Professional Documents

Culture Documents

21BCM0023 VL2023240501286 Ast07

21BCM0023 VL2023240501286 Ast07

Uploaded by

prateekbanerjee40 ratings0% found this document useful (0 votes)

2 views6 pagesOriginal Title

21BCM0023_VL2023240501286_AST07

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views6 pages21BCM0023 VL2023240501286 Ast07

21BCM0023 VL2023240501286 Ast07

Uploaded by

prateekbanerjee4Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 6

CHE 305P Process Dynamics and Control Laboratory

School of Chemical Engineering (SCHEME)

Experiment No: 10 Registration No: 21BCM0023

Date :21/03/24 Name: Prateek Banerjee

Dynamic Simulation

AIM: To develop the model in Aspen Hysys for controlling the level of the liquid in the tank

for the given problem statement.

Problem Statement: An inlet stream with the following specifications is fed to a tank

• Temperature of the feed 20oC

• Tank volume 5 m3

• Maintain tank level at 50%

• Controller: PI (Level and flow controllers)

Tank Feed:

• Pressure: 5 bar

• Temperature: 25 °C

• Mass flow rate: 1000 kg/h

• Composition: Water: 0.95, air: 0.05

Consider the pressure drop in each valve is 1bar

Feed valve Cv=75; outlet valve=53;

Controller Specs:

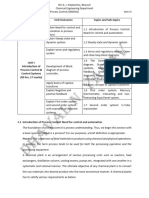

Controller Specs Flow indicator controller Level Indicator Controller

Sp 1000 50%

Min Pv 0 0%

Max Pv 3000 100%

Kc (Process gain) 0.5 0.5

Ti(Initial time for calc) 1 min 5 min

THEORY:

Discuss the importance of dynamic models

Course Instructor: Dr. Bandaru Kiran

Schematic PFD of dynamic model of tank

PROCEDURE:

Follow the instructions of model development in Aspen Hysys

RESULTS

Course Instructor: Dr. Bandaru Kiran

Course Instructor: Dr. Bandaru Kiran

Course Instructor: Dr. Bandaru Kiran

Course Instructor: Dr. Bandaru Kiran

DISCUSSION:

• Discuss the step response, impulse response of the given system

Course Instructor: Dr. Bandaru Kiran

You might also like

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewFrom EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewRating: 5 out of 5 stars5/5 (1)

- Calibration of Peristaltic Pumps - Lab 1Document12 pagesCalibration of Peristaltic Pumps - Lab 1mmccomas08100% (2)

- Lab Report PFR PDFDocument11 pagesLab Report PFR PDFMohd Saiful RidzuanNo ratings yet

- Instruction Manual.: Plug Flow ReactorDocument4 pagesInstruction Manual.: Plug Flow ReactorDhananjay KadamNo ratings yet

- 3 Introduction To ChemcadDocument29 pages3 Introduction To ChemcadJulius Tandji OnanaNo ratings yet

- T N U S: HE Ational Niversity IngaporeDocument4 pagesT N U S: HE Ational Niversity IngaporeHaha WoNgNo ratings yet

- Fluid Mechanics LabDocument12 pagesFluid Mechanics LabRonald Muñez BadicNo ratings yet

- Uitm Lab Report Plug Flow ReactorDocument15 pagesUitm Lab Report Plug Flow ReactorNabilah SyaheeraNo ratings yet

- Plug Flow ReactorDocument15 pagesPlug Flow ReactorSeiji Kyousei91% (11)

- CPB30004 Process Dynamics and Control Experiment 1: Level Flow Cascade Process Control Lab ReportDocument8 pagesCPB30004 Process Dynamics and Control Experiment 1: Level Flow Cascade Process Control Lab ReportSiti Hajar Mohamed100% (5)

- Continuous Stirred Tank ReactorDocument7 pagesContinuous Stirred Tank ReactordeepshikhasinghNo ratings yet

- Calibration of HPLC NewDocument8 pagesCalibration of HPLC NewAmsmrit BorahNo ratings yet

- Hysys Process Simulation TrainingDocument17 pagesHysys Process Simulation TrainingIqbal Safirul Barqi100% (1)

- ABO & LightupDocument5 pagesABO & Lightupsrigirisetty208No ratings yet

- I. Prelab Questions: Metallurgical Thermodynamics LaboratoryDocument1 pageI. Prelab Questions: Metallurgical Thermodynamics LaboratoryCJPATAGANNo ratings yet

- CSTRDocument11 pagesCSTRfarahanisiliasNo ratings yet

- Analysis and DiscussionDocument13 pagesAnalysis and Discussiondelwi8788% (8)

- Lab Seesion No 2 FMDocument6 pagesLab Seesion No 2 FMm.sheraz malikNo ratings yet

- Fluid Mechanics Lab ManualDocument53 pagesFluid Mechanics Lab ManualprashanthreddyhNo ratings yet

- IPC CH 1-1Document35 pagesIPC CH 1-1yashy4032No ratings yet

- Cre Lab UbaidDocument40 pagesCre Lab UbaidHarry potterNo ratings yet

- MÔ PHỎNG VÀ TỐI ƯU NHÀ MÁY LỌC DẦUDocument84 pagesMÔ PHỎNG VÀ TỐI ƯU NHÀ MÁY LỌC DẦUTường DuyNo ratings yet

- 3rd Year Part - II - MTO-II LAB MANUALDocument35 pages3rd Year Part - II - MTO-II LAB MANUALTambu GoodnessNo ratings yet

- Class Test 2 31 JULY 2021: Process Fluid FlowDocument6 pagesClass Test 2 31 JULY 2021: Process Fluid FlowEnabewhkom OhpmNo ratings yet

- Chemical Engineering Laboratory Ii: /DT Term Is Zero SinceDocument9 pagesChemical Engineering Laboratory Ii: /DT Term Is Zero SinceKayathre Raveendran100% (1)

- Quechers Sep 2010Document48 pagesQuechers Sep 2010Fernando Andrés OlNo ratings yet

- Fluid Mechanics Lab ReportDocument35 pagesFluid Mechanics Lab ReportBilal Akhundzada0% (1)

- 025 Procedure For Calibration of of GC Final-08 On 20072023Document8 pages025 Procedure For Calibration of of GC Final-08 On 20072023surendra varmaNo ratings yet

- Answer: 99.96 C: Petroleum Refinery Engineering (CHL 794) Department of Chemical Engineering, Iitd Tutorial Sheet - 1Document2 pagesAnswer: 99.96 C: Petroleum Refinery Engineering (CHL 794) Department of Chemical Engineering, Iitd Tutorial Sheet - 1Varun SoganiNo ratings yet

- AERODYNAMICS Lab ManualDocument39 pagesAERODYNAMICS Lab Manualbalusapps75% (4)

- CHP303 PDFDocument43 pagesCHP303 PDFPrakhar MisraNo ratings yet

- Chemical Process Control Laboratory Manual: Department of Chemical Engineering 1999Document66 pagesChemical Process Control Laboratory Manual: Department of Chemical Engineering 1999Łuis MTNo ratings yet

- Lab Report Effect of Residence Time On TDocument26 pagesLab Report Effect of Residence Time On TMuhammad IqmalNo ratings yet

- Lab Report FinalDocument13 pagesLab Report Finalidyllic20No ratings yet

- 4 - (PFR BP101)Document15 pages4 - (PFR BP101)Aisyah Addia AzizanNo ratings yet

- Laboratory ExperimentsDocument70 pagesLaboratory ExperimentsKarl TristanNo ratings yet

- Chapter 1 - IntroductionDocument33 pagesChapter 1 - IntroductionHuy Nguyen LuongNo ratings yet

- Ammonia RecoveryDocument136 pagesAmmonia RecoveryWagus GinanjarNo ratings yet

- Lab-4 Verification of Bernoulis TheoremDocument5 pagesLab-4 Verification of Bernoulis TheoremMr V. Phaninder ReddyNo ratings yet

- Mechanical Engg Lab2 Midterm Module 5 Reciprocating PumpDocument7 pagesMechanical Engg Lab2 Midterm Module 5 Reciprocating PumpKurt PalacioNo ratings yet

- Chlorine Contact Time Calculations: Factor DescriptionDocument7 pagesChlorine Contact Time Calculations: Factor DescriptionYosif BabekerNo ratings yet

- PW 06 Piping EquipmentDocument9 pagesPW 06 Piping EquipmentMõ ÖnNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 8Document7 pages20-ME-9 Uzair Akram FM Lab 8uzair akramNo ratings yet

- Carrier GAs in GCDocument52 pagesCarrier GAs in GCcksoni1No ratings yet

- PFR ReactorDocument19 pagesPFR Reactorkhairi100% (1)

- Closed-Loop System Marlin 2002Document24 pagesClosed-Loop System Marlin 2002Debora Fitriyana SitorusNo ratings yet

- Process Design Engineering Test-1Document6 pagesProcess Design Engineering Test-1Vague FruitsNo ratings yet

- 4 - Best Practices For Sodium Hypochlorite Storage and Metering SystemsDocument48 pages4 - Best Practices For Sodium Hypochlorite Storage and Metering SystemsZain Ali100% (1)

- Calibration of GcDocument5 pagesCalibration of GcAmsmrit BorahNo ratings yet

- A DRAFT Chemtrac SOP - 120216Document12 pagesA DRAFT Chemtrac SOP - 120216Akin A. OkupeNo ratings yet

- Project 111Document65 pagesProject 111Sifa Tsalsabila HasyifahNo ratings yet

- Droplet Formation in A Cross-Junction With Non-Newtonian Dispersed PhaseDocument20 pagesDroplet Formation in A Cross-Junction With Non-Newtonian Dispersed PhaseNandiniNo ratings yet

- Dr. K. Sivagami, Associate Professor, School of Chemical Engineering, VIT VelloreDocument57 pagesDr. K. Sivagami, Associate Professor, School of Chemical Engineering, VIT VelloreAmol RastogiNo ratings yet

- Hemax530 Training VVVDocument30 pagesHemax530 Training VVVÂn ĐìnhNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Transverse Disciplines in Metrology: Proceedings of the 13th International Metrology Congress, 2007 - Lille, FranceFrom EverandTransverse Disciplines in Metrology: Proceedings of the 13th International Metrology Congress, 2007 - Lille, FranceNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- Process Engineering: Facts, Fiction and FablesFrom EverandProcess Engineering: Facts, Fiction and FablesRating: 3 out of 5 stars3/5 (2)

- Liu Wilcox 2012 Molecular Simulation Studies of Co2 Adsorption by Carbon Model Compounds For Carbon Capture andDocument7 pagesLiu Wilcox 2012 Molecular Simulation Studies of Co2 Adsorption by Carbon Model Compounds For Carbon Capture andprateekbanerjee4No ratings yet

- Aditya SteelDocument12 pagesAditya Steelprateekbanerjee4No ratings yet

- Li Et Al 2016 Molecular Dynamics Simulations of Co2 n2 Separation Through Two Dimensional Graphene Oxide MembranesDocument6 pagesLi Et Al 2016 Molecular Dynamics Simulations of Co2 n2 Separation Through Two Dimensional Graphene Oxide Membranesprateekbanerjee4No ratings yet

- PDC AspenDocument6 pagesPDC Aspenprateekbanerjee4No ratings yet

- Ai Da2Document9 pagesAi Da2prateekbanerjee4No ratings yet

- 21BCM0023 VL2023240501291 Da02Document17 pages21BCM0023 VL2023240501291 Da02prateekbanerjee4No ratings yet