Professional Documents

Culture Documents

Site Visit Report: Kryfs

Site Visit Report: Kryfs

Uploaded by

Tech 5Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Site Visit Report: Kryfs

Site Visit Report: Kryfs

Uploaded by

Tech 5Copyright:

Available Formats

Aavishkar Sales And Technical Services Pvt. Ltd.

06, Corporate Avenue, Sonawala Road,

Goregaon (E), Mumbai – 400063

Tel/Fax: +91-22-269850957, Tel: 26868606

Email: info@aavishkargroup.com

Site Visit Report

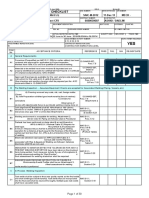

Report No. AG/KRYFS/270224/SR-001 Client. KRYFS

Kherdi, UT. Of Dadra & Nagar

Date of visit 27-02-2024 Location of visit

Haveli (Silvasa)

Weld visual inspection of

Fabricator Desai Construction Job Description

Columns, New Building Unit-5

Gayatri Group Precision

Sub-Contractor Purpose of Visit Weld visual Inspection

Fabrication Services

Based on a request for Inspecting Column welding a site visit was carried out at KRYPS, Building Unit 5. In

Kherdi Village, UT of Dadra Nagar Haveli

Reference Doc.

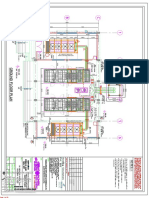

Proposed ITP - KRYFS/FAB/ITP/2024-25/01

Drawing- SMK-DCPL-KPL-AMPL-MCPL-FB-Unit-5-FAB-002

IS 7215-Tolerances for Fabrication of Steel Structures

IS 12843-Tolerances for Erection of Steel Structures

AWS D1.1 (Structural Welding Code)

Review Documents:

1) ITP not finalized by involved parties.

2) Welding machine and Mother Oven are calibrated.

3) WPS, PQR & WPQ (Welding test witnessed report are found but final document not received at site.

4) Material Test certificate found IS 2062 Gr. 250 BR for stiffener plate, IS 2062 Gr. 350 A, IS 2062 Gr. 350 C

for main structure plate

5) Filler wire test certificate are found satisfactory as per ASME Section II Part C

Observation:

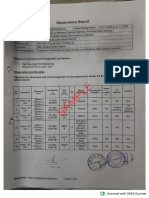

1. Column No C-21: Both side welding done but as per drawing its required only 300 mm Stitch weld.

2. Fillet Leg measure and leg size found 8 mm, but throat Thickness is not found as per requirement need

to be rectify.

3. Both side concave weld profile observed, rectification required.

4. Fit up Inspection for C-1, C-13, C-33, C-41, and C-21 Found satisfactory.

5. In fit-up of column to base plate, root face and root gap in two plate found more than 3 mm.

6. Bevel angle not found satisfactory.

7. Approximate 10 mm distortion found in full length of column.

8. Gas cutting is not been done properly.

9. After gas cutting straightening check and found approximate 10 to 20 mm out of the line, need to be

rectify.

Recommendation:

1. Proper stand or leveling required for gas cutting.

2. Use proper gas cutting for less distortion after welding.

3. Repair to all mock up sample column for proper weld size as per drawing.

4. All sharp edges must be clean properly

Report No: AG/KRYFS/270224/SR-001, Page 01 of 03

Aavishkar Sales And Technical Services Pvt. Ltd.

06, Corporate Avenue, Sonawala Road,

Goregaon (E), Mumbai – 400063

Tel/Fax: +91-22-269850957, Tel: 26868606

Email: info@aavishkargroup.com

5. Column to Base Plate Proper bevel angle require for (CJP) complete joint penetration joint,

6. Proper root gap and root face require for CJP joint.

7. After completed one side welding do back chipping in back side and check DP test and if it is okay than

complete the other side welding.

8. Proper grinding required for gas cutting edges

9. There was Distortion found because no proper gas cutting practice.

10. There should be Step wise visual inspection carried out.

11. Gas cutting is not been done is straight line there is approx. 10 to 20 mm out of line level

12. All Sharp Edge should be clean.

13. SAW parameters were changed and check the leg size and found more than 10 mm and throat

thickness found more than 6 mm

14. Material handling, Drawing , Filler wire handling, WPS, PQR & WPQ record all soft excel sheet format

are submitted to Desai Construction for need to be proper data collected in working time.

Weld Size app. 8 mm Weld Size app. 8 mm

Throat size not match, Concave weld found Throat size not match, Concave weld found

Report No: AG/KRYFS/270224/SR-001, Page 02 of 03

Aavishkar Sales And Technical Services Pvt. Ltd.

06, Corporate Avenue, Sonawala Road,

Goregaon (E), Mumbai – 400063

Tel/Fax: +91-22-269850957, Tel: 26868606

Email: info@aavishkargroup.com

Straightening not proper for column Root gap not proper

Gas cutting not doing proper Root face & Grinding not proper

Date: 27/02/2024

Mr. Sydney Rozario

ASTSPL Rep. Client Rep. Fabricator Rep.

Report No: AG/KRYFS/270224/SR-001, Page 03 of 03

You might also like

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 4 out of 5 stars4/5 (9)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Procedure - Fit-Up & AssemblyDocument8 pagesProcedure - Fit-Up & AssemblyRakesh Ranjan100% (1)

- Ms - Removal of Damaged Anchor BoltsDocument5 pagesMs - Removal of Damaged Anchor Boltsmoytabura96No ratings yet

- Victora ReportDocument28 pagesVictora ReportAmit Sharma100% (1)

- MultiMill IQOQPQDocument32 pagesMultiMill IQOQPQAtul Sharma78% (9)

- Q.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteDocument5 pagesQ.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteAws Mohamed100% (1)

- Colloid IQOQPQDocument31 pagesColloid IQOQPQAtul Sharma100% (1)

- Ms - Replacing Damaged Bended BoltDocument5 pagesMs - Replacing Damaged Bended Boltmoytabura96No ratings yet

- Inspection and Test PlanDocument28 pagesInspection and Test Planmfvallega88% (17)

- Religion and Belief Systems in Australia Post 1945Document6 pagesReligion and Belief Systems in Australia Post 1945Jananee SundarakumarNo ratings yet

- Detailed Lesson Plan in TLE VIIDocument3 pagesDetailed Lesson Plan in TLE VIIJose Nilo Pastorall70% (10)

- Comtech Metal Company Profile As On 30.04.2011Document17 pagesComtech Metal Company Profile As On 30.04.2011palsNo ratings yet

- T, K & Y Shape Joint Steel StructureDocument23 pagesT, K & Y Shape Joint Steel StructurePrabu VenkatNo ratings yet

- Site Visit Technopolis Knowledge ParkDocument2 pagesSite Visit Technopolis Knowledge ParkTech 5No ratings yet

- RevisedMethodStatementforStructuralSteelWorksofCP 02Document155 pagesRevisedMethodStatementforStructuralSteelWorksofCP 02Brayand Colonia MarquinaNo ratings yet

- MSB-TPL-REW-BV-HYD-8705-FIR 003 Dated 16-02-2023Document4 pagesMSB-TPL-REW-BV-HYD-8705-FIR 003 Dated 16-02-2023pl_arunachalam79No ratings yet

- MES - Construction Quality Manual - Rev - 0Document55 pagesMES - Construction Quality Manual - Rev - 0Ishaan ThakerNo ratings yet

- RQF 10406905 RepsDocument11 pagesRQF 10406905 Repsdavid selekaNo ratings yet

- SBC T 0022 21057423 S08 Pi Ram 000 0006Document9 pagesSBC T 0022 21057423 S08 Pi Ram 000 0006Jai Sam DanielNo ratings yet

- Avs ProfileDocument20 pagesAvs ProfileUjwalNo ratings yet

- Industrial Training ReportDocument23 pagesIndustrial Training Reportadhithianjayan7No ratings yet

- SAIC M 2012 (Structural Welding)Document30 pagesSAIC M 2012 (Structural Welding)rubda11100% (1)

- Saudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 MechDocument15 pagesSaudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Deck-Jose B Correa-6-7-17Document3 pagesDeck-Jose B Correa-6-7-17Virginio Ed EnriquezNo ratings yet

- SSR UW DNIP 0003 ESC XXXX 001 00 Signed PDFDocument12 pagesSSR UW DNIP 0003 ESC XXXX 001 00 Signed PDFKrishna KnsNo ratings yet

- Company Profile - SveDocument22 pagesCompany Profile - Svetgmanjunath151No ratings yet

- Global Casitngs IndiaDocument26 pagesGlobal Casitngs IndiaRajNo ratings yet

- DR KAISER Grinding WheelsDocument20 pagesDR KAISER Grinding Wheelsnestor333No ratings yet

- Tender For Earthing - AmbikapurDocument26 pagesTender For Earthing - AmbikapurKrishna ManandharNo ratings yet

- 009 Bts SWSM RJ P Plate 2000aDocument1 page009 Bts SWSM RJ P Plate 2000aajustin84No ratings yet

- Shree Shakti Engineering (G) Pvt. Ltd.Document16 pagesShree Shakti Engineering (G) Pvt. Ltd.Krunal JaniNo ratings yet

- Candidate Package 1Document15 pagesCandidate Package 1vascocarrico68No ratings yet

- Ir - EFFRA INDUSTRIES LLP - MEW MS PO 02 2022 23 - 462023 - 472023ICS4199Document2 pagesIr - EFFRA INDUSTRIES LLP - MEW MS PO 02 2022 23 - 462023 - 472023ICS4199Voltonix InfratechNo ratings yet

- Resume Abdul Hafiza: Work ExperienceDocument4 pagesResume Abdul Hafiza: Work ExperienceShashwat PandeyNo ratings yet

- General Specification FOR Material, Fabrication and Installation of StructureDocument58 pagesGeneral Specification FOR Material, Fabrication and Installation of Structuredang_noex56% (9)

- Company Introduction - Quadrant EngineeringDocument32 pagesCompany Introduction - Quadrant EngineeringMitul Patel100% (1)

- Procedure For WQTDocument13 pagesProcedure For WQTdevikar8umNo ratings yet

- Welder Qualification Procedure PDFDocument13 pagesWelder Qualification Procedure PDFEngineersEDGE Coimbatore0% (1)

- Request For N.D.E Services: Mr. PatelDocument1 pageRequest For N.D.E Services: Mr. PatelRifanjshshNo ratings yet

- Cwi Program Information: Faxed Applications Are Not AcceptedDocument7 pagesCwi Program Information: Faxed Applications Are Not Acceptedfeihung20120% (1)

- QC Welding Inspector (CSWIP 3.2)Document5 pagesQC Welding Inspector (CSWIP 3.2)Tanveer Ahmed QuadriNo ratings yet

- Welding Inspector May 2021Document8 pagesWelding Inspector May 2021SUNIL BABURAO GAVADENo ratings yet

- Fabrication Procedure DMW-4820M00250-000120-19Document8 pagesFabrication Procedure DMW-4820M00250-000120-19mohd as shahiddin jafriNo ratings yet

- Comment - Design of 24 M Comp Girder-R5 FINAL PDFDocument60 pagesComment - Design of 24 M Comp Girder-R5 FINAL PDFNilay Gandhi100% (2)

- MQP 2Document10 pagesMQP 2prithvirajd20No ratings yet

- Fabrication Procedure SA-4200-70621Document8 pagesFabrication Procedure SA-4200-70621mohd as shahiddin jafriNo ratings yet

- Fabrication Procedure SA-4200-70621Document24 pagesFabrication Procedure SA-4200-70621mohd as shahiddin jafriNo ratings yet

- Handrail RailingDocument11 pagesHandrail RailingphilipyapNo ratings yet

- Sri Ganesh Engg - ProfileDocument19 pagesSri Ganesh Engg - Profileshikharc100% (1)

- Updated CV Suraj K 2021Document43 pagesUpdated CV Suraj K 2021NIYAS AHAMMEDNo ratings yet

- JP For Structural WorksDocument4 pagesJP For Structural WorksRajeev KumarNo ratings yet

- Shadman Zeya c.v5Document5 pagesShadman Zeya c.v5Raj AryanNo ratings yet

- Company Name Key Information Questions Answers File Reference Reviews & ApprovalsDocument7 pagesCompany Name Key Information Questions Answers File Reference Reviews & ApprovalsMAT-LIONNo ratings yet

- Field Query / Site Query: Form No.: 9686-QAQC-FRM-0036 Rev B3Document2 pagesField Query / Site Query: Form No.: 9686-QAQC-FRM-0036 Rev B3ANIL PLAMOOTTILNo ratings yet

- YogiDocument4 pagesYogiashok kuteNo ratings yet

- 60.9 X 60.9-QuoteDocument11 pages60.9 X 60.9-QuoteJoe NadakkalanNo ratings yet

- Northern EnterprisesDocument35 pagesNorthern EnterprisesJagdev SinghNo ratings yet

- Shop InvestigationDocument10 pagesShop InvestigationMcmiltondmordomNo ratings yet

- SAP Order No. 4611019248 (Contractor Acceptance)Document10 pagesSAP Order No. 4611019248 (Contractor Acceptance)Tech 5No ratings yet

- Ag Av GF SVR 01 - 29 11 2023Document2 pagesAg Av GF SVR 01 - 29 11 2023Tech 5No ratings yet

- Sample Inspection Report - MMRDADocument45 pagesSample Inspection Report - MMRDATech 5No ratings yet

- Site Visit Technopolis Knowledge ParkDocument2 pagesSite Visit Technopolis Knowledge ParkTech 5No ratings yet

- Technical Services at Presentation at AG - OptDocument112 pagesTechnical Services at Presentation at AG - OptTech 5No ratings yet

- Various Artists - The Joy of ClassicsDocument82 pagesVarious Artists - The Joy of ClassicsCarlos Toledo88% (16)

- Memoria Proyecto Informativo de Alcantarillado Domiciliario Miguel CorralDocument7 pagesMemoria Proyecto Informativo de Alcantarillado Domiciliario Miguel CorralCarlos MoralesNo ratings yet

- CH 3 Online Advertising vs. Offline AdvertisingDocument4 pagesCH 3 Online Advertising vs. Offline AdvertisingKRANTINo ratings yet

- Internship Report On GPDocument45 pagesInternship Report On GPpavel2051No ratings yet

- SDL Atlas Catalog 23 2015Document150 pagesSDL Atlas Catalog 23 2015Tahir NizamNo ratings yet

- Solution Manual For Transportation: A Global Supply Chain Perspective, 8th Edition, John J. Coyle, Robert A. Novack, Brian Gibson, Edward J. BardiDocument34 pagesSolution Manual For Transportation: A Global Supply Chain Perspective, 8th Edition, John J. Coyle, Robert A. Novack, Brian Gibson, Edward J. Bardielizabethsantosfawmpbnzjt100% (21)

- Second Practice First Partial English IIIDocument5 pagesSecond Practice First Partial English IIICamiloNo ratings yet

- Module 2 - Assessment ActivitiesDocument3 pagesModule 2 - Assessment Activitiesaj dumpNo ratings yet

- Palanca vs. CADocument16 pagesPalanca vs. CASherwin Anoba CabutijaNo ratings yet

- Davis Michael 1A Resume 1Document1 pageDavis Michael 1A Resume 1Alyssa HowellNo ratings yet

- How To Install The Data Protector License KeyDocument4 pagesHow To Install The Data Protector License KeyHillary Johnson0% (1)

- Bowthorpe News May 2017Document36 pagesBowthorpe News May 2017Anonymous AySEIwycNo ratings yet

- Brigada Solicitation and InvitationDocument3 pagesBrigada Solicitation and Invitationguendolyn templadoNo ratings yet

- Time Clauses - That Vs Which-Relative ClausesDocument8 pagesTime Clauses - That Vs Which-Relative ClausesZuza AlexandrinaNo ratings yet

- Services Provided by Merchant BanksDocument4 pagesServices Provided by Merchant BanksParul PrasadNo ratings yet

- Dg-1 (Remote Radiator) Above Control Room Slab: 05-MAR-2018 Atluri Mohan Krishna (B845)Document32 pagesDg-1 (Remote Radiator) Above Control Room Slab: 05-MAR-2018 Atluri Mohan Krishna (B845)Shaik AbdullaNo ratings yet

- Marketable Avenues: 14,15,16 April 2023Document31 pagesMarketable Avenues: 14,15,16 April 2023Avaneesh Natraj GujranNo ratings yet

- SAE-J524, 525, 526, 365 Tubing Pressure RatingDocument1 pageSAE-J524, 525, 526, 365 Tubing Pressure RatingSamuel RochetteNo ratings yet

- Collection of Windows 10 Hidden Secret Registry TweaksDocument9 pagesCollection of Windows 10 Hidden Secret Registry TweaksLiyoNo ratings yet

- Chapter Ii Review of Related LiteratureDocument12 pagesChapter Ii Review of Related LiteratureJane Drelle AgustinNo ratings yet

- Proforma Invoice: TOTAL:300000 Meters $3,900,000Document3 pagesProforma Invoice: TOTAL:300000 Meters $3,900,000Eslam A. AliNo ratings yet

- Ebook Contemporary Issues in Accounting 2Nd Edition Rankin Solutions Manual Full Chapter PDFDocument53 pagesEbook Contemporary Issues in Accounting 2Nd Edition Rankin Solutions Manual Full Chapter PDFfideliamaximilian7pjjf100% (11)

- Zero Moment Point ZMP Elysium LabsDocument3 pagesZero Moment Point ZMP Elysium LabsKaren DuarteNo ratings yet

- Scopes of Marketing AssignmentDocument4 pagesScopes of Marketing AssignmentKhira Xandria AldabaNo ratings yet

- UIL Calculator Applications Study ListDocument7 pagesUIL Calculator Applications Study ListRocket FireNo ratings yet

- Course Guide For Simplified Accounting For Entrepreneurs & Professionals (Safe&P)Document7 pagesCourse Guide For Simplified Accounting For Entrepreneurs & Professionals (Safe&P)Darwin Dionisio ClementeNo ratings yet

- All The World's A StageDocument9 pagesAll The World's A StagesonynmurthyNo ratings yet

- Addiction Is A Family IllnessDocument21 pagesAddiction Is A Family IllnessMarla100% (1)