Professional Documents

Culture Documents

HBR. The 787 Pb.

HBR. The 787 Pb.

Uploaded by

shaikhabdulwaheed18Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HBR. The 787 Pb.

HBR. The 787 Pb.

Uploaded by

shaikhabdulwaheed18Copyright:

Available Formats

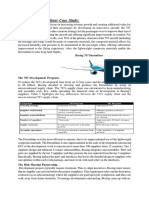

The 787’s Problems Run Deeper Than Outsourcing

Harvard Business Review- Innovation - by James Allworth - JANUARY 30, 2013

The 787 Dreamliner was supposed to be a big jump forward for Boeing — notably, the first plane to be

made entirely of composites rather than aluminum. It consumes 20% less fuel than an equivalent 767;

which, given today’s increasing fuel prices and airlines’ diminishing profit margins, should make it an

extremely desirable aircraft. Unfortunately, things haven’t quite worked out as planned.

While the first 787 was originally scheduled to be delivered back in 2008, a string of delays and cost

overruns meant that deliveries didn’t start until 2011. Boeing looked to have turned the corner with the

787 once deliveries had started, but since launch it has been plagued with a number of high-profile

problems — fuel leaks, smoke in the cabin, and fires. The troubled plane has been grounded as global

regulators investigate whether it’s safe to fly. Now, it is true that problems like these are always a

feature of new plane launches. But the extent to which the 787 has been troubled both in gestation and

post-launch suggests that something more is at work.

Boeing undertook one of the most extensive outsourcing campaigns that it has ever attempted in its

history. That decision has received a lot of press coverage, and the common wisdom is coalescing

around this as a cause of the problems. But Boeing is no stranger to subcontracting. And while

outsourcing can certainly lead to problems, I’m not convinced it’s the cause of these problems.

Outsourcing leads to business model risk — you open the door to outsourcing your profits (in fact, a

2001 Boeing paper that is incredibly prescient and worth the time to read identified exactly this

problem). But this isn’t the problem that the 787 is suffering from. At least not yet. Rather, the issues

the plane has been facing have much more to do with Boeing’s decision to treat the design and

production of such a radically new and different aircraft as a modular system so early in its

development.

In the creation of any truly new product or product category, it is almost invariably a big advantage to

start out as integrated as possible. Why? Well, put simply, the more elements of the design that are

under your control, the more effectively you’re able to radically change the design of a product — you

give your engineers more degrees of freedom. Similarly, being integrated means you don’t have to

understand what all the interdependencies are going to be between the components in a

product that you haven’t created yet (which, obviously, is pretty hard to do). And, as a result of that, you

don’t need to ask suppliers to contract over interconnects that haven’t been created yet, either. Instead,

you can put employees together of different disciplines and tell them to solve the problems together.

Many of the problems they will encounter would not have been possible to anticipate; but that’s ok,

because they’re not under contract to build a component — they’ve been employed to solve a problem.

Their primary focus is on what the optimal solution is, and if that means changing multiple elements of

the design, then they’re not fighting a whole set of organizational incentives that discourage them from

doing it.

Conversely, if you’re trying to modularize something — particularly if you’re trying to do it across

organizational boundaries — you want to be absolutely sure that you know how all the pieces optimally

work together, so everyone can just focus on their piece of the puzzle. If you’ve done it too soon and

tried to modularize parts of an unsolved puzzle across suppliers, then each time one of those

unanticipated problems or interdependencies arises, you have to cross corporate boundaries to make

the necessary changes — changes which could dramatically impact the P&L of a supplier. Lawyers will

probably need to get involved. So too might the other suppliers, who could quite possibly be required to

change the design of their component, also (chances are, you’ve already contracted with them, too).

The whole thing snowballs.

Historically, Boeing understood that, and had worked with its subcontractors on that basis. If it was

going to rely on them, it would provide them with detailed blueprints of the parts that were required —

after Boeing had already created them. That, in turn, meant that Boeing had to design all the relevant

pieces of the puzzle itself, first. But with the 787, it appears that Boeing tried a very different approach:

rather than having the puzzle solved and asking the suppliers to provide a defined puzzle piece, they

asked suppliers to create their own blueprints for parts. The puzzle hadn’t been properly solved when

Boeing asked suppliers for the pieces. It should come as little surprise then, that as the components

came back from far-flung suppliers, for the first plane ever made of composite materials… those parts

didn’t all fit together. Time and cost blew out accordingly.

It’s easy to blame the outsourcing. But, in this instance, it wasn’t so much the outsourcing, as it was the

decision to modularize a complicated problem too soon. Boeing’s experience bears comparing to

another company, one which has mastered the art of managing design as an integrated process, while

still utilizing outsourcing — Apple. Apple doesn’t manufacture their own products; but anyone who has

used an Apple device can tell you that having someone else doing the manufacturing hasn’t

compromised the quality of the product at all. But Apple treats both the design process and its suppliers

very differently to the way that Boeing does — or at least did, in the case of the 787.

Two key questions remain: Has Boeing learned from the mistake? Recent comments from their

leadership suggest that they may have: Jim Albaugh, who only just retired as the company’s commercial

aviation chief after a 35 year career with Boeing, noted that “in hindsight, we spent a lot more money in

trying to recover than we ever would have spent if we tried to keep many of the key technologies

closer to Boeing. The pendulum swung too far.” The company’s Chief Executive, Jim McNerney, said that

he “would draw the lines in a different place” — but don’t mistake that for ditching the outsourcing,

because he also said that he “would still have the same supplier/partner concept.” And why did Boeing

decide to do this in the first place? The New Yorker provides some context on this question — and it

relates to McDonnell Douglas.

While ostensibly Boeing took over McDonnell Douglas, what really happened was more akin to a reverse

takeover — McDonnell Douglas took over Boeing. Several of the top positions in the merged Boeing

were assigned to executives who had previously worked in St. Louis, where the heritage of McDonnell

Aircraft had been one of fighter and attack aircraft for the military. The thing about these Government

contracts is that they are paid as development proceeds. This is entirely different — and a lot less risky

— than the development model for a traditional commercial airliner, where an aerospace company

needs to find all the capital. My hypothesis is that McDonnell’s mindset from its defense work -

minimizing the amount of capital put at risk during R&D — was applied to the 787. They didn’t want to

pay full price for the Dreamliner’s development, so, they didn’t — or at least, that’s what they thought.

But as Henry Ford warned almost a century earlier:

if you need a machine and don’t buy it, then you will ultimately find that you have paid for it and don’t

have it.

---------------------------------------------------------- ---------------------------- --------------------------------

James Allworth is the Director of Strategy for Medallia, Inc, co-host of the Exponent podcast, and co-

author of How Will You Measure Your Life?.

You might also like

- Matthew Lesko Let Uncle Sam Pay Your Bills PDFDocument33 pagesMatthew Lesko Let Uncle Sam Pay Your Bills PDFCarol100% (4)

- Philip Condit and The 777 Project - Case Study SolutionDocument9 pagesPhilip Condit and The 777 Project - Case Study Solution123youwanna321100% (1)

- Strategic Leadership Case Study of BoeingDocument2 pagesStrategic Leadership Case Study of BoeingPat0% (1)

- Boeing AnalysisDocument3 pagesBoeing Analysiskwathom150% (2)

- Boeing Case AssignmentDocument3 pagesBoeing Case AssignmentVasanth Subramanyam100% (2)

- Boeing Case StudyDocument7 pagesBoeing Case Studyaakriti aroraNo ratings yet

- Analyzing Boeing'S Supply Chain Design Forb787 (Dreamliner)Document37 pagesAnalyzing Boeing'S Supply Chain Design Forb787 (Dreamliner)varekar_akshay91100% (1)

- Main Approach For The Case StudyDocument15 pagesMain Approach For The Case StudyMeghna Cm0% (1)

- Management FOCUS: Boeing's Global Production SystemDocument1 pageManagement FOCUS: Boeing's Global Production SystemMinh Trang100% (1)

- The 21st Century Jet: The Boeing 777 Multimedia Case StudyDocument26 pagesThe 21st Century Jet: The Boeing 777 Multimedia Case Studytrex84No ratings yet

- LESSON 2. Projects: 1. Read and Translate The Text: To Manage A Project Up, Up and AwayDocument9 pagesLESSON 2. Projects: 1. Read and Translate The Text: To Manage A Project Up, Up and Awayfkj grdgNo ratings yet

- BoeingDocument42 pagesBoeingHarsh SaxenaNo ratings yet

- RealTime Web Appication Tech History PDFDocument45 pagesRealTime Web Appication Tech History PDFPradeep KumarNo ratings yet

- IBUS 2301 - GroupReport PDFDocument7 pagesIBUS 2301 - GroupReport PDFChloechiaNo ratings yet

- Procurement Case StudyDocument4 pagesProcurement Case StudySukanya SomNo ratings yet

- Course Name: MRGO Assignment: Boeing 787 The Dreamliner Submitted By: Group 104Document4 pagesCourse Name: MRGO Assignment: Boeing 787 The Dreamliner Submitted By: Group 104Manuj KumarNo ratings yet

- POSTED CASE Leadership Implications in Complex Projects Nov 2016 2Document4 pagesPOSTED CASE Leadership Implications in Complex Projects Nov 2016 2Iftekhar Nizam0% (1)

- Managerial Economics Assignment Outsourcing at Boeing (Case Study Analysis)Document4 pagesManagerial Economics Assignment Outsourcing at Boeing (Case Study Analysis)AsitNo ratings yet

- What Went Wrong at BoeingDocument8 pagesWhat Went Wrong at BoeingNyeko FrancisNo ratings yet

- Case QuestionsDocument7 pagesCase QuestionsAnubhavNo ratings yet

- Boeing Dreamliner Case Study (Updated 2020) - 2Document4 pagesBoeing Dreamliner Case Study (Updated 2020) - 2Garima1976No ratings yet

- The Boeing 787 Dreamliner CaseDocument7 pagesThe Boeing 787 Dreamliner CasejasolomoncharlesNo ratings yet

- 2 Structural Frame Worksheet BullerDocument4 pages2 Structural Frame Worksheet Bullerapi-239499123No ratings yet

- Case QuestionsDocument9 pagesCase QuestionsAnubhavNo ratings yet

- Building The Boeing 787 Case Study SolutionDocument4 pagesBuilding The Boeing 787 Case Study Solutioncedie100% (1)

- Boeing's 787 Dreamliner Vision Case StudyDocument6 pagesBoeing's 787 Dreamliner Vision Case StudyChole HuNo ratings yet

- Boeing Dream Liner Outsourcing StudyDocument9 pagesBoeing Dream Liner Outsourcing StudyDave Heimsch100% (1)

- SCH4801 F1 Consesion 2024Document10 pagesSCH4801 F1 Consesion 2024chikomborero maranduNo ratings yet

- Outsourcing of The Boeing 787: David Mahmoodi 01/31/2009Document27 pagesOutsourcing of The Boeing 787: David Mahmoodi 01/31/2009Arif PranandaNo ratings yet

- Case1 - Troubles With Organization StructureDocument2 pagesCase1 - Troubles With Organization StructureTHE PROFESSOR SERGIONo ratings yet

- Boeing Commercial Aircraft:comeback?: Nur Nahar Lima 2017-1-10-247Document7 pagesBoeing Commercial Aircraft:comeback?: Nur Nahar Lima 2017-1-10-247Nur Nahar LimaNo ratings yet

- Boeing Final 787Document27 pagesBoeing Final 787Eugen Ionescu0% (1)

- Assignment 1Document6 pagesAssignment 1kyawNo ratings yet

- Boeing PDFDocument9 pagesBoeing PDFvickyNo ratings yet

- Boeing 787 Case StudyDocument17 pagesBoeing 787 Case StudyJosh Krisha100% (1)

- 2024 FI Case StudyDocument3 pages2024 FI Case Studychikomborero maranduNo ratings yet

- Fly by WireDocument2 pagesFly by WireAnkita PruthiNo ratings yet

- SCMDocument8 pagesSCMParthShahNo ratings yet

- BoengDocument3 pagesBoengSaadia Arshad0% (1)

- Affordable AirplaneDocument8 pagesAffordable Airplaneviorelu99No ratings yet

- The 21st Century Jet: The Boeing 777 Multimedia Case StudyDocument26 pagesThe 21st Century Jet: The Boeing 777 Multimedia Case StudyRahul Jayanti JoshiNo ratings yet

- Leadership at BoeingDocument6 pagesLeadership at BoeingNimesh IshankaNo ratings yet

- Strategic Management of BoeingDocument22 pagesStrategic Management of BoeingAz Othman100% (3)

- Financial Statements Analysis Boeing ArticleDocument8 pagesFinancial Statements Analysis Boeing ArticleCarolina BecerraNo ratings yet

- Boeing 787:case Analysis: Ashish Jude MichaelDocument15 pagesBoeing 787:case Analysis: Ashish Jude MichaelprashantNo ratings yet

- Boeing 787:case Analysis: Ashish Jude MichaelDocument15 pagesBoeing 787:case Analysis: Ashish Jude MichaelMaverick CardsNo ratings yet

- Boeing 787:case Analysis: Ashish Jude MichaelDocument15 pagesBoeing 787:case Analysis: Ashish Jude MichaelprashantNo ratings yet

- Case Analysis No.9.Document5 pagesCase Analysis No.9.Ruby Ann RuizNo ratings yet

- Future Concepts: Core CompetencyDocument3 pagesFuture Concepts: Core CompetencyPrashanthNo ratings yet

- 1.1 What Is Design For Manufacture and Assembly?Document41 pages1.1 What Is Design For Manufacture and Assembly?Carlos REynagaNo ratings yet

- Om PresentationDocument5 pagesOm PresentationTanmeet kourNo ratings yet

- BCG Case 1-Increasing ProfitsDocument4 pagesBCG Case 1-Increasing ProfitsAvid Boustani100% (1)

- 13 - Why 787 Slips Were InevitableDocument17 pages13 - Why 787 Slips Were InevitableRatna PermatasariNo ratings yet

- CASE BOEING (English) - CHAPTER 4Document4 pagesCASE BOEING (English) - CHAPTER 42121012623No ratings yet

- Research Papers Boeing Case StudyDocument8 pagesResearch Papers Boeing Case Studygz8xbnex100% (1)

- Streamlined Plane Making: 'Integrating Study 6 'Document2 pagesStreamlined Plane Making: 'Integrating Study 6 'SHRUTI PILLAINo ratings yet

- Planned Obsolesce Isn't Real - Stop Perpetuating The Myth That It IsDocument5 pagesPlanned Obsolesce Isn't Real - Stop Perpetuating The Myth That It IsRex RexNo ratings yet

- Broken Buildings, Busted Budgets: How to Fix America's Trillion-Dollar Construction IndustryFrom EverandBroken Buildings, Busted Budgets: How to Fix America's Trillion-Dollar Construction IndustryRating: 3.5 out of 5 stars3.5/5 (4)

- The Ridiculously Simple Guide to Pixel Go, Pixelbook, and Pixel Slate: Getting Started With Chrome OSFrom EverandThe Ridiculously Simple Guide to Pixel Go, Pixelbook, and Pixel Slate: Getting Started With Chrome OSNo ratings yet

- Object-Oriented Programming in ColdFusionFrom EverandObject-Oriented Programming in ColdFusionRating: 4.5 out of 5 stars4.5/5 (3)

- Formal Verification: An Essential Toolkit for Modern VLSI DesignFrom EverandFormal Verification: An Essential Toolkit for Modern VLSI DesignNo ratings yet

- Stellar One: GH-09, Sector-1, Greater Noida WestDocument7 pagesStellar One: GH-09, Sector-1, Greater Noida WestRavi BhattacharyaNo ratings yet

- Functional RequirementDocument3 pagesFunctional RequirementRithinMenezesNo ratings yet

- Asia Pacific Resoures Vs Paperone Unfair CompetitionDocument24 pagesAsia Pacific Resoures Vs Paperone Unfair CompetitionChatNo ratings yet

- (EXCEL 2016) Mocktest 1Document9 pages(EXCEL 2016) Mocktest 1Huyền Trang NguyễnNo ratings yet

- 1.2 Terms and Conditions For Subcontractor Rev. 01.2022Document11 pages1.2 Terms and Conditions For Subcontractor Rev. 01.2022melisbbNo ratings yet

- NC LT NoticeDocument219 pagesNC LT NoticeEsha ChaudharyNo ratings yet

- Formation of CorporationDocument8 pagesFormation of CorporationMark Francis SolanteNo ratings yet

- CH 4 Globalisation and The Indian Economy Class 10Document33 pagesCH 4 Globalisation and The Indian Economy Class 10Adhish RNo ratings yet

- SatSure Broucher - USA - CompressedDocument4 pagesSatSure Broucher - USA - Compressedsarvesh kuraneNo ratings yet

- Behaviour of Bem Female Student Toward Purchasing BeautyDocument24 pagesBehaviour of Bem Female Student Toward Purchasing Beautykaladevi21No ratings yet

- 09 Yi Accounts Payable Risk AssessmentDocument2 pages09 Yi Accounts Payable Risk AssessmentMalik Khayyam OmerNo ratings yet

- Why Renting Is Better Than BuyingDocument4 pagesWhy Renting Is Better Than BuyingMonali MathurNo ratings yet

- Entrepreneurship: Antique National School - Senior High Lourene J. Guanzon, T-IIDocument410 pagesEntrepreneurship: Antique National School - Senior High Lourene J. Guanzon, T-IILourene Jauod- GuanzonNo ratings yet

- Black ScholesDocument3 pagesBlack ScholesAditiNo ratings yet

- B) Write Briefly On Financial Planning For Disaster ManagementDocument4 pagesB) Write Briefly On Financial Planning For Disaster ManagementLevingstan YesudhasNo ratings yet

- Kimia Kertas 2 T5Document9 pagesKimia Kertas 2 T5miszhoneymNo ratings yet

- 25 CRM Analyst Interview Questions and AnswersDocument12 pages25 CRM Analyst Interview Questions and Answersjamilabano1409No ratings yet

- Accra Technical University: Department of Building TechnologyDocument13 pagesAccra Technical University: Department of Building TechnologyKj mingle100% (1)

- Layton7e PPT ch08Document20 pagesLayton7e PPT ch08Cyan SeaNo ratings yet

- Job Sheet KosongDocument33 pagesJob Sheet KosongHatta Rasyida SulaimanNo ratings yet

- Agricultural Extension in Asia Constraints and Options For ImprovementDocument15 pagesAgricultural Extension in Asia Constraints and Options For ImprovementMarejen Almedilla VillaremoNo ratings yet

- HTG - Distribution Equipment - OfficialRelease - V1.0Document59 pagesHTG - Distribution Equipment - OfficialRelease - V1.0Altamir Nunes JuniorNo ratings yet

- Disbursement Voucher (New Orence)Document4 pagesDisbursement Voucher (New Orence)user computerNo ratings yet

- Crypto Trading For Beginner TradersDocument25 pagesCrypto Trading For Beginner Tradersrehman.gdriveNo ratings yet

- MeetFounders Nov 2020 HandoutDocument17 pagesMeetFounders Nov 2020 HandoutAndrew BottNo ratings yet

- Enclosures - Nuova ASPDocument156 pagesEnclosures - Nuova ASPNicolae VisanNo ratings yet

- CV TemplateDocument2 pagesCV TemplateahoyigbyNo ratings yet

- Waiters and Waitress Job DescriptionDocument3 pagesWaiters and Waitress Job Descriptionobabaru gaddis ivanNo ratings yet