Professional Documents

Culture Documents

Fall Protection Inspection Checklist 1

Fall Protection Inspection Checklist 1

Uploaded by

Narantsatsralt Ravdandorj0 ratings0% found this document useful (0 votes)

2 views2 pagesFALL PROTECTION INSPECTION CHECKLIST BEST PRACTICE

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFALL PROTECTION INSPECTION CHECKLIST BEST PRACTICE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views2 pagesFall Protection Inspection Checklist 1

Fall Protection Inspection Checklist 1

Uploaded by

Narantsatsralt RavdandorjFALL PROTECTION INSPECTION CHECKLIST BEST PRACTICE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

Best Practices

BEST PRACTICE #13

FALL PROTECTION INSPECTION CHECKLIST

Best Practices provided by CAMSAFETY are intended for reference purposes only and are not intended

to cover all aspects of the topics discussed. MIOSHA & OSHA standards were the predominant

references used for this document. It is highly recommended that any documents put into practice by

your company be thoroughly reviewed and analyzed by a qualified safety professional.

Full Body Harnesses – Inspect before each use

1. Nylon webbing is free of cuts, burn marks, and chemical damage Yes N/A

2. Webbing is free of tears, broken fibers, frayed edges, and pulled stitches Yes N/A

3. D-rings are free of excessive wear, pits, deterioration, cracks, and sharp edges Yes N/A

4. D-rings pivot freely Yes N/A

5. Buckles are not deformed or cracked, and will operate correctly Yes N/A

6. All grommets are secure and not deformed Yes N/A

7. Harness webbing has no additional holes Yes N/A

8. All rivets are tight and not deformed Yes N/A

9. Tongue/straps show no excessive wear from repeated buckling Yes N/A

Snaphooks – Inspect before each use

1. Snaphooks have no hook and eye distortions Yes N/A

2. Snaphooks have no cracks and pitted surfaces Yes N/A

3. Keeper latches are not be bent, distorted, or obstructed Yes N/A

4. Keeper latches seat into the nose without binding Yes N/A

5. Keeper springs securely close the keeper latches Yes N/A

6. Locking mechanism was tested to verify that keeper latches lock properly Yes N/A

7. All rivets are tight and not deformed Yes N/A

8. Tongue/straps show no excessive wear from repeated buckling Yes N/A

Horizontal Lifelines – Inspect before each use

1. All labels are present, legible, and securely attached Yes N/A

2. Lifeline rope has no visible physical damage Yes N/A

Copyright 2009 Construction Association of Michigan

Best Practices

3. All metallic parts for evidence of defects, damage, alteration, and missing parts Yes N/A

Lanyard/Shock-Absorbing Lanyard – Inspect before each use

1. Nylon webbing is free of cuts, abrasions, burn marks, and chemical damage Yes N/A

2. Webbing is free of tears, broken fibers, frayed edges, and pulled stitches Yes N/A

3. Wire rope lanyard is free of cuts, frayed areas, and unusual wearing patterns Yes N/A

4. Shock absorber pack is free of burn holes and tears Yes N/A

5. Shock absorber pack stitching is free of loose strands, rips, and deterioration Yes N/A

6. Flag on shock-absorbing lanyard has not been activated Yes N/A

7. D-rings are free of excessive wear, pits, deterioration, cracks, and sharp edges Yes N/A

8. D-rings pivot freely Yes N/A

Self-Retracting Lanyards – Inspect before each use

1. Body has no visible physical damage Yes N/A

2. All back nuts or rivets are tight Yes N/A

3. Nylon strap is free of any burns, kinks, knots, and excessive wear Yes N/A

4. Nylon strap is free of tears, broken fibers, frayed edges, and pulled stitches Yes N/A

5. Nylon strap retracts freely Yes N/A

6. Unit was tested to verify that the locking mechanism is operating correctly Yes N/A

Tie-Off Adaptors/Anchorages – Inspect before each use

1. Tie-off adaptor is free of cuts, abrasions, burn marks, and chemical damage Yes N/A

2. Tie-off adaptor is free of tears, broken fibers, frayed edges, and pulled stitches Yes N/A

3. Tie-off adaptor is free of signs of deterioration, heat damage, and stretching Yes N/A

4. Unit was tested to verify that the locking mechanism is operating correctly Yes N/A

Copyright 2009 Construction Association of Michigan

You might also like

- PARACHUTE-MC1-1C User Manual-Packing and Maintenance GuidelinesDocument30 pagesPARACHUTE-MC1-1C User Manual-Packing and Maintenance Guidelinesaba distributor100% (3)

- Ladder Log Ladder Inspection ChecklistDocument2 pagesLadder Log Ladder Inspection Checklistkhalis100% (1)

- Manual, Craftsman Table Saw, Model 113-298720 and 750Document52 pagesManual, Craftsman Table Saw, Model 113-298720 and 750Eng-JR80% (5)

- Fall Protection Equipment ChecklistDocument2 pagesFall Protection Equipment ChecklistMubashir AbbasNo ratings yet

- Port and TerminalsDocument12 pagesPort and TerminalsSharon Amondi100% (2)

- Boracay Smoking BanDocument3 pagesBoracay Smoking BanGMA News OnlineNo ratings yet

- Code 4&7Document4 pagesCode 4&7Ir Ahmad Afiq100% (1)

- Mark Peters Company: Safety Harness InspectionDocument9 pagesMark Peters Company: Safety Harness InspectionJustice AkuboNo ratings yet

- Cleaning: Inspection and Maintenance Checklist For Fall Arrest SystemsDocument3 pagesCleaning: Inspection and Maintenance Checklist For Fall Arrest Systemsal mubarokNo ratings yet

- Swivel Head Fittings.: Blocks - Care and MaintenanceDocument1 pageSwivel Head Fittings.: Blocks - Care and MaintenanceMin SoeNo ratings yet

- Harness LanyardInspectionReportDocument3 pagesHarness LanyardInspectionReportNarantsatsralt RavdandorjNo ratings yet

- FK7 U NJT JWIZIa KE8 C 8 Pydw RQDocument1 pageFK7 U NJT JWIZIa KE8 C 8 Pydw RQClarabelle Mae Dela RosaNo ratings yet

- Harness Insp. and Maint. Daily ChecklistDocument3 pagesHarness Insp. and Maint. Daily ChecklistSarojini VeeraraghavanNo ratings yet

- Harness LanyardInspectionReportDocument3 pagesHarness LanyardInspectionReportHamza Shehzad100% (1)

- Checklist - Steel Structure and Roofing Fall ArrestDocument1 pageChecklist - Steel Structure and Roofing Fall ArrestMovies StoreNo ratings yet

- MDC - Power Tools Inspection Checklist FR-01-EHS-045-Rev.0Document1 pageMDC - Power Tools Inspection Checklist FR-01-EHS-045-Rev.0Aaron CastañedaNo ratings yet

- HarnesschecklistDocument1 pageHarnesschecklistgroshan20No ratings yet

- Toolbox Training Session - Harness and LanyardDocument3 pagesToolbox Training Session - Harness and LanyardSarah AjodhaNo ratings yet

- TBT Harnesses PDFDocument2 pagesTBT Harnesses PDFHassan AbdullahNo ratings yet

- Sling Inspection Checklist: Sling Type: Size: Manufactured By: Serial NoDocument3 pagesSling Inspection Checklist: Sling Type: Size: Manufactured By: Serial NoJuan de la Cruz100% (1)

- Confined Space Equipment Inspection Report FormDocument4 pagesConfined Space Equipment Inspection Report FormtmamputsiNo ratings yet

- LGP-10 Leg Press 45 DegreeDocument11 pagesLGP-10 Leg Press 45 Degreealessromero76No ratings yet

- Materials Handling: in ConstructionDocument41 pagesMaterials Handling: in ConstructionSatya NaiduNo ratings yet

- Warning: Synthetic Tie Down Safety BulletinDocument3 pagesWarning: Synthetic Tie Down Safety BulletinAlejandro CampomarNo ratings yet

- Slings and Rigging: Workforce Safety & InsuranceDocument2 pagesSlings and Rigging: Workforce Safety & InsuranceDedi MulyadiNo ratings yet

- Safety Belt - 39Document3 pagesSafety Belt - 39Darius DsouzaNo ratings yet

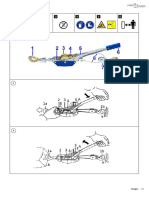

- 2. Инструкции Apple Ръчна лебедкаDocument2 pages2. Инструкции Apple Ръчна лебедкаeliaNo ratings yet

- 8 Tips Memastikan Mooring Winch & Anchor Windlass Berfungsi Dengan SempurnaDocument3 pages8 Tips Memastikan Mooring Winch & Anchor Windlass Berfungsi Dengan SempurnaOctavian YudhaNo ratings yet

- Instructions For The Safe Use Of: Fibre Rope SlingsDocument2 pagesInstructions For The Safe Use Of: Fibre Rope SlingsMontadhar SaeedNo ratings yet

- css1 Lesson5 LO2 PREPARE HAND TOOLSDocument11 pagescss1 Lesson5 LO2 PREPARE HAND TOOLSGen GonNo ratings yet

- Boom Truck Instructors NotesDocument76 pagesBoom Truck Instructors NotesWill RodriguezNo ratings yet

- Lesson 1 9867Document9 pagesLesson 1 9867EricNo ratings yet

- Iquipment and Maintenance ScheduleDocument42 pagesIquipment and Maintenance ScheduleAlbert Uy Dayrit100% (1)

- Chain Sling ChecklistDocument1 pageChain Sling Checklistswarnajit paulNo ratings yet

- All PagesDocument12 pagesAll PagesNastyaNo ratings yet

- Full Body Harness ChecklistDocument1 pageFull Body Harness Checklistmohammad sarfarazNo ratings yet

- 6 Monthly Thorough Sling Inspection ChecklistDocument1 page6 Monthly Thorough Sling Inspection ChecklistTor-tahan Chanasongkram OnchuNo ratings yet

- Totem InstructionsDocument2 pagesTotem InstructionsTheDoctorFeelGoodNo ratings yet

- Diversified Fall Protection PPE Pre-Use ChecklistDocument3 pagesDiversified Fall Protection PPE Pre-Use ChecklistMuhammad SaleemNo ratings yet

- Pre Use Inspection (Webbing Sling)Document9 pagesPre Use Inspection (Webbing Sling)Agil Wahyu PamungkasNo ratings yet

- Pre Use Inspection (Webbing Sling)Document9 pagesPre Use Inspection (Webbing Sling)Agil Wahyu PamungkasNo ratings yet

- A5 - 1107 Cradles Checklist ASAKDocument2 pagesA5 - 1107 Cradles Checklist ASAKotega CyrilNo ratings yet

- Checklist - Clamp MeterDocument1 pageChecklist - Clamp MeterJustice AbbanNo ratings yet

- Rope - Inspection - Log - Cuerda de Seguridad Hoja de SeguimientoDocument1 pageRope - Inspection - Log - Cuerda de Seguridad Hoja de SeguimientoLuis Esteban RamírezNo ratings yet

- Harness (And Body Belt) Inspection: WebbingDocument3 pagesHarness (And Body Belt) Inspection: WebbingUlviyye ElesgerovaNo ratings yet

- Serba Serbi Safety BeltsDocument2 pagesSerba Serbi Safety BeltsEHS BppNo ratings yet

- HSE-F-NEOM-018 - Weekly Site Safety Inspection ChecklistDocument3 pagesHSE-F-NEOM-018 - Weekly Site Safety Inspection ChecklistAhmed MohamedNo ratings yet

- important points on wires and ropes - копияDocument2 pagesimportant points on wires and ropes - копияВлад РайлиNo ratings yet

- Chains and Lifting Gear - 8890Document2 pagesChains and Lifting Gear - 8890anisaanNo ratings yet

- AIRS / R.RRFT$ M RN - : Owners ManualDocument24 pagesAIRS / R.RRFT$ M RN - : Owners ManualLesley RuseNo ratings yet

- Initial Inspection Information HarnessDocument2 pagesInitial Inspection Information HarnessAlejandro Silva ValenciaNo ratings yet

- Body Belts InspectionDocument4 pagesBody Belts InspectionI LucianaNo ratings yet

- Rope Ladder FormDocument1 pageRope Ladder FormJeffrey RamosNo ratings yet

- Admin 4 2 R0Document2 pagesAdmin 4 2 R0Stephen MalobaNo ratings yet

- M-OSH-002-PPE ChecklistDocument1 pageM-OSH-002-PPE Checklistmulugeta114985No ratings yet

- 531..full Body Harness ChecklistDocument1 page531..full Body Harness ChecklistAmit BhattNo ratings yet

- MF Prensa Tuberia Ridgid Tristand 460-6Document36 pagesMF Prensa Tuberia Ridgid Tristand 460-6Edwin Restrepo SalazarNo ratings yet

- Instructions For The Safe Use Of: Flat Woven Webbing SlingsDocument2 pagesInstructions For The Safe Use Of: Flat Woven Webbing SlingsMontadhar SaeedNo ratings yet

- Full Body Harness Inspection ChecklistDocument2 pagesFull Body Harness Inspection ChecklistMuhammad SaleemNo ratings yet

- Wire Rope Slings Si 2 - 2 EmmDocument2 pagesWire Rope Slings Si 2 - 2 EmmheppyfaebanffNo ratings yet

- Safety Flash: Synthetic Web SlingDocument1 pageSafety Flash: Synthetic Web SlingarslanahmedkhawajaNo ratings yet

- AS Pre Use InspectionGuideDocument4 pagesAS Pre Use InspectionGuideriven.ngNo ratings yet

- Knots: An Illustrated Practical Guide to the Essential Knot Types and their UsesFrom EverandKnots: An Illustrated Practical Guide to the Essential Knot Types and their UsesNo ratings yet

- The Facility Manager's Risk Assessment Matrix FINALDocument2 pagesThe Facility Manager's Risk Assessment Matrix FINALNarantsatsralt RavdandorjNo ratings yet

- Ladder SafetyDocument3 pagesLadder SafetyNarantsatsralt RavdandorjNo ratings yet

- Workplace Safety Preventing Accidents in The WorkplaceDocument18 pagesWorkplace Safety Preventing Accidents in The WorkplaceNarantsatsralt RavdandorjNo ratings yet

- Vocabulary Stage 5 PrintDocument13 pagesVocabulary Stage 5 PrintNarantsatsralt RavdandorjNo ratings yet

- AnilineDocument6 pagesAnilineMUHAMMAD AKRAM0% (1)

- Law Enforcement and Traffic Adjudication SystemDocument6 pagesLaw Enforcement and Traffic Adjudication SystemMa Lorely Liban-CanapiNo ratings yet

- Applied TelecommunicationDocument100 pagesApplied TelecommunicationTech ProffesorNo ratings yet

- Advertisement - UPPSCDocument10 pagesAdvertisement - UPPSCHimanshu MauryaNo ratings yet

- Taylor vs. Uy Tieng Piao (1922)Document2 pagesTaylor vs. Uy Tieng Piao (1922)xxxaaxxx100% (4)

- Practice - Inventory Valuation: FIFO, LIFO and WAC (AVERAGE)Document2 pagesPractice - Inventory Valuation: FIFO, LIFO and WAC (AVERAGE)medha surNo ratings yet

- Movil 75 SANY STC300HDocument9 pagesMovil 75 SANY STC300HGermán CampoyNo ratings yet

- اعادة التامينDocument23 pagesاعادة التامينfaiza elabidNo ratings yet

- Project Report On Rihand STPP Stage-II 2x500mwDocument175 pagesProject Report On Rihand STPP Stage-II 2x500mwSathesh ThangathuraiNo ratings yet

- Oisd STD 118Document31 pagesOisd STD 118rajwadi50% (2)

- Utilization of Plastic Waste For Road Construction: Presented byDocument14 pagesUtilization of Plastic Waste For Road Construction: Presented byDhiraj KapureNo ratings yet

- 1.1.2.a Assignment - Partnership Formation and OperationDocument14 pages1.1.2.a Assignment - Partnership Formation and OperationGiselle MartinezNo ratings yet

- ErrorDocument26 pagesErrorShashi WaghNo ratings yet

- Free Proxy ListDocument5 pagesFree Proxy ListWalid TorkhaniNo ratings yet

- GGGDocument35 pagesGGGfan girlNo ratings yet

- Suspension ReportDocument5 pagesSuspension Reportadithiyan saravananNo ratings yet

- Party ListDocument46 pagesParty ListMarie CecileNo ratings yet

- Proof of Residency TemplateDocument1 pageProof of Residency Templateshelley lovellNo ratings yet

- G.R. No. 178713 LORENZO SHIPPING CORPORATION, Petitioner, vs. FLORENCIO O. VILLARINDocument4 pagesG.R. No. 178713 LORENZO SHIPPING CORPORATION, Petitioner, vs. FLORENCIO O. VILLARINMark VirayNo ratings yet

- Bgy. Sindalan Vs CA - DigestDocument2 pagesBgy. Sindalan Vs CA - Digestremoveignorance100% (1)

- CEO and Executive Director - CV HICHAM FRAOUIDocument4 pagesCEO and Executive Director - CV HICHAM FRAOUIHicham FraouiNo ratings yet

- IRI E1926.ssrt0435Document16 pagesIRI E1926.ssrt0435AaaaaNo ratings yet

- ASR 3E Book 3 Unit 1Document66 pagesASR 3E Book 3 Unit 1Lee YuhshiNo ratings yet

- 2022-04-12 - Affidavit No 1 of B. EmersonDocument119 pages2022-04-12 - Affidavit No 1 of B. EmersonCanadian Society for the Advancement of Science in Public PolicyNo ratings yet

- Centrifugal Pump Piping Design LayoutDocument19 pagesCentrifugal Pump Piping Design LayoutzhangjieNo ratings yet

- FINAL REPORT Group IIIDocument87 pagesFINAL REPORT Group IIICUSTOMSNo ratings yet

- PacmakerDocument37 pagesPacmakerSalman HabeebNo ratings yet