SplicesDocument22 pagesTable 14.3 - Column SplicesUpadrasta HarishNo ratings yet

- Table 2-5 - Applicable ASTM Specifications For Various Types of Structural FastenersDocument1 pageTable 2-5 - Applicable ASTM Specifications For Various Types of Structural FastenersUpadrasta HarishNo ratings yet

- Table 7-17 - Entering & Tightening ClearanceDocument1 pageTable 7-17 - Entering & Tightening ClearanceUpadrasta HarishNo ratings yet

- Table 7-2 - Available Shear Strength of Bolts, KipsDocument1 pageTable 7-2 - Available Shear Strength of Bolts, KipsUpadrasta HarishNo ratings yet

- Table 6.1 - Washer RequirementsDocument1 pageTable 6.1 - Washer RequirementsUpadrasta HarishNo ratings yet

- Table 7-16 - Entering & Tightening ClearanceDocument1 pageTable 7-16 - Entering & Tightening ClearanceUpadrasta HarishNo ratings yet

- Table 7-15 - Dimensions of High Strength FastenersDocument1 pageTable 7-15 - Dimensions of High Strength FastenersUpadrasta HarishNo ratings yet

- AISC 13th - Material GradesDocument5 pagesAISC 13th - Material GradesUpadrasta HarishNo ratings yet

- Table 2-4 - Applicable ASTM Specifications For Plates & BarsDocument1 pageTable 2-4 - Applicable ASTM Specifications For Plates & BarsUpadrasta HarishNo ratings yet

- Required Marks For Acceptable BoltsDocument1 pageRequired Marks For Acceptable BoltsUpadrasta HarishNo ratings yet

- AISC Base Plate Hole Size InformationDocument1 pageAISC Base Plate Hole Size InformationUpadrasta HarishNo ratings yet

- Adventure Cycles DashboardDocument2 pagesAdventure Cycles DashboardUpadrasta HarishNo ratings yet

- Tableau Internship DashboardDocument1 pageTableau Internship DashboardUpadrasta HarishNo ratings yet

- HTI Hydraulic NutDocument2 pagesHTI Hydraulic NutLoveNo ratings yet

- (WWW - Entrance-Exam - Net) - SSC Paper For Mechanical Engineering PDFDocument14 pages(WWW - Entrance-Exam - Net) - SSC Paper For Mechanical Engineering PDFVaisakh SomakumarNo ratings yet

- Chapter 5 Unsteady FlowDocument18 pagesChapter 5 Unsteady Flowhamadamjad047No ratings yet

- Rotary Drilling Rig ComponentsDocument130 pagesRotary Drilling Rig Componentsgarry_dirak100% (22)

- Welded JointDocument24 pagesWelded Jointعزالدين محمدNo ratings yet

- Electromechanical Systems & ActuatorsDocument8 pagesElectromechanical Systems & ActuatorsanandakumarNo ratings yet

- Third Quarterly Test in ScienceDocument9 pagesThird Quarterly Test in ScienceMarilyn EscobillaNo ratings yet

- Black Smithy ShopDocument31 pagesBlack Smithy ShopArun kumar rouniyarNo ratings yet

- DrillingDocument28 pagesDrillingsititukiniNo ratings yet

- WI-INSP-02 R1 Work Instruction - Heat Exchanger InspectionDocument5 pagesWI-INSP-02 R1 Work Instruction - Heat Exchanger InspectionRakesh MishraNo ratings yet

- BertoR Brochure21x21 PREVIEW PDFDocument2 pagesBertoR Brochure21x21 PREVIEW PDFfahmulhidayatNo ratings yet

- PGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri7Document1 pagePGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri7wibowo wibowoNo ratings yet

- SPH LAMMPS UserguideDocument23 pagesSPH LAMMPS UserguideJakler NicheleNo ratings yet

- 2008 - 2 - Tube & PipeDocument7 pages2008 - 2 - Tube & PipecanettijNo ratings yet

- Double AveragingDocument274 pagesDouble AveragingVijit RathoreNo ratings yet

- mf8160 PDFDocument717 pagesmf8160 PDFigorkovNo ratings yet

- Hydraulics Chapter 5Document27 pagesHydraulics Chapter 5tekalign yerangoNo ratings yet

- Jou Mec Eng Sci 226 04 1004-1015 2012Document13 pagesJou Mec Eng Sci 226 04 1004-1015 2012Sanjeet KumarNo ratings yet

- Case Studies in Fracture MechanicsDocument475 pagesCase Studies in Fracture MechanicsBenjamin Rohit100% (1)

- EM Sai PDFDocument23 pagesEM Sai PDFKaranShindeNo ratings yet

- Basic Test - Theory Examination (4 Sets)Document32 pagesBasic Test - Theory Examination (4 Sets)varun yadav100% (1)

- HKL Ope Manual EngDocument25 pagesHKL Ope Manual Engmjl47No ratings yet

- Ultra Centri Fug at I OnDocument33 pagesUltra Centri Fug at I Onimi4No ratings yet

- Humidification and Cooling Towers - 2nd 2011Document46 pagesHumidification and Cooling Towers - 2nd 2011Vona Sophia MalvarNo ratings yet

- Operation Manual For Model SP 305Document104 pagesOperation Manual For Model SP 305alexnobinarie04No ratings yet

- Sonalika Service ManualDocument469 pagesSonalika Service Manualkvsj2001No ratings yet

- Bombas BerkeleyDocument136 pagesBombas BerkeleyDaniel Alejandro GuerreroNo ratings yet

- Complete Report On HvacDocument57 pagesComplete Report On HvacJunaid Khan100% (2)

- ASTM A312-2004 (Especificaciones Tuberia Acero Inoxidable) PDFDocument11 pagesASTM A312-2004 (Especificaciones Tuberia Acero Inoxidable) PDFcesar_p80-1No ratings yet