Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

3 viewsHeat Exchanger: E-107: Connections Tube Side Shell Side

Heat Exchanger: E-107: Connections Tube Side Shell Side

Uploaded by

keyCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- HTRI Input Design Basis - Rev. 0Document33 pagesHTRI Input Design Basis - Rev. 0Swath M Murali100% (5)

- Heat Exchangers in AspenDocument30 pagesHeat Exchangers in AspenMicheal Brooks33% (3)

- ORIFICEDocument1 pageORIFICEhardavNo ratings yet

- Blank Tema SheetDocument1 pageBlank Tema SheetYosua ChangNo ratings yet

- VG 320 Oil CoolerDocument32 pagesVG 320 Oil CoolergsdaundhNo ratings yet

- 2019-12-20 Reboiler - Spec. SheetDocument1 page2019-12-20 Reboiler - Spec. SheetVasiljka Đordan JelacaNo ratings yet

- Selection of TEMA Type and Thermal Design Optimization of Shell and Tube Heat ExchangerDocument6 pagesSelection of TEMA Type and Thermal Design Optimization of Shell and Tube Heat ExchangerPawan PatilNo ratings yet

- E 105jewkbdjdDocument2 pagesE 105jewkbdjdkeyNo ratings yet

- Heat Exchanger: E-3711: Connections Tube Side Shell SideDocument1 pageHeat Exchanger: E-3711: Connections Tube Side Shell SidealiNo ratings yet

- Practica 4-ReporteDocument13 pagesPractica 4-ReporteLIZETH MANUEL CELAYANo ratings yet

- Deleted HYSYS Print E100Document3 pagesDeleted HYSYS Print E100Ash YehiaNo ratings yet

- Heat Exchanger: E-100 ( Specs Only ) : Connections Tube Side Shell SideDocument11 pagesHeat Exchanger: E-100 ( Specs Only ) : Connections Tube Side Shell SideGABRIEL PINEDA0% (1)

- Lab 2 (Ii) HeDocument8 pagesLab 2 (Ii) HeSchaieraNo ratings yet

- Hysys 2Document4 pagesHysys 2محمد عليNo ratings yet

- Reporte Final de Simulacion ICDocument6 pagesReporte Final de Simulacion ICJuan CarlosNo ratings yet

- Simple Heat ExchangerDocument9 pagesSimple Heat ExchangerAbdullah KutbiNo ratings yet

- Pipe Segment: Subsea Piping: Connections Inlet StreamDocument16 pagesPipe Segment: Subsea Piping: Connections Inlet StreamRaseuki MahadinaNo ratings yet

- Reboiler DatasheetDocument6 pagesReboiler DatasheetMIHNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- Heat Exchanger: E-100: Connections Tube Side Shell SideDocument8 pagesHeat Exchanger: E-100: Connections Tube Side Shell SideJuan CarlosNo ratings yet

- CH-RA3 Page 2Document1 pageCH-RA3 Page 2Sonya LoveraNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- Heat Exchanger Specification Sheet SI-BARG UnitsDocument2 pagesHeat Exchanger Specification Sheet SI-BARG Unitsshahbaz akramNo ratings yet

- HE Inputs RequiredDocument1 pageHE Inputs RequireddinakaranpatelNo ratings yet

- Pipe Segment: Subsea Piping: Connections Inlet StreamDocument8 pagesPipe Segment: Subsea Piping: Connections Inlet StreamRaseuki MahadinaNo ratings yet

- Heat Exchanger Specification SheetDocument2 pagesHeat Exchanger Specification SheetDycka Anugerah PuryantoroNo ratings yet

- Intercambiador de CalorDocument6 pagesIntercambiador de CalorLeonardo Ramirez GuzmanNo ratings yet

- Field Data: Item Description Symbol Unit Value Step 1 Rectangle-1 (GIS Hall)Document2 pagesField Data: Item Description Symbol Unit Value Step 1 Rectangle-1 (GIS Hall)MELVINNo ratings yet

- Earthing Design Substation IEEE 80Document2 pagesEarthing Design Substation IEEE 80MELVIN0% (1)

- WTS Sample PrintoutDocument21 pagesWTS Sample Printoutsaka dewaNo ratings yet

- Hump Hydraulics CalculationsDocument13 pagesHump Hydraulics CalculationsrutujaNo ratings yet

- TD HE THE v2020.00Document43 pagesTD HE THE v2020.00Claudia BonocoreNo ratings yet

- Earthing DesignDocument1 pageEarthing DesignTen ApolinarioNo ratings yet

- SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21Document3 pagesSQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21SRINo ratings yet

- Exchanger Tube Min ThicknessDocument2 pagesExchanger Tube Min ThicknessMohamed ElshehnyNo ratings yet

- Hot Di PDFDocument5 pagesHot Di PDFZahrotul HayatiNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Datasheet For Restriction OrificeDocument1 pageDatasheet For Restriction OrificeRajesh Rajesh67% (3)

- Data Teknis Pompa EbaraDocument3 pagesData Teknis Pompa EbaraCendrawasih PrNo ratings yet

- LiquidDocument2 pagesLiquidsiddhesh_guessNo ratings yet

- 3... 80x65 FS JA (22 KW)Document5 pages3... 80x65 FS JA (22 KW)tinhNo ratings yet

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- Anexo 2 - Hoja de Datos Valvula de Diagragma (30-XV-4069)Document1 pageAnexo 2 - Hoja de Datos Valvula de Diagragma (30-XV-4069)Antezana RodriguezNo ratings yet

- Spesifikasi Alat Tugas 2 - Pabrik Lauryl Glucoside - Belinda Liana Devy (D500191099) Ratna Kartika (D500191005) Hammami Fajar (D500191027)Document10 pagesSpesifikasi Alat Tugas 2 - Pabrik Lauryl Glucoside - Belinda Liana Devy (D500191099) Ratna Kartika (D500191005) Hammami Fajar (D500191027)belindaNo ratings yet

- ChE 301 PartII Lecture IVDocument45 pagesChE 301 PartII Lecture IVMahmudur Rahman RiadNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- Dust Collection System Technical Sheet - 9000 CFM Specification Isha Sr. No. Dust Collector DetailsDocument2 pagesDust Collection System Technical Sheet - 9000 CFM Specification Isha Sr. No. Dust Collector DetailsOmkarNo ratings yet

- 100-Mc-417-Ra3-Hx-Ra3 - HDB Condensador ReactorDocument1 page100-Mc-417-Ra3-Hx-Ra3 - HDB Condensador ReactorSonya LoveraNo ratings yet

- Pages FromThakore, Shuchen B. - Bhatt Introduction To Process Engineering and DesignDocument191 pagesPages FromThakore, Shuchen B. - Bhatt Introduction To Process Engineering and DesignAhmed HassanNo ratings yet

- Detail DesignDocument67 pagesDetail DesignBHAVISHA GOHILNo ratings yet

- Bơm Chiller 80m3, 5bargDocument5 pagesBơm Chiller 80m3, 5bargPhượng NguyễnNo ratings yet

- 1Document1 page1kkkprotNo ratings yet

- ExchangerDocument4 pagesExchangeradrian ospino canteroNo ratings yet

- Pump: P-100: Stream Name Liq-1Document2 pagesPump: P-100: Stream Name Liq-1Sebastian Camilo Garcia PradaNo ratings yet

- Level ControllerDocument1 pageLevel Controllerkhasim15No ratings yet

- Heat Transfer Area For Fin Tube Heat Exchanger For FBDDocument8 pagesHeat Transfer Area For Fin Tube Heat Exchanger For FBDPrathmesh GujaratiNo ratings yet

- E 104DKXBNWKDNXKDocument1 pageE 104DKXBNWKDNXKkeyNo ratings yet

- Heat Exchanger Rev - 02Document1 pageHeat Exchanger Rev - 02TKT ConsultantNo ratings yet

- Tower-Process-Data-Sheet - Ex (Version 1)Document1 pageTower-Process-Data-Sheet - Ex (Version 1)Abraham Burgos CelisNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Sekiro: See Runtime Message Report For Warning MessagesDocument1 pageSekiro: See Runtime Message Report For Warning MessagesĐinh Hoàng ViệtNo ratings yet

- Data Sheet of Magnetic Level Gauge For Feed Coalescer PackageDocument1 pageData Sheet of Magnetic Level Gauge For Feed Coalescer PackageHemant NimaseNo ratings yet

- Heat Exchanger Design SummaryDocument3 pagesHeat Exchanger Design SummaryKvvPrasadNo ratings yet

- Horizontal vs. Vertical Baffles - Which To Choose For Your Shell and Tube Heat ExchangerDocument5 pagesHorizontal vs. Vertical Baffles - Which To Choose For Your Shell and Tube Heat Exchangeradil alameenNo ratings yet

- Heat Exchanger Specification SheetDocument4 pagesHeat Exchanger Specification SheetAnita PanthiNo ratings yet

- Shell Tube Heat ExchangerDocument9 pagesShell Tube Heat ExchangerdonyaNo ratings yet

- 2.2 - Details of Shell & Tube H.EDocument110 pages2.2 - Details of Shell & Tube H.ENader GaafarNo ratings yet

- Detail DesignDocument67 pagesDetail DesignBHAVISHA GOHILNo ratings yet

- Heat Exchangers Course Baher Part03Document18 pagesHeat Exchangers Course Baher Part03Baher ElsheikhNo ratings yet

- J. J. Tabarek, Dale E. Klein and James R. Fair Center For Energy Studies The University Aftexas at Austin Austin, Texas 78712Document6 pagesJ. J. Tabarek, Dale E. Klein and James R. Fair Center For Energy Studies The University Aftexas at Austin Austin, Texas 78712José Blanco MosqueraNo ratings yet

- Heat ExchangerDocument34 pagesHeat ExchangerDwi Mariska SNo ratings yet

- ATV Primary Heat ExchangerDocument41 pagesATV Primary Heat Exchangeroverlord5555No ratings yet

- E 101Document21 pagesE 101EberVelazquezChantacaNo ratings yet

- Vibrations in Heat ExchangersDocument67 pagesVibrations in Heat ExchangersNader GaafarNo ratings yet

- Shell and Tube Heat Exchangers DesignDocument27 pagesShell and Tube Heat Exchangers DesignAlëJaMürciaNo ratings yet

- Tema Shell and Tube Heat Exchangers: 8-1-1 BP Oil Co. RPDocument25 pagesTema Shell and Tube Heat Exchangers: 8-1-1 BP Oil Co. RPHardik AcharyaNo ratings yet

- Heat Exchanger Thermal Design Shell&Tube V7.3.1 CP1Page 1: Basic GeometryDocument8 pagesHeat Exchanger Thermal Design Shell&Tube V7.3.1 CP1Page 1: Basic GeometryaminNo ratings yet

- ANZ Technical Guide Heat Exchanger DesigDocument13 pagesANZ Technical Guide Heat Exchanger DesigvikramNo ratings yet

- SHELL and TUBE HEAT EXCHANGERDocument10 pagesSHELL and TUBE HEAT EXCHANGERdanena88No ratings yet

- Baffle (Heat Transfer)Document2 pagesBaffle (Heat Transfer)ХристинаГулеваNo ratings yet

- 882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDocument6 pages882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDavid Alemán Sánchez100% (1)

- Compiled Correlation For Shell Side Heat Transfer CoefficientDocument20 pagesCompiled Correlation For Shell Side Heat Transfer Coefficientscranderi100% (1)

- Shell and Tube Heat Exchanger With Helical BafflesDocument42 pagesShell and Tube Heat Exchanger With Helical BafflesAtul SanghaviNo ratings yet

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDocument37 pagesDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTORONo ratings yet

- Details of Engineering Design and Selection of Heat ExchangerDocument25 pagesDetails of Engineering Design and Selection of Heat ExchangerthejusNo ratings yet

- Heat Exchanger ChecklistDocument9 pagesHeat Exchanger Checklistraja rani75% (4)

- 3 Shell and Tube Heat Exchanger Features That Affect Shell-Side Pressure DropDocument10 pages3 Shell and Tube Heat Exchanger Features That Affect Shell-Side Pressure DropRanjani J DeepakNo ratings yet

- IIT Delhi Heat ExchangerDocument19 pagesIIT Delhi Heat ExchangersunilNo ratings yet

- Design of Shell and Tube Heat Exchanger PDFDocument55 pagesDesign of Shell and Tube Heat Exchanger PDFShawez sayyed100% (1)

Heat Exchanger: E-107: Connections Tube Side Shell Side

Heat Exchanger: E-107: Connections Tube Side Shell Side

Uploaded by

key0 ratings0% found this document useful (0 votes)

3 views2 pagesOriginal Title

E-107

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views2 pagesHeat Exchanger: E-107: Connections Tube Side Shell Side

Heat Exchanger: E-107: Connections Tube Side Shell Side

Uploaded by

keyCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

1

Case Name: P&ID6_rev.hsc

2 Company Name Not Available

3 Bedford, MA Unit Set: SI10

4 USA

5

Date/Time: Wed Mar 20 23:20:49 2024

6

7

8

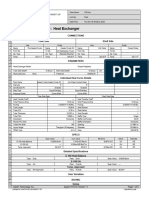

Heat Exchanger: E-107

9

10

CONNECTIONS

11

12

Tube Side Shell Side

13 Inlet Outlet Inlet Outlet

14 Name 9 Name 10 Name WAT3 Name WAT4

15 From Op. K-105 To Op. From Op. E-104 To Op.

16 Op. Type Compressor Op. Type Op. Type Heat Exchanger Op. Type

17 Temp 143.72 C Temp 130.00 C * Temp 60.00 C * Temp 104.72 C

18

19

PARAMETERS

20

Heat Exchanger Model: Simple End Point

21

22 Tube Side DeltaP: 70.00 kPa * Shell Side DeltaP: 70.00 kPa * Passes: ---

23 UA: 1196 kJ/C-h Tolerance: 1.0000e-04

24 Tube Side Data Shell Side Data

25 Heat Transfer Coeff --- Heat Transfer Coeff ---

26 Tube Pressure Drop 70.00 kPa * Shell Pressure Drop 70.00 kPa *

27 Fouling 0.00000 C-h-m2/kJ Fouling 0.00000 C-h-m2/kJ

28 Tube Length 6.00 m Shell Passes 1

29 Tube O.D. 20.00 mm Shell Series 1

30 Tube Thickness 2.0000 mm Shell Parallel 1

31 Tube Pitch 50.0000 mm Baffle Type Single

32 Orientation Horizontal Baffle Cut(%Area) 20.00

33 Passes Per Shell 4* Baffle Orientation Horizontal

34 Tubes Per Shell 160 * Spacing 800.0000 mm

35 Layout Angle Triangular (30 degrees) Diameter 739.0488 mm

36 TEMA Type AE L Area 60.32 m2

37

38

RATING

39

40

Sizing

41 Overall Data

42 Configuration

43 # of Shells in Series 1 Tube Passes per Shell 4* Elevation (Base) 0.0000 m

44 # of Shells in Parallel 1 Exchange Orientation Horizontal First Tube Pass Flow Direction Counter

45 TEMA Type: A E L

46 Calculated Information

47 Shell HT Coeff --- Tube HT Coeff ---

48 Overall U 19.82 kJ/h-m2-C Overall UA 1196 kJ/C-h

49 Shell DP 70.00 kPa * Tube DP 70.00 kPa *

50 Shell Vol per Shell 2.272 m3 Tube Vol per Shell 0.1930 m3

51 HT Area per Shell 60.32 m2

52 Shell Data

53 Shell and Tube Bundle

54 Shell Diameter Tube Pitch Shell Fouling

739.0 50.00 0.0000

55 (mm) (mm) (C-h-m2/kJ)

56 # of Tubes per Shell 160 * Tube Layout Angle Triangular (30 degrees)

57 Shell Baffles

58 Shell Baffle Type Single Shell Baffle Orientation Horizontal

59 Baffle Cut (%Area) 20.00 Baffle Spacing 800.0 mm

60 Tube Data

61 Dimensions

62 OD ID Tube Thickness Tube Length

20.00 16.00 2.000 6.000

63 (mm) (mm) (mm) (m)

64 Tube Properties

65 Tube Fouling Thermal Cond. Wall Cp Wall Density

0.0000 45.00 --- ---

66 (C-h-m2/kJ) (W/m-K) (kJ/kg-C) (kg/m3)

67

68

DETAILS

69

70

Overall/Detailed Performance

71 Duty: 6.094e+04 kJ/h UA Curv. Error: 0.00e-01 kJ/C-h

72 Heat Leak: 0.000e-01 kJ/h Hot Pinch Temp: 143.7 C

73 Heat Loss: 0.000e-01 kJ/h Cold Pinch Temp: 104.7 C

74 UA: 1.196e+03 kJ/C-h Ft Factor: ---

75 Aspen Technology Inc. Aspen HYSYS Version 12.1 Page 1 of 2

1

Case Name: P&ID6_rev.hsc

2 Company Name Not Available

3 Bedford, MA Unit Set: SI10

4 USA

5

Date/Time: Wed Mar 20 23:20:49 2024

6

7

8

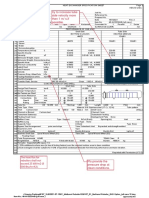

Heat Exchanger: E-107 (continued)

9

10

Overall/Detailed Performance

11 Min. Approach: 39.00 C Uncorrected Lmtd: 53.00 C

12 Lmtd: 50.97 C

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75 Aspen Technology Inc. Aspen HYSYS Version 12.1 Page 2 of 2

You might also like

- HTRI Input Design Basis - Rev. 0Document33 pagesHTRI Input Design Basis - Rev. 0Swath M Murali100% (5)

- Heat Exchangers in AspenDocument30 pagesHeat Exchangers in AspenMicheal Brooks33% (3)

- ORIFICEDocument1 pageORIFICEhardavNo ratings yet

- Blank Tema SheetDocument1 pageBlank Tema SheetYosua ChangNo ratings yet

- VG 320 Oil CoolerDocument32 pagesVG 320 Oil CoolergsdaundhNo ratings yet

- 2019-12-20 Reboiler - Spec. SheetDocument1 page2019-12-20 Reboiler - Spec. SheetVasiljka Đordan JelacaNo ratings yet

- Selection of TEMA Type and Thermal Design Optimization of Shell and Tube Heat ExchangerDocument6 pagesSelection of TEMA Type and Thermal Design Optimization of Shell and Tube Heat ExchangerPawan PatilNo ratings yet

- E 105jewkbdjdDocument2 pagesE 105jewkbdjdkeyNo ratings yet

- Heat Exchanger: E-3711: Connections Tube Side Shell SideDocument1 pageHeat Exchanger: E-3711: Connections Tube Side Shell SidealiNo ratings yet

- Practica 4-ReporteDocument13 pagesPractica 4-ReporteLIZETH MANUEL CELAYANo ratings yet

- Deleted HYSYS Print E100Document3 pagesDeleted HYSYS Print E100Ash YehiaNo ratings yet

- Heat Exchanger: E-100 ( Specs Only ) : Connections Tube Side Shell SideDocument11 pagesHeat Exchanger: E-100 ( Specs Only ) : Connections Tube Side Shell SideGABRIEL PINEDA0% (1)

- Lab 2 (Ii) HeDocument8 pagesLab 2 (Ii) HeSchaieraNo ratings yet

- Hysys 2Document4 pagesHysys 2محمد عليNo ratings yet

- Reporte Final de Simulacion ICDocument6 pagesReporte Final de Simulacion ICJuan CarlosNo ratings yet

- Simple Heat ExchangerDocument9 pagesSimple Heat ExchangerAbdullah KutbiNo ratings yet

- Pipe Segment: Subsea Piping: Connections Inlet StreamDocument16 pagesPipe Segment: Subsea Piping: Connections Inlet StreamRaseuki MahadinaNo ratings yet

- Reboiler DatasheetDocument6 pagesReboiler DatasheetMIHNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- Heat Exchanger: E-100: Connections Tube Side Shell SideDocument8 pagesHeat Exchanger: E-100: Connections Tube Side Shell SideJuan CarlosNo ratings yet

- CH-RA3 Page 2Document1 pageCH-RA3 Page 2Sonya LoveraNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- Heat Exchanger Specification Sheet SI-BARG UnitsDocument2 pagesHeat Exchanger Specification Sheet SI-BARG Unitsshahbaz akramNo ratings yet

- HE Inputs RequiredDocument1 pageHE Inputs RequireddinakaranpatelNo ratings yet

- Pipe Segment: Subsea Piping: Connections Inlet StreamDocument8 pagesPipe Segment: Subsea Piping: Connections Inlet StreamRaseuki MahadinaNo ratings yet

- Heat Exchanger Specification SheetDocument2 pagesHeat Exchanger Specification SheetDycka Anugerah PuryantoroNo ratings yet

- Intercambiador de CalorDocument6 pagesIntercambiador de CalorLeonardo Ramirez GuzmanNo ratings yet

- Field Data: Item Description Symbol Unit Value Step 1 Rectangle-1 (GIS Hall)Document2 pagesField Data: Item Description Symbol Unit Value Step 1 Rectangle-1 (GIS Hall)MELVINNo ratings yet

- Earthing Design Substation IEEE 80Document2 pagesEarthing Design Substation IEEE 80MELVIN0% (1)

- WTS Sample PrintoutDocument21 pagesWTS Sample Printoutsaka dewaNo ratings yet

- Hump Hydraulics CalculationsDocument13 pagesHump Hydraulics CalculationsrutujaNo ratings yet

- TD HE THE v2020.00Document43 pagesTD HE THE v2020.00Claudia BonocoreNo ratings yet

- Earthing DesignDocument1 pageEarthing DesignTen ApolinarioNo ratings yet

- SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21Document3 pagesSQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21SRINo ratings yet

- Exchanger Tube Min ThicknessDocument2 pagesExchanger Tube Min ThicknessMohamed ElshehnyNo ratings yet

- Hot Di PDFDocument5 pagesHot Di PDFZahrotul HayatiNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Datasheet For Restriction OrificeDocument1 pageDatasheet For Restriction OrificeRajesh Rajesh67% (3)

- Data Teknis Pompa EbaraDocument3 pagesData Teknis Pompa EbaraCendrawasih PrNo ratings yet

- LiquidDocument2 pagesLiquidsiddhesh_guessNo ratings yet

- 3... 80x65 FS JA (22 KW)Document5 pages3... 80x65 FS JA (22 KW)tinhNo ratings yet

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- Anexo 2 - Hoja de Datos Valvula de Diagragma (30-XV-4069)Document1 pageAnexo 2 - Hoja de Datos Valvula de Diagragma (30-XV-4069)Antezana RodriguezNo ratings yet

- Spesifikasi Alat Tugas 2 - Pabrik Lauryl Glucoside - Belinda Liana Devy (D500191099) Ratna Kartika (D500191005) Hammami Fajar (D500191027)Document10 pagesSpesifikasi Alat Tugas 2 - Pabrik Lauryl Glucoside - Belinda Liana Devy (D500191099) Ratna Kartika (D500191005) Hammami Fajar (D500191027)belindaNo ratings yet

- ChE 301 PartII Lecture IVDocument45 pagesChE 301 PartII Lecture IVMahmudur Rahman RiadNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- Dust Collection System Technical Sheet - 9000 CFM Specification Isha Sr. No. Dust Collector DetailsDocument2 pagesDust Collection System Technical Sheet - 9000 CFM Specification Isha Sr. No. Dust Collector DetailsOmkarNo ratings yet

- 100-Mc-417-Ra3-Hx-Ra3 - HDB Condensador ReactorDocument1 page100-Mc-417-Ra3-Hx-Ra3 - HDB Condensador ReactorSonya LoveraNo ratings yet

- Pages FromThakore, Shuchen B. - Bhatt Introduction To Process Engineering and DesignDocument191 pagesPages FromThakore, Shuchen B. - Bhatt Introduction To Process Engineering and DesignAhmed HassanNo ratings yet

- Detail DesignDocument67 pagesDetail DesignBHAVISHA GOHILNo ratings yet

- Bơm Chiller 80m3, 5bargDocument5 pagesBơm Chiller 80m3, 5bargPhượng NguyễnNo ratings yet

- 1Document1 page1kkkprotNo ratings yet

- ExchangerDocument4 pagesExchangeradrian ospino canteroNo ratings yet

- Pump: P-100: Stream Name Liq-1Document2 pagesPump: P-100: Stream Name Liq-1Sebastian Camilo Garcia PradaNo ratings yet

- Level ControllerDocument1 pageLevel Controllerkhasim15No ratings yet

- Heat Transfer Area For Fin Tube Heat Exchanger For FBDDocument8 pagesHeat Transfer Area For Fin Tube Heat Exchanger For FBDPrathmesh GujaratiNo ratings yet

- E 104DKXBNWKDNXKDocument1 pageE 104DKXBNWKDNXKkeyNo ratings yet

- Heat Exchanger Rev - 02Document1 pageHeat Exchanger Rev - 02TKT ConsultantNo ratings yet

- Tower-Process-Data-Sheet - Ex (Version 1)Document1 pageTower-Process-Data-Sheet - Ex (Version 1)Abraham Burgos CelisNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Sekiro: See Runtime Message Report For Warning MessagesDocument1 pageSekiro: See Runtime Message Report For Warning MessagesĐinh Hoàng ViệtNo ratings yet

- Data Sheet of Magnetic Level Gauge For Feed Coalescer PackageDocument1 pageData Sheet of Magnetic Level Gauge For Feed Coalescer PackageHemant NimaseNo ratings yet

- Heat Exchanger Design SummaryDocument3 pagesHeat Exchanger Design SummaryKvvPrasadNo ratings yet

- Horizontal vs. Vertical Baffles - Which To Choose For Your Shell and Tube Heat ExchangerDocument5 pagesHorizontal vs. Vertical Baffles - Which To Choose For Your Shell and Tube Heat Exchangeradil alameenNo ratings yet

- Heat Exchanger Specification SheetDocument4 pagesHeat Exchanger Specification SheetAnita PanthiNo ratings yet

- Shell Tube Heat ExchangerDocument9 pagesShell Tube Heat ExchangerdonyaNo ratings yet

- 2.2 - Details of Shell & Tube H.EDocument110 pages2.2 - Details of Shell & Tube H.ENader GaafarNo ratings yet

- Detail DesignDocument67 pagesDetail DesignBHAVISHA GOHILNo ratings yet

- Heat Exchangers Course Baher Part03Document18 pagesHeat Exchangers Course Baher Part03Baher ElsheikhNo ratings yet

- J. J. Tabarek, Dale E. Klein and James R. Fair Center For Energy Studies The University Aftexas at Austin Austin, Texas 78712Document6 pagesJ. J. Tabarek, Dale E. Klein and James R. Fair Center For Energy Studies The University Aftexas at Austin Austin, Texas 78712José Blanco MosqueraNo ratings yet

- Heat ExchangerDocument34 pagesHeat ExchangerDwi Mariska SNo ratings yet

- ATV Primary Heat ExchangerDocument41 pagesATV Primary Heat Exchangeroverlord5555No ratings yet

- E 101Document21 pagesE 101EberVelazquezChantacaNo ratings yet

- Vibrations in Heat ExchangersDocument67 pagesVibrations in Heat ExchangersNader GaafarNo ratings yet

- Shell and Tube Heat Exchangers DesignDocument27 pagesShell and Tube Heat Exchangers DesignAlëJaMürciaNo ratings yet

- Tema Shell and Tube Heat Exchangers: 8-1-1 BP Oil Co. RPDocument25 pagesTema Shell and Tube Heat Exchangers: 8-1-1 BP Oil Co. RPHardik AcharyaNo ratings yet

- Heat Exchanger Thermal Design Shell&Tube V7.3.1 CP1Page 1: Basic GeometryDocument8 pagesHeat Exchanger Thermal Design Shell&Tube V7.3.1 CP1Page 1: Basic GeometryaminNo ratings yet

- ANZ Technical Guide Heat Exchanger DesigDocument13 pagesANZ Technical Guide Heat Exchanger DesigvikramNo ratings yet

- SHELL and TUBE HEAT EXCHANGERDocument10 pagesSHELL and TUBE HEAT EXCHANGERdanena88No ratings yet

- Baffle (Heat Transfer)Document2 pagesBaffle (Heat Transfer)ХристинаГулеваNo ratings yet

- 882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDocument6 pages882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDavid Alemán Sánchez100% (1)

- Compiled Correlation For Shell Side Heat Transfer CoefficientDocument20 pagesCompiled Correlation For Shell Side Heat Transfer Coefficientscranderi100% (1)

- Shell and Tube Heat Exchanger With Helical BafflesDocument42 pagesShell and Tube Heat Exchanger With Helical BafflesAtul SanghaviNo ratings yet

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDocument37 pagesDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTORONo ratings yet

- Details of Engineering Design and Selection of Heat ExchangerDocument25 pagesDetails of Engineering Design and Selection of Heat ExchangerthejusNo ratings yet

- Heat Exchanger ChecklistDocument9 pagesHeat Exchanger Checklistraja rani75% (4)

- 3 Shell and Tube Heat Exchanger Features That Affect Shell-Side Pressure DropDocument10 pages3 Shell and Tube Heat Exchanger Features That Affect Shell-Side Pressure DropRanjani J DeepakNo ratings yet

- IIT Delhi Heat ExchangerDocument19 pagesIIT Delhi Heat ExchangersunilNo ratings yet

- Design of Shell and Tube Heat Exchanger PDFDocument55 pagesDesign of Shell and Tube Heat Exchanger PDFShawez sayyed100% (1)