Professional Documents

Culture Documents

Unit Pu - Abbreviations and General Notes

Unit Pu - Abbreviations and General Notes

Uploaded by

AKHIL RAJCopyright:

Available Formats

You might also like

- Briggs Engine Failure GuideDocument50 pagesBriggs Engine Failure GuideWILKILM83% (12)

- Conduction Problems & Solutions Conduction Problems & SolutionsDocument30 pagesConduction Problems & Solutions Conduction Problems & SolutionsRoronoaNo ratings yet

- Heat Recovery Steam Generator Operation ManualDocument45 pagesHeat Recovery Steam Generator Operation ManualReyes Sanchez100% (2)

- 4300 VZ DM Pu0001000 01 IspDocument1 page4300 VZ DM Pu0001000 01 IspreachgscommNo ratings yet

- 180 R Iso 46000 001 - RCDocument8 pages180 R Iso 46000 001 - RCvigneshNo ratings yet

- JO003-10-LB - MDD-IDM-001-3 P&ID Steam and Bypass SystemDocument9 pagesJO003-10-LB - MDD-IDM-001-3 P&ID Steam and Bypass SystemHasan MustafaNo ratings yet

- General Notes: / B RCA-F-001-ADocument55 pagesGeneral Notes: / B RCA-F-001-Acarmela alburqueque100% (1)

- Isometric View Lifting Detail: NotesDocument2 pagesIsometric View Lifting Detail: NotesRajveer SinghNo ratings yet

- 4300 AI DU 126100001 - Q Combined PDFDocument5 pages4300 AI DU 126100001 - Q Combined PDFSaid AlzamarehNo ratings yet

- Pm210011-Nui900-Rd2-00026 - 01 - Slab On Grade - Grade Beam SCH, Sec & Details...Document1 pagePm210011-Nui900-Rd2-00026 - 01 - Slab On Grade - Grade Beam SCH, Sec & Details...MOHAMMAD JAKARIA HASANNo ratings yet

- Double Cut Tee Plan Brace Connection On Beam WebDocument1 pageDouble Cut Tee Plan Brace Connection On Beam WebRajveer SinghNo ratings yet

- Pm210011-Nui900-Rd2-00025 - 01 - Raft Foundation Section, Column & Wall Deta...Document1 pagePm210011-Nui900-Rd2-00025 - 01 - Raft Foundation Section, Column & Wall Deta...MOHAMMAD JAKARIA HASANNo ratings yet

- HVAC Schematic Drawing - WMO Rev ADocument2 pagesHVAC Schematic Drawing - WMO Rev Aarief bahtiarNo ratings yet

- Isolation Package For 25-T-01: Remove SpoolDocument2 pagesIsolation Package For 25-T-01: Remove SpoolAdel Moustafa NafrawyNo ratings yet

- Structural Engineering DrawingsDocument7 pagesStructural Engineering DrawingsObaidullah ObaidNo ratings yet

- PEDWPRTS771025A1 - Main Compressor B Train 1 - 5Document1 pagePEDWPRTS771025A1 - Main Compressor B Train 1 - 5macielNo ratings yet

- 9 Sketch Shear ConnectionDocument1 page9 Sketch Shear ConnectionER Deepak SutharNo ratings yet

- The Basic Balanced Scorecard TemplateDocument2 pagesThe Basic Balanced Scorecard TemplateomzoerNo ratings yet

- 2047 1803 Est Dla 7012 - ADocument1 page2047 1803 Est Dla 7012 - ArameshbathalaNo ratings yet

- 3 P 132 9301 1a3a N 01 - Rev01Document1 page3 P 132 9301 1a3a N 01 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- Schedule of Member Splice Connection Notes:: F H G E D C B ADocument1 pageSchedule of Member Splice Connection Notes:: F H G E D C B ARajveer SinghNo ratings yet

- FGP Legend Sheets May 15Document20 pagesFGP Legend Sheets May 15erzhik1997No ratings yet

- Mwihoko 3DDocument1 pageMwihoko 3DNewtonNo ratings yet

- Obtuse Corner Acute and Perpendicular Corner: Match The Slope of The GirderDocument1 pageObtuse Corner Acute and Perpendicular Corner: Match The Slope of The GirderProfessor PuppiesNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozNo ratings yet

- Acp Master P&id Oct 20 NewDocument65 pagesAcp Master P&id Oct 20 NewAhmedNo ratings yet

- 3 P 132 9401 1a3a N 03 - Rev01Document1 page3 P 132 9401 1a3a N 03 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- P203 Sie DWG 008 Arc 600010Document1 pageP203 Sie DWG 008 Arc 600010viswanathanNo ratings yet

- Construction NotesDocument1 pageConstruction NotesAthanNo ratings yet

- Plano ASPRODocument1 pagePlano ASPROMiguel Angel Cardozo MolinaNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozNo ratings yet

- N 665.500 Drawing Limit C ROAD N 662.000 L: Model Need To UpdateDocument2 pagesN 665.500 Drawing Limit C ROAD N 662.000 L: Model Need To UpdatephanikrishnabNo ratings yet

- 3 P 132 9501 1a3a N 02 - Rev01Document1 page3 P 132 9501 1a3a N 02 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- 21BP002-351-DD0-1GR020 - R0 - GirderDocument1 page21BP002-351-DD0-1GR020 - R0 - GirderDang TranNo ratings yet

- Contrato Vertical Contrato Teck: Job No. 25800Document1 pageContrato Vertical Contrato Teck: Job No. 25800Gabriel PulidoNo ratings yet

- SS-1 Deep Well Earth PitDocument1 pageSS-1 Deep Well Earth PitM&N ProjectsNo ratings yet

- 5-2-4 LOGIQ E9 Overall Block Diagram (Cont'd)Document1 page5-2-4 LOGIQ E9 Overall Block Diagram (Cont'd)Nguyen TanNo ratings yet

- 03 FinalDocument1 page03 FinalMeghana NavuluruNo ratings yet

- RB A225 Approval Rev 1 - 10 10Document1 pageRB A225 Approval Rev 1 - 10 10TariqMahmoodNo ratings yet

- Hoist Way Plans - Tower A - Basement 1: Under CoordinationDocument1 pageHoist Way Plans - Tower A - Basement 1: Under Coordinationprasahnthrk07No ratings yet

- 907-Q-PED-50002-001: General Arrangement Drawing SLEEPER WAY 907-SL-100Document1 page907-Q-PED-50002-001: General Arrangement Drawing SLEEPER WAY 907-SL-100KhaleelNo ratings yet

- Major1107202x12.2pscslab V4 Approve P11Document1 pageMajor1107202x12.2pscslab V4 Approve P11rushi123No ratings yet

- Odisha Studio - Acoustic - Floor Plan - 25-4-24Document1 pageOdisha Studio - Acoustic - Floor Plan - 25-4-24tahasildarjanardhanNo ratings yet

- 773F & 773F OEM Quarry Truck Hydraulic System 775F & 775F OEM Off-Highway TruckDocument2 pages773F & 773F OEM Quarry Truck Hydraulic System 775F & 775F OEM Off-Highway TruckVictor Rivera EspejoNo ratings yet

- SCU-2290-PP-XIS-320134 - 3 FirmadoDocument6 pagesSCU-2290-PP-XIS-320134 - 3 FirmadoCristopher MosqueiraNo ratings yet

- Amueblado Pottery Barn Leon Plaza MayorDocument1 pageAmueblado Pottery Barn Leon Plaza MayorethelNo ratings yet

- Grand l21 Scut Roa 20201209Document1 pageGrand l21 Scut Roa 20201209Ricardo Alejandro Oyarce ArmijoNo ratings yet

- I-DE-3010.92-1263-944-OVX-001 - Hypocloride AftDocument1 pageI-DE-3010.92-1263-944-OVX-001 - Hypocloride AftAdalton BritoNo ratings yet

- ER-HW-SEC-20 - Estado Reformado - Secciones GeneralesDocument1 pageER-HW-SEC-20 - Estado Reformado - Secciones GeneralesYoni BacaNo ratings yet

- Vermer PipeDocument4 pagesVermer PipeVermer FabregasNo ratings yet

- EASTWICK SITE 68 THE GATES APPROVED SUBMISSION DRAWINGS 30 04 20 Site Plan and Loft 1Document1 pageEASTWICK SITE 68 THE GATES APPROVED SUBMISSION DRAWINGS 30 04 20 Site Plan and Loft 1kimNo ratings yet

- Pimple Saudagar-Rccd - (13-05-19)Document4 pagesPimple Saudagar-Rccd - (13-05-19)Yogesh ChaudhariNo ratings yet

- Preliminary: Drawings NotesDocument1 pagePreliminary: Drawings Notesbatopotcholo03No ratings yet

- CITIIS PEDAWALTAIR School ARCHDocument21 pagesCITIIS PEDAWALTAIR School ARCHKingSantoshNo ratings yet

- B Block PitDocument1 pageB Block PitAPS DESIGN INFRA PVT.LTD.No ratings yet

- A31.1 Fourth Floor Furniture Wing-1Document1 pageA31.1 Fourth Floor Furniture Wing-1Azkagul 28No ratings yet

- A31.1 Fourth Floor Furniture Wing-1Document1 pageA31.1 Fourth Floor Furniture Wing-1Azkagul 28No ratings yet

- Ol1 2G43 0020 3 PidDocument1 pageOl1 2G43 0020 3 PidBình VănNo ratings yet

- ZX110to130LCN CIRCUITDocument17 pagesZX110to130LCN CIRCUITSaul Baquero Quevedo100% (2)

- ER-HW-SEC-20-Estado Reformado. Secciones Generales PDFDocument1 pageER-HW-SEC-20-Estado Reformado. Secciones Generales PDFrafaell474No ratings yet

- CAI - DWG-S-DD-S-W2-1001 Piling Plan - r1Document1 pageCAI - DWG-S-DD-S-W2-1001 Piling Plan - r1Ikade SuartanaNo ratings yet

- 1-MEPs-ELECT-LTG-B4&7-0001 (SH 1-1) - R-2 (FND Reviewed) - LTG-B4-0001Document1 page1-MEPs-ELECT-LTG-B4&7-0001 (SH 1-1) - R-2 (FND Reviewed) - LTG-B4-0001muzeek306No ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Fire Water LineDocument1 pageFire Water LineAKHIL RAJNo ratings yet

- 4300 NCR NSH 010Document4 pages4300 NCR NSH 010AKHIL RAJNo ratings yet

- TEST MANIFOLD ModelDocument1 pageTEST MANIFOLD ModelAKHIL RAJNo ratings yet

- Po - Sub-System (Ug)Document43 pagesPo - Sub-System (Ug)AKHIL RAJNo ratings yet

- HMT 2marksDocument85 pagesHMT 2marksyogesh sNo ratings yet

- Physics: Heat TransferDocument18 pagesPhysics: Heat TransferDuncan KingNo ratings yet

- Developing A MATLAB Model For Flat Solar CollectorsDocument7 pagesDeveloping A MATLAB Model For Flat Solar Collectorsgonzalez2678No ratings yet

- Internal Energy and Energy Transfers 2Document39 pagesInternal Energy and Energy Transfers 2muhammadshadid4No ratings yet

- Exhaust Mount Christie & Grey Pl003-Issue-l-crmDocument4 pagesExhaust Mount Christie & Grey Pl003-Issue-l-crmResul UygunNo ratings yet

- H2 Type Direct Fire Chiller Operation ManualDocument79 pagesH2 Type Direct Fire Chiller Operation ManualPoon Yew ChanNo ratings yet

- Belzona 3211Document2 pagesBelzona 3211Bobby SatheesanNo ratings yet

- Insulation of Marine Piping and EquipmentDocument2 pagesInsulation of Marine Piping and EquipmentNicoletaNo ratings yet

- 5 2 ICAIIT 2024 Part 2 Paper 15Document7 pages5 2 ICAIIT 2024 Part 2 Paper 15kimtinh18012005No ratings yet

- Mil STD 2223Document96 pagesMil STD 2223Standards IndiaNo ratings yet

- CEL 18663 UK 003 MS01 - Rev A0Document8 pagesCEL 18663 UK 003 MS01 - Rev A0TASNEEMNo ratings yet

- (AHU) Clivet AHU and Modular Air Handling UnitDocument27 pages(AHU) Clivet AHU and Modular Air Handling UnitDoniNo ratings yet

- Frost Protected Shallow Foundations FINALDocument4 pagesFrost Protected Shallow Foundations FINALDarren Winslow0% (1)

- Energy Audit: Unit - 2Document61 pagesEnergy Audit: Unit - 2Nikhil TiruvaipatiNo ratings yet

- Thermashield PDFDocument8 pagesThermashield PDFromeo pedranoNo ratings yet

- Basics Roof ConstructionDocument76 pagesBasics Roof ConstructionPeixuan Xu100% (1)

- Unit 2 FinalDocument58 pagesUnit 2 Finalshankar kmNo ratings yet

- Thermal Insulation Materials Made of Rigid Polyurethane FoamDocument33 pagesThermal Insulation Materials Made of Rigid Polyurethane FoamAdrian MorarNo ratings yet

- Stress Relieving Procedure 01Document6 pagesStress Relieving Procedure 01VikasShelkeNo ratings yet

- Extreme Temperature ClothingDocument16 pagesExtreme Temperature ClothingNeeraj BalaNo ratings yet

- Manuscript Design Fabrication and Testing of A Biomass Insulated Cooking PotDocument99 pagesManuscript Design Fabrication and Testing of A Biomass Insulated Cooking PotwahahahhasiafiadgNo ratings yet

- Lab Manual: Heat Transfer Lab 5ME4-22 Mechanical Engineering YearDocument68 pagesLab Manual: Heat Transfer Lab 5ME4-22 Mechanical Engineering YearAbhishek SNo ratings yet

- Astmc 411 - 97Document4 pagesAstmc 411 - 97Yogesh BalarNo ratings yet

- Process Design Manual LurgiDocument25 pagesProcess Design Manual LurgiMarcelo Peretti91% (11)

- 02 - Plant DesignDocument60 pages02 - Plant DesignAaron RoyNo ratings yet

- Simulation of Thermal Ablation Process Using ANSYS Software: Vijaya Kanth P, Balakrishna Murthy V, Chandra Mohan RDocument2 pagesSimulation of Thermal Ablation Process Using ANSYS Software: Vijaya Kanth P, Balakrishna Murthy V, Chandra Mohan RYasirNo ratings yet

Unit Pu - Abbreviations and General Notes

Unit Pu - Abbreviations and General Notes

Uploaded by

AKHIL RAJOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unit Pu - Abbreviations and General Notes

Unit Pu - Abbreviations and General Notes

Uploaded by

AKHIL RAJCopyright:

Available Formats

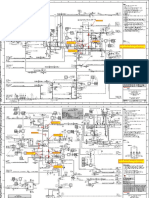

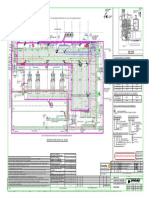

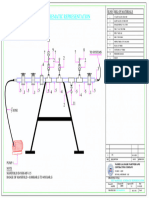

A B C D E F G H

GENERAL NOTES

INTERNAL TREATMENT

PIPING SYMBOL COATING / INSULATION / TRACING AND JACKETING CODE NOTES:

EXTERNAL TREATMENT

NOTE TREATED 1) FOR EQUIPMENT, PIPELINE AND INSTRUMENT TAG NUMBERING REFER TO PROJECT PROCEDURE B4-GG-103-00001.

MAIN PROCESS LINE, ARROW INDICATES GATE VALVE (WEDGE TYPE) STEAM TRAP ASSEMBLY NONE N 2) FOR INTERFACE POINT NUMBERING REFER TO PROJECT PROCEDURE B4-DM-103-00010

DIRECTION OF FLOW STA COATED ONLY B A

GATE VALVE (WEDGE TYPE) (POLYOLEFINS ONLY) (FOR DETAILS SEE STEAM TRAP ARRANGEMENT

SECONDARY PROCESS OR UTILITY LINE (X) (X) IS REPLACED WITH FOLLOWING PAINTED ONLY V S

IDENTIFICATION LETTERS: TYPICAL ON P&ID B4-PP-152-01000-03)

UNDERGROUND LINE

US COLD INSULATED AND PAINTED F

4300-VZ-DM-PU0001000-01

EXISTING LINE LS-WITH TWO LIMIT SWITCHES UTILITY STATION

1 WL-GATE VALVE WITH LOCK; 773-GATE VALVE 300#) HOT INSULATED AND PAINTED I 1

FUTURE (EQUIPMENT/PIPEWORK) XS-GATE VALVE WITH EXTENDED STEM

LUBE OIL/SEAL OIL XL-GATE VALVE WITH EXTENDED STEM WITH LOCK T DUAL TEMPERATURE J

STEAM TRAP

SKID OR PACKAGE LIMIT DIAPHRAGM VALVE JACKETED PARTIAL JP

PU-PP-152-01000-01

- -% JACKETED REDUCED JR

SLOPE (SPECIFY PERCENTAGE) DIAPHRAGM VALVE (POLYOLEFINS ONLY) T CONDENSATE LIFT SYSTEM (PUMPING TRAP) JACKETED TOTAL JT

GRAVITY FLOW GRAVITY FLOW LINE (NO POCKETS EXCEPT FOR STANDARD GLOBE VALVE VACUUM COLD INSULATION C

DEFLECTION BETWEEN PIPE SUPPORTS) (X) (X) = WL; WITH LOCK BELLOWS STEAM TRACED AND INSULATED AND PAINTED T

STEAM OR ELECTRIC TRACED LINE/EQUIPMENT SAMPLE POINT STEAM JACKET AND INSULATED AND PAINTED W

(X) PLUG VALVE (POLYOLEFINS ONLY) X=SEE SAMPLE CONNECTION CODE LISTING (THIS DRAWING)

S ELECTRIC TRACED AND INSULATED AND PAINTED E

CONTRACTOR :

INSULATED LINE

NEEDLE VALVE (X) FOR APPLICABLE LETTER CODE PERSONNEL PROTECTION AND PAINTED (POLYOLEFINS) PP

X = SEE INSULATION CODE (POLYOLEFINS ONLY)

BOROUGE :

SEE SHEET 2

LIMITS ON PIPELINES: NEEDLE VALVE (POLYOLEFINS ONLY) PERSONNEL PROTECTION AND PAINTED (OLEFINS) P

SAMPLE POINT (POLYOLEFINS ONLY)

A = CONSTRUCTION AREA LINE NUMBER BREAK BUTTERFLY VALVE (UNIT)-S-(NO)-(X) HEAT CONSERVATION FOR COMBUSTIBLE LIQUIDS FK

X= SEE SAMPLE CONNECTION CODE LISTING FOR

B = MATERIAL BALANCE POINT INCLUDES LIMITS FOR PLUG VALVE APPLICABLE NUMBER CODE (SEE SH.02)

ACOUSTIC ATTENUATION INSULATION AND PAINTED DX *

C = CONSTRUCTION STATUS B,G,J,M,S,R HOT ACOUSTIC KX *

D D DRAIN CONNECTION (TYPE ACCORDING TO SPECIFICATION)

D = DESIGN CONDITIONS HD/HV-HYDROSTATIC DRAIN/VENT COLD ACOUSTIC LX *

G = CONTROL GROUP OR SPECIAL APPLICATION AS REQUIRED

H = INSIDE BUILDING V ANTI SWEAT (POLYOLEFINS) AS

V VENT CONNECTION (TYPE ACCORDING TO SPECIFICATION)

J = TYPE OR THICKNESS OF INSULATION ANTI SWEAT (OLEFINS) G

RAM OR FLUSH BOTTOM VALVE

L = LIMIT OF SUPPLY FIRE PROTECTION FPP

FG

FLOW GLASS * WHERE X=INSULATION CLASS AS BELOW

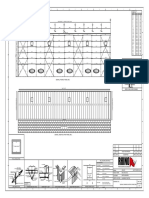

2 M = MEDIUM CODE 2

P = PIPE SIZE CLASS THICKNESS OF POROUS MINIMUM MASS PER UNIT

S = PIPE SPECIFICATION SG (OLEFINS) LAYER (MM) AREA OF CLADDING

SELF CLOSING VALVE SIGHT GLASS (KG/M2)

R = CLEANING REQUIREMENTS (ONLY ASU) (X) (X) = MC: METAL SEALED

A 50 2

SCOPE SPLIT VENDOR (WHITE SIDE)/

PURCHASER (BLACK SIDE) ADJUSTABLE SPRING-LOADED VALVE FO B 100 5

UG AG C 100 10

UNDERGROUND/ABOVE GROUND CHECK VALVE

D 50+50 6+10

ANY CONTENT & INFORMATION OF THIS DOCUMENT SHALL NOT BE USED, DISCLOSED OR REPRODUSED IN WHOLE OR IN PART TO ANYONE OUTSIDE OF BOROUGE AND SUBSIDIARIES WITHOUT WRITTEN PERMISSION OR AGREEMENT WITH BOROUGE.

STOP CHECK VALVE FLOW RESTRICTION ORIFICE

(XXXX) (YYYY)

BATTERY LIMIT E.G. DB=100MM POROUS LAYER

EXCESS FLOW VALVE FO KA150 = 150MM HOT = 50MM POROUS LAYER

BL

(XXXX) (YYYY) KNIFE GATE VALVE PIPING SPECIAL ITEMS PACKAGE UNIT OR RESPONSIBILITY BOUNDARY

SPEC. OR SCOPE CHANGE (POLYOLEFINS ONLY) SLIDE VALVE COMBINATION OF ORIFICE AND BLIND PIPING SPECIAL ITEM NUMBER P INDICATES PIPING

(BLIND IN OPEN POSITION) V V INDICATES "VENDOR" P DEPARTMENT

AV AUTOMATIC AIR VENT VALVE XX - XXXXX - SP - X - XXX

J-X RX COOLANT JACKET RETURN (POLYOLEFINS ONLY)

SERIAL NUMBER B B INDICATES "BOROUGE" I INDICATES INSTRUMENT

DESIGN CONDITIONS I

ANGLE VALVE AREA CODE DEPARTMENT

PIPING SPECIAL CODE E INDICATES ELECTRICAL

DILUENT FLUSH (POLYOLEFINS ONLY) E DEPARTMENT V V INDICATES "VENDOR"

PXX DESIGN TEMPERATURE °C PACKAGE ITEM Nr.

THREE-WAY VALVE

DESIGN PRESSURE BAR (G) (only for packages) M M INDICATES MECHANICAL V INDICATES OTHER "VENDOR"

STC V

UNIT NUMBER DEPARTMENT

FG. FLUSH GAS POINT (POLYOLEFINS ONLY) FOUR-WAY VALVE SHORT TIME CONDITION

3 3

FLUSH-BOTTOM VALVE

LINE IDENTIFICATION

STEAM JACKETED VALVE (GENERAL) GENERAL XX - XX - XX - AXXXX - XXXXXXX - XX

JACKETED LINES (HEATING MEDIUM IS STEAM

UNLESS OTHERWISE NOTED) INTERLOCK NUMBER COATING/INSULATED TRACED OR JACKETED (SEE ABOVE) STREAM NUMBER

XXXX

INT-XX MECHANICALLY LOCKED PIPING SERVICE CLASS

LINE JUNCTION BLOCK VALVES SERIAL NUMBER (FIRST CHARACTER FOR AREA)

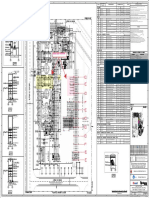

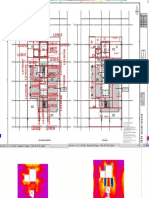

WATER STREAMS

THIS DOCUMENT SHALL BE UTILIZED BY BOROUGE FOR ANY PURPOSE RELATING TO THE CONSTRUCTION, MAINTENANCE OR OPERATION OF THE PLANT.

LINE CROSSING, NOT CONNECTED LINE DESIGNATION CODE (SEE BELOW) AW ACIDIC WATER OILS AND CHEMICALS

HVL UNIT/SYSTEM NUMBER BW BOILER FEED WATER CH CHEMICALS (GENERAL)

ECCENTRIC REDUCER - TOP FLAT NOMINAL PIPE SIZE (INCHES) CW SEA WATER (MAKEUP / BLOWDOWN) FC FRESH CAUSTIC

FLARE AND BLOW DOWN STEAM AND CONDENSATE CWS COOLING WATER SUPPLY (SEA WATER) FO FLUSHING OIL

ECCENTRIC REDUCER - BOTTOM FLAT MANUAL VALVE WITH LIMIT SWITCHES BA BOILER BLOWDOWN DS DILUTION STEAM

HVS P PROCESS CWR COOLING WATER RETURN (SEA WATER) HO HOT OIL

CONCENTRIC REDUCER BD HYDROCARBON BLOWDOWN HC HIGH PRESSURE CONDENSATE DW DRINKING WATER (POTABLE)

CL COLD LIQUID HS HIGH PRESSURE STEAM PL PROCESS LIQUID LO LUBE OIL

FLANGED END WITH BLIND FLANGE CG COLD GAS FW FIRE WATER

KS VERY HIGH PRESSURE STEAM PP POLYPROPYLENE PO PROCESS OIL

THIS DOCUMENT CONTAINS CONFIDENTIAL AND PROPRIETARY INFORMATION OF BOROUGE WITH ALL RIGHTS RESERVED.

END CAP BUTT WELDED SPECIAL MANUAL VALVE HF HIGH PRESSURE FLARE LC LOW PRESSURE CONDENSATE GWS GLYCOL WATER SUPPLY SC SPENT CAUSTIC

PR PROPYLENE

LF LOW PRESSURE FLARE GWR GLYCOL WATER RETURN

SCREWED CAP LS LOW PRESSURE STEAM RE REFRIGERANT

P PURGE CONNECTION (VALVE TYPE ACC. TO SPEC) WL WARM LIQUID

MC MEDIUM PRESSURE CONDENSATE RG RECYCLE GAS CHWS CHILLED WATER SUPPLY

PIPE PLUG WG WARM GAS

FA SG SOUR GAS MS MEDIUM PRESSURE STEAM SF CHWR CHILLED WATER RETURN

FLAME ARRESTOR SOUR GAS (FLARE & BLOWDOWN)

SPADE BLIND/PADDLE BLIND HD CLOSED DRAIN HMS HIGH MEDIUM PRESSURE STEAM JW JACKET COOLING WATER

SL POLYMER SLURRY

SILENCER GASES PROCESS MW DEMINERALIZED WATER

4 TA COCATALYST (TEAL) 4

RING SPACER AA ATMOSPHERIC AIR-ASSOCIATED WITH AP AIR + PELLET TRANSPORT PEW PELLET WATER

STATIC MIXER VENTS VACUUM BREAKERS/FANS SA SOLID ADDITIVE

ET ETHYLENE PW PROCESS WATER

AT AT AIR TRANSPORT PO LIQUID FUEL

VA ATMOSPHERIC VENT CM CO-MONOMER (1-BUTENE) CHX CYCLO HEXANE SWS SECONDARY COOLING WATER SUPPLY (CLOSED LOOP)

SPECTACLE BLIND, OPEN POSITION SWR SECONDARY COOLING WATER RETURN (CLOSED LOOP)

INJECTION QUILL CO2 CARBON DIOXIDE CO CARBON MONOXIDE WX WAXES

FG FUEL GAS CT CATALYST TDW TREATED DISTILLATE WATER

HN HIGH PRESSURE PURIFIED NITROGEN CRG CIRCULATION RECYCLE GAS TW TREATED WASTE WATER

SPECTACLE BLIND, CLOSED POSITION TP IA INSTRUMENT AIR

TIE-IN POINT (WITH VENDOR) DI UW UTILITY (SERVICE) WATER

DA DECOKING AIR DILUENT (PROPANE)

ISOLATING JOINT NG NATURAL GAS DO DONOR WW WASTE WATER

TRANSITION PIECE LINE FROM /TO ANOTHER DRAWING NR NITROGEN RETURN GAS LINE HE HEXANE SEWERS

NT NITROGEN TRANSPORT HY HYDROGEN AY ACCIDENTALLY OILY WASTE WATER

DISMANTLING JOINT OG OFF GAS HX CO-MONOMER (HEXENE) CY CHEMICAL SEWER

PIPING LINE ARROW INDICATES PN PURIFIED NITROGEN LA LIQUID ADDITIVE NY SANITARY SEWER

SWING ELBOW BATTERY LIMIT RHN RECYCLED NITROGEN MO MODIFER

UA UTILITY (PLANT) AIR SY OILY SEWER

IP-X-AA/BB-YY-NNN INTERFACE POINT NOTE 2 NP NITROGEN + POWDER TRANSPORT

UHN HOT NITROGEN PE POLYETHYLENE WY NON-OILY SEWER

HOSE CONNECTION

UN NITROGEN PG PROCESS GAS VZ VESSEL TRIM

HOSE CONNECTION MALE/FEMALE (POLYOLEFINS ONLY) VG LEAKAGE LINE

SC SAMPLE COOLER

HOSE CONNECTION MALE/FEMALE FOR NITROGEN RN RECYCLE NITROGEN FROM MEMBRANE UNIT TO PO PLANT

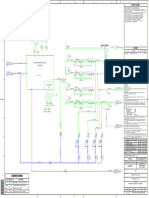

(POLYOLEFINS ONLY) ABBREVIATIONS

SP FCV AFL - AIR FAIL LAST

SPOOL PIECE (REMOVABLE) THE FOLLOWING ABBREVIATIONS ARE TO BE USED TO SUPPLEMENT THE GRAPHICAL REPRESENTATIONS OF COMPONENTS WHERE REQUIRED

AG - ABOVE GROUND ESD - EMERGENCY SHUT DOWN LP - LOW PRESSURE FOR POLYMER GRADES:

RTU - REMOTE TERMINAL UNIT

OPEN DRAIN TO FUNNEL OR TRENCH (XX-SPECIFY TYPE) AMB - AMBIENT ET - ELETRIC TRACE LUB - LUBRICATED

(XX) I.G. OILY WATER APC - ADVANCED PROCESS CONTROL RV - RELIEF VALVE LLD - LINEAR LOW DENSITY

5

CHEMICAL SELF REGULATING FLOW VALVE E.G ELEV - ELEVATION M - MOTOR/DRIVER 5

ASU - AIR SEPARATION UNIT RX - REACTOR FILM POLYETHYLENE

STORM WATER YARWAY VALVE' FA - FLAME ARRESTOR MAX - MAXIMUM

ATM - ATMOSPHERE SC - SAMPLE CONNECTION

SANITARY FB - FULL BORE MCC - MOTOR CONTROL CENTRE HD - HIGH DENSITY FILM

AG CLOSED DRAIN BF - BLIND FLANGE SER - SEQUENCE OF EVENT

CD FILTER OR STRAINER (GENERAL) FC - FAIL CLOSED ME - METERING POLYETHYLENE

UG BFW - BOILER FEEDWATER RECORDING

WELDED CONNECTION BL - BATTERY LIMIT FL - FAIL LOCKED (LAST POSITION) MFR - MELT FLOWRATE SO - STEAMING OUT HIC - HIGH DENSITY BLOW

BMS - BURNER MANAGENENT SYSTEM FLC - FAIL LAST-TENDS TO CLOSE MH - MANHOLE

SP - SET POINT MOULDING

ATM OPEN VENT TO ATMOSPHERE C - CLOSED MIN - MINIMUM

FLO - FAIL LAST-TENDS TO OPEN SS - STAINLESS STEEL POLYETHYLENE

DRIP RING MN - MOBILE PIPE

CC - CABLE CONTROL FO - FAIL OPEN ST - STEAM TRACE

MOV - MOTOR OPERATED VALVE MD - MEDIUM DENSITY

BIRD SCREEN CO - CARBON MONOXIDE FMC - FORCE MANUAL CLOSED

_-SP-_ PAD FLANGE (SPECIAL ITEM) MP - MEDIUM PRESSURE/MAX.POINTER STA - STEAM TRAP ASSEMBLY POLYETHYLENE

CS - CARBON STEEL FMO - FORCE MANUAL OPEN

EXHAUST HEAD MR - MANUAL RESET TC - THERMOCOUPLE

FLANGED CONNECTION CSC - CAR SEAL CLOSED GO - GEAR-OPERATED FOR REACTORS:

NC - NORMALLY CLOSED TP - TIE-IN POINT

WITH STEAM RING HC - HOSE CONNECTION

RAIN SHIELD CSO - CAR SEAL OPEN NNF - NORMALLY NO FLOW LOOP - LOOP REACTOR

CONICAL STRAINER ('WITCHES HAT, HH - HAND HOLE TSO - TIGHT SHUT-OFF

CWR - COOLING WATER RETURN HOA - HAND OFF AUTO NO - NORMALLY OPEN PREPOLY - PREPOLYMERIZATION L 18.Feb.2022 ISSUED FOR COMPANY REVIEW A.Waykole P.Perego P.Perego

BALL VALVE (FULL BORE) USE ONLY WHERE PERMANENTLY TS - TEMPORARY STRAINER

(X) CWS - COOLING WATER SUPPLY HP - HIGH PRESSURE O - OPEN REACTOR Rev. Date Description

Prepared Checked Approved

INSTALLED, OTHERWISE BELOW.) T - STEAM TRAP By By By

BALL VALVE (REDUCED BORE) TS D - DRAIN HS - HOSE STATION OSBL - OUTSIDE BATTERY LIMIT GPR - GAS PHASE REACTOR

(X) IS REPLACED WITH FOLLOWING IDENTIFICATION LETTERS: TEMPORARY LINE STRAINER DB - SPRAY BALL P - PURGE TW - THERMOWELL ABU DHABI POLYMERS COMPANY LIMITED

(X) IA - INSTRUMENT AIR

T- PTFE SEATED VALVE; TE3-PTFE SEATED VALVE 300#; ('WITCHES HAT') DCS - DISTRIBUTED CONTROL SYSTEM INT - INTERLOCK PD - PULSATION DAMPNER UC - UTILITY CONNECTION (BOROUGE)

TL1-PTFE SEATED WITH LIMIT SWITCH DE - DE-ENERGIZED PLC - PROGRAMMABLE LOGIC CONTROLLER UG - UNDERGROUND

TL2-PTFE SEATED WITH TWO LIMIT SWITCHES 'Y'-TYPE STRAINER INST - INSTRUMENTS

TE6-PTFE SEATED VALVE 600# DH - DIP HATCH I/P - I/P CONVERTER POV - POWER-OPERATED VALVE US - UTILITY STATION PETROCHEMICALS PROJECT

M- METAL SEATED VALVE; ME3-METAL SEATED VALVE 300# IPCS - INTERGRATED PROTECTION & (PNEUMATIC OR HYDRAULIC) V - VENT COMPANY PROJECT NO

ML1-METAL SEATED WITH LIMIT SWITCH 'T'-STRAINER DISP - DISPLACER PROJECT TITLE:

6 CONTROL SYSTEM (FOR MCC) PES - PROGRAMMABLE ELECTRICAL SIGNAL - 6

ML2-METAL SEATED WITH TWO LIMIT SWITCHES VFD - VARIABLE FREQUENCY DRIVE

G- PENTA FITE SEATED VALVE OR EQUIVALENT

DJ - SPRAY NOZZLE ISBL - INSIDE BATTERY LIMIT PSA - PRESSURE SWING ABSORTION CONTRACTOR PROJECT NO BOROUGE 4 - OVERALL EPC PROJECT

FLEXIBLE HOSE DP - DELTA P (PRESSURE DROP) KCM - K-TRON CONTROL MODULE VS - VENDOR SUPPLIED 4300 - PU

S- SPECIAL SOFT SEATED VALVE FOR HIGH DESIGN P/T - PRESSURE/TEMPERATURE COMPENSATION

PRESSURE AND TEMPERATURE DPV - EMERGENCY DEPRESSURING VALVE KSM - K-TRON SMART COMMANDER VIBR - VIBRATION SENSOR DRAWING TITLE: PIPING AND INSTRUMENTATION DIAGRAM

FLEXIBLE CLAMP L/R - LOCAL/REMOTE PV - PROCESS VARIABLE

TX- VALVE WITH EXTENDED STEM. DR - DRAIN WH - WEEP HOLE UNIT PU - GENERAL BOROUGE 4

PL1-PEEK SEATED WITH LIMIT SWITCH EBV - EMERGENCY BLOCK-IN VALVE LC - LOCKED CLOSED KEY LOCKING SYSTEM RB - REDUCED BORE

TRENCH LOCKABLE IN CLOSED POSITION) RCI - REMOTE COMMUNICATION INTERFACE SYMBOLS, ABBREVIATIONS AND GENERAL NOTES

PL2-PEEK SEATED WITH TWO LIMIT SWITCHES EFC - ELECTRIC FAILURE CLOSE

LEQ - PIPING EQUIVALENT LENGTH MODULE BOROUGE DOCUMENT CLASS' N PROJECT DRAWING NO REV:

EFO - ELECTRIC FAILURE OPEN LO - LOCKED OPENED (KEY LOCKING SYSTEM RSP - RING SPACER

EFL - ELECTRIC FAILURE LAST LOCKABLE IN OPEN POSITION) RTD - RESISTANCE TEMPERATURE DETECTOR CONTRACTOR: 4300-VZ-DM-PU0001000-01 SHEET UNIT: PU

ES - EXTENDED SPINDLE LOC - LOCAL 1 BOROUGE: PU-PP-152-01000-01 OF AREA: 0

CADD SHEET

A B C D E F REF. PU-PP-152-01000-01-ISL SCALE: SIZE A1

You might also like

- Briggs Engine Failure GuideDocument50 pagesBriggs Engine Failure GuideWILKILM83% (12)

- Conduction Problems & Solutions Conduction Problems & SolutionsDocument30 pagesConduction Problems & Solutions Conduction Problems & SolutionsRoronoaNo ratings yet

- Heat Recovery Steam Generator Operation ManualDocument45 pagesHeat Recovery Steam Generator Operation ManualReyes Sanchez100% (2)

- 4300 VZ DM Pu0001000 01 IspDocument1 page4300 VZ DM Pu0001000 01 IspreachgscommNo ratings yet

- 180 R Iso 46000 001 - RCDocument8 pages180 R Iso 46000 001 - RCvigneshNo ratings yet

- JO003-10-LB - MDD-IDM-001-3 P&ID Steam and Bypass SystemDocument9 pagesJO003-10-LB - MDD-IDM-001-3 P&ID Steam and Bypass SystemHasan MustafaNo ratings yet

- General Notes: / B RCA-F-001-ADocument55 pagesGeneral Notes: / B RCA-F-001-Acarmela alburqueque100% (1)

- Isometric View Lifting Detail: NotesDocument2 pagesIsometric View Lifting Detail: NotesRajveer SinghNo ratings yet

- 4300 AI DU 126100001 - Q Combined PDFDocument5 pages4300 AI DU 126100001 - Q Combined PDFSaid AlzamarehNo ratings yet

- Pm210011-Nui900-Rd2-00026 - 01 - Slab On Grade - Grade Beam SCH, Sec & Details...Document1 pagePm210011-Nui900-Rd2-00026 - 01 - Slab On Grade - Grade Beam SCH, Sec & Details...MOHAMMAD JAKARIA HASANNo ratings yet

- Double Cut Tee Plan Brace Connection On Beam WebDocument1 pageDouble Cut Tee Plan Brace Connection On Beam WebRajveer SinghNo ratings yet

- Pm210011-Nui900-Rd2-00025 - 01 - Raft Foundation Section, Column & Wall Deta...Document1 pagePm210011-Nui900-Rd2-00025 - 01 - Raft Foundation Section, Column & Wall Deta...MOHAMMAD JAKARIA HASANNo ratings yet

- HVAC Schematic Drawing - WMO Rev ADocument2 pagesHVAC Schematic Drawing - WMO Rev Aarief bahtiarNo ratings yet

- Isolation Package For 25-T-01: Remove SpoolDocument2 pagesIsolation Package For 25-T-01: Remove SpoolAdel Moustafa NafrawyNo ratings yet

- Structural Engineering DrawingsDocument7 pagesStructural Engineering DrawingsObaidullah ObaidNo ratings yet

- PEDWPRTS771025A1 - Main Compressor B Train 1 - 5Document1 pagePEDWPRTS771025A1 - Main Compressor B Train 1 - 5macielNo ratings yet

- 9 Sketch Shear ConnectionDocument1 page9 Sketch Shear ConnectionER Deepak SutharNo ratings yet

- The Basic Balanced Scorecard TemplateDocument2 pagesThe Basic Balanced Scorecard TemplateomzoerNo ratings yet

- 2047 1803 Est Dla 7012 - ADocument1 page2047 1803 Est Dla 7012 - ArameshbathalaNo ratings yet

- 3 P 132 9301 1a3a N 01 - Rev01Document1 page3 P 132 9301 1a3a N 01 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- Schedule of Member Splice Connection Notes:: F H G E D C B ADocument1 pageSchedule of Member Splice Connection Notes:: F H G E D C B ARajveer SinghNo ratings yet

- FGP Legend Sheets May 15Document20 pagesFGP Legend Sheets May 15erzhik1997No ratings yet

- Mwihoko 3DDocument1 pageMwihoko 3DNewtonNo ratings yet

- Obtuse Corner Acute and Perpendicular Corner: Match The Slope of The GirderDocument1 pageObtuse Corner Acute and Perpendicular Corner: Match The Slope of The GirderProfessor PuppiesNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozNo ratings yet

- Acp Master P&id Oct 20 NewDocument65 pagesAcp Master P&id Oct 20 NewAhmedNo ratings yet

- 3 P 132 9401 1a3a N 03 - Rev01Document1 page3 P 132 9401 1a3a N 03 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- P203 Sie DWG 008 Arc 600010Document1 pageP203 Sie DWG 008 Arc 600010viswanathanNo ratings yet

- Construction NotesDocument1 pageConstruction NotesAthanNo ratings yet

- Plano ASPRODocument1 pagePlano ASPROMiguel Angel Cardozo MolinaNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozNo ratings yet

- N 665.500 Drawing Limit C ROAD N 662.000 L: Model Need To UpdateDocument2 pagesN 665.500 Drawing Limit C ROAD N 662.000 L: Model Need To UpdatephanikrishnabNo ratings yet

- 3 P 132 9501 1a3a N 02 - Rev01Document1 page3 P 132 9501 1a3a N 02 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- 21BP002-351-DD0-1GR020 - R0 - GirderDocument1 page21BP002-351-DD0-1GR020 - R0 - GirderDang TranNo ratings yet

- Contrato Vertical Contrato Teck: Job No. 25800Document1 pageContrato Vertical Contrato Teck: Job No. 25800Gabriel PulidoNo ratings yet

- SS-1 Deep Well Earth PitDocument1 pageSS-1 Deep Well Earth PitM&N ProjectsNo ratings yet

- 5-2-4 LOGIQ E9 Overall Block Diagram (Cont'd)Document1 page5-2-4 LOGIQ E9 Overall Block Diagram (Cont'd)Nguyen TanNo ratings yet

- 03 FinalDocument1 page03 FinalMeghana NavuluruNo ratings yet

- RB A225 Approval Rev 1 - 10 10Document1 pageRB A225 Approval Rev 1 - 10 10TariqMahmoodNo ratings yet

- Hoist Way Plans - Tower A - Basement 1: Under CoordinationDocument1 pageHoist Way Plans - Tower A - Basement 1: Under Coordinationprasahnthrk07No ratings yet

- 907-Q-PED-50002-001: General Arrangement Drawing SLEEPER WAY 907-SL-100Document1 page907-Q-PED-50002-001: General Arrangement Drawing SLEEPER WAY 907-SL-100KhaleelNo ratings yet

- Major1107202x12.2pscslab V4 Approve P11Document1 pageMajor1107202x12.2pscslab V4 Approve P11rushi123No ratings yet

- Odisha Studio - Acoustic - Floor Plan - 25-4-24Document1 pageOdisha Studio - Acoustic - Floor Plan - 25-4-24tahasildarjanardhanNo ratings yet

- 773F & 773F OEM Quarry Truck Hydraulic System 775F & 775F OEM Off-Highway TruckDocument2 pages773F & 773F OEM Quarry Truck Hydraulic System 775F & 775F OEM Off-Highway TruckVictor Rivera EspejoNo ratings yet

- SCU-2290-PP-XIS-320134 - 3 FirmadoDocument6 pagesSCU-2290-PP-XIS-320134 - 3 FirmadoCristopher MosqueiraNo ratings yet

- Amueblado Pottery Barn Leon Plaza MayorDocument1 pageAmueblado Pottery Barn Leon Plaza MayorethelNo ratings yet

- Grand l21 Scut Roa 20201209Document1 pageGrand l21 Scut Roa 20201209Ricardo Alejandro Oyarce ArmijoNo ratings yet

- I-DE-3010.92-1263-944-OVX-001 - Hypocloride AftDocument1 pageI-DE-3010.92-1263-944-OVX-001 - Hypocloride AftAdalton BritoNo ratings yet

- ER-HW-SEC-20 - Estado Reformado - Secciones GeneralesDocument1 pageER-HW-SEC-20 - Estado Reformado - Secciones GeneralesYoni BacaNo ratings yet

- Vermer PipeDocument4 pagesVermer PipeVermer FabregasNo ratings yet

- EASTWICK SITE 68 THE GATES APPROVED SUBMISSION DRAWINGS 30 04 20 Site Plan and Loft 1Document1 pageEASTWICK SITE 68 THE GATES APPROVED SUBMISSION DRAWINGS 30 04 20 Site Plan and Loft 1kimNo ratings yet

- Pimple Saudagar-Rccd - (13-05-19)Document4 pagesPimple Saudagar-Rccd - (13-05-19)Yogesh ChaudhariNo ratings yet

- Preliminary: Drawings NotesDocument1 pagePreliminary: Drawings Notesbatopotcholo03No ratings yet

- CITIIS PEDAWALTAIR School ARCHDocument21 pagesCITIIS PEDAWALTAIR School ARCHKingSantoshNo ratings yet

- B Block PitDocument1 pageB Block PitAPS DESIGN INFRA PVT.LTD.No ratings yet

- A31.1 Fourth Floor Furniture Wing-1Document1 pageA31.1 Fourth Floor Furniture Wing-1Azkagul 28No ratings yet

- A31.1 Fourth Floor Furniture Wing-1Document1 pageA31.1 Fourth Floor Furniture Wing-1Azkagul 28No ratings yet

- Ol1 2G43 0020 3 PidDocument1 pageOl1 2G43 0020 3 PidBình VănNo ratings yet

- ZX110to130LCN CIRCUITDocument17 pagesZX110to130LCN CIRCUITSaul Baquero Quevedo100% (2)

- ER-HW-SEC-20-Estado Reformado. Secciones Generales PDFDocument1 pageER-HW-SEC-20-Estado Reformado. Secciones Generales PDFrafaell474No ratings yet

- CAI - DWG-S-DD-S-W2-1001 Piling Plan - r1Document1 pageCAI - DWG-S-DD-S-W2-1001 Piling Plan - r1Ikade SuartanaNo ratings yet

- 1-MEPs-ELECT-LTG-B4&7-0001 (SH 1-1) - R-2 (FND Reviewed) - LTG-B4-0001Document1 page1-MEPs-ELECT-LTG-B4&7-0001 (SH 1-1) - R-2 (FND Reviewed) - LTG-B4-0001muzeek306No ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Fire Water LineDocument1 pageFire Water LineAKHIL RAJNo ratings yet

- 4300 NCR NSH 010Document4 pages4300 NCR NSH 010AKHIL RAJNo ratings yet

- TEST MANIFOLD ModelDocument1 pageTEST MANIFOLD ModelAKHIL RAJNo ratings yet

- Po - Sub-System (Ug)Document43 pagesPo - Sub-System (Ug)AKHIL RAJNo ratings yet

- HMT 2marksDocument85 pagesHMT 2marksyogesh sNo ratings yet

- Physics: Heat TransferDocument18 pagesPhysics: Heat TransferDuncan KingNo ratings yet

- Developing A MATLAB Model For Flat Solar CollectorsDocument7 pagesDeveloping A MATLAB Model For Flat Solar Collectorsgonzalez2678No ratings yet

- Internal Energy and Energy Transfers 2Document39 pagesInternal Energy and Energy Transfers 2muhammadshadid4No ratings yet

- Exhaust Mount Christie & Grey Pl003-Issue-l-crmDocument4 pagesExhaust Mount Christie & Grey Pl003-Issue-l-crmResul UygunNo ratings yet

- H2 Type Direct Fire Chiller Operation ManualDocument79 pagesH2 Type Direct Fire Chiller Operation ManualPoon Yew ChanNo ratings yet

- Belzona 3211Document2 pagesBelzona 3211Bobby SatheesanNo ratings yet

- Insulation of Marine Piping and EquipmentDocument2 pagesInsulation of Marine Piping and EquipmentNicoletaNo ratings yet

- 5 2 ICAIIT 2024 Part 2 Paper 15Document7 pages5 2 ICAIIT 2024 Part 2 Paper 15kimtinh18012005No ratings yet

- Mil STD 2223Document96 pagesMil STD 2223Standards IndiaNo ratings yet

- CEL 18663 UK 003 MS01 - Rev A0Document8 pagesCEL 18663 UK 003 MS01 - Rev A0TASNEEMNo ratings yet

- (AHU) Clivet AHU and Modular Air Handling UnitDocument27 pages(AHU) Clivet AHU and Modular Air Handling UnitDoniNo ratings yet

- Frost Protected Shallow Foundations FINALDocument4 pagesFrost Protected Shallow Foundations FINALDarren Winslow0% (1)

- Energy Audit: Unit - 2Document61 pagesEnergy Audit: Unit - 2Nikhil TiruvaipatiNo ratings yet

- Thermashield PDFDocument8 pagesThermashield PDFromeo pedranoNo ratings yet

- Basics Roof ConstructionDocument76 pagesBasics Roof ConstructionPeixuan Xu100% (1)

- Unit 2 FinalDocument58 pagesUnit 2 Finalshankar kmNo ratings yet

- Thermal Insulation Materials Made of Rigid Polyurethane FoamDocument33 pagesThermal Insulation Materials Made of Rigid Polyurethane FoamAdrian MorarNo ratings yet

- Stress Relieving Procedure 01Document6 pagesStress Relieving Procedure 01VikasShelkeNo ratings yet

- Extreme Temperature ClothingDocument16 pagesExtreme Temperature ClothingNeeraj BalaNo ratings yet

- Manuscript Design Fabrication and Testing of A Biomass Insulated Cooking PotDocument99 pagesManuscript Design Fabrication and Testing of A Biomass Insulated Cooking PotwahahahhasiafiadgNo ratings yet

- Lab Manual: Heat Transfer Lab 5ME4-22 Mechanical Engineering YearDocument68 pagesLab Manual: Heat Transfer Lab 5ME4-22 Mechanical Engineering YearAbhishek SNo ratings yet

- Astmc 411 - 97Document4 pagesAstmc 411 - 97Yogesh BalarNo ratings yet

- Process Design Manual LurgiDocument25 pagesProcess Design Manual LurgiMarcelo Peretti91% (11)

- 02 - Plant DesignDocument60 pages02 - Plant DesignAaron RoyNo ratings yet

- Simulation of Thermal Ablation Process Using ANSYS Software: Vijaya Kanth P, Balakrishna Murthy V, Chandra Mohan RDocument2 pagesSimulation of Thermal Ablation Process Using ANSYS Software: Vijaya Kanth P, Balakrishna Murthy V, Chandra Mohan RYasirNo ratings yet