Professional Documents

Culture Documents

Pipe Class 43 A

Pipe Class 43 A

Uploaded by

Ali RaheemCopyright:

Available Formats

You might also like

- Operating Instruction ASL 94Document291 pagesOperating Instruction ASL 94Bayanaka Tehnik100% (1)

- LPG CylindersDocument21 pagesLPG Cylindersafic219473100% (2)

- Pfaudler Mavag Filtration - DryingDocument16 pagesPfaudler Mavag Filtration - DryingmanojNo ratings yet

- For ConstructionDocument5 pagesFor ConstructionBasem AlsaftliNo ratings yet

- Butterfly ValvesDocument6 pagesButterfly ValvestezgidenNo ratings yet

- FPS 100 Informacion ExtraDocument1 pageFPS 100 Informacion ExtraLuis Daniel Aguirre RuizNo ratings yet

- Dce DW ST BLG C Col 1st 2nd 029bDocument1 pageDce DW ST BLG C Col 1st 2nd 029bMidhun Babu NTNo ratings yet

- GRP Pipe ClassDocument1 pageGRP Pipe ClassAli RaheemNo ratings yet

- ED1801 Ventilation Fan WOKDocument46 pagesED1801 Ventilation Fan WOKJOHAN VILCHEZNo ratings yet

- Rod, Cable, and SW Wind BracingDocument19 pagesRod, Cable, and SW Wind BracingNyein ZawNo ratings yet

- Malkhedi To Khurai Lopcsd KM 986Document1 pageMalkhedi To Khurai Lopcsd KM 986santosh iyerNo ratings yet

- G.V & AIR VALVE-ModelDocument1 pageG.V & AIR VALVE-ModelAnand KP100% (1)

- 5900 FlexBalance Plus Series Separators Submittal 401-082 102319Document1 page5900 FlexBalance Plus Series Separators Submittal 401-082 102319Rafael SalazarNo ratings yet

- Ds-pp-0016 - Data Sheet For Flexible Joint (Rev.0)Document2 pagesDs-pp-0016 - Data Sheet For Flexible Joint (Rev.0)Panisa BanimaNo ratings yet

- Tri-Clamp: Item Qty. Description MaterialDocument2 pagesTri-Clamp: Item Qty. Description MaterialSivateja NallamothuNo ratings yet

- CC Schedule HEGDocument16 pagesCC Schedule HEGvomicih221No ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- Low SupportDocument1 pageLow SupportMDhana SekarNo ratings yet

- G.V & AIR VALVE-ModelDocument1 pageG.V & AIR VALVE-ModelAnand KPNo ratings yet

- Gen PNG STD 001 - 02Document40 pagesGen PNG STD 001 - 02Jose C. MelendezNo ratings yet

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)Document1 pageService: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)AliZenatiNo ratings yet

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- Dimensions Are For Reference Only. All Dimensions Are Subject To Change Upon Production. Unless Otherwise SpecifiedDocument1 pageDimensions Are For Reference Only. All Dimensions Are Subject To Change Upon Production. Unless Otherwise SpecifiedRUN GONo ratings yet

- Gama Completa de Vane Piese de Montaj Si InterventieiDocument56 pagesGama Completa de Vane Piese de Montaj Si InterventieiMoHammadNashatSabbahNo ratings yet

- Pms Eil BPCLDocument79 pagesPms Eil BPCLManjunatha VNo ratings yet

- Welding BookDocument16 pagesWelding BookRenzo BellotaNo ratings yet

- Diaphragm ValveDocument2 pagesDiaphragm ValveHardik ShahNo ratings yet

- Products Specification ADVANSTAR HOSE Series: Sumitomo Riko GroupDocument10 pagesProducts Specification ADVANSTAR HOSE Series: Sumitomo Riko GroupFaridNo ratings yet

- 250YTDocument1 page250YTjesus_manrique2753No ratings yet

- Snamprogetti: Gaskets For Flanged PipingDocument10 pagesSnamprogetti: Gaskets For Flanged PipingTerrance Badree100% (3)

- Brida Flexible VitaulicDocument3 pagesBrida Flexible VitaulicG Abigail MorenoNo ratings yet

- Part List - bd05s1100-1200 - Door Latch AssyDocument4 pagesPart List - bd05s1100-1200 - Door Latch Assyskrohilla1673No ratings yet

- Descripcion de Poleas de Fajas Overland BambasDocument1 pageDescripcion de Poleas de Fajas Overland BambasRichard GuevaraNo ratings yet

- Specification Description Design Code ContentDocument1 pageSpecification Description Design Code Contentsushant_jhawerNo ratings yet

- FP1.0 Engineering Data A-C Pumps 8100Document12 pagesFP1.0 Engineering Data A-C Pumps 8100Christian FernandezNo ratings yet

- 700V Series: High Throughput Cartridge Filter HousingsDocument7 pages700V Series: High Throughput Cartridge Filter HousingsRosamunde NaitNo ratings yet

- Tbe For Osbl (SBS)Document5 pagesTbe For Osbl (SBS)benidbb100% (3)

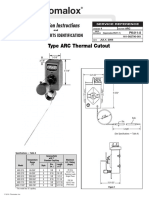

- Chromalox: Installation InstructionsDocument4 pagesChromalox: Installation InstructionsJorgeAlorRodriguezNo ratings yet

- DWG CP18 20755 01 REV01 Ga Drawing PDFDocument1 pageDWG CP18 20755 01 REV01 Ga Drawing PDFEnriquinoNo ratings yet

- Hdpe 81aDocument1 pageHdpe 81aAli RaheemNo ratings yet

- Forged Gate, Globe & Check ValvesDocument4 pagesForged Gate, Globe & Check ValvesRavi KantNo ratings yet

- Sae 1000 PsiDocument6 pagesSae 1000 PsiAnonymous uL3JlWfhNo ratings yet

- Fwir Wellhead Instrume Bleed LineDocument2 pagesFwir Wellhead Instrume Bleed LineMuhamad Hifni SyahbanaNo ratings yet

- Reductor Presiune Abur RP45 DN15-100Document2 pagesReductor Presiune Abur RP45 DN15-100vvlad34No ratings yet

- 1.03.E.DT32 Thermodynamic Steam Traps DN15-25Document1 page1.03.E.DT32 Thermodynamic Steam Traps DN15-25Son Trinh PhuongNo ratings yet

- 1.02.E.DT42S Thermodynamic Steam Traps DN15-25Document2 pages1.02.E.DT42S Thermodynamic Steam Traps DN15-25Son Trinh PhuongNo ratings yet

- Categorias Pipin ClassGRI 3007567 18007 ID MET If 001 - A01 0Document26 pagesCategorias Pipin ClassGRI 3007567 18007 ID MET If 001 - A01 0Geovanny MarquezNo ratings yet

- Commercial: UninsulatedDocument4 pagesCommercial: UninsulatedJovenal TuplanoNo ratings yet

- Dimensional Fitup Inspection ReportDocument1 pageDimensional Fitup Inspection ReportSalesNo ratings yet

- GCC Supplier List 1Document14 pagesGCC Supplier List 1niks dNo ratings yet

- Welding and Inspection Plan (Wip) Part 1: Design: Issued By: DateDocument4 pagesWelding and Inspection Plan (Wip) Part 1: Design: Issued By: DateJorgeAgustínSalgadoMirandaNo ratings yet

- 3827-E10-062 - Two Position Valve - DDocument4 pages3827-E10-062 - Two Position Valve - DMohamed Elsaid El ShallNo ratings yet

- Technical Data Sheet and Ga of Condenser Water Pumps (Ac System)Document15 pagesTechnical Data Sheet and Ga of Condenser Water Pumps (Ac System)Ashok reddyNo ratings yet

- Samples Spection Report Signify Fio Sólido Vermelho 0,50mm2 440610001241Document1 pageSamples Spection Report Signify Fio Sólido Vermelho 0,50mm2 440610001241Moises NogueiraNo ratings yet

- JosamDocument274 pagesJosamdavid0775No ratings yet

- Uniflange - Serie 900Document1 pageUniflange - Serie 900JohanAndrésVillarrealNo ratings yet

- Samggh Catlog .Document84 pagesSamggh Catlog .Man BurstNo ratings yet

- Welder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122Document4 pagesWelder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122R.A. AbriantoNo ratings yet

- Wps 22Document2 pagesWps 22Avishek GuptaNo ratings yet

- Ms Trading Pipefittingcatalogue Dec2016 ElectronicDocument44 pagesMs Trading Pipefittingcatalogue Dec2016 ElectronicANV100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- GRP Pipe ClassDocument1 pageGRP Pipe ClassAli RaheemNo ratings yet

- GRP 86A PipelineDocument1 pageGRP 86A PipelineAli RaheemNo ratings yet

- 252100dbqa00044 Exde04 56Document56 pages252100dbqa00044 Exde04 56Ali RaheemNo ratings yet

- KIMMCO Duct InsulationDocument5 pagesKIMMCO Duct InsulationAli RaheemNo ratings yet

- كنز العمال12 PDFDocument336 pagesكنز العمال12 PDFAli RaheemNo ratings yet

- 0106-7 Section A-BDocument161 pages0106-7 Section A-BAliArababadiNo ratings yet

- En - Eu I 3 Plus OtDocument60 pagesEn - Eu I 3 Plus OtSzilard ZsigmondNo ratings yet

- Accessories For Systems and Power Packs: Selection of Standard ItemsDocument6 pagesAccessories For Systems and Power Packs: Selection of Standard ItemsMarceloGuayllaNo ratings yet

- Valves Q.S For Fire Pump Room - Eng Ahmed HassanDocument1 pageValves Q.S For Fire Pump Room - Eng Ahmed Hassanmujassam noorNo ratings yet

- Valco Power - Eng.Document16 pagesValco Power - Eng.dhmbasNo ratings yet

- Instruction Manual: Deckma Hamburg GMBHDocument14 pagesInstruction Manual: Deckma Hamburg GMBHMiroslaw LabudaNo ratings yet

- Inv FMC Cusiana y Cupiagua 1Document10 pagesInv FMC Cusiana y Cupiagua 1Pocholo Mario Pineda ForeroNo ratings yet

- DRF 100Document374 pagesDRF 100Ducthien VoNo ratings yet

- 722 - 9 VB Removal-Installation Guide EditedDocument7 pages722 - 9 VB Removal-Installation Guide EditedAqidi MohammadNo ratings yet

- NTSB LJ Final 000502Document64 pagesNTSB LJ Final 000502bombardierwatchNo ratings yet

- Honda Marine BF20DK0 LHTA POWER TRIM-TILT - Babbitts Honda PartshouseDocument3 pagesHonda Marine BF20DK0 LHTA POWER TRIM-TILT - Babbitts Honda PartshouseFacundo Manuel RamatNo ratings yet

- 2-Way Flow Control Bosch-RexrothDocument12 pages2-Way Flow Control Bosch-RexrothKemal GokovicNo ratings yet

- B90 B100 B110 TLB2 2WS SPB 380925 (Eco14114)Document16 pagesB90 B100 B110 TLB2 2WS SPB 380925 (Eco14114)Mepita Mecânica100% (1)

- CAIRN-TSG-L-SP-0015-A1-Specification For Piping Fabrication and Installation For Offshore Application PDFDocument11 pagesCAIRN-TSG-L-SP-0015-A1-Specification For Piping Fabrication and Installation For Offshore Application PDFMahesh Pandit Pandit100% (1)

- P1IU A9 80445059 B WatermarkedDocument32 pagesP1IU A9 80445059 B WatermarkedNaoufel SmatiNo ratings yet

- Script Hamilton c3 Service Software Elo20210108n00 3 PDF FreeDocument19 pagesScript Hamilton c3 Service Software Elo20210108n00 3 PDF FreeFarEast MedSolNo ratings yet

- TPS Ci XR Aa 001 (B01) Cause&effect Diagram PDFDocument8 pagesTPS Ci XR Aa 001 (B01) Cause&effect Diagram PDFabboudNo ratings yet

- Manual de Instalacion - Contador Barton-Floco-F500 PDFDocument32 pagesManual de Instalacion - Contador Barton-Floco-F500 PDFElkin TorresNo ratings yet

- Tender Bunduan 9897Document29 pagesTender Bunduan 9897Pja MahsumNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechaneeshNo ratings yet

- 4-Cylinder Direct Injection Engine (1 8 2 0 LTR 4-Valve TFSI - Generation III)Document315 pages4-Cylinder Direct Injection Engine (1 8 2 0 LTR 4-Valve TFSI - Generation III)Martin huntNo ratings yet

- طراحی پایپینگ اطراف پمپ هاDocument25 pagesطراحی پایپینگ اطراف پمپ هاMorteza DianatfarNo ratings yet

- Piping Design and Plant LayoutDocument44 pagesPiping Design and Plant LayoutVp Singh RawatNo ratings yet

- P Prro Od Du Uc Ctts S: Supplying Superior Instrumentation Fittings & ValvesDocument1 pageP Prro Od Du Uc Ctts S: Supplying Superior Instrumentation Fittings & ValveskrishnakumarsistNo ratings yet

- Installation Instructions Residential Reverse Osmosis Drinking Water Systems 3,4, and 5 Stage SystemsDocument6 pagesInstallation Instructions Residential Reverse Osmosis Drinking Water Systems 3,4, and 5 Stage SystemsSunil TiwariNo ratings yet

- 750-137 Electric Boilers S CR HSB 2019Document36 pages750-137 Electric Boilers S CR HSB 2019patricia cebajosNo ratings yet

Pipe Class 43 A

Pipe Class 43 A

Uploaded by

Ali RaheemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Class 43 A

Pipe Class 43 A

Uploaded by

Ali RaheemCopyright:

Available Formats

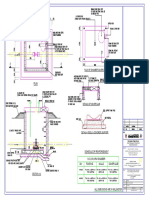

PIPING PROJECT SPECIFICATION

eni iraq b.v. SPECIFICA DI PROGETTO TUBAZIONI

Revisions/Rev. 0

Sht/Foglio of/di Compiled/Compilato Date/Data

1 1 IT 19/06/2022

SERVICE: SEVERELY CORROSIVE HYDROCARBONS - WATER INJECTION - ITEM CORR.ALLOWANCE

Sigla 43A Sovraspes. di Corr. 6 mm

FIRE WATER (ABOVEGROUND) RATING & FACING

Serie e Faccia 150# RF 125Ra

DESIGN CONDITION: T - °C -10÷38 50 100 150 200 - - - - - - - - CODES- Design: ASME B 31.3/B16.5/B16.34/B16.47 Cl.A

Condizioni di Progetto: P - bar 19.6 19.2 17.7 15.8 13.8 - - - - - - - - Norme-Progetto:

NOMINAL SIZE/Diametro nom. INCH - 1/2" 3/4" 1" 1½" 2" 3" 4" 6" 8" 10" 12" 14" 16" 18" 20" 24" 26" 28" 30" 32"

WALL THK./Spessore mm - 7.47 7.82 9.09 10.15 8.74 7.62 8.56 10.97 10.31 9.27 10.31 11.13 12.70 11.13 12.70 12.70 12.70 12.70 15.88 15.88

PIPES

SCHEDULE/Schedula No. - XXS XXS XXS XXS 160 80 80 80 60 40 40 40 XS 30 XS XS XS XS 30 30

MATERIAL/Materiale ASTM A106 Gr. B ASTM A672 Gr. C60 Cl. 32 EFW

MANUFACTURE/Costruzione SMLS WLDD

WELDING NECK/Sald. di Testa A105/600#-RF125Ra A105/150#-RF125Ra (80)

FLANGES

SOCKET WELD/Sald.a Tasca ---- ----

Flange

THREADED/Filettate ---- ----

SLIP ON/Sald. a Sovrapposizione ---- ----

LAP JOINT/Libere ---- ----

BLIND/Cieche A105/600#-RF125Ra A105/150#-RF125Ra

GASKETS/Guarnizioni 32 C 28

STUD BOLTS & NUTS/Tiranti-Bulloni A 193 Gr.B7M / A 194 Gr.2HM (ZINC COATED) (1)

Ball Valve API 608 - ASTM A182 F316L -

Ball SW - Class 800 - Handlevel operated -

API 608; ASTM A351 CF3M BODY; API 6D; ASTM A216 WCB + CF3M WELD OVERLAY (ON ALL WETTED PARTS) BODY;

Two pieces bolted body - Ball and stem:

SS316L TRIM; METAL SEAT; ASTM A105 + CF3M WELD OVERLAY TRIM; METAL SEAT; TRUNION; FB; GR - OP;

Aisi 316/316L - Seat: R-PTFE - Floating

ball design - 100 mm pipe extension on FLOATING; FB; LV - OP; FLGD-FF 150# FLGD-FF 150#

both sides

API 600; ASTM A216

Gate WCB + CF3M WELD

Gate valve API 602 - ASTM A182 OVERLAY (ON ALL

API 600; ASTM A351 WETTED PARTS)

F316L - SW - Class 800 - API 600; ASTM A216 WCB + CF3M WELD OVERLAY (ON ALL WETTED PARTS)

CF3M BODY; CF3M TRIM; BODY; ASTM A105 +

Handwheel operated - Bolted BODY; ASTM A105 + CF3M WELD OVERLAY TRIM; OS&Y; BB; FLX WGD; GR -

OS&Y; BB; FLX WGD; HW CF3M WELD

bonnet - Outside yoke and stem - OVERLAY TRIM; OP; FLGD-FF 150#

- OP; FLGD-FF 150#

Trim: Aisi316L - Seat: Aisi316L OS&Y; BB; FLX WGD;

VALVES

HW - OP; FLGD-FF

150#

BS 1873; ASTM A216 WCB +

Globe valve API 602 - ASTM A182

CF3M WELD OVERLAY (ON ALL

F316L - SW - Class 800 - BS 1873; ASTM A351

WETTED PARTS) BODY; ASTM

Handwheel operated - Bolted CF3M BODY; CF3M TRIM;

Globe A105 + CF3M WELD OVERLAY

bonnet - Outside yoke and stem - T TYPE; OS&Y; BB; DISC;

TRIM; STRAIGHT PATTERN;

Trim: Aisi316L - Seat: Aisi316L - HW - OP; FLGD-FF 150#

OS&Y; BB; DISC; GR - OP;

Loose plug or ball type

FLGD-FF 150#

API 609 - ASTM A351 CF3M - Ansi 150lb - RF - Serrated -

API 609; ASTM A216 WCB + CF3M WELD OVERLAY (ON ALL WETTED PARTS);

Butterfly Handlevel operated - Flanged - Disc: Aisi 316/316L - Seat:

TRPL OFFSET; DBL FLGD; FIRE TESTED; GR - OP; FLGD-FF 150#

PTFE - API 609 cat. B short pattern

BS 1868; ASTM A351

API 602 - ASTM A182 F316L - SW

CF3M BODY; CF3M TRIM; API 594; ASTM A216 WCB + CF3M WELD OVERLAY (ON ALL WETTED PARTS) BODY; ASTM A105 +

Check - Class 800 - Trim: Aisi316L - Seat:

DUAL PLATE; FLGD-FF CF3M WELD OVERLAY TRIM; DUAL PLATE; FLGD-FF 150#

Aisi316L - Lift type disc

150#

Special Use

" Y "STRAINERS/Filtri a "Y" FT 935 AG 2R1 - RF 125 Ra FT 911 AG 2C3 - RF 125 Ra

90°-45° ELBOWS/Curve 90°-45° A 234 Gr. WPB

ECC.-CONC.REDUCT./Rid.Conc.-Ecc. A 234 Gr. WPB

ELLIPT.CAPS/Fondelli Bombati A 234 Gr. WPB

LJ STUB ENDS/Collari Flg.Libere ----

PIPE BENDS/Curve da Tubo ---- ----

MITER ELBOWS/Curve a Spicchi ---- ----

S.W. FITTINGS/Raccorderia S.W. ---- ---- COMPONENTS/Componenti MAT./Mat.

THDD FITTINGS/Raccorderia Fil. ---- ---- RED.FLG.S/FLG di Rid. THDD./Filet. S.O./a Sovr. ---

NORMAL /Normali ---- ---- TEMP. STRAINERS/Filtri Temporanei AISI 316

NIPPLES

Nippli

SWAGES/Di Riduzione ---- ---- DRIP RINGS/Anelli di Drenaggio A 105

THICKNESS/Spessori mm - - - - - - - - - SPECTACLE & SPACERS-BLINDS/Dischi a 8-Sezionatori A 105

1/2 STEE REFERENCE SPECIFICATIONS/Specifiche di riferimento

3/4 STEE WELDING AND HEAT TREATMENT/Saldature e Trattamenti Termici 20368.PIP.MEC.FUN

1 STEE PIPING CLASS/Classe Tubazione 20367.PIP.MEC.FUN

1½ RTEE STEE WELDS EXAMINATION/Controllo Saldature 20377.PIP.MEC.FUN

2 STEE MATERIALS (if not otherw.stated)/Materiali(se non div.indicato) ASTM STANDARDS

3 STEE PIPING COMPONENTS/Componenti per tubazioni 05892.PIP.MEC.FUN

HEADER SIZE/Collettore

4 STEE

6 STEE POS. Components/Comp. Mat./Mat .

8 STEE INTERSECTIONS STEE STRAIGHT BW TEE/ T da Sald.di Testa A 234 Gr. WPB

10 STEE Intersezioni RTEE REDUCTION BW TEE/T rid.Sald.di Testa A 234 Gr. WPB

12 STEE STSC STRAIGHT THDD TEE/ T Filettato

14 STEE RTSC REDUCTION THDD TEE/ T rid. Filettato

16 STEE STSW STRAIGHT SW TEE/ T da Sal.a Tasca

18 STEE RTSW REDUCTION SW TEE/T rid.Sald.Tasca

DN"

20 WLET STEE SWLT SWEEPOLETS

24 RTEE STEE WLET WELDOLETS A 105

26 STEE TLET THREDOLETS ---

28 STEE SLET SOCKOLETS

30 STEE NLET NIPOLETS THDD / Nipolets Filettate

32 STEE PTOP PIPE TO PIPE/ Tubo su Tubo

1/2 3/4 1 1½ 2 3 4 6 8 10 12 14 16 18 20 24 26 28 30 32

DN" BRANCH SIZE/Derivazione

NOTES/Note : 31) Corrosion allowance to be considered and verified also for Flanges, Body Valves and "Y" Strainers. /

1) All carbon steel bolting on flanges, valves & "Y" strainers shall be zinc coated (hot-dip) 31) La corrosione ammessa dovrà essere considerata e verificata per le Flange, i corpi Valvole e i Filtri.

1) to ASTM A-153. / Tutta la bulloneria in acciaio al carbonio di flange, valvole e filtri a "Y" 61) Butterfly valves shall be used for the services PRODUCED WATER,

1) deve essere zincata (a caldo) per ASTM A 153. 61) FRESH WATER, WATER INJECTION and FIRE WATER; with the following design condition:

2) To be used where required by P&I drawings only. / Impiegare solo dove richiesto dagli T - °C -10 38 50 100

2) schemi di marcia. P - bar (20 bar) 20.0 20.0 19.7 17.3

80) Use A105/300# - RF125 Ra for Control Valves installation /

Usare flange A105/300# - RF125 Ra per l'installazione delle Valvole di Controllo

This document is CONFIDENTIAL and the sole property of eni iraq b.v. It shall neither be shown to third parties nor used for purposes other than those for which it has been sent.

Il presente documento è RISERVATO ed è di proprietà di eni iraq b.v. Esso non sarà mostrato a Terzi né sarà utilizzato per scopi diversi da quelli per i quali è stato inviato.

You might also like

- Operating Instruction ASL 94Document291 pagesOperating Instruction ASL 94Bayanaka Tehnik100% (1)

- LPG CylindersDocument21 pagesLPG Cylindersafic219473100% (2)

- Pfaudler Mavag Filtration - DryingDocument16 pagesPfaudler Mavag Filtration - DryingmanojNo ratings yet

- For ConstructionDocument5 pagesFor ConstructionBasem AlsaftliNo ratings yet

- Butterfly ValvesDocument6 pagesButterfly ValvestezgidenNo ratings yet

- FPS 100 Informacion ExtraDocument1 pageFPS 100 Informacion ExtraLuis Daniel Aguirre RuizNo ratings yet

- Dce DW ST BLG C Col 1st 2nd 029bDocument1 pageDce DW ST BLG C Col 1st 2nd 029bMidhun Babu NTNo ratings yet

- GRP Pipe ClassDocument1 pageGRP Pipe ClassAli RaheemNo ratings yet

- ED1801 Ventilation Fan WOKDocument46 pagesED1801 Ventilation Fan WOKJOHAN VILCHEZNo ratings yet

- Rod, Cable, and SW Wind BracingDocument19 pagesRod, Cable, and SW Wind BracingNyein ZawNo ratings yet

- Malkhedi To Khurai Lopcsd KM 986Document1 pageMalkhedi To Khurai Lopcsd KM 986santosh iyerNo ratings yet

- G.V & AIR VALVE-ModelDocument1 pageG.V & AIR VALVE-ModelAnand KP100% (1)

- 5900 FlexBalance Plus Series Separators Submittal 401-082 102319Document1 page5900 FlexBalance Plus Series Separators Submittal 401-082 102319Rafael SalazarNo ratings yet

- Ds-pp-0016 - Data Sheet For Flexible Joint (Rev.0)Document2 pagesDs-pp-0016 - Data Sheet For Flexible Joint (Rev.0)Panisa BanimaNo ratings yet

- Tri-Clamp: Item Qty. Description MaterialDocument2 pagesTri-Clamp: Item Qty. Description MaterialSivateja NallamothuNo ratings yet

- CC Schedule HEGDocument16 pagesCC Schedule HEGvomicih221No ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- Low SupportDocument1 pageLow SupportMDhana SekarNo ratings yet

- G.V & AIR VALVE-ModelDocument1 pageG.V & AIR VALVE-ModelAnand KPNo ratings yet

- Gen PNG STD 001 - 02Document40 pagesGen PNG STD 001 - 02Jose C. MelendezNo ratings yet

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)Document1 pageService: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)AliZenatiNo ratings yet

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- Dimensions Are For Reference Only. All Dimensions Are Subject To Change Upon Production. Unless Otherwise SpecifiedDocument1 pageDimensions Are For Reference Only. All Dimensions Are Subject To Change Upon Production. Unless Otherwise SpecifiedRUN GONo ratings yet

- Gama Completa de Vane Piese de Montaj Si InterventieiDocument56 pagesGama Completa de Vane Piese de Montaj Si InterventieiMoHammadNashatSabbahNo ratings yet

- Pms Eil BPCLDocument79 pagesPms Eil BPCLManjunatha VNo ratings yet

- Welding BookDocument16 pagesWelding BookRenzo BellotaNo ratings yet

- Diaphragm ValveDocument2 pagesDiaphragm ValveHardik ShahNo ratings yet

- Products Specification ADVANSTAR HOSE Series: Sumitomo Riko GroupDocument10 pagesProducts Specification ADVANSTAR HOSE Series: Sumitomo Riko GroupFaridNo ratings yet

- 250YTDocument1 page250YTjesus_manrique2753No ratings yet

- Snamprogetti: Gaskets For Flanged PipingDocument10 pagesSnamprogetti: Gaskets For Flanged PipingTerrance Badree100% (3)

- Brida Flexible VitaulicDocument3 pagesBrida Flexible VitaulicG Abigail MorenoNo ratings yet

- Part List - bd05s1100-1200 - Door Latch AssyDocument4 pagesPart List - bd05s1100-1200 - Door Latch Assyskrohilla1673No ratings yet

- Descripcion de Poleas de Fajas Overland BambasDocument1 pageDescripcion de Poleas de Fajas Overland BambasRichard GuevaraNo ratings yet

- Specification Description Design Code ContentDocument1 pageSpecification Description Design Code Contentsushant_jhawerNo ratings yet

- FP1.0 Engineering Data A-C Pumps 8100Document12 pagesFP1.0 Engineering Data A-C Pumps 8100Christian FernandezNo ratings yet

- 700V Series: High Throughput Cartridge Filter HousingsDocument7 pages700V Series: High Throughput Cartridge Filter HousingsRosamunde NaitNo ratings yet

- Tbe For Osbl (SBS)Document5 pagesTbe For Osbl (SBS)benidbb100% (3)

- Chromalox: Installation InstructionsDocument4 pagesChromalox: Installation InstructionsJorgeAlorRodriguezNo ratings yet

- DWG CP18 20755 01 REV01 Ga Drawing PDFDocument1 pageDWG CP18 20755 01 REV01 Ga Drawing PDFEnriquinoNo ratings yet

- Hdpe 81aDocument1 pageHdpe 81aAli RaheemNo ratings yet

- Forged Gate, Globe & Check ValvesDocument4 pagesForged Gate, Globe & Check ValvesRavi KantNo ratings yet

- Sae 1000 PsiDocument6 pagesSae 1000 PsiAnonymous uL3JlWfhNo ratings yet

- Fwir Wellhead Instrume Bleed LineDocument2 pagesFwir Wellhead Instrume Bleed LineMuhamad Hifni SyahbanaNo ratings yet

- Reductor Presiune Abur RP45 DN15-100Document2 pagesReductor Presiune Abur RP45 DN15-100vvlad34No ratings yet

- 1.03.E.DT32 Thermodynamic Steam Traps DN15-25Document1 page1.03.E.DT32 Thermodynamic Steam Traps DN15-25Son Trinh PhuongNo ratings yet

- 1.02.E.DT42S Thermodynamic Steam Traps DN15-25Document2 pages1.02.E.DT42S Thermodynamic Steam Traps DN15-25Son Trinh PhuongNo ratings yet

- Categorias Pipin ClassGRI 3007567 18007 ID MET If 001 - A01 0Document26 pagesCategorias Pipin ClassGRI 3007567 18007 ID MET If 001 - A01 0Geovanny MarquezNo ratings yet

- Commercial: UninsulatedDocument4 pagesCommercial: UninsulatedJovenal TuplanoNo ratings yet

- Dimensional Fitup Inspection ReportDocument1 pageDimensional Fitup Inspection ReportSalesNo ratings yet

- GCC Supplier List 1Document14 pagesGCC Supplier List 1niks dNo ratings yet

- Welding and Inspection Plan (Wip) Part 1: Design: Issued By: DateDocument4 pagesWelding and Inspection Plan (Wip) Part 1: Design: Issued By: DateJorgeAgustínSalgadoMirandaNo ratings yet

- 3827-E10-062 - Two Position Valve - DDocument4 pages3827-E10-062 - Two Position Valve - DMohamed Elsaid El ShallNo ratings yet

- Technical Data Sheet and Ga of Condenser Water Pumps (Ac System)Document15 pagesTechnical Data Sheet and Ga of Condenser Water Pumps (Ac System)Ashok reddyNo ratings yet

- Samples Spection Report Signify Fio Sólido Vermelho 0,50mm2 440610001241Document1 pageSamples Spection Report Signify Fio Sólido Vermelho 0,50mm2 440610001241Moises NogueiraNo ratings yet

- JosamDocument274 pagesJosamdavid0775No ratings yet

- Uniflange - Serie 900Document1 pageUniflange - Serie 900JohanAndrésVillarrealNo ratings yet

- Samggh Catlog .Document84 pagesSamggh Catlog .Man BurstNo ratings yet

- Welder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122Document4 pagesWelder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122R.A. AbriantoNo ratings yet

- Wps 22Document2 pagesWps 22Avishek GuptaNo ratings yet

- Ms Trading Pipefittingcatalogue Dec2016 ElectronicDocument44 pagesMs Trading Pipefittingcatalogue Dec2016 ElectronicANV100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- GRP Pipe ClassDocument1 pageGRP Pipe ClassAli RaheemNo ratings yet

- GRP 86A PipelineDocument1 pageGRP 86A PipelineAli RaheemNo ratings yet

- 252100dbqa00044 Exde04 56Document56 pages252100dbqa00044 Exde04 56Ali RaheemNo ratings yet

- KIMMCO Duct InsulationDocument5 pagesKIMMCO Duct InsulationAli RaheemNo ratings yet

- كنز العمال12 PDFDocument336 pagesكنز العمال12 PDFAli RaheemNo ratings yet

- 0106-7 Section A-BDocument161 pages0106-7 Section A-BAliArababadiNo ratings yet

- En - Eu I 3 Plus OtDocument60 pagesEn - Eu I 3 Plus OtSzilard ZsigmondNo ratings yet

- Accessories For Systems and Power Packs: Selection of Standard ItemsDocument6 pagesAccessories For Systems and Power Packs: Selection of Standard ItemsMarceloGuayllaNo ratings yet

- Valves Q.S For Fire Pump Room - Eng Ahmed HassanDocument1 pageValves Q.S For Fire Pump Room - Eng Ahmed Hassanmujassam noorNo ratings yet

- Valco Power - Eng.Document16 pagesValco Power - Eng.dhmbasNo ratings yet

- Instruction Manual: Deckma Hamburg GMBHDocument14 pagesInstruction Manual: Deckma Hamburg GMBHMiroslaw LabudaNo ratings yet

- Inv FMC Cusiana y Cupiagua 1Document10 pagesInv FMC Cusiana y Cupiagua 1Pocholo Mario Pineda ForeroNo ratings yet

- DRF 100Document374 pagesDRF 100Ducthien VoNo ratings yet

- 722 - 9 VB Removal-Installation Guide EditedDocument7 pages722 - 9 VB Removal-Installation Guide EditedAqidi MohammadNo ratings yet

- NTSB LJ Final 000502Document64 pagesNTSB LJ Final 000502bombardierwatchNo ratings yet

- Honda Marine BF20DK0 LHTA POWER TRIM-TILT - Babbitts Honda PartshouseDocument3 pagesHonda Marine BF20DK0 LHTA POWER TRIM-TILT - Babbitts Honda PartshouseFacundo Manuel RamatNo ratings yet

- 2-Way Flow Control Bosch-RexrothDocument12 pages2-Way Flow Control Bosch-RexrothKemal GokovicNo ratings yet

- B90 B100 B110 TLB2 2WS SPB 380925 (Eco14114)Document16 pagesB90 B100 B110 TLB2 2WS SPB 380925 (Eco14114)Mepita Mecânica100% (1)

- CAIRN-TSG-L-SP-0015-A1-Specification For Piping Fabrication and Installation For Offshore Application PDFDocument11 pagesCAIRN-TSG-L-SP-0015-A1-Specification For Piping Fabrication and Installation For Offshore Application PDFMahesh Pandit Pandit100% (1)

- P1IU A9 80445059 B WatermarkedDocument32 pagesP1IU A9 80445059 B WatermarkedNaoufel SmatiNo ratings yet

- Script Hamilton c3 Service Software Elo20210108n00 3 PDF FreeDocument19 pagesScript Hamilton c3 Service Software Elo20210108n00 3 PDF FreeFarEast MedSolNo ratings yet

- TPS Ci XR Aa 001 (B01) Cause&effect Diagram PDFDocument8 pagesTPS Ci XR Aa 001 (B01) Cause&effect Diagram PDFabboudNo ratings yet

- Manual de Instalacion - Contador Barton-Floco-F500 PDFDocument32 pagesManual de Instalacion - Contador Barton-Floco-F500 PDFElkin TorresNo ratings yet

- Tender Bunduan 9897Document29 pagesTender Bunduan 9897Pja MahsumNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechaneeshNo ratings yet

- 4-Cylinder Direct Injection Engine (1 8 2 0 LTR 4-Valve TFSI - Generation III)Document315 pages4-Cylinder Direct Injection Engine (1 8 2 0 LTR 4-Valve TFSI - Generation III)Martin huntNo ratings yet

- طراحی پایپینگ اطراف پمپ هاDocument25 pagesطراحی پایپینگ اطراف پمپ هاMorteza DianatfarNo ratings yet

- Piping Design and Plant LayoutDocument44 pagesPiping Design and Plant LayoutVp Singh RawatNo ratings yet

- P Prro Od Du Uc Ctts S: Supplying Superior Instrumentation Fittings & ValvesDocument1 pageP Prro Od Du Uc Ctts S: Supplying Superior Instrumentation Fittings & ValveskrishnakumarsistNo ratings yet

- Installation Instructions Residential Reverse Osmosis Drinking Water Systems 3,4, and 5 Stage SystemsDocument6 pagesInstallation Instructions Residential Reverse Osmosis Drinking Water Systems 3,4, and 5 Stage SystemsSunil TiwariNo ratings yet

- 750-137 Electric Boilers S CR HSB 2019Document36 pages750-137 Electric Boilers S CR HSB 2019patricia cebajosNo ratings yet