Professional Documents

Culture Documents

8-Numerical Estimations of Heat Release From A Railcar Fire Based On Varying Ventilation Speed

8-Numerical Estimations of Heat Release From A Railcar Fire Based On Varying Ventilation Speed

Uploaded by

sbaia amineOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8-Numerical Estimations of Heat Release From A Railcar Fire Based On Varying Ventilation Speed

8-Numerical Estimations of Heat Release From A Railcar Fire Based On Varying Ventilation Speed

Uploaded by

sbaia amineCopyright:

Available Formats

Proceedings of the World Tunnel Congress 2014 – Tunnels for a better Life. Foz do Iguaçu, Brazil.

Numerical estimations of heat release from a railcar fire based on

varying ventilation speed

W.-H. Park

Korea Railroad Research Institute, Uiwang-si, Republic of Korea.

H. B. Kim and C. H. Lee

JSC Solution, Inc., Uiwang-si, Republic of Korea.

D. H. Lee and W. S. Jung

Korea Railroad Research Institute, Uiwang-si, Republic of Korea.

S. J. Yang

Hyundai Rotem, Uiwang-si, Republic of Korea.

ABSTRACT: To design the ventilation system of a railway tunnel that can handle fire emergencies,

the energy released from a railcar fire has to be considered. The maximum heat release rate is

particularly important. Traditionally, the Kennedy equation is used to calculate the critical velocity of

tunnel fire, which is the minimum ventilation speed required to control smoke and heat originating

from the railcar fire. However, in a confined fire such as a tunnel fire, the maximum heat release rate

varies with the tunnel ventilation speed. In this study, the heat release rates from a passenger railcar

in a tunnel were obtained for different tunnel ventilation velocities using the computation fluid

dynamics model, Fire Dynamics Simulator, developed by the NIST. The properties of the interior

materials of the railcar were obtained from bench-scale tests and literature. Among these properties,

the effective heat of combustion and reaction velocity constants were obtained by carrying out cone

calorimeter and thermogravimetric analysis.

1 INTRODUCTION fire propagation in the railcar. For the modeling

of fire behavior on the solid, interior materials

One of the factors to be considered while of the rail car, the pyrolysis model is adopted

designing the ventilation system of a railway and the input data for the pyrolysis model are

tunnel is whether the system can effectively the properties of the interior materials of the rail

control smoke flow originating from train fires. car. The rate of the pyrolysis, fire propagation is

One design factor is the fire size in railcars. dependent by the material properties. The

Therefore, the Korea Railroad Research Institute properties of the interior materials of the railcar

(KRRI) carried out full-size fire tests at the were obtained from bench-scale tests and

NRC in collaboration with Carlton University literature. Among these properties, the effective

(Hadjisophocleous et al., 2012). Fire sizes in heat of combustion and reaction velocity

railcars determined on the basis of these test constants were obtained by carrying out cone

results have been published in the “Guideline calorimeter and thermogravimetric analysis.

for assessment of fire safety in railway tunnels”

(KRRI, 2009). However, Roh et al. (2007)

conducted reduced-scale tests that demonstrated 2 CONSIDERED TUNNEL AND RAILCAR

that the airflow velocity in a tunnel affects the

fire sizes of pool pans. In this study, the heat

2.1 Single-track tunnel

release rates from a passenger railcar fire in a

tunnel were computed for different tunnel The tunnel considered in this study has a single

ventilation velocities using the computation track, and the length, width, and height of the

fluid dynamics model, Fire Dynamics Simulator tunnel are 39.6, 4.4, and 5 m, respectively. For

(FDS, Version 5) (McGrattan et al., 2010). Fire the boundary condition for numerical analysis

can grow when there is the sufficient oxidant, all tunnel are assumed the adiabatic walls.

sufficient external heat and the objects which

burns. The ventilation in tunnel may be effected

1

Proceedings of the World Tunnel Congress 2014 – Tunnels for a better Life. Foz do Iguaçu, Brazil.

2.2 Intercity car (Saemaul-ho)

The railcar is an intercity railcar called

Saemaul-ho in Korea. The railcar length, width,

and height are 23, 3, and 3.4 m, respectively. A

schematic of the intercity railcar is shown in

Figure 1. The railcar has 64 seats, with 17 rows

of 4 seats each arranged at an equal distance

from each other.

The interior materials of the intercity railcar

are polyester fiber reinforced plastic (FRP) for

the wall, PVC for the floor, glass fiber for

Figure 1. Schematic of intercity railcar insulation, urethane foam for seats, and

polyester fiber for seat covers. The details of the

Table 1. Interior materials of intercity railcar materials are listed in Table 1.

Interiors Material

3 NUMERICAL ANALYSIS

Wall panel FRP

PE foam The fire development characteristics and fire

size in the intercity railcar for different

Ceiling panel MPAL ventilation speeds in the tunnel are obtained by

FDS Version 5. FDS considers Navier-Stokes

Coving and Lack MPAL

equations as hydrodynamic models, and these

Floor Center PVC equations are solved by large eddy simulation

calculations using a Smagorinsky model

adhesive (Smagorinsky, 1963). Temperature fields are

obtained by solving the energy equations of

plywood

radiative transfer. The finite volume method is

PE foam also adopted for radiative transfer equations.

One-dimensional energy equations for pyrolysis

Floor side PVC in solids are simultaneously solved. The

pyrolysis rates are functions of local mass

adhesive

concentration and temperature, and calculated as

plywood a combination of Arrhenius and power

functions:

PE foam

E n

Partition MPAL m=Aexp max 0, T Tign (1)

RT

Seat base PE moquette

PU foam m is the pyrolysis rate and pyrolysis rate is

decided by parameter A, E and n. These values

Seat back PE moquette are properties for the materials of the interiors in

the rail car. Combustible gases originating from

PU foam a solid via pyrolysis react in the gaseous phase,

Foot rest ABS plastic and combustion in the gaseous phase is

analyzed using a two-parameter mixture fraction

Seat arm Integral skin foam combustion model. All equations are discretized

in an orthogonal coordinate system, and finally,

Seat back panel ABS plastic unsteady properties are obtained in FDS.

Seat side cover ABS plastic Figure 2 shows the computational domain

and railcar. The railcar structure is 0.9 m above

Seat leg rest PE moquette the tunnel ground because the bogie is located

below the railcar. The velocity inlet for the

PU foam ventilation flow is at the right end, which is

2

Proceedings of the World Tunnel Congress 2014 – Tunnels for a better Life. Foz do Iguaçu, Brazil.

Figure 2. Computational domain and divided zone for parallel processing

open to the atmosphere. All walls are assumed physical values are necessary. Test equipment

to be adiabatic. The right end of the railcar is such as a thermogravimetric analyzer and

located 2.8 m from the right end of the tunnel. differential scanning calorimeter were used to

The railcar is located near the inlet because obtain the physical values for each material. The

combustible gases formed by pyrolysis of the fire curve was predicted by applying the thermal

interior materials of the railcar can react under decomposition model to the same scenario and

the tunnel ventilation within the computational fire source. Although the thermal pyrolysis

domain. If any portion of the combustible gas is model follows a very microscopic approach and

not burned in the computational domain and consequently offers microscopic rigor, its

escapes through the open left end of the tunnel, disadvantage is that microscopic error (if any) is

the fire size in the railcar is considered to be accumulated. The ventilation speeds considered

underestimated. in this study are 0, 1, and 2.5 m/s. The minimum

The tunnel is divided into 8 equidistant ventilation speed of subway tunnels in Korea is

sections, and parallel processing is employed 2.5 m/s. Figures 4–6 show pictures of the railcar

using a computer having 8 CPU nodes, a Xeon on fire at maximum heat release rates for

2.27 GHz processor, and 24 GB memory. The different tunnel ventilation speeds. The heat

number of total grids is approximately 7 release rates for different tunnel ventilation

million, and the length of each grid is 0.05 m. speeds are shown in Figure 7. The maximum

The door destruction temperature is set to heat release rates from the railcar on fire are

600°C. The ignition source fire scenario 24.2, 35.3, and 51.9 MW for ventilation speeds

followed the predetermined fire curve of 0, 1, and 2.5 m/s, respectively. The maximum

(EN45545-1, 2013), as shown in Figure 3. heat release rate for a tunnel ventilation speed of

2.5 m/s is over 2 times that for a tunnel with no

ventilation. Hence, the tunnel ventilation speed

is one of the most important factors in deciding

the fire size in railcars during the design of

tunnel ventilation.

Figure 4. Fire propagation at maximum fire size

Figure 3. Heat release rate of fire source (no ventilation)

To obtain the fire curve using the thermal

pyrolysis model, the effective heat of

combustion from the interior materials and the

3

Proceedings of the World Tunnel Congress 2014 – Tunnels for a better Life. Foz do Iguaçu, Brazil.

these properties, the effective heat of

combustion and reaction velocity constants were

obtained by carrying out cone calorimeter and

thermogravimetric analysis. The more

ventilation speed, the faster fire propagation.

The time of the windows of the railcar is shorten

with large ventilations. The heat release rates

for large ventilation speed are going up fast and

the maximum heat release rate is larger than

with no/smaller ventilation. So the fire

phenomena of the railcar in the tunnel is under-

Figure 5. Fire propagation at maximum fire size

( 1 m/s ventilation speed) ventilation which means the fire propagation is

mainly governed by oxygen, i.e. the tunnel

ventilation speeds. The maximum heat release

rate for a tunnel ventilation speed of 2.5 m/s is

over 2 times that for a tunnel with no

ventilation. Hence, the tunnel ventilation speed

is one of the most important factors in deciding

the fire size in railcars during the design of

tunnel ventilation.

ACKNOWLEDGEMENTS

Figure 6. Fire propagation at maximum fire size

( 2.5 m/s ventilation speed)

This work was carried out within a project,

by the Korea Ministry of Land, Infrastructure

and Transport and Korea Agency for

Infrastructure Technology Advancement. These

supports are gratefully acknowledged..

REFERENCES

EN 45545-1; 2013. Railway applications - Fire protection

on railway vehicles - Part 1: General.

KRRI: 2009. Guideline for assessment of fire safety in

railway tunnels.

Hadjisophocleous, G.; Lee D.H. and Park W.-H. 2012.

Full-scale Experiments for Heat Release Rate

Measurements of Railcar Fires. In: The 5th

International Symposium on Tunnel Safety and

Security. New York; SP.

McGrattan, K; McDermott, R.; Hostikka, S.; Floyd, J.

2010. Fire Dynamics Simulator (Version 5) User’s

Figure 7. Heat release rates for different Guide. NIST.

tunnel ventilation speeds Roh. J.S.; Ryou, H.S.; Kim D.H.; Jung W.S. and Jang

Y. J. 2007. Critical velocity and burning rate in pool

fire during longitudinal ventilation, Tunnelling and

4 CONCLUSION Underground Space Technology, v.22.p. 262–271

In this study, the heat release rates from a .

passenger railcar fire in a tunnel were obtained

for different tunnel velocities using the

computation fluid dynamics model, FDS,

developed by the NIST. The properties of the

interior materials of the railcar were obtained

from bench-scale tests and literature. Among

4

You might also like

- Mechanised Shield TunnellingDocument256 pagesMechanised Shield Tunnellingsbaia amineNo ratings yet

- Chapter 8 ACCA F2Document9 pagesChapter 8 ACCA F2sikshaNo ratings yet

- DHIS Monthly Reporting Form (PHC Facilities)Document4 pagesDHIS Monthly Reporting Form (PHC Facilities)Usman89% (9)

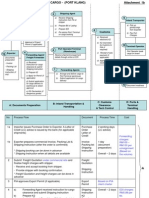

- Export + Import Process Flow - Break Bulk Cargo 27072010Document11 pagesExport + Import Process Flow - Break Bulk Cargo 27072010Ahmad Fauzi Mehat100% (1)

- References ASEAN2Document3 pagesReferences ASEAN2M IrwaniNo ratings yet

- Material Characterization of Filament-Wound Composite PipesDocument10 pagesMaterial Characterization of Filament-Wound Composite PipesMatheusNo ratings yet

- Lectura MNDocument13 pagesLectura MNAdrian Ocampo DorantesNo ratings yet

- 1 s2.0 S0950061817309194 MainDocument11 pages1 s2.0 S0950061817309194 Mainclara97No ratings yet

- An Undergraduate Electrochemical Laboratory ExperimentDocument2 pagesAn Undergraduate Electrochemical Laboratory Experimentsanjit singhNo ratings yet

- Computational Materials Science: Chenyang Zheng, Fan Geng, Zhonghao RaoDocument7 pagesComputational Materials Science: Chenyang Zheng, Fan Geng, Zhonghao RaoPavel IslamNo ratings yet

- Thermal Conductivity of Polymer Composites Filled With NanofillersDocument9 pagesThermal Conductivity of Polymer Composites Filled With NanofillerschotuNo ratings yet

- Poles DeignDocument24 pagesPoles DeignIbrahim TalaatNo ratings yet

- Numerical Investigations On The Seismic Behavior of FRP and TRM Upgraded RC Exterior Beam-Column JointsDocument15 pagesNumerical Investigations On The Seismic Behavior of FRP and TRM Upgraded RC Exterior Beam-Column JointsJamal Eddine HamiltonNo ratings yet

- 2019-Mechanical and Fatigue Properties of CFRP at Low TemperatureDocument7 pages2019-Mechanical and Fatigue Properties of CFRP at Low TemperatureZUOJIA WANGNo ratings yet

- J Matpr 2020 11 449Document7 pagesJ Matpr 2020 11 449Sankeeth SivaananthanNo ratings yet

- Fire in Cable TunnelDocument11 pagesFire in Cable TunnelMohamed MostafaNo ratings yet

- Cilamce 2017-FlorianopolisDocument13 pagesCilamce 2017-Florianopolisingenauta7282No ratings yet

- Kiefer 2020Document18 pagesKiefer 2020valeriacostacivilNo ratings yet

- Numerical Analysis of Solar Tower System UtilizedDocument8 pagesNumerical Analysis of Solar Tower System Utilized1032202176No ratings yet

- Road Tunnel Fire CFD Simulation PaperDocument18 pagesRoad Tunnel Fire CFD Simulation PaperNajaf HussainNo ratings yet

- CFD Simulations of A Bubble Column With and Without Internals by Using OpenFOAMDocument18 pagesCFD Simulations of A Bubble Column With and Without Internals by Using OpenFOAMvishalNo ratings yet

- NCCS-2019-1023: NomenclatureDocument3 pagesNCCS-2019-1023: Nomenclaturesaju_s_rajNo ratings yet

- International Journal of Thermal Sciences: Mohammad Kazem Hassanzadeh-Aghdam, Reza Ansari, Hamed Mohaddes DeylamiDocument15 pagesInternational Journal of Thermal Sciences: Mohammad Kazem Hassanzadeh-Aghdam, Reza Ansari, Hamed Mohaddes DeylamiAlireza Alidoust.LNo ratings yet

- Experimental Investigation and Numerical Simulation of Secondary Combustor Flow in Boron-Based Propellant Ducted RocketDocument8 pagesExperimental Investigation and Numerical Simulation of Secondary Combustor Flow in Boron-Based Propellant Ducted RocketAzeem KhanNo ratings yet

- Creep - Longterm Cree Prediction Polymetcrylin Foam Usinh Neural NetworkDocument10 pagesCreep - Longterm Cree Prediction Polymetcrylin Foam Usinh Neural NetworkTONNY LESMANANo ratings yet

- 07 Ananth Ramawamy-Thermomechancal Prop of ConcreteDocument6 pages07 Ananth Ramawamy-Thermomechancal Prop of ConcreteRaja RajanNo ratings yet

- Materials 16 072331Document24 pagesMaterials 16 072331Yaakoub FetimiNo ratings yet

- Experimental Study of Mechanical and Electrical Properties of CarbonDocument8 pagesExperimental Study of Mechanical and Electrical Properties of CarbonSufian HijazNo ratings yet

- Finite Element Analysis of Reinforced Concrete Beam Strengthened With CFRP SheetsDocument6 pagesFinite Element Analysis of Reinforced Concrete Beam Strengthened With CFRP SheetsVikramNo ratings yet

- Evaluation of Thermal Conductivity of Porous Silicon Layers by A Photoacoustic MethodDocument5 pagesEvaluation of Thermal Conductivity of Porous Silicon Layers by A Photoacoustic MethodElizabeth EspitiaNo ratings yet

- 2003 - Barra Et Al. Numerical Study of The Effects of Material PropertDocument11 pages2003 - Barra Et Al. Numerical Study of The Effects of Material Propertvivek joshiNo ratings yet

- Water 10 00299 v3Document16 pagesWater 10 00299 v3Angelo HadithNo ratings yet

- Computational Materials Science: Zhonghao Rao, Chenyang Zheng, Fan GengDocument7 pagesComputational Materials Science: Zhonghao Rao, Chenyang Zheng, Fan GengPavel IslamNo ratings yet

- Dynamic Bending Response of CFRP Thin Walled Square Beams Filled With Aluminium HoneycombDocument10 pagesDynamic Bending Response of CFRP Thin Walled Square Beams Filled With Aluminium HoneycombIeva MisiūnaitėNo ratings yet

- 1 s2.0 S0094576518302844 MainDocument6 pages1 s2.0 S0094576518302844 MainArezoo NajafianNo ratings yet

- Jayamani Lu 2020 A Study of Detonation Driven Shock Tube Using The Method of CharacteristicsDocument23 pagesJayamani Lu 2020 A Study of Detonation Driven Shock Tube Using The Method of Characteristicstouqeer anwarNo ratings yet

- Validation of A Post-Cracking Law in Tensile For A Sustainable UHPFRC Using Fracture Energy and Finite Element MethodDocument11 pagesValidation of A Post-Cracking Law in Tensile For A Sustainable UHPFRC Using Fracture Energy and Finite Element MethodIJAERS JOURNALNo ratings yet

- Ahmadi2017 Article EvaluationOfEffectiveThermalDiDocument14 pagesAhmadi2017 Article EvaluationOfEffectiveThermalDiDevarajuNo ratings yet

- Thermomechanical Properties of A New Small Scale Reinforced Concrete Thermo Active Pile For Centrifuge TestingDocument8 pagesThermomechanical Properties of A New Small Scale Reinforced Concrete Thermo Active Pile For Centrifuge TestingMARCOSNo ratings yet

- Raman WorkDocument20 pagesRaman WorkMuhammad AdnanNo ratings yet

- Rafique 2021Document14 pagesRafique 2021ganeshNo ratings yet

- Article The Experimental Analysis of BondingDocument8 pagesArticle The Experimental Analysis of BondingAKSHAYNo ratings yet

- Three Point Bending Test and Finite Element Analysis 20110103howDocument8 pagesThree Point Bending Test and Finite Element Analysis 20110103howDanielNo ratings yet

- I em Journal Vehicular Blockage EffectDocument7 pagesI em Journal Vehicular Blockage EffectbaranNo ratings yet

- Flexural Behaviour of RC Beams Wrapped With Hybrid Fiber Reinforced Polymer Under Static LoadingDocument5 pagesFlexural Behaviour of RC Beams Wrapped With Hybrid Fiber Reinforced Polymer Under Static LoadingDr NNHNo ratings yet

- Coatings 09 00271 PDFDocument12 pagesCoatings 09 00271 PDFSteph BredenhannNo ratings yet

- 2019 Fischer - Dynamic CO2 Methanation in A Wall-Cooled Fixed Bed Reactor-Comparative Evaluation of Reactor ModelsDocument15 pages2019 Fischer - Dynamic CO2 Methanation in A Wall-Cooled Fixed Bed Reactor-Comparative Evaluation of Reactor ModelsOliver FermaniNo ratings yet

- Establishment of The Falling Film Evaporation Model and Correlation of The Overall Heat Transfer CoefficientDocument16 pagesEstablishment of The Falling Film Evaporation Model and Correlation of The Overall Heat Transfer CoefficientsriniNo ratings yet

- Composites: Part A: K. Sanada, Y. Tada, Y. ShindoDocument7 pagesComposites: Part A: K. Sanada, Y. Tada, Y. Shindobishnu ppNo ratings yet

- 1 s2.0 S0360319916318687 MainDocument9 pages1 s2.0 S0360319916318687 MainOlukayode Niyi EzekielNo ratings yet

- 1 s2.0 S2214914717300302 MainDocument8 pages1 s2.0 S2214914717300302 MainkhaledNo ratings yet

- Thermo-Mechanical Behaviour of Energy Pile in Underground Railway Construction SiteDocument6 pagesThermo-Mechanical Behaviour of Energy Pile in Underground Railway Construction SiteAnonymous U6pIEKQghNo ratings yet

- 8ing) Kroetz, HM 2018Document9 pages8ing) Kroetz, HM 2018Jairo FuentesNo ratings yet

- Thermal 1Document5 pagesThermal 1AnandNo ratings yet

- Calibration of Hyperelastic and Hyperfoam Constitutive Models For An Indentation Event of Rigid Polyurethane FoamDocument6 pagesCalibration of Hyperelastic and Hyperfoam Constitutive Models For An Indentation Event of Rigid Polyurethane FoamzhuhaitingtaoNo ratings yet

- Thermal and Electrical Transport Properties of Some Polymer Materials For Manufacturing Electronic DevicesDocument4 pagesThermal and Electrical Transport Properties of Some Polymer Materials For Manufacturing Electronic DevicesIoana BiticaNo ratings yet

- Modeling of Propane-Air Combustion in Meso-Scale Tubes With Wire MeshDocument7 pagesModeling of Propane-Air Combustion in Meso-Scale Tubes With Wire Meshherdi sutanto adigunaNo ratings yet

- Heat Transfer Performance of Aluminum Foams: Simone Mancin Claudio Zilio Luisa Rossetto Alberto CavalliniDocument9 pagesHeat Transfer Performance of Aluminum Foams: Simone Mancin Claudio Zilio Luisa Rossetto Alberto Cavalliniboni eselNo ratings yet

- Ranjbarnia 2018Document11 pagesRanjbarnia 2018SaeedNo ratings yet

- P. SenthilkumarDocument6 pagesP. SenthilkumarasdfNo ratings yet

- Analysis at Cell Scale of Porosity Effect On Forced Co 2022 International JoDocument13 pagesAnalysis at Cell Scale of Porosity Effect On Forced Co 2022 International JoAsmamaw FirewNo ratings yet

- Composites Part B: D.A. Pohoryles, D.A. BournasDocument10 pagesComposites Part B: D.A. Pohoryles, D.A. BournasTesfayeNo ratings yet

- IJEAS0305013Document3 pagesIJEAS0305013erpublicationNo ratings yet

- SynopsisDocument27 pagesSynopsisSaheera HazarikaNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Strength Properties of Various Types of Fiber-Reinforced Concrete For Production of Driven PilesDocument20 pagesStrength Properties of Various Types of Fiber-Reinforced Concrete For Production of Driven Pilessbaia amineNo ratings yet

- wtc2015 Full DalnegroDocument10 pageswtc2015 Full Dalnegrosbaia amineNo ratings yet

- PAP497Document10 pagesPAP497sbaia amineNo ratings yet

- 4-The Successful Use of Galvanized Rebar For Corrosion ProtectionDocument6 pages4-The Successful Use of Galvanized Rebar For Corrosion Protectionsbaia amineNo ratings yet

- PAP692Document7 pagesPAP692sbaia amineNo ratings yet

- Pap 109Document8 pagesPap 109sbaia amineNo ratings yet

- Loi de Janssen - Explication ThéoriqueDocument2 pagesLoi de Janssen - Explication Théoriquesbaia amineNo ratings yet

- Etude Du Comportement Des Tunnels Creusés en Terrains MeublesDocument50 pagesEtude Du Comportement Des Tunnels Creusés en Terrains Meublessbaia amineNo ratings yet

- Pap 224Document10 pagesPap 224sbaia amineNo ratings yet

- PLAXIS Older Versions Using PLAXIS Remote Scripting With The Python WrapperDocument4 pagesPLAXIS Older Versions Using PLAXIS Remote Scripting With The Python Wrappersbaia amineNo ratings yet

- Pap 494Document10 pagesPap 494sbaia amineNo ratings yet

- MUSKAT PROBLEM-Water FlowDocument4 pagesMUSKAT PROBLEM-Water Flowsbaia amineNo ratings yet

- Cot - Math 3Document5 pagesCot - Math 3Lorimae Vallejos100% (7)

- User S Manual Bedienungsanleitung: Version 1.0 October 1998Document32 pagesUser S Manual Bedienungsanleitung: Version 1.0 October 1998Ojit QuizonNo ratings yet

- Texi Post DD ErsatzteillisteDocument52 pagesTexi Post DD ErsatzteillisteJozsef TomoriNo ratings yet

- Hematology Report:: MRN: Visit NoDocument1 pageHematology Report:: MRN: Visit Nojuniadsheikh6No ratings yet

- Generalized Analysis of Quasi-Steady-State and Quasi-Transient Measurements of Carrier Lifetimes in SemiconductorsDocument4 pagesGeneralized Analysis of Quasi-Steady-State and Quasi-Transient Measurements of Carrier Lifetimes in SemiconductorsMohaimen UzzamanNo ratings yet

- Rate of Burning And/or Extent and Time of Burning of Plastics in A Horizontal PositionDocument8 pagesRate of Burning And/or Extent and Time of Burning of Plastics in A Horizontal PositionjoseNo ratings yet

- Tutorial L298N Driver MotorDocument5 pagesTutorial L298N Driver MotorHairul Anam SNo ratings yet

- Tejashwini Internship ReportDocument35 pagesTejashwini Internship ReportBro FistoNo ratings yet

- E-CatvScope Catalog PDFDocument80 pagesE-CatvScope Catalog PDFAlexander PischulinNo ratings yet

- Pharmaceutics 14 02240Document17 pagesPharmaceutics 14 02240oliverasrommelNo ratings yet

- What Aspects of "Life" Are Covered by Vedic AstrologyDocument4 pagesWhat Aspects of "Life" Are Covered by Vedic AstrologyMariana SantosNo ratings yet

- Grammar Exam Pre Int PDFDocument2 pagesGrammar Exam Pre Int PDFSandra Lazovska100% (1)

- Indra Motion MLC - Trainning Manual PDFDocument36 pagesIndra Motion MLC - Trainning Manual PDFjorfleitasNo ratings yet

- Percussion Laser DrillingDocument1 pagePercussion Laser DrillingBefzzNo ratings yet

- Renoise User ManualDocument198 pagesRenoise User Manualdrkstr77No ratings yet

- History Medicine Knowledge OrganiserDocument4 pagesHistory Medicine Knowledge OrganiserabidaNo ratings yet

- Fortran CF DDocument160 pagesFortran CF DLahcen AkerkouchNo ratings yet

- AB 14 para Tranzystorow DarlingtonaDocument23 pagesAB 14 para Tranzystorow DarlingtonavengalamahenderNo ratings yet

- VC - SM TransportDocument2 pagesVC - SM Transportsureshkumar mNo ratings yet

- Ecs2602 Tests Bank-1Document97 pagesEcs2602 Tests Bank-1corlia100% (2)

- STAAD - Pro Plates and Solid Elements (FAQ) - RAM - STAAD Wiki - RAM - STAAD - Bentley CommunitiesDocument15 pagesSTAAD - Pro Plates and Solid Elements (FAQ) - RAM - STAAD Wiki - RAM - STAAD - Bentley CommunitiesKamal RaoNo ratings yet

- Dynalene PG FG (Heat Transfer Fluid) : 1. Product and Company IdentificationDocument5 pagesDynalene PG FG (Heat Transfer Fluid) : 1. Product and Company IdentificationIvan DumontNo ratings yet

- Gasoline Specifications: S. No Characteristic Bsii Bsiii Bsiv 1 2 3 (A) 3 (B) 4 5 (A) (B) (C)Document2 pagesGasoline Specifications: S. No Characteristic Bsii Bsiii Bsiv 1 2 3 (A) 3 (B) 4 5 (A) (B) (C)Velshankar MJNo ratings yet

- Hypomorphic Mutations in PRF1, MUNC13-4, and STXBP2 Are Associated With Adult-Onset Familial HLHDocument6 pagesHypomorphic Mutations in PRF1, MUNC13-4, and STXBP2 Are Associated With Adult-Onset Familial HLHLeyla SaabNo ratings yet

- Context CluesDocument7 pagesContext CluesasherNo ratings yet

- Physics of Everyday Phenomena A Conceptual Introduction To Physics 8th Edition Griffith Test BankDocument14 pagesPhysics of Everyday Phenomena A Conceptual Introduction To Physics 8th Edition Griffith Test Bankdavidhallwopkseimgc100% (32)