Professional Documents

Culture Documents

EPM iSeriesPumpsTB11111P1

EPM iSeriesPumpsTB11111P1

Uploaded by

Farhan MalekOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EPM iSeriesPumpsTB11111P1

EPM iSeriesPumpsTB11111P1

Uploaded by

Farhan MalekCopyright:

Available Formats

Technical Note

iSeries Instrument Platform of Gas Analyzers

Vacuum Pumps

Bulletin #11111P1 Rev 12/2011

Introduction

The Thermo Scientific iSeries of gas analyzers have incorporated several different

internal vacuum pumps. In order to aid in identifying the correct vacuum pump and

its corresponding rebuild kit, the following guide has been developed.

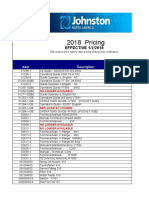

iSeries Vacuum Pump and Rebuild Kit Matrix

Discontinued Rebuild Kit Rebuild Kit

Rebuild Kit "New "New Discontinued for "Old

for Active Technology" Technology" "Old Style" Style"

Model Active Pump Shim'd Pump Pump Shim'd Pump Pump Shim'd Pump

146i 111553-01 108002-00 101426-00 108002-00 101426-00 8606

410i 111553-01 108002-00 101426-00 108002-00 101426-00 8606

42i 101011-01 107751-00 101011-00 107751-00 101011-00 9267

42i-D 101011-01 107751-00 101011-00 107751-00 101011-00 9267

42i-LS 101011-01 107751-00 101011-00 107751-00 101011-00 9267

42i-J 101011-01 107751-00 101011-00 107751-00 101011-00 9267

42i-Y 111553-01 108002-00 101426-00 108002-00 101426-00 8606

43i 111553-01 108002-00 101426-00 108002-00 101426-00 8606

43i-HL 101011-01 107751-00 101011-00 107751-00 101011-00 9267

43i-TL 111553-01 108002-00 101426-00 108002-00 101426-00 8606

450i 111553-01 108002-00 101426-00 108002-00 101426-00 8606

46i 111553-01 108002-00 101426-00 108002-00 101426-00 8606

46i-HL 111553-01 108002-00 101426-00 108002-00 101426-00 8606

48i 111553-01 108002-00 101426-00 108002-00 101426-00 8606

48i-HL 111553-01 108002-00 101426-00 108002-00 101426-00 8606

48i-TLE 111553-01 108002-00 101426-00 108002-00 101426-00 8606

49i 111553-01 108002-00 101426-00 108002-00 101426-00 8606

49i-PS 111553-01 108002-00 101426-00 108002-00 101426-00 8606

5020i 111553-01 108002-00 101426-00 108002-00 101426-00 8606

Comments:

Please note Rebuild Kit P/N 108002-00 is common to P/N’s 111553-01, 111553-00

and 101426-00 and includes replacement Shims.

P/N‘s 111553-01 and 111553-00 are designed as a low vibration “Shim-less” pumps.

Shims included in rebuild kit 108002-00 should be discarded.

P/N 101426-00 is “Shim-less” in its “Old Style” and “Shim’d” in its “New Technology”

design. Shims included with rebuild kit 108002-00 sould be discarded for “Old Style”

pumps and can be used as replacements for those incorporated in the “New

Technology” pump.

P/N’s which end in “-01” include the replacement pump (101011-00 and 111553-00)

and a Shock Bumper Kit (P/N 112021-00). P/N’s 101011-00 and 111553-00 are not

available for sale therefore please order P/N 111553-01 or 101011-01.

Additional guidence can be found within this document.

Air Quality Instruments. 27 Forge Parkway (508) 520-0430 www.thermoscientific.com/aqi

Franklin, MA (866) 282-0430

02038 (508) 520-2800 fax

Models: 42i, 42i-J, 42i-LS, 42i-D, 42i-D and 43i-HL

Active Pump - P/N 101011-01 “New Technology”

Active Rebuild Kit - P/N 107751-00

*Note: P/N 101011-00 does not include Shock Bumper kit and is not available for sale

P/N 101011-01 Shim Label

(added to pumps manufactured after August 2011)

P/N 101011-01 Side View

P/N 101011-01 Top View

Air Quality Instruments. 27 Forge Parkway (508) 520-0430 www.thermoscientific.com/aqi

Franklin, MA (866) 282-0430

02038 (508) 520-2800 fax

Models: 42i, 42i-J, 42i-LS, 42i-D, 42i-D and 43i-HL

Discontinued Pumps - P/N 101011-00 “Old Style”

Active Rebuild Kit - P/N 9267

P/N 101011-00 “Old Style” P/N 101011-01 “New Technology”

NOTE: Some “Old Style” and “New Technology” pumps may be labeled with the raw

pump motor of part number of 102639-00 which is not commercially available.

Models: 42i-Y, 43i, 43i-TL, 48i, 48i-HL, 48i, 48i-HL, 48i-TLE, 49i, 49i-PS, 146i,

410i, 450i and 5020i

Active Pump* – P/N 111553-01

Active Rebuild Kit – P/N 108002-00

* Effective October 2011

** Note: P/N 111553-00 does not include Shock Bumper kit and is not available for sale

P/N 111553-01 Side View

Air Quality Instruments. 27 Forge Parkway (508) 520-0430 www.thermoscientific.com/aqi

Franklin, MA (866) 282-0430

02038 (508) 520-2800 fax

Models: 42i-Y, 43i, 43i-TL, 48i, 48i-HL, 48i, 48i-HL, 48i-TLE, 49i, 49i-PS, 146i,

410i, 450i and 5020i

Discontinued Pump* – P/N 101426-00 “New Technology”

Active Rebuild Kit – P/N 108002-00

* Effective October 2011

P/N 101426-00 “New Technology” Side View

Models: 42i-NOY, 43i, 43i-TL, 46i, 46i-HL,48i, 48i-HL, 48i-TLE, 49i, 49i-PS, 146i,

410i, 450i and 5020i

Discontinued Pump – P/N 101426-00 “Old Style”

Active Rebuild Kit – P/N 8606

P/N 101426-00 “Old Style” Side View

Air Quality Instruments. 27 Forge Parkway (508) 520-0430 www.thermoscientific.com/aqi

Franklin, MA (866) 282-0430

02038 (508) 520-2800 fax

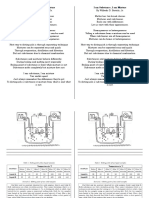

Diaphragm and Valve Replacement Procedure for

Thermo Scientific # 101011-00 and 101011-01

SHIMS UNDER DIAPHRAM SUPPORT CUP ARE REQUIRED

(KNF # PU2386-N811-3.07 or PU 1961-N811-3.07)

Tools and Materials required:

• Thermo Scientific Pump Rebuild Kit #107751-00 • Marking pencil or marker

• #1 Phillips head screwdriver • 2.5 mm Allen Wrench

Exploded View of Pump Head:

Seq. Description

010 Headplate

020 Intermediate plate

030 Valveplate

040 Diaphragm support cup

050 Diaphragm

060 Shim ring

070 Socket cap screw

Disassembly:

1. Disconnect the pump from electrical power. Make a sketch of the position of any tubes and fittings for ease of re-

assembly later.

2. Mark the position of the pump headplate (010), intermediate plate (020) and compressor housing relative to each

other by drawing a line on the edges with a pencil or marker to insure proper re-assembly.

3. One of the aluminum compressor housing covers must be removed to gain access to the inside of the compressor

housing. Remove the four screws and then remove the cover. Re-use any gasketing. Remove any debris that may

have accumulated in the bottom of the compressor housing.

4. Remove the four screws (070) with the 2.5 mm allen wrench and remove the headplate (010). Note the positioning of

the valveplate (030) relative to the valve ports on the headplate (010) and intermediate plate (020). Lift off the

valveplate (030).

5. Remove the intermediate plate (020).

6. Check that all parts are free from dirt and clean as necessary. DO NOT scratch the parts.

7. Removal of the old diaphragm (050): Rotate the fan so that the diaphragm is positioned at the top dead center. This

will help unseat the edge of the diaphragm. If required, push up from underneath the diaphragm or use a non-

metallic tool to pry up the diaphragm from the housing groove. Do not scratch the head components. Unscrew the

old diaphragm (050) by turning it counterclockwise using both hands. Lift up and grip the edges of the diaphragm at

10 and 4 o’clock. High initial force may be required to break the diaphragm loose. DO NOT use tools! (Note: - Take

care not to lose any shim ring(s) (060) positioned between the diaphragm support cup (040) and connecting rod, as

the exact number of shim ring(s) must be used during re-assembly.) While unscrewing the diaphragm with one hand,

use your other hand to secure the support cup and shim ring(s) onto the diaphragm stud. Lift the diaphragm (050),

support cup (040) and shim ring(s) (060) from the pump. The compressor housing cover must be removed to gain

access to and secure the support cup and shim ring(s) onto the stud. Note: the quantity and thickness of shim ring(s)

will vary from pump to pump. Parts removed must be replaced exactly as found. If repairing multiple pumps, take

care not to mix parts.

Assembly with new diaphragm and valveplate:

1. Place the parts removed in step 7 above onto the threaded stud of the new diaphragm. Carefully screw the new

diaphragm (050) into the connecting rod. Secure the support cup and small parts onto the diaphragm stud using a

technique similar to that used during removal. It is helpful to hold the connecting rod at a slight angle until the threads

are started. Spin the diaphragm on until it is snug. Lift and grip the edges of the diaphragm at 7 and 2 o’clock and

tighten firmly using both hands. DO NOT use tools!

(TIP: If the pump is loose and not mounted, position and hold the pump with the motor shaft vertical when starting the

threaded diaphragm stud into the connecting rod. This helps to prevent the small parts from falling off the stud.)

2. Turn the fan until the diaphragm is flat across (mid-point of the stroke). With the diaphragm centered over the

compressor housing, firmly seat the diaphragm edge into the compressor housing groove.

3. Place the clean intermediate plate (020) onto the compressor housing using the reference mark made earlier to insure

the correct orientation. Then place the new valveplate (030) on top of the intermediate plate.

4. Place the clean headplate (010) on top of the intermediate plate (020) using the reference mark made earlier to insure

the correct orientation. Tighten the four head screws (070) snugly in a diagonal pattern and then tighten to a

maximum torque of 6-7 inch-lbs. Turn the fan by hand to confirm that the pump turns freely.

5. Replace the compressor housing cover and gasket. Install the four cover screws. Do not over-tighten.

6. If the fittings are removed from the headplate: Remove any old Teflon® tape from all fittings. Carefully apply two

layers of Teflon® tape around any fittings before reinstalling into the pump head. Install the tubing and fittings as

previously sketched in step 1 above.

7. Do not apply tape beyond threads, as excess tape may tear off and lodge in the valves. Do not substitute any other

type of tape. Do not over-tighten metal fittings.

Air Quality Instruments. 27 Forge Parkway (508) 520-0430 www.thermoscientific.com/aqi

Franklin, MA (866) 282-0430

02038 (508) 520-2800 fax

Diaphragm and Valve Replacement Procedure for Thermo Scientific # 101426-00

SHIMS UNDER DIAPHRAGM ARE REQUIRED

(KNF # PU1959-N86-3.07)

Tools and Materials required:

• Thermo Scientific Pump Rebuild Kit #108002-00 • Marking pencil or marker

• #1 Phillips head screwdriver • 2.5 mm Allen Wrench

Exploded View of Compressor Housing:

Exploded View of Pump Head:

Disassembly:

1. Disconnect the pump from electrical power. Make a sketch of the position of any tubes and fittings for ease of re-

assembly later.

2. Mark the position of the pump head plate (A), intermediate plate (B) and compressor housing relative to each other by

drawing a line on the edges with a pencil or marker to insure proper re-assembly.

3. The aluminum compressor housing cover must be removed to gain access to the inside of the compressor housing.

Remove the four screws and then remove the cover. Re-use any gasketing. Remove any debris that may have

accumulated in the bottom of the compressor housing.

4. Remove the four screws (G), spring washers (H) and flat washers (J) and remove the head plate (A). Note the

positioning of the valve plate (C) relative to the valve ports on the head plate (A) and intermediate plate (B). Lift off the

valve plate (C).

5. Remove the intermediate plate (B).

6. Check that all parts are free from dirt and clean as necessary. DO NOT scratch the parts.

7. Removal of the old diaphragm (D): Rotate the fan so that the diaphragm is positioned at the top dead center. This will

help unseat the edge of the diaphragm. If required, push up from underneath the diaphragm or use a non-metallic

tool to pry up the diaphragm from the housing groove. Do not scratch the head components. Unscrew the old

diaphragm (D) by turning it counterclockwise using both hands. Lift up and grip the edges of the diaphragm at 10 and

4 o’clock. High initial force may be required to break the diaphragm loose. DO NOT use tools! (Note: - Take care

not to lose any shim ring(s) (F) positioned between the diaphragm support cup (E) and connecting rod, as the exact

number of shim ring(s) must be used during re-assembly.) While unscrewing the diaphragm with one hand, use your

other hand to secure the support cup and shim ring(s) onto the diaphragm stud. Lift the diaphragm (D), support cup

(E) and shim ring(s) (F) from the pump. The compressor housing cover must be removed to gain access to and

secure the support cup and shim ring(s) onto the stud. Note: the quantity and thickness of shim ring(s) will vary from

pump to pump. Parts removed must be replaced exactly as found. If repairing multiple pumps, take care not to mix

parts.

Assembly with new diaphragm and valve plate:

1. Place the parts removed in step 7 above onto the threaded stud of the new diaphragm. Carefully screw the new

diaphragm (D) into the connecting rod. Secure the support cup and small parts onto the diaphragm stud using a

technique similar to that used during removal. It is helpful to hold the connecting rod at a slight angle until the threads

are started. Spin the diaphragm on until it is snug. Lift and grip the edges of the diaphragm at 7 and 2 o’clock and

tighten firmly using both hands. DO NOT use tools!

(TIP: If the pump is loose and not mounted, position and hold the pump with the motor shaft vertical when starting the

threaded diaphragm stud into the connecting rod. This helps to prevent the small parts from falling off the stud.)

2. Turn the fan until the diaphragm is flat across (mid-point of the stroke). With the diaphragm centered over the

compressor housing, firmly seat the diaphragm edge into the compressor housing groove.

3. Place the clean intermediate plate (B) onto the compressor housing using the reference mark made earlier to insure

the correct orientation. Then place the new valve plate (C) on top of the intermediate plate.

4. Place the clean head plate (A) on top of the intermediate plate (B) using the reference mark made earlier to insure the

correct orientation. Tighten the four head screws (G) snugly in a diagonal pattern and then tighten to a maximum

torque of 6-7 inch-lbs. Turn the fan by hand to confirm that the pump turns freely.

5. Replace the compressor housing cover and gasket. Install the four cover screws. Do not over-tighten.

6. Remove any old Teflon® tape from all fittings. Carefully apply two layers of Teflon® tape around any fittings before

reinstalling into the pump head. Install the tubing and fittings as previously sketched in step 1 above.

7. Do not apply tape beyond threads, as excess tape may tear off and lodge in the valves. Do not substitute any other

type of tape. Do not over-tighten metal fittings.

Air Quality Instruments. 27 Forge Parkway (508) 520-0430 www.thermoscientific.com/aqi

Franklin, MA (866) 282-0430

02038 (508) 520-2800 fax

Diaphragm and Valve Replacement Procedure for

Thermo Scientific # 111553-00 and 111553-01

NO SHIMS REQUIRED

(KNF # PU2737-N86)

Tools and Materials required:

• Thermo Scientific Pump Rebuild Kit #108002-00 • Marking pencil or marker

• #1 Phillips head screwdriver • 2.5 mm Allen Wrench

Exploded View of Compressor Housing: Exploded View of Pump Head:

Disassembly:

1. Disconnect the pump from electrical power. Make a sketch of the position of any tubes and fittings for ease of re-

assembly later.

2. Mark the position of the pump headplate, intermediate plate and compressor housing relative to each other by drawing

a line on the edges with a pencil or marker to ensure proper re-assembly.

3. The aluminum compressor housing covers must be removed to gain access to the inside of the compressor housing.

Remove the screws and then remove the covers. Re-use the gasket material. Remove any debris that may have

accumulated in the bottom of the compressor housing.

4. Remove the four socket cap screws and remove the headplate. Note the positioning of the valve plate relative to the

valve ports on the head plate and intermediate plate. Lift off the valve plate.

5. Remove the intermediate plate.

6. Check that all parts are free from dirt and clean as necessary. Remove any Teflon® tape from the head plate ports.

DO NOT scratch the parts.

7. Removal of the old structured diaphragm: Rotate the fan so that the diaphragm is positioned at the top dead center.

This will help unseat the edge of the diaphragm. If required, push up from underneath the diaphragm or use a non-

metallic tool to pry up the diaphragm from the housing groove. Do not scratch the head components. Lift up and grip

the edges of the diaphragm at 10 and 4 o’clock. Unscrew the old diaphragm by turning it counterclockwise using both

hands. High initial force may be required to break the diaphragm loose. DO NOT use tools! Lift the diaphragm from

the pump. Parts removed must be replaced exactly as found. If repairing multiple pumps, take care not to mix parts.

Assembly with new diaphragm and valve plate:

1. Carefully screw the new diaphragm (no shims are needed) into the connection rod. It is helpful to hold the connecting

rod at a slight angle until the threads are started. Spin the diaphragm on until it is snug. Secure the diaphragm stud

using a technique similar to that used during removal. Lift and grip the edges of the diaphragm at 7 and 2 o’clock and

tighten firmly using both hands. DO NOT use tools!

2. Turn the fan until the diaphragm is flat across (mid-point of the stroke). With the diaphragm centered over the

compressor housing, firmly seat the diaphragm edge into the compressor housing groove.

3. Place the clean intermediate plate onto the compressor housing using the reference mark made earlier to ensure the

correct orientation. Then place the new valve plate on top of the intermediate plate.

4. Place the clean head plate on top of the intermediate plate using the reference mark made earlier to ensure the

correct orientation. Tighten the four socket cap screws snugly in a diagonal pattern and then tighten to a maximum

torque of 6-7 inch-lbs. Turn the fan by hand to confirm the pump turns freely.

5. Replace the compressor housing covers with gasket and install the cover screws. Do not over-tighten.

6. Remove any old Teflon® tape from all fittings. Carefully apply two layers of Teflon® tape around any fittings. Do not

apply tape beyond threads, as excess tape may tear off and lodge in the valves. Do not substitute any other type of

tape.

7. Reinstall fittings into the pump head. Do not over-tighten fittings.

Air Quality Instruments. 27 Forge Parkway (508) 520-0430 www.thermoscientific.com/aqi

Franklin, MA (866) 282-0430

02038 (508) 520-2800 fax

P/N 112021-00 Shock Bumper Kit Installation Instructions

Remove adhesive backing from the Shock Bumpers (P/N TR101RP) and locate them on the

floor plate approximately at the locations called out below on Figures 1 and 2. Five (5)

Shock Bumpers are required per each installation.

PUMP P/N'S 101426-00 & 111553-00 and 111553-01

FIGURE 1

PUMP P/N'S 102639-00 & 101011-00 and 101011-01

FIGURE 2

If you have any questions about this bulletin or require technical assistance, please

contact your local distributor or our Technical Support team via telephone at (508)

520-0430 or by e-mail at AQIservice@thermofisher.com.

Air Quality Instruments. 27 Forge Parkway (508) 520-0430 www.thermoscientific.com/aqi

Franklin, MA (866) 282-0430

02038 (508) 520-2800 fax

You might also like

- 大型蓄能器Document39 pages大型蓄能器HayLenLeeNo ratings yet

- EDocument23 pagesEUliAlejandroRodriguezCorianga100% (2)

- Experiment 8 RefractometerDocument7 pagesExperiment 8 RefractometerJoshua80% (5)

- Evaporator Data Sheet - SKO0501049 Rev0Document10 pagesEvaporator Data Sheet - SKO0501049 Rev0chublackNo ratings yet

- Final Drawings Incl. Installation & Instruction Manual:: H2712: Hyundai Mipo Dockyard Co., Ltd. Hull No. CustomerDocument190 pagesFinal Drawings Incl. Installation & Instruction Manual:: H2712: Hyundai Mipo Dockyard Co., Ltd. Hull No. CustomerThomas Liontos100% (1)

- Spare Parts Master N (8105.181)Document20 pagesSpare Parts Master N (8105.181)Julian M. AndrettiNo ratings yet

- Data Mould/Tooling Pt. Inoac Polytechno Indonesia: Part Code Part Name Year CustomerDocument15 pagesData Mould/Tooling Pt. Inoac Polytechno Indonesia: Part Code Part Name Year CustomerEgbert ManggalaNo ratings yet

- A537 4010 1005 Enq Rev0Document293 pagesA537 4010 1005 Enq Rev0jayakumar100% (1)

- Service BulletinDocument9 pagesService BulletinjussmeeeNo ratings yet

- JCI Cataloge 2014Document60 pagesJCI Cataloge 2014KAZIMALI25No ratings yet

- Pilot System Pressure - TestDocument4 pagesPilot System Pressure - Testالبراق للتوريدات وصيانة المعداتNo ratings yet

- Quincy CompressorDocument112 pagesQuincy CompressorRichard EV100% (2)

- Servicemanual Panasonic kv-s5046h 5076h s8Document8 pagesServicemanual Panasonic kv-s5046h 5076h s8Ralf KöhlerNo ratings yet

- Gardner Denver QD2500Q QD2500HD Fluid End Parts ListDocument37 pagesGardner Denver QD2500Q QD2500HD Fluid End Parts ListG SchmidtNo ratings yet

- Dokumen - Tips - Ve Pump Denso Repair ManualDocument32 pagesDokumen - Tips - Ve Pump Denso Repair Manualko koNo ratings yet

- EDocument34 pagesEEdinson Ariel Chavarro Quintero100% (1)

- Transmittal # - AQS-DAN-SUB-0005 - Rev.00Document2 pagesTransmittal # - AQS-DAN-SUB-0005 - Rev.00AchRaf OudjertniNo ratings yet

- So21970 Engine Parts Catalog: Shandong Lingong Construction Machinery Co.,LtdDocument156 pagesSo21970 Engine Parts Catalog: Shandong Lingong Construction Machinery Co.,LtdBazzie100% (1)

- Service Replacements For Noncurrent Piston Pumps 6E-1278 120G 4HDDocument15 pagesService Replacements For Noncurrent Piston Pumps 6E-1278 120G 4HDpacman2803No ratings yet

- Goodrich Actuation Systems Sas A Utc Aerospace Systems Company Product Support DepartmentDocument14 pagesGoodrich Actuation Systems Sas A Utc Aerospace Systems Company Product Support Departmentrobertas negudinasNo ratings yet

- DC4012 Literature Pop-A-Plug IIDocument2 pagesDC4012 Literature Pop-A-Plug IIyusoffdNo ratings yet

- Start HereDocument23 pagesStart HereAntónio Correia100% (2)

- Catalogo Condensato 2019 Revisione 18 10 2019Document217 pagesCatalogo Condensato 2019 Revisione 18 10 2019phankhoa83-1No ratings yet

- 62-02460 - Rev - C - Manual de Peças, Compressor 05KDocument19 pages62-02460 - Rev - C - Manual de Peças, Compressor 05KBianca PinudoNo ratings yet

- KENCODocument2 pagesKENCOIDA HAMIDAHNo ratings yet

- T20000 SeriesDocument11 pagesT20000 Seriesandrés florentin pizarro lazarteNo ratings yet

- LIT2663 R3 Link Belt Service BulletinDocument3 pagesLIT2663 R3 Link Belt Service BulletinBimo Cungkring IINo ratings yet

- 2T75H Parts Catalog (For Toyota)Document63 pages2T75H Parts Catalog (For Toyota)Галина КарташоваNo ratings yet

- Lista de Partes Bomba MATADORDocument18 pagesLista de Partes Bomba MATADORmauro_pmNo ratings yet

- Planos Electrico Champion KB44Document195 pagesPlanos Electrico Champion KB44mitchellltdaNo ratings yet

- Indesit Wt100csiDocument48 pagesIndesit Wt100csimarc_2ice@yahoo.comNo ratings yet

- Sykes Pump BookletDocument105 pagesSykes Pump BooklethipsterzNo ratings yet

- Ve Pump Denso Repair Manual PDFDocument32 pagesVe Pump Denso Repair Manual PDFNikola Mitev100% (2)

- 642 (r09)Document62 pages642 (r09)Kevin MillaNo ratings yet

- K 20009, K 20010, K 20011, K 78076, K 78077, K 78078, K 20341 (1288805)Document21 pagesK 20009, K 20010, K 20011, K 78076, K 78077, K 78078, K 20341 (1288805)Lê Duy NguyễnNo ratings yet

- E381b215ak601 (VLG0938L F0600203-VLG0938L F0600323) PDFDocument353 pagesE381b215ak601 (VLG0938L F0600203-VLG0938L F0600323) PDFadelmomouraNo ratings yet

- Prueba de Chorreo de Valvula de AlivioDocument4 pagesPrueba de Chorreo de Valvula de AlivioCarlos GomezNo ratings yet

- 30168700Document38 pages30168700gr8rlNo ratings yet

- Catalogo Produtos WeiyuanDocument153 pagesCatalogo Produtos WeiyuanVENDAS HDNo ratings yet

- COMPRESORES q370Document118 pagesCOMPRESORES q370Aldebaran AlcazarNo ratings yet

- Relief Valve (Torque Converter Inlet) Pressure - TestDocument5 pagesRelief Valve (Torque Converter Inlet) Pressure - TestMARTIN GONZALEZNo ratings yet

- Servicing The Outlet Check Plugs On The Fuel Injection Pump On C6.6 and C4.4 Engines (1251, 1290)Document5 pagesServicing The Outlet Check Plugs On The Fuel Injection Pump On C6.6 and C4.4 Engines (1251, 1290)teobaldo criatian silva casca100% (1)

- 2018 RETAIL Price UPDATED 1 19 18Document362 pages2018 RETAIL Price UPDATED 1 19 18tylerNo ratings yet

- Alco To Parker To San Hua Unloader Valve MB Draft Rev 4-13-18!1!1 en Us 4284396Document6 pagesAlco To Parker To San Hua Unloader Valve MB Draft Rev 4-13-18!1!1 en Us 4284396EduardoNo ratings yet

- Cat Konik 9Document11 pagesCat Konik 9Soma GhoshNo ratings yet

- TOX Powerpackage-line-Q 10Q 201404 enDocument4 pagesTOX Powerpackage-line-Q 10Q 201404 enPurece EugenNo ratings yet

- ppt260 Parts Catalog Serial Number E09113001001e09113999999Document44 pagesppt260 Parts Catalog Serial Number E09113001001e09113999999NunoNo ratings yet

- 15-ScanJet SC 15TW Instruction ManualDocument43 pages15-ScanJet SC 15TW Instruction Manualogurmehmetali07No ratings yet

- Blackmer Tx15 To Tx4aDocument24 pagesBlackmer Tx15 To Tx4aedwinramonNo ratings yet

- Parts Manual EP16N-20CN 98753-32100Document248 pagesParts Manual EP16N-20CN 98753-32100ea5hkehotmail.comNo ratings yet

- 03-2016-061 (Evia)Document13 pages03-2016-061 (Evia)Abelardo BrazilNo ratings yet

- Denison (P6, P7, P8, P11, P14, P24, P30) Axial Piston PumpsDocument11 pagesDenison (P6, P7, P8, P11, P14, P24, P30) Axial Piston Pumpsfrancisco50% (2)

- Invoice # 1Document2 pagesInvoice # 1Fadi YasinNo ratings yet

- Hydraulic ClutchDocument12 pagesHydraulic Clutchmrkadu_610% (1)

- PR-378 Process Detailed Engineering Support Rev B - UnpricedDocument7 pagesPR-378 Process Detailed Engineering Support Rev B - UnpricedmatsuruNo ratings yet

- VERTICUS 5 (K12.14) (2013 Till End of 2017) : Version 05/2019Document4 pagesVERTICUS 5 (K12.14) (2013 Till End of 2017) : Version 05/2019BRUNONo ratings yet

- Aw60 40le Zip in PDFDocument10 pagesAw60 40le Zip in PDFBrian Torres90% (10)

- Ceg Elettronica - Master FileDocument24 pagesCeg Elettronica - Master FilePHAM PHI HUNGNo ratings yet

- Algebra Bald OrcDocument7 pagesAlgebra Bald OrcGilberto Morales CaldasNo ratings yet

- KMC Master Crossreference 6-12-17Document307 pagesKMC Master Crossreference 6-12-17Paul RyanNo ratings yet

- Alpha Motor Driven Diaphragm Metering Pumps Spare PartsDocument2 pagesAlpha Motor Driven Diaphragm Metering Pumps Spare PartsFarhan MalekNo ratings yet

- Alignment TolerancesDocument7 pagesAlignment TolerancesFarhan MalekNo ratings yet

- Flowrun Pump 11Document12 pagesFlowrun Pump 11Farhan MalekNo ratings yet

- P000216 Hypoid Gear Oil (GL5) SAE 85W 90 49 en - GBDocument1 pageP000216 Hypoid Gear Oil (GL5) SAE 85W 90 49 en - GBFarhan MalekNo ratings yet

- 02 Port of Ras TanuraDocument30 pages02 Port of Ras TanuraFarhan MalekNo ratings yet

- Brylle Teves - InclinedPlaneSimpleMachineSEDocument9 pagesBrylle Teves - InclinedPlaneSimpleMachineSEThe odd savageNo ratings yet

- I Am SubstanceDocument2 pagesI Am SubstanceART JOSHUA MARANo ratings yet

- Petrochem Engineering ScheDocument158 pagesPetrochem Engineering ScheDobariya Poonam Dobariya PoonamNo ratings yet

- Rolls Royce Kamewa WaterjetsDocument23 pagesRolls Royce Kamewa WaterjetscharlyNo ratings yet

- Chm131 Chapter 1 Atoms Molecules Ions Chemical EqDocument106 pagesChm131 Chapter 1 Atoms Molecules Ions Chemical EqAdibah Qistina QistinaNo ratings yet

- Sus 306 - Aisi 306Document24 pagesSus 306 - Aisi 306Jacob StrifeNo ratings yet

- (R. Felder, R. Rousseau) Elementary Principles ofDocument13 pages(R. Felder, R. Rousseau) Elementary Principles ofAli AshrafNo ratings yet

- Scaffold Safe Working Load Normal Value and CalculationDocument6 pagesScaffold Safe Working Load Normal Value and CalculationAda LaurelNo ratings yet

- Centrifugal PumpDocument11 pagesCentrifugal PumpJamie Shane DemosthenousNo ratings yet

- 0.0 Daily Report Juli TB. Bomas Profit - WB 358 P S JDocument25 pages0.0 Daily Report Juli TB. Bomas Profit - WB 358 P S JLCT MITRA SEJATI 07 KENDARINo ratings yet

- Halogen Bonding in Perovskite Solar Cells A New Tool For Improving Solar EnergyDocument8 pagesHalogen Bonding in Perovskite Solar Cells A New Tool For Improving Solar EnergyAnonymous hz3n3HK1RNNo ratings yet

- Zohnson Price For Led t8 Tubes-2020.01Document16 pagesZohnson Price For Led t8 Tubes-2020.01Ekhlas SayeedNo ratings yet

- Tesis PDFDocument120 pagesTesis PDFdaniel sernaNo ratings yet

- XXX 2111Document9 pagesXXX 2111Jhon IzaguirreNo ratings yet

- Linear Vs Non-Linear AnalysisDocument6 pagesLinear Vs Non-Linear AnalysisMithun DNo ratings yet

- LAS 1.1 Science 8 Forces On Object at RestDocument2 pagesLAS 1.1 Science 8 Forces On Object at RestRuby rubellsNo ratings yet

- EENG 271 Signals and Systems: Linear FunctionDocument13 pagesEENG 271 Signals and Systems: Linear Functionmohammed alansariNo ratings yet

- VAC Science and Society Lecture Notes Part 1Document99 pagesVAC Science and Society Lecture Notes Part 1aarush aryaNo ratings yet

- MPZ Operating ManualDocument48 pagesMPZ Operating Manualweslley.luzNo ratings yet

- Metal Halides. LampsDocument13 pagesMetal Halides. LampsJohnFred CativoNo ratings yet

- Ilaya Bharathi M 714021413001 2021 31 - May - 1998 Male APR 2022 M.E. - Structural EngineeringDocument10 pagesIlaya Bharathi M 714021413001 2021 31 - May - 1998 Male APR 2022 M.E. - Structural EngineeringRaguRamanNo ratings yet

- Biomedical EPR - Part A - Free Radicals, Metals, Medicine and PhysiologyDocument536 pagesBiomedical EPR - Part A - Free Radicals, Metals, Medicine and PhysiologypauloNo ratings yet

- January 2009 MS - M3 OCRDocument4 pagesJanuary 2009 MS - M3 OCRyuviyuktNo ratings yet

- FLOW MEASUREMENT - Course NotesDocument38 pagesFLOW MEASUREMENT - Course Notespawan deepNo ratings yet

- Study of Hydraulic Machines: Reaction TurbinesDocument16 pagesStudy of Hydraulic Machines: Reaction TurbinesSatyendra VishwakarmaNo ratings yet

- 3.3a VSEPR Theory PDFDocument21 pages3.3a VSEPR Theory PDFSarvesh Kanaujia100% (8)

- Unit-3 Forensic Chemistry 2ND YearDocument8 pagesUnit-3 Forensic Chemistry 2ND YearAfable MaricrisNo ratings yet

- MTC 5Document1 pageMTC 5Muthazhagan SaravananNo ratings yet

- Fabricators For Cryogenic Pressure VesselsDocument1 pageFabricators For Cryogenic Pressure VesselsIshaan JindalNo ratings yet