Professional Documents

Culture Documents

Falcon 20 - ATA Chapter 5

Falcon 20 - ATA Chapter 5

Uploaded by

zoolmiatOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Falcon 20 - ATA Chapter 5

Falcon 20 - ATA Chapter 5

Uploaded by

zoolmiatCopyright:

Available Formats

MAINTENANCE MANUAL

GENERAL

1 . Foreword

This manual is Chapter 5 of the MYSTERE–FALCON 20–() 5 MAINTENANCE MANUAL (ATA 100,

specifications). The sections 5-00, 5-10, 5-20 and 5-50 of this manual define maintenance operations

and frequencies recommended by DASSAULT AVIATION to guarantee the aircraft’s airworthiness

(Maintenance Planning Document). The technical content of these sections is approved under the

authority of DOA nr. EASA.21J.051.

In addition, this Manual contains the “Airworthiness Limitations” section 5–40–00. These Airworthi-

ness Limitations are limitations established for the airframe systems and items of equipment. This

section is approved by EASA (European Aviation Safety Agency).

This manual forms an entity, and the operations described in one of the sections take into account

the correct accomplishment of all operations contained in the other sections.

This maintenance program is applicable to aircraft on a fleet–wide basis regardless of the regulations

of the country in which the aircraft is registered. It includes the maintenance inspections required for

operation in the RVSM airspace.

However, the operator shall comply with the specific requirements as prescribed by the Authority of

his country of registration, e.g.:

– EASA Part M (unless National Authority regulations are still applicable).

– F.A.A. regulations applicable to the USA and certain countries in the Western Hemisphere,

particularly FAR Part 91, FAR Part 135.

– Regulations established by the representative authorities of other countries,

The parenthesis appearing in MYSTERE–FALCON 20–() 5 designation in this manual means that this

manual concerns the four models of MY20 with new engine (SB N° 731). These four models are:

– MYSTERE–FALCON 20–C5 (previously FJF Basic)

– MYSTERE–FALCON 20–D5 (previously FJF Series D)

– MYSTERE–FALCON 20–E5 (previously FJF Series E)

– MYSTERE–FALCON 20–F5 (previously FJF Series F)

This maintenance program is valid for “stripped aircraft” equipped with “standard” options defined by

DASSAULT AVIATION and listed in the Maintenance manual.

Consequently, the operators shall add operations required for maintenance of different or

supplementary installations to the maintenance program recommended by DASSAULT AVIATION.

This manual refers only to installations designed or approved by the airplane manufacturer and

incorporated in the aircraft type design.

Other changes such as STC’s, P.M.A. (Parts Manufacturer Approval) or any major change not

approved by the airplane manufacturer, or change of the type of operation, which may have an impact

on the maintenance program (training aircraft, maritime patrol aircraft, etc.) are not included in this

manual.

EFFECTIVITY: ALL 5–00–00

Page 1

October 2010

“DASSAULT AVIATION Proprietary Data”

MAINTENANCE MANUAL

The aircraft must be maintained with spares and tools recommended by DASSAULT AVIATION,

unless alternate tools are developed and acceptable to the local Autority.

It is recommended to use the tools and special equipment listed in the Maintenance Manual. This

manual is based on a standard flight defined as follows:

– one take-off,

– one climb,

– one descent,

– one landing.

If the aircraft operations is different than the above description, or specific, the maintenance program

must be modified.

With approval of the relevant authorities of the country in which the aircraft is registered, the operator

of the aircraft may adapt the maintenance program recommended by the manufacturer. The operator

is held responsible for these changes.

These changes enable to adapt the maintenance program:

– in relation to the aircraft grounding possibility for the maintenance and desired operational

availability,

– in relation with the aircraft operation (flying hours by years, environmental condition, etc.).

Only the most recent revision of the present document corresponds to the recommendations of the

manufacturer DASSAULT AVIATION. Consequently, only the whole document incorporating this most

recent revision is approved and it supersedes all previous revisions or reissues.

2 . Manual breakdown

The manual consists of four sections:

A . Section 5–10: Aircraft maintenance operations.

This section lists all the scheduled maintenance operations to be carried out on the aircraft with

their time frequencies. It does not include maintenance operations performed in the workshop on

items of equipment removed from the aircraft, which are addressed in Section 5–20.

B . Section 5–20: Maintenance on components, time between overhauls and life limits.

This section lists all scheduled maintenance operations for items of equipment and provides their

time frequencies; for some items of equipment requiring a major overhaul, it also states the time

between each overhaul and for certain items of equipment, their life limit.

C . Section 5–40: Airworthiness limitations.

This section lists all the Airworthiness Limitations concerning the aircraft itself. It is approved by

the EASA.

D . Section 5–50: Special unscheduled operations.

This section lists all maintenance operations (Inspection/Check or Test) justified by a particular type

of aircraft operation or unscheduled maintenance operations associated with aircraft safety.

EFFECTIVITY: ALL 5–00–00

Page 2

October 2010

“DASSAULT AVIATION Proprietary Data”

MAINTENANCE MANUAL

3 . Purpose of the maintenance schedule

The purpose of the maintenance schedule is to prevent degradation of maintenance standards directly

related to reliability and flight safety. In addition, this schedule is intended to maintain these standards

at a minimum cost.

The Chapter 5 and OCIP recommended maintenance programs are designed for

MYSTERE–FALCON 20–( )5 aircraft produced by Dassault, under the specified type certificate

granted by the airworthiness authorities.

The “standard” Chapter 5 or OCIP maintenance programs may not apply to MYSTERE–FALCON

20–( )5 aircraft that are involved in accidents and/or incidents which result in structural damage or

other major or unusual damage to the aircraft.

MYSTERE–FALCON 20–( )5 aircraft involved in such accident or incident will require the review and/or

the inspection of all structure/equipment that has sustained significant or unusual damage associated

with the accident/incident.

Only the manufacturer or its authorized representative can determine if the recommended

maintenance program is still applicable to such aircraft.

Subject aircraft may have to be supplemented by additional inspection criteria should this

review/inspection reveal that the recommended maintenance program is not suitable, based upon the

facts involved.

EFFECTIVITY: ALL 5–00–00

Page 3

October 2002

“DASSAULT AVIATION Proprietary Data”

MAINTENANCE MANUAL

4 . Maintenance cycle

A . General

The FALCON 20 maintenance cycle is based on five types of inspection:

– A inspection,

– B inspection,

– Z inspection (Zone),

– C inspection

– Major corrosion inspection (M.C.I.).

Maintenance cycle:

11)

Key:

A INSPECTION: every 300 flying hours or 6 months whichever is reached first. (See

NOTE (2) for tolerance).

B INSPECTION: every 1200 flying hours. (See NOTE (3) for tolerance).

Z INSPECTION: every 2 years or 2400 flying hours whichever is reached first. (See

NOTE (4) for tolerance).

C INSPECTION: every 6 years. (See NOTE (5) for tolerance).

MAJOR CORROSION INSPECTION (M.C.I.): 24 years (Mandatory: See 5–40–00), then

every 12 years thereafter (French D.G.A.C. Airworthiness Directive No.

90.090.019 (B) R2 dated February 05, 2000). (See NOTE (6) for tolerance).

NOTE (1) : The mandatory maintenance operations due as part of the S.S.I.P. are not

incorporated in this document. They are covered in document DMD No. 45184.

EFFECTIVITY: ALL 5–00–00

Page 4

October 2002

“DASSAULT AVIATION Proprietary Data”

MAINTENANCE MANUAL

A inspection

– The A inspection must be carried out at 300 flying hours or 6 months, whichever limit is reached

first.

0

300 A A A A A A A A

hours & & & &

or 2A 2A 2A 2A

6 months

1200 hours or 2 years

NOTE (2) : Tolerance: to facilitate scheduling the A inspections, the manufacturer authorizes a

tolerance of + 30 hours for the flying hours or + 1 month for the calendar limit.

These tolerances are not cumulative.

The due time of any A inspection (or multiple) must never be exceeded by more than

30 flying hours or 1 month. In addition, the period of time between two A inspections must

not exceed 330 flying hours or 7 months.

0

2A or 2A +

A 2A or 2A +

300 hrs or 6 months 600 hrs or 12 months 1200 hrs or 24 months

Tolerance + 30 h + 30 h + 30 h

or or or

+ 1 month + 1 month + 1 month

330 hrs maxi 630 hrs maxi 1230 hrs maxi

or or or

7 months maxi 13 months 25 months maxi

– The A, 2A, etc., inspections are basic maintenance inspections which mainly include the servicing

operations (greasing and lubrication, inspection/check) whose basic purpose is to ensure regular

verification of the aircraft regardless of its utilization rate.

– A certain number of operations are carried out at multiples of the A inspection (identified as 2A).

They are complementary to the A inspection but are to be carried out only at the times specified

for a multiple inspection. The 2A operations are therefore to be scheduled every two A inspections.

Example: The 4th A inspection (1200 hours or 2 years) will include the A inspection operations,

plus 2A operations.

– The operations complementary to A identified by the “+” symbol are essentially calendar time

operations. Consequently, they should be carried out every year for a 2A +.

EFFECTIVITY: ALL 5–00–00

Page 5

November 2003

“DASSAULT AVIATION Proprietary Data”

MAINTENANCE MANUAL

– It is possible to separate the A check from multiple of the A check, however the following tolerances

between two same type of inspection have to be respected:

A = 300 h + 30 h or 6 months + 1 month

2A = 600 h + 30 h or 12 months + 1 month

EFFECTIVITY: ALL 5–00–00

Page 6

November 2003

“DASSAULT AVIATION Proprietary Data”

MAINTENANCE MANUAL

B inspection

– 1200 flying hours must be considered as a limit.

0

B B B B B B B B

& & & & &

1200 2B 3B 2B 2B 2B

hours & & &

4B 3B 4B

NOTE (3) : Tolerance: In the case of an absolute necessity to fly, the manufacturer authorizes

exceptionally a tolerance of plus 50 flying hours maximum beyond the B inspection due

time (or multiple thereof).

These tolerances are not cumulative.

The due time of any B inspection (or multiple) must never be exceeded by more than

50 flight hours. In addition, the period of time between two B inspections must not exceed

1250 flight hours.

0

B 2B 3B 4B

1200 hrs 2400 hrs 3600 hrs 4800 hrs

Tolerance + 50 hrs + 50 hrs + 50 hrs + 50 hrs

1250 hrs 2450 hrs 3650 hrs 4850 hrs

Max. Max. Max. Max.

– The purpose of the B inspection is to ensure operational and/or functional capacities of systems

whose condition is mainly related to flying hours.

– A certain number of operations are carried out at multiples of the B inspection (identified as 2B, 3B,

etc...). They are complementary to the B inspection but are to be carried out only at the times

specified for such operation.

Example: A 2B inspection will include B inspection operations and operations specific to the 2B

inspection.

EFFECTIVITY: ALL 5–00–00

Page 7

November 2003

“DASSAULT AVIATION Proprietary Data”

MAINTENANCE MANUAL

Z inspection (Zone inspection)

The Z inspection is to be carried out every 2 years, without however exceeding 2400 flying hours

between each inspection.

0 Z Z

2 years

or 2400 hours

NOTE (4) : Tolerance: to avoid grounding aircraft for logistics reasons, the manufacturer authorizes

a tolerance of + 1 month for the calendar limit or + 100 hours for the flying hours limit.

These tolerances are not cumulative.

The due time of Z inspection must never be exceeded by more than 1 month or 100 flying

hours. In addition, the period of time between two Z inspections must not exceed 25

months or 2500 flying hours.

0

Z Z

24 months (2 years) 48 months (4 years)

or 2400 hours or 4800 hours

+ 1 month + 1 month

Tolerance Tolerance

or or

+ 100 hours + 100 hours

25 months Max or 49 months Max or

2500 hours Max 4900 hours Max

– The Z inspection consists of maintenance operations, organized per zone, which are essentially

visual inspections of box structures, (check for absence of corrosion, checks of the condition and

attachment of equipment contained in the box structures), and the greasing/lubrication/servicing

of mechanical components fitted in the box structures.

– The Z inspection is a major inspection for the maintenance of the structure and systems.

– The existence of the Z inspection justifies scheduling the C inspection every 6 years.

– The Z inspection must be supplemented by all the operation of the A, 2A and 2A+ inspections.

EFFECTIVITY: ALL 5–00–00

Page 8

October 2010

“DASSAULT AVIATION Proprietary Data”

MAINTENANCE MANUAL

The incorporation of the Z inspection into the C inspection cycle is given by the following table:

¬

LAST

C Z Z C

2 years 4 years 6 years

¬ Less than 2 years since last C:

– Z inspection to be performed at 2 years/4 years to allow next C at 6 years.

Between 2 and 4 years since last C:

– Z inspection to be performed at 4 years to allow next C at 6 years.

EFFECTIVITY: ALL 5–00–00

Page 9

October 2002

“DASSAULT AVIATION Proprietary Data”

MAINTENANCE MANUAL

C inspection

– The 6 years periodicity must be considered as a limit.

0 1st C 0 2nd C 0 3rd C

6 years (72 months) 6 years (72 months) 6 years (72 months)

2 2

Tolerance months Tolerance months

Duration of Duration of

C inspection C inspection

NOTE (5) : The manufacturer authorizes a maximum tolerance of plus 2 months beyond the

C inspection calendar due time. No tolerance is allowed beyond the C inspection flights

due time.

The interval between two C inspections must be reckoned from the end of the C inspection

if the duration of the inspection does not exceed 3 months. If the duration of the

C inspection exceeds 3 months, the interval must be reckoned 3 months after the

beginning of the C inspection.

NOTE (6) : Cumulate tolerances on the C inspection is authorized. As 5-20-00 operations are

independant of the C operation, tolerances on C inspection cannot be applied to 5-20-00

operations.

– The C inspection must be considered as a detailed inspection of the airframe and systems after

opening all doors and access panels.

– The C inspection must also be considered as an inspection which, considering the extended down

time of the aircraft, reconditioning work to be done as well as the application of Service Bulletins

recommended by the manufacturer, which are not already applied.

– The C inspection must be supplemented by all operations of the A inspection and multiples of A

with flying hours and calendar time limits (A, 2A, 2A +) and the Z inspection operations.

– The C inspection must be supplemented by the B inspection operations if a B inspection has not

been performed since new or since the last C inspection.

However the cycle of multiples of B inspection (2B, 3B, 4B) continues independently of the

C inspection cycle.

– A certain number of operations multiples of C (identified as 2C, 3C, etc.) are to be accomplished

only at the time of the multiple inspection.

A 2C inspection will include C inspection operations plus the operations specific to the 2C

inspection.

EFFECTIVITY: ALL 5–00–00

Page 10

October 2010

“DASSAULT AVIATION Proprietary Data”

MAINTENANCE MANUAL

Major Corrosion Inspection (M.C.I.):

– The Major Corrosion Inspection consists of the following operations:

– detailed inspection of the aircraft structure,

– curative and preventive treatment of the corrosion and renewal of the structure protection

plan.

– This inspection is mandatory before 24 years since new, then every 12 years, and consequently,

all the operations of the M.C.I. are listed in section 5–40–00.

– The major Corrosion Inspection is one of the operations required to be carried out before

20000 flights/30000 flying hours as a pre requisite to the S.S.I.P. (SUPPLEMENTAL

STRUCTURAL INSPECTION PROGRAM: F.A.A. Advisory Circular No. 91–56).

– If an aircraft reaches 20000 flights/30000 flying hours without an M.C.I. already performed, this

inspection is automatically scheduled as a pre requisite to the Service Bulletin No. 730

(compliance with S.S.I.P.).

NOTE (7) : Tolerance: To avoid grounding aircraft for logistics reasons, the manufacturer authorizes

exceptionally a maximum tolerance of plus 6 months on the repeat interval of the M.C.I.

(12 years). No tolerance can be granted for the first M.C.I. at 24 years.

EFFECTIVITY: ALL 5–00–00

Page 11

October 2010

“DASSAULT AVIATION Proprietary Data”

MAINTENANCE MANUAL

B . Date of the Calendar Inspections

– The date of calendar inspections (A, 2A +, Z, C) following a C inspection is reckoned from the

date of completion of the C inspection.

– The date of the first calendar inspections (A, 2A +, Z, C and the M.C.I.), must be reckoned from

the delivery date of the aircraft to the customer by DASSAULT AVIATION (date Airworthiness

Certificate is obtained), in the case of aircraft fully equipped by the manufacturer. For aircraft

delivered by DASSAULT AVIATION and equipped by a service station, the date of the first

calendar inspections must be reckoned from the delivery date to the customer by the service

station. However, if the period of aircraft completion by the service station exceeds 7 months,

the date of the first inspections may be reckoned from the date the stripped aircraft was

delivered by DASSAULT AVIATION (date at which it obtained its Airworthiness Certificate) plus

7 months.

C . Engine inspection cycle

– For engine inspection cycle, see GARRETT maintenance documentation (Service Bulletin

TFE 731–72–3263).

Moreover, it is essential to add up the engine cycles in order to take into account the time limits of

the internal components of the TFE 731–5AR–1C engine. These limitations are given in the

GARRETT technical publications (Service Bulletin TFE 731–72–3001).

D . Adaptation of the maintenance schedule to suit operation of the aircraft

With approval of the relevant authorities of the country in which the aircraft is registered, the

operators of the aircraft may adapt the maintenance cycle recommended by the manufacturer as

follows (the operators are held responsible for these changes):

– in relation to the type of aircraft operation (flying hours per year, weather conditions, etc...),

– in relation to the grounding possibilities of the aircraft for maintenance; the operator, for example,

may perform progressive maintenance so as to reduce down–time; he may, for example, split

C inspection into several steps to be performed whenever the aircraft is grounded or during an

A, 2A, Z, or B inspection.

E . Structural maintenance

With regard to fatigue, the object of airworthiness is to ensure that no severe damage likely to

jeopardize aircraft safety during the number of flights corresponding to the operating period

considered by the manufacturer will be encountered.

In this respect, fatigue testing was carried out at the beginning of the FALCON 20 program to reach

20000 flights or 30000 flying hours and an associated maintenance schedule has been established

which will be regularly revised by the manufacturer.

The schedule contains:

– periodic operations to be systematically performed during Z inspections and C inspections.

These operations are described in the different chapters,

– random testing of leader aircraft, that is those with the most, flying hours, enabling detection of

premature damage and optimization of recommended maintenance operations before issuing

them to all operators.

EFFECTIVITY: ALL 5–00–00

Page 12

October 2002

“DASSAULT AVIATION Proprietary Data”

MAINTENANCE MANUAL

The aircraft structure is of “FAIL–SAFE” design except for certain parts which are of “SAFE–LIFE”

design. Up to 20000 flights/30000 flying hours the service life of these “SAFE–LIFE” elements is

indicated in section 5–40–00, paragraph A of this present document. This section is updated

periodically.

NOTE : Servicing intervals, TBO and service lives are determined as follows:

– in “FLYING HOURS” for structural components, where maximum stress is encountered

during flight,

– in “LANDINGS” for structural components, where maximum stress is encountered during

landing and take–off,

– in “FLIGHTS”, for structural components mainly affected by cabin pressurization.

A “FLIGHT” corresponds to a pressurization cycle which may be broken down as follows:

take–off, climb, descent and landing.

A mission, including one or more descents to a low altitude followed by a climb to a cruise

altitude, shall be considered as several “FLIGHTS” depending on the number of

pressurization cycles.

A “FLIGHT” usually corresponds to a “LANDING”.

However a training flight with “TOUCH AND GO” shall be considered as several

“LANDINGS” depending on how many times the wheels touched the ground.

After the 20000 flights/30000 flying hours justified by fatigue tests, a Supplemental Structural

inspection Program has been elaborated (DOC DMD No. 45184), according to F.A.A. Advisory

circular No. 91.56; it will be sent to the users, when they need it, with the S.S.I.P. Service bulletin

No. 730. It will take into account the experience gained from the whole fleet and in particular the

leader aircraft. Section 5–40–01 of this Supplemental program specifically list components with a

limited service life lower than or equal to 40000 flights/60000 flying hours. All the operations of the

S.S.I.P. are also listed at their mandatory threshold limit. Moreover, in order to participate in the

S.S.I.P., the M.C.I. must be performed at the mandatory limit of 24 years.

In order to reduce maintenance costs and grounding time, removal/installation of structural

components scheduled about 20000 flights/30000 flying hours will be used to carry out certain

operations due as part of the S.S.I.P. These operations, marked S.S.I.P. in the section 5–10–00

inspection column may be carried out between 16250 and 20000 flights.

The threshold for calculation of the scheduled inspection beyond 20000 flights/30000 flying hours

will be determined by the number of flights at which the operation has been carried out

(i.e. threshold: 18300 flights, scheduled inspection interval: 7500 flights, thus 18300

flights + 7500 = 25800 flights, time at which next inspection is due.

EFFECTIVITY: ALL 5–00–00

Page 13

October 2002

“DASSAULT AVIATION Proprietary Data”

MAINTENANCE MANUAL

F . Optimized Continuous Inspection Program (O.C.I.P.)

Following the request of operators, DASSAULT AVIATION has developped some optimized

continuous inspection programs, which are customized for each operator covering the A and Z,

or A, B and Z inspections and multiples.

These maintenance programs are an option available for operators who request it from the

manufacturer. In order to satisfy a maximum number of operators, two cycles have been retained.

– high rate of use > 600 flight hours per year,

– low and medium rate of use < 600 flight hours per year.

This program is presented as an appendix to the present Chapter 5 and is recognized by the

G.S.A.C. (Groupement pour la Sécurité des Avions Civils). This document indicates how to “enter”

and “leave” the program, and gives the rules and instructions for use.

5 . Maintenance manuals to be consulted

– FALCON 20 MAINTENANCE MANUAL (Abbreviated: MM).

– GARRETT turbofan engine model TFE 731–5A–2C MAINTENANCE MANUALS.

– Aircraft Component MAINTENANCE MANUALS (Abbreviated : CMM).

– APU MAINTENANCE MANUALS (if APU installed).

6 . Communications and navigation equipment

Communications and navigation equipment (chapters 23 and 34) shall be tested every 24 months to

obtain the license for airborne radio equipment (French regulations), or in accordance with the

regulations of the country in which the aircraft is registered.

EFFECTIVITY: ALL 5–00–00

Page 14

October 2002

“DASSAULT AVIATION Proprietary Data”

You might also like

- Multi-Engine Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideFrom EverandMulti-Engine Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideRating: 5 out of 5 stars5/5 (4)

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- TM 1-1520-237-PMI - Helicopter - EH-60 - UH-60 - 2005Document137 pagesTM 1-1520-237-PMI - Helicopter - EH-60 - UH-60 - 2005Wurzel194675% (4)

- Commercial Pilot Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideFrom EverandCommercial Pilot Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideRating: 3 out of 5 stars3/5 (2)

- Helicopter Pilot Oral Exam Guide: When used with the corresponding Oral Exam Guide, this book prepares you for the oral portion of the Private, Instrument, Commercial, Flight Instructor, or ATP Helicopter CheckrideFrom EverandHelicopter Pilot Oral Exam Guide: When used with the corresponding Oral Exam Guide, this book prepares you for the oral portion of the Private, Instrument, Commercial, Flight Instructor, or ATP Helicopter CheckrideNo ratings yet

- Basics of Aircraft Maintenance Programs For Financiers v1Document23 pagesBasics of Aircraft Maintenance Programs For Financiers v1Denilson Ribeiro100% (2)

- CHAPTER 5 - TIME LIMITS and MAINTENANCE CHECKSDocument39 pagesCHAPTER 5 - TIME LIMITS and MAINTENANCE CHECKSAlvaro Lemos100% (1)

- Instructor Support Airbus A330Document202 pagesInstructor Support Airbus A330RBipin Raj100% (2)

- CHAPTER 17 Aircraft Airworthiness InspectionDocument48 pagesCHAPTER 17 Aircraft Airworthiness Inspectionখালিদহাসান100% (3)

- Us Air Force Afi 11-202v3Document93 pagesUs Air Force Afi 11-202v3lpardNo ratings yet

- Ceramics and Clay ProductsDocument50 pagesCeramics and Clay ProductsDeathribbon100% (2)

- FAA 2016 5464 0004 - Attachment - 1Document22 pagesFAA 2016 5464 0004 - Attachment - 1peterNo ratings yet

- Time Limits/Maintenance Checks 1. Time Limits/Maintenance Checks - GeneralDocument2 pagesTime Limits/Maintenance Checks 1. Time Limits/Maintenance Checks - GeneralRizqi PerdanaNo ratings yet

- Caa-Ac-Gen005a Minimum Equipment ListDocument14 pagesCaa-Ac-Gen005a Minimum Equipment ListbenNo ratings yet

- ML B 1900d b19dmm11Document10 pagesML B 1900d b19dmm11ramzi30No ratings yet

- 05 00 00 inDocument8 pages05 00 00 inÜmit KazanNo ratings yet

- Service Manual CE-172 - 1969 - 1976Document13 pagesService Manual CE-172 - 1969 - 1976Kyle BrandonNo ratings yet

- Question AnswersDocument13 pagesQuestion Answersfahad_malik215214No ratings yet

- Time Limits / Maintenance Checks A. GeneralDocument6 pagesTime Limits / Maintenance Checks A. GeneralAlexis CabreraNo ratings yet

- ML C Ser c206hmm15Document3 pagesML C Ser c206hmm15Juan TapiaNo ratings yet

- Amm 05-10-00 Time Limits and Maintenance ChecksDocument21 pagesAmm 05-10-00 Time Limits and Maintenance ChecksLUCIENE ORECCHIO VIEIRANo ratings yet

- Series CDocument11 pagesSeries CAryan LahariaNo ratings yet

- C Part 1Document11 pagesC Part 1Prathmesh DixitNo ratings yet

- D2B B1 PDFDocument5 pagesD2B B1 PDFHemanthNo ratings yet

- 05 00 00 inDocument4 pages05 00 00 inMarco Antonio PrietoNo ratings yet

- D2B-B1 (Draft Sept2017)Document5 pagesD2B-B1 (Draft Sept2017)Sheik AbdullahNo ratings yet

- Amm 5Document762 pagesAmm 5dsenpen100% (2)

- Chapter5 - General InspectionDocument2 pagesChapter5 - General InspectionElmer VillegasNo ratings yet

- SB Compliance CodeDocument7 pagesSB Compliance CodeRS BANo ratings yet

- Government of India Technical Centre, Opp Safdurjung Airport, New DelhiDocument11 pagesGovernment of India Technical Centre, Opp Safdurjung Airport, New DelhiHemanthNo ratings yet

- C1-Defect Recording Reporting InvestigationDocument13 pagesC1-Defect Recording Reporting InvestigationSingh Vineet Kumar -No ratings yet

- 13 Biennial Scheduled Inspection ProgramDocument4 pages13 Biennial Scheduled Inspection ProgramWilly GrNo ratings yet

- CAANZ Airworthiness Directives - Helicopter GeneralDocument9 pagesCAANZ Airworthiness Directives - Helicopter GeneralTaiNo ratings yet

- Advisory Circular: Aircraft Wiring Systems Training ProgramDocument6 pagesAdvisory Circular: Aircraft Wiring Systems Training ProgramKaung MyatToeNo ratings yet

- Atr 72-600 Mel Rev0.0Document107 pagesAtr 72-600 Mel Rev0.0Honorio Perez M100% (4)

- Office of The Director General of Civil AviationDocument4 pagesOffice of The Director General of Civil Aviationconfirm@No ratings yet

- Special Inspection Manual Empennage and Associated StructureDocument16 pagesSpecial Inspection Manual Empennage and Associated StructureLeoNo ratings yet

- MEL DATA For A320Document5 pagesMEL DATA For A320amitNo ratings yet

- Hercules Service Bulletin: Lockheed Martin Aeronautics Company Marietta, Georgia 30063Document35 pagesHercules Service Bulletin: Lockheed Martin Aeronautics Company Marietta, Georgia 30063Windhi AerospaceNo ratings yet

- Company Procedure Checpoint MNSDocument7 pagesCompany Procedure Checpoint MNSمحمد هافيزيNo ratings yet

- 56melcl 06 00Document197 pages56melcl 06 00JuanOñateNo ratings yet

- TSO Service Bulletin Tailbeacon Upgrade To ADS B 1.5.1 UAV 1004407 002 Rev ADocument15 pagesTSO Service Bulletin Tailbeacon Upgrade To ADS B 1.5.1 UAV 1004407 002 Rev ANathanNo ratings yet

- CAR & MOE, TPM NotesDocument75 pagesCAR & MOE, TPM Notesbirendra67% (3)

- AMM 5-20 Scheduled Maintenance ChecksDocument16 pagesAMM 5-20 Scheduled Maintenance ChecksLeandro CalientoNo ratings yet

- EASA SIB 2011-07-1 (Functional Check Flights)Document3 pagesEASA SIB 2011-07-1 (Functional Check Flights)Paul HodsonNo ratings yet

- TM - 55 1520 240 PMDDocument4 pagesTM - 55 1520 240 PMDMinsung ChoNo ratings yet

- Advisory Circular: U.S. Department of TransportationDocument29 pagesAdvisory Circular: U.S. Department of TransportationVinayNo ratings yet

- EASA Changes To The Requirements For Continuing Airworthiness Records CAWDocument7 pagesEASA Changes To The Requirements For Continuing Airworthiness Records CAWrubenarisNo ratings yet

- AFI21-101 Aircraft and Equipment Maintenance ManagementDocument380 pagesAFI21-101 Aircraft and Equipment Maintenance ManagementPrinses1234567No ratings yet

- Service Bulletin: TitleDocument12 pagesService Bulletin: TitleLuis EnriqueNo ratings yet

- Civil Aviation Requirements Section 2 - Airworthiness Series 'C', Part I Effective: ForthwithDocument12 pagesCivil Aviation Requirements Section 2 - Airworthiness Series 'C', Part I Effective: ForthwithChalla AmarsrinuNo ratings yet

- Subject:-Defect Recording, Reporting, Investigation, Rectification and Analysis. 1Document13 pagesSubject:-Defect Recording, Reporting, Investigation, Rectification and Analysis. 1rashmiameNo ratings yet

- Ac 05002 Amo Manual Caav A2009Document48 pagesAc 05002 Amo Manual Caav A2009Thanh Hao LuongNo ratings yet

- Flight Standardization Board (FSB) Report: U.S. Department of Transportation Federal Aviation AdministrationDocument25 pagesFlight Standardization Board (FSB) Report: U.S. Department of Transportation Federal Aviation AdministrationLaura MelloNo ratings yet

- Civil Aviation Requirements Section 2 - Airworthiness Series I' Part I Issue Ii, 15Th March, 1976 Effective: ForthwithDocument6 pagesCivil Aviation Requirements Section 2 - Airworthiness Series I' Part I Issue Ii, 15Th March, 1976 Effective: ForthwithManish MishraNo ratings yet

- Fast46 6 Repair Design PDFDocument10 pagesFast46 6 Repair Design PDFJokenny WilliamNo ratings yet

- Model 525C: Section I - IntroductionDocument8 pagesModel 525C: Section I - Introductiontloeffelmann100% (1)

- 1.1.008 - Approval of MEL and CDL - Rev 2Document28 pages1.1.008 - Approval of MEL and CDL - Rev 2Mansour Bu MusabNo ratings yet

- SBDocument4 pagesSBPanneer SelvamNo ratings yet

- AC 20-97 Amdt 0Document13 pagesAC 20-97 Amdt 0Harry NuryantoNo ratings yet

- 208comp 08 00Document133 pages208comp 08 00mothboy100% (1)

- F20 - HoistingDocument2 pagesF20 - HoistingzoolmiatNo ratings yet

- F20 - ATA 10 - MooringDocument6 pagesF20 - ATA 10 - MooringzoolmiatNo ratings yet

- Falcon 20 - ATA 27Document10 pagesFalcon 20 - ATA 27zoolmiatNo ratings yet

- Special Slide - Stall Warning VaneDocument4 pagesSpecial Slide - Stall Warning VanezoolmiatNo ratings yet

- A Review On Tecoma StansDocument3 pagesA Review On Tecoma StansBaru Chandrasekhar RaoNo ratings yet

- Semi-Detailed Lesson Plan inDocument2 pagesSemi-Detailed Lesson Plan inMichael Anthony EsmoloNo ratings yet

- Business InfographicDocument1 pageBusiness InfographicCarla Sofía López MorenoNo ratings yet

- SPE Data Analytics in Reservoir EngineeringDocument108 pagesSPE Data Analytics in Reservoir EngineeringNindy Sherli ParamitaNo ratings yet

- University of Cambridge International Examinations International General Certificate of Secondary EducationDocument20 pagesUniversity of Cambridge International Examinations International General Certificate of Secondary Educationluines78No ratings yet

- Bahawalpur District Profile 2013Document138 pagesBahawalpur District Profile 2013Shaheer Rizvi100% (1)

- SelectaDocument55 pagesSelectaHuong Cam ThuyNo ratings yet

- PQRST 08 Puzzle Competition Equate: PUZZLE 01 (10 Points Penalty For A Wrong Answer) 30 PointsDocument5 pagesPQRST 08 Puzzle Competition Equate: PUZZLE 01 (10 Points Penalty For A Wrong Answer) 30 PointsCernică AlexandruNo ratings yet

- PSYCHOSOCIAL Care in elderly-MODULE 5Document8 pagesPSYCHOSOCIAL Care in elderly-MODULE 5camile buhangin100% (1)

- 2008 Computer Testing Supplement For IA Testing Ct-8080-8d - WebDocument675 pages2008 Computer Testing Supplement For IA Testing Ct-8080-8d - Webgerezair100% (1)

- Department of Education: Awareness On School Disaster Risk Reduction Management ObjectivesDocument2 pagesDepartment of Education: Awareness On School Disaster Risk Reduction Management ObjectivesJohn Dale EvangelioNo ratings yet

- What Is New in SolidCAM GPPTool 2011Document37 pagesWhat Is New in SolidCAM GPPTool 2011pannickNo ratings yet

- 02nd To 04th December 2023 International Cotton Advisory Committee - 81st Plenary Meeting 2023Document11 pages02nd To 04th December 2023 International Cotton Advisory Committee - 81st Plenary Meeting 2023sabirNo ratings yet

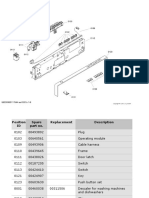

- ΕΓΧΕΙΡΙΔΙΟ ΠΛΥΝΤΗΡΙΟΥ ΠΙΑΤΩΝ - ΑΝΤΑΛΛΑΚΤΙΚΑDocument16 pagesΕΓΧΕΙΡΙΔΙΟ ΠΛΥΝΤΗΡΙΟΥ ΠΙΑΤΩΝ - ΑΝΤΑΛΛΑΚΤΙΚΑΤΣΙΜΠΙΔΗΣ ΠΑΝΑΓΙΩΤΗΣNo ratings yet

- Cosme Lab3 Mens Toiletries Group 1Document54 pagesCosme Lab3 Mens Toiletries Group 1just loveNo ratings yet

- Troubleshooting Manual For I/O Link Communication Alarm: (System Alarm PC050/PC150/971)Document22 pagesTroubleshooting Manual For I/O Link Communication Alarm: (System Alarm PC050/PC150/971)huutan12345No ratings yet

- Seiko v175Document19 pagesSeiko v175Rob van HerptNo ratings yet

- ABS Welding With Backing StripDocument1 pageABS Welding With Backing StripAbuBakarSiddkeRumiNo ratings yet

- Cognitive Approaches To TranslationDocument10 pagesCognitive Approaches To TranslationKhali74No ratings yet

- Super Duper MoxonDocument8 pagesSuper Duper Moxonrus comaresNo ratings yet

- Clay BricksDocument21 pagesClay BricksKhalid Réda100% (3)

- Bowaon and TotoonDocument1 pageBowaon and TotoonKharine Grace Ursal100% (1)

- Rubins-Q A ENDOCRINEDocument14 pagesRubins-Q A ENDOCRINECRUZ Jill EraNo ratings yet

- Vertiv Liebert PCW Brochure With PH 250Document8 pagesVertiv Liebert PCW Brochure With PH 250Asad Nizam100% (1)

- Ix-Biology - Target Paper 2024 - Homelander GroupDocument3 pagesIx-Biology - Target Paper 2024 - Homelander GroupTaroobaNo ratings yet

- MHT CET 2023 Cutoff Round 2 Maharashtra CandidatesDocument1,365 pagesMHT CET 2023 Cutoff Round 2 Maharashtra Candidatestodankarpratham15No ratings yet

- Wolfgang Pauli and Modern PhysicsDocument17 pagesWolfgang Pauli and Modern PhysicsahsbonNo ratings yet

- Helicopter Chapter5Document34 pagesHelicopter Chapter5juanNo ratings yet

- Overview of Literature On Sustainability in Projects and Project ManagementDocument8 pagesOverview of Literature On Sustainability in Projects and Project ManagementRalf BrauneNo ratings yet