Professional Documents

Culture Documents

Jack-203 MPI Reports

Jack-203 MPI Reports

Uploaded by

Angel PerdomoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jack-203 MPI Reports

Jack-203 MPI Reports

Uploaded by

Angel PerdomoCopyright:

Available Formats

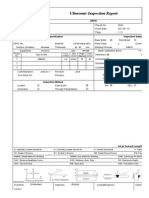

L5-SAU-130A

JACK-203 - MPI Examination Register Country Level Document

Certificate Location Item ID Description Date of Inspection Remarks Result

Number

03-24-0051- Rig floor DS L-G3 9021 Pipe spinner back post 3/7/2024 Accept Thorough examination was carried out on critical weld areas and

NDE/MT1 heat affected zones. No discontinuities were found at the time of

inspection.

03-24-0051- Rig floor DS L-G3 9019 Tong post assembly DS 3/7/2024 Accept Thorough examination was carried out on critical weld areas and

NDE/MT2 heat affected zones. No discontinuities were found at the time of

inspection.

03-24-0051- Rig floor ODS L-G3 9020 Tong post assembly ODS 3/7/2024 Accept Thorough examination was carried out on critical weld areas and

NDE/MT3 heat affected zones. No discontinuities were found at the time of

inspection.

03-24-0051- Rig floor DS YXJ750/14/3/11 V door post DS 3/7/2024 Accept Thorough examination was carried out on critical weld areas and

NDE/MT4 21135012 heat affected zones. No discontinuities were found at the time of

inspection.

03-24-0051- Rig floor ODS YXJ750/14/3/11 V door post ODS 3/7/2024 Accept Thorough examination was carried out on critical weld areas and

NDE/MT5 21135011 heat affected zones. No discontinuities were found at the time of

inspection.

03-24-0051- Rig site 01980 Big bag ring 3/7/2024 Accept Thorough examination was carried out on critical weld areas and

NDE/MT6 heat affected zones. No discontinuities were found at the time of

inspection.

03-24-0051- Rig site 01981 Big bag ring 3/7/2024 Accept Thorough examination was carried out on critical weld areas and

NDE/MT7 heat affected zones. No discontinuities were found at the time of

inspection.

03-24-0051- Rig site 01982 Big bag ring 3/7/2024 Accept Thorough examination was carried out on critical weld areas and

NDE/MT8 heat affected zones. No discontinuities were found at the time of

inspection.

03-24-0051- Rig site 3071GR16/37 Crane main hook block 3/7/2024 Accept Thorough examination was carried out on critical load bearing

NDE/MT9 9-16 areas. No discontinuities were found at the time of inspection.

03-24-0051- Rig site SHO10/17 Crane auxilary hook block 3/7/2024 Accept Thorough examination was carried out on critical load bearing

NDE/MT10 9-16 areas. No discontinuities were found at the time of inspection.

Template Rev No. 0 Template Revision Date 01-May-2023 Page 1 of 2

*Singapore - Applus Singapore Pte Ltd, 521 Bukit Batok St 23 Unit 05-E, Singapore 659544

*Middle East - K2 Specialist Services FZE, #201, Block B, Abu Dhabi Business Hub, ICAD -1, Mussafah, P.O Box 114182, Abu Dhabi, UAE

*Brazil - K2 do Brasil Serviços Ltda , Rua Maria Backer Motta, n°. 400, Qd Comercial, Lote 35, Mar do Norte, Rio das Ostras, CEP 28898-016

*USA - Applus K2 America LLC, 11777 South Sam Houston Parkway West, SuiteC Houston Texas, USA 77031

*Velosi Saudi Arabia Co. Ltd, Al-Qusur, Talal Al-Doha Building,Sub of Prince Mohammad bin Fahd Road, P.O Box-7031, Dhahran 34247-2958, Kingdom of Saudi Arabia

L5-SAU-130A

JACK-203 - MPI Examination Register Country Level Document

Certificate Location Item ID Description Date of Inspection Remarks Result

Number

03-24-0051- Rig site NA Cross bar 3/7/2024 Accept Thorough examination was carried out on critical weld areas and

NDE/MT11 heat affected zones. No discontinuities were found at the time of

inspection.

Couldn't find the item ID and inspection was carried out

according to client instruction.

Total number of items : 11

Template Rev No. 0 Template Revision Date 01-May-2023 Page 2 of 2

*Singapore - Applus Singapore Pte Ltd, 521 Bukit Batok St 23 Unit 05-E, Singapore 659544

*Middle East - K2 Specialist Services FZE, #201, Block B, Abu Dhabi Business Hub, ICAD -1, Mussafah, P.O Box 114182, Abu Dhabi, UAE

*Brazil - K2 do Brasil Serviços Ltda , Rua Maria Backer Motta, n°. 400, Qd Comercial, Lote 35, Mar do Norte, Rio das Ostras, CEP 28898-016

*USA - Applus K2 America LLC, 11777 South Sam Houston Parkway West, SuiteC Houston Texas, USA 77031

*Velosi Saudi Arabia Co. Ltd, Al-Qusur, Talal Al-Doha Building,Sub of Prince Mohammad bin Fahd Road, P.O Box-7031, Dhahran 34247-2958, Kingdom of Saudi Arabia

L5-SAU-130

Country Level Document

MAGNETIC PARTICLE TEST REPORT

Project No. : 03-24-0051 Report No. : 03-24-0051-NDE/MT1

Client / Owner : HAJJAN

Name of Vessel / Item : JACK-203 Date of Inspection : 07 March, 2024

Location : Rig floor DS Cleaner Make, Batch No : NA

Equipment & S/N : AC YOKE-110/0220 WCP Make, Batch No : MR-CHEMI-2307081

Material Tested : CARBON STEEL M.Particles Make, Batch No : MR-CHEMI-2310013

Surface Condition : CLEAN Measured Light Level : VISIBLE

Drawing Reference : NA Light Meter S.No : NA

Reference Procedure : L4-SAU-108 REV 0 & Client Inst UV lamp S.No : NA

Acceptance Criteria : ASTM E709, AWS D1.1 Measured UV Intensity : NA

(µW/cm2)

Demagnetization : NA

Technique Current Type of Detection Media Field Strength Verification QC Check

Yoke AC Wet Colour Contrast Pie Gauge Lifting Force

Coil DC Wet Fluorescent Castrol Strip

Central Conductor Permanent Magnet

Item ID Item Description Accept / Reject

L-G3 9021 Pipe spinner back post Accept

Inspection Result & Remarks:

Magnetic particle inspection was carried out on critical weld areas and heat affected zones, no defects or surface

breaking discontinuities found at the time of inspection.

This is to confirm that the equipment stated herein was attended by the Company’s competent person and particulars & findings stated herein are correct at the time of inspection.

Inspectedby: Ibrahim Reviewedby: Nafa Al Rowaie

NDT Level II Thouseef

Date and Sign: 07 Mar, 2024 Date and Sign: 07 Mar, 2024

Name & Address of the Employer: Velosi Saudi Arabia Co. Ltd, Al-Qusur, Talal Al-Doha Building,Sub of Prince Mohammad bin Fahd Road, P.O Box-7031, Dhahran

34247-2958, Kingdom of Saudi Arabia

Template Rev No. 0 Template Revision Date 18-May-2018 Page 1 of 10

L5-SAU-130

Country Level Document

MAGNETIC PARTICLE TEST REPORT

Project No. : 03-24-0051 Report No. : 03-24-0051-NDE/MT2

Client / Owner : HAJJAN

Name of Vessel / Item : JACK-203 Date of Inspection : 07 March, 2024

Location : Rig floor DS Cleaner Make, Batch No : NA

Equipment & S/N : AC YOKE-110/0220 WCP Make, Batch No : MR-CHEMI-2307081

Material Tested : CARBON STEEL M.Particles Make, Batch No : MR-CHEMI-2310013

Surface Condition : CLEAN Measured Light Level : VISIBLE

Drawing Reference : NA Light Meter S.No : NA

Reference Procedure : L4-SAU-108 REV 0 & Client Inst UV lamp S.No : NA

Acceptance Criteria : ASTM E709, AWS D1.1 Measured UV Intensity : NA

(µW/cm2)

Demagnetization : NA

Technique Current Type of Detection Media Field Strength Verification QC Check

Yoke AC Wet Colour Contrast Pie Gauge Lifting Force

Coil DC Wet Fluorescent Castrol Strip

Central Conductor Permanent Magnet

Item ID Item Description Accept / Reject

L-G3 9019 Tong post assembly DS Accept

Inspection Result & Remarks:

Magnetic particle inspection was carried out on critical weld areas and heat affected zones, no defects or surface

breaking discontinuities found at the time of inspection.

This is to confirm that the equipment stated herein was attended by the Company’s competent person and particulars & findings stated herein are correct at the time of inspection.

Inspectedby: Ibrahim Reviewedby: Nafa Al Rowaie

NDT Level II Thouseef

Date and Sign: 07 Mar, 2024 Date and Sign: 07 Mar, 2024

Name & Address of the Employer: Velosi Saudi Arabia Co. Ltd, Al-Qusur, Talal Al-Doha Building,Sub of Prince Mohammad bin Fahd Road, P.O Box-7031, Dhahran

34247-2958, Kingdom of Saudi Arabia

Template Rev No. 0 Template Revision Date 18-May-2018 Page 2 of 10

L5-SAU-130

Country Level Document

MAGNETIC PARTICLE TEST REPORT

Project No. : 03-24-0051 Report No. : 03-24-0051-NDE/MT3

Client / Owner : HAJJAN

Name of Vessel / Item : JACK-203 Date of Inspection : 07 March, 2024

Location : Rig floor ODS Cleaner Make, Batch No : NA

Equipment & S/N : AC YOKE-110/0220 WCP Make, Batch No : MR-CHEMI-2307081

Material Tested : CARBON STEEL M.Particles Make, Batch No : MR-CHEMI-2310013

Surface Condition : CLEAN Measured Light Level : VISIBLE

Drawing Reference : NA Light Meter S.No : NA

Reference Procedure : L4-SAU-108 REV 0 & Client Inst UV lamp S.No : NA

Acceptance Criteria : ASTM E709, AWS D1.1 Measured UV Intensity : NA

(µW/cm2)

Demagnetization : NA

Technique Current Type of Detection Media Field Strength Verification QC Check

Yoke AC Wet Colour Contrast Pie Gauge Lifting Force

Coil DC Wet Fluorescent Castrol Strip

Central Conductor Permanent Magnet

Item ID Item Description Accept / Reject

L-G3 9020 Tong post assembly ODS Accept

Inspection Result & Remarks:

Magnetic particle inspection was carried out on critical weld areas and heat affected zones, no defects or surface

breaking discontinuities found at the time of inspection.

This is to confirm that the equipment stated herein was attended by the Company’s competent person and particulars & findings stated herein are correct at the time of inspection.

Inspectedby: Ibrahim Reviewedby: Nafa Al Rowaie

NDT Level II Thouseef

Date and Sign: 07 Mar, 2024 Date and Sign: 07 Mar, 2024

Name & Address of the Employer: Velosi Saudi Arabia Co. Ltd, Al-Qusur, Talal Al-Doha Building,Sub of Prince Mohammad bin Fahd Road, P.O Box-7031, Dhahran

34247-2958, Kingdom of Saudi Arabia

Template Rev No. 0 Template Revision Date 18-May-2018 Page 3 of 10

L5-SAU-130

Country Level Document

MAGNETIC PARTICLE TEST REPORT

Project No. : 03-24-0051 Report No. : 03-24-0051-NDE/MT4

Client / Owner : HAJJAN

Name of Vessel / Item : JACK-203 Date of Inspection : 07 March, 2024

Location : Rig floor DS Cleaner Make, Batch No : NA

Equipment & S/N : AC YOKE-110/0220 WCP Make, Batch No : MR-CHEMI-2307081

Material Tested : CARBON STEEL M.Particles Make, Batch No : MR-CHEMI-2310013

Surface Condition : CLEAN Measured Light Level : VISIBLE

Drawing Reference : NA Light Meter S.No : NA

Reference Procedure : L4-SAU-108 REV 0 & Client Inst UV lamp S.No : NA

Acceptance Criteria : ASTM E709, AWS D1.1 Measured UV Intensity : NA

(µW/cm2)

Demagnetization : NA

Technique Current Type of Detection Media Field Strength Verification QC Check

Yoke AC Wet Colour Contrast Pie Gauge Lifting Force

Coil DC Wet Fluorescent Castrol Strip

Central Conductor Permanent Magnet

Item ID Item Description Accept / Reject

YXJ750/14/3/11211350 V door post DS Accept

12

Inspection Result & Remarks:

Magnetic particle inspection was carried out on critical weld areas and heat affected zones, no defects or surface

breaking discontinuities found at the time of inspection.

This is to confirm that the equipment stated herein was attended by the Company’s competent person and particulars & findings stated herein are correct at the time of inspection.

Inspectedby: Ibrahim Reviewedby: Nafa Al Rowaie

NDT Level II Thouseef

Date and Sign: 07 Mar, 2024 Date and Sign: 07 Mar, 2024

Name & Address of the Employer: Velosi Saudi Arabia Co. Ltd, Al-Qusur, Talal Al-Doha Building,Sub of Prince Mohammad bin Fahd Road, P.O Box-7031, Dhahran

34247-2958, Kingdom of Saudi Arabia

Template Rev No. 0 Template Revision Date 18-May-2018 Page 4 of 10

L5-SAU-130

Country Level Document

MAGNETIC PARTICLE TEST REPORT

Project No. : 03-24-0051 Report No. : 03-24-0051-NDE/MT5

Client / Owner : HAJJAN

Name of Vessel / Item : JACK-203 Date of Inspection : 07 March, 2024

Location : Rig floor ODS Cleaner Make, Batch No : NA

Equipment & S/N : AC YOKE-110/0220 WCP Make, Batch No : MR-CHEMI-2307081

Material Tested : CARBON STEEL M.Particles Make, Batch No : MR-CHEMI-2310013

Surface Condition : CLEAN Measured Light Level : VISIBLE

Drawing Reference : NA Light Meter S.No : NA

Reference Procedure : L4-SAU-108 REV 0 & Client Inst UV lamp S.No : NA

Acceptance Criteria : ASTM E709, AWS D1.1 Measured UV Intensity : NA

(µW/cm2)

Demagnetization : NA

Technique Current Type of Detection Media Field Strength Verification QC Check

Yoke AC Wet Colour Contrast Pie Gauge Lifting Force

Coil DC Wet Fluorescent Castrol Strip

Central Conductor Permanent Magnet

Item ID Item Description Accept / Reject

YXJ750/14/3/11211350 V door post ODS Accept

11

Inspection Result & Remarks:

Magnetic particle inspection was carried out on critical weld areas and heat affected zones, no defects or surface

breaking discontinuities found at the time of inspection.

This is to confirm that the equipment stated herein was attended by the Company’s competent person and particulars & findings stated herein are correct at the time of inspection.

Inspectedby: Ibrahim Reviewedby: Nafa Al Rowaie

NDT Level II Thouseef

Date and Sign: 07 Mar, 2024 Date and Sign: 07 Mar, 2024

Name & Address of the Employer: Velosi Saudi Arabia Co. Ltd, Al-Qusur, Talal Al-Doha Building,Sub of Prince Mohammad bin Fahd Road, P.O Box-7031, Dhahran

34247-2958, Kingdom of Saudi Arabia

Template Rev No. 0 Template Revision Date 18-May-2018 Page 5 of 10

L5-SAU-130

Country Level Document

MAGNETIC PARTICLE TEST REPORT

Project No. : 03-24-0051 Report No. : 03-24-0051-NDE/MT6

Client / Owner : HAJJAN

Name of Vessel / Item : JACK-203 Date of Inspection : 07 March, 2024

Location : Rig site Cleaner Make, Batch No : NA

Equipment & S/N : AC YOKE-110/0220 WCP Make, Batch No : MR-CHEMI-2307081

Material Tested : CARBON STEEL M.Particles Make, Batch No : MR-CHEMI-2310013

Surface Condition : BUFFED TO BARE METAL Measured Light Level : VISIBLE

Drawing Reference : NA Light Meter S.No : NA

Reference Procedure : L4-SAU-108 REV 0 & Client Inst UV lamp S.No : NA

Acceptance Criteria : ASTM E709, AWS D1.1 Measured UV Intensity : NA

(µW/cm2)

Demagnetization : NA

Technique Current Type of Detection Media Field Strength Verification QC Check

Yoke AC Wet Colour Contrast Pie Gauge Lifting Force

Coil DC Wet Fluorescent Castrol Strip

Central Conductor Permanent Magnet

Item ID Item Description Accept / Reject

01980 Big bag ring Accept

Inspection Result & Remarks:

Magnetic particle inspection was carried out on critical weld areas and heat affected zones after buffing it to baremetal,

Previous inspection report shows the evidence of MPI, no defects or surface breaking discontinuities found at the time

of inspection

This is to confirm that the equipment stated herein was attended by the Company’s competent person and particulars & findings stated herein are correct at the time of inspection.

Inspectedby: Ibrahim Reviewedby: Nafa Al Rowaie

NDT Level II Thouseef

Date and Sign: 07 Mar, 2024 Date and Sign: 07 Mar, 2024

Name & Address of the Employer: Velosi Saudi Arabia Co. Ltd, Al-Qusur, Talal Al-Doha Building,Sub of Prince Mohammad bin Fahd Road, P.O Box-7031, Dhahran

34247-2958, Kingdom of Saudi Arabia

Template Rev No. 0 Template Revision Date 18-May-2018 Page 6 of 10

L5-SAU-130

Country Level Document

MAGNETIC PARTICLE TEST REPORT

Project No. : 03-24-0051 Report No. : 03-24-0051-NDE/MT7

Client / Owner : HAJJAN

Name of Vessel / Item : JACK-203 Date of Inspection : 07 March, 2024

Location : Rig site Cleaner Make, Batch No : NA

Equipment & S/N : AC YOKE-110/0220 WCP Make, Batch No : MR-CHEMI-2307081

Material Tested : CARBON STEEL M.Particles Make, Batch No : MR-CHEMI-2310013

Surface Condition : BUFFED TO BARE METAL Measured Light Level : VISIBLE

Drawing Reference : NA Light Meter S.No : NA

Reference Procedure : L4-SAU-108 REV 0 & Client Inst UV lamp S.No : NA

Acceptance Criteria : ASTM E709, AWS D1.1 Measured UV Intensity : NA

(µW/cm2)

Demagnetization : NA

Technique Current Type of Detection Media Field Strength Verification QC Check

Yoke AC Wet Colour Contrast Pie Gauge Lifting Force

Coil DC Wet Fluorescent Castrol Strip

Central Conductor Permanent Magnet

Item ID Item Description Accept / Reject

01981 Big bag ring Accept

Inspection Result & Remarks:

Magnetic particle inspection was carried out on critical weld areas and heat affected zones after buffing it to baremetal,

Previous inspection report shows the evidence of MPI, no defects or surface breaking discontinuities found at the time

of inspection

This is to confirm that the equipment stated herein was attended by the Company’s competent person and particulars & findings stated herein are correct at the time of inspection.

Inspectedby: Ibrahim Reviewedby: Nafa Al Rowaie

NDT Level II Thouseef

Date and Sign: 07 Mar, 2024 Date and Sign: 07 Mar, 2024

Name & Address of the Employer: Velosi Saudi Arabia Co. Ltd, Al-Qusur, Talal Al-Doha Building,Sub of Prince Mohammad bin Fahd Road, P.O Box-7031, Dhahran

34247-2958, Kingdom of Saudi Arabia

Template Rev No. 0 Template Revision Date 18-May-2018 Page 7 of 10

L5-SAU-130

Country Level Document

MAGNETIC PARTICLE TEST REPORT

Project No. : 03-24-0051 Report No. : 03-24-0051-NDE/MT8

Client / Owner : HAJJAN

Name of Vessel / Item : JACK-203 Date of Inspection : 07 March, 2024

Location : Rig site Cleaner Make, Batch No : NA

Equipment & S/N : AC YOKE-110/0220 WCP Make, Batch No : MR-CHEMI-2307081

Material Tested : CARBON STEEL M.Particles Make, Batch No : MR-CHEMI-2310013

Surface Condition : BUFFED TO BARE METAL Measured Light Level : VISIBLE

Drawing Reference : NA Light Meter S.No : NA

Reference Procedure : L4-SAU-108 REV 0 & Client Inst UV lamp S.No : NA

Acceptance Criteria : ASTM E709, AWS D1.1 Measured UV Intensity : NA

(µW/cm2)

Demagnetization : NA

Technique Current Type of Detection Media Field Strength Verification QC Check

Yoke AC Wet Colour Contrast Pie Gauge Lifting Force

Coil DC Wet Fluorescent Castrol Strip

Central Conductor Permanent Magnet

Item ID Item Description Accept / Reject

01982 Big bag ring Accept

Inspection Result & Remarks:

Magnetic particle inspection was carried out on critical weld areas and heat affected zones after buffing it to baremetal,

Previous inspection report shows the evidence of MPI, no defects or surface breaking discontinuities found at the time

of inspection

This is to confirm that the equipment stated herein was attended by the Company’s competent person and particulars & findings stated herein are correct at the time of inspection.

Inspectedby: Ibrahim Reviewedby: Nafa Al Rowaie

NDT Level II Thouseef

Date and Sign: 07 Mar, 2024 Date and Sign: 07 Mar, 2024

Name & Address of the Employer: Velosi Saudi Arabia Co. Ltd, Al-Qusur, Talal Al-Doha Building,Sub of Prince Mohammad bin Fahd Road, P.O Box-7031, Dhahran

34247-2958, Kingdom of Saudi Arabia

Template Rev No. 0 Template Revision Date 18-May-2018 Page 8 of 10

L5-SAU-130

Country Level Document

MAGNETIC PARTICLE TEST REPORT

Project No. : 03-24-0051 Report No. : 03-24-0051-NDE/MT9

Client / Owner : HAJJAN

Name of Vessel / Item : JACK-203 Date of Inspection : 07 March, 2024

Location : Rig site Cleaner Make, Batch No : NA

Equipment & S/N : AC YOKE-110/0220 WCP Make, Batch No : MR-CHEMI-2307081

Material Tested : CARBON STEEL M.Particles Make, Batch No : MR-CHEMI-2310013

Surface Condition : CLEAN Measured Light Level : VISIBLE

Drawing Reference : NA Light Meter S.No : NA

Reference Procedure : L4-SAU-108 REV 0 & Client Inst UV lamp S.No : NA

Acceptance Criteria : ASTM E709 Measured UV Intensity : NA

(µW/cm2)

Demagnetization : NA

Technique Current Type of Detection Media Field Strength Verification QC Check

Yoke AC Wet Colour Contrast Pie Gauge Lifting Force

Coil DC Wet Fluorescent Castrol Strip

Central Conductor Permanent Magnet

Item ID Item Description Accept / Reject

3071GR16/37 Crane main hook block Accept

9-16

Inspection Result & Remarks:

Magnetic particle inspection was carried out on critical weld areas and heat affected zones, no defects or surface

breaking discontinuities found at the time of inspection.

This is to confirm that the equipment stated herein was attended by the Company’s competent person and particulars & findings stated herein are correct at the time of inspection.

Inspectedby: Ibrahim Reviewedby: Nafa Al Rowaie

NDT Level II Thouseef

Date and Sign: 07 Mar, 2024 Date and Sign: 07 Mar, 2024

Name & Address of the Employer: Velosi Saudi Arabia Co. Ltd, Al-Qusur, Talal Al-Doha Building,Sub of Prince Mohammad bin Fahd Road, P.O Box-7031, Dhahran

34247-2958, Kingdom of Saudi Arabia

Template Rev No. 0 Template Revision Date 18-May-2018 Page 9 of 10

L5-SAU-130

Country Level Document

MAGNETIC PARTICLE TEST REPORT

Project No. : 03-24-0051 Report No. : 03-24-0051-NDE/MT10

Client / Owner : HAJJAN

Name of Vessel / Item : JACK-203 Date of Inspection : 07 March, 2024

Location : Rig site Cleaner Make, Batch No : NA

Equipment & S/N : AC YOKE-110/0220 WCP Make, Batch No : MR-CHEMI-2307081

Material Tested : CARBON STEEL M.Particles Make, Batch No : MR-CHEMI-2310013

Surface Condition : CLEAN Measured Light Level : VISIBLE

Drawing Reference : NA Light Meter S.No : NA

Reference Procedure : L4-SAU-108 REV 0 & Client Inst UV lamp S.No : NA

Acceptance Criteria : ASTM E709 Measured UV Intensity : NA

(µW/cm2)

Demagnetization : NA

Technique Current Type of Detection Media Field Strength Verification QC Check

Yoke AC Wet Colour Contrast Pie Gauge Lifting Force

Coil DC Wet Fluorescent Castrol Strip

Central Conductor Permanent Magnet

Item ID Item Description Accept / Reject

SHO10/17 Crane auxilary hook block Accept

9-16

Inspection Result & Remarks:

Magnetic particle inspection was carried out on critical weld areas and heat affected zones, no defects or surface

breaking discontinuities found at the time of inspection.

This is to confirm that the equipment stated herein was attended by the Company’s competent person and particulars & findings stated herein are correct at the time of inspection.

Inspectedby: Ibrahim Reviewedby: Nafa Al Rowaie

NDT Level II Thouseef

Date and Sign: 07 Mar, 2024 Date and Sign: 07 Mar, 2024

Name & Address of the Employer: Velosi Saudi Arabia Co. Ltd, Al-Qusur, Talal Al-Doha Building,Sub of Prince Mohammad bin Fahd Road, P.O Box-7031, Dhahran

34247-2958, Kingdom of Saudi Arabia

Template Rev No. 0 Template Revision Date 18-May-2018 Page 10 of 10

You might also like

- Visual Testing ReportDocument2 pagesVisual Testing Reportm.rasheed400010No ratings yet

- FCPG-00000-CPP143-00-QA-6050-00011-002 - RT ProcedureDocument19 pagesFCPG-00000-CPP143-00-QA-6050-00011-002 - RT Procedurem.rasheed400010No ratings yet

- Ultrasonic Examination Report: Details of JobDocument3 pagesUltrasonic Examination Report: Details of JobF A D L YNo ratings yet

- Inspection and Quality Control in ManufacturingDocument598 pagesInspection and Quality Control in Manufacturingsaeed.pdNo ratings yet

- FCPG-00000-CPP143-00-QA-6050-00010-001 MT ProcedureDocument21 pagesFCPG-00000-CPP143-00-QA-6050-00010-001 MT Procedurem.rasheed400010No ratings yet

- 23-10-16 UT Thickness Fire ExtinguisherDocument1 page23-10-16 UT Thickness Fire ExtinguisherAmranNo ratings yet

- Shear Wave PDFDocument6 pagesShear Wave PDFcutefrenzyNo ratings yet

- rfq3000278081-1 Xls EncryptDocument8 pagesrfq3000278081-1 Xls EncryptRiyaz AhmedNo ratings yet

- Sop 151-1Document4 pagesSop 151-1m_armoutiNo ratings yet

- RT-Procedure-Native File - For Easy Edit Urgent Doc Submission PurposeDocument19 pagesRT-Procedure-Native File - For Easy Edit Urgent Doc Submission PurposeShanmuga NavaneethanNo ratings yet

- 3-Lcd Defectology RadiografiDocument108 pages3-Lcd Defectology RadiografiMuhammad Bio EranataNo ratings yet

- Iqwq Ce1091 VPNDT D7 4562 - 0Document49 pagesIqwq Ce1091 VPNDT D7 4562 - 0Bello Friday JacksonNo ratings yet

- En Magnetic Particle TestingDocument7 pagesEn Magnetic Particle TestingkingstonNo ratings yet

- Sample RT Report PipelineDocument1 pageSample RT Report Pipelinekhalid hidayatullahNo ratings yet

- ISO-TC135-SC7-WG9 N0024 Review of ISO TR 25107 ISO TR 2510Document253 pagesISO-TC135-SC7-WG9 N0024 Review of ISO TR 25107 ISO TR 2510jbrizuelasanchez4706No ratings yet

- Insulation Inspection ReportDocument1 pageInsulation Inspection ReportKarthikNo ratings yet

- Introduction To IR Detectors: Slawomir PiatekDocument73 pagesIntroduction To IR Detectors: Slawomir PiatekAnbarasan PerumalNo ratings yet

- 23 GinzelDocument12 pages23 Ginzelmusaismail8863No ratings yet

- RT Pratical Exam FormulasDocument2 pagesRT Pratical Exam FormulasKartik SharmaNo ratings yet

- Welder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, WeldingDocument1 pageWelder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, WeldingReza100% (1)

- Radiation Safety Program 2Document16 pagesRadiation Safety Program 2Ahmed shabanNo ratings yet

- Ut TwiDocument266 pagesUt TwiADAMJSRAONo ratings yet

- Weld - Tee Weld Csa w59 Aws d1Document5 pagesWeld - Tee Weld Csa w59 Aws d1Siggy LaiNo ratings yet

- PR DIV03 NDT 0008 Radiation Safety ProcedureDocument41 pagesPR DIV03 NDT 0008 Radiation Safety ProcedureFAYAZ YousuffNo ratings yet

- RT ProcedureDocument10 pagesRT ProcedureSandeep SundriyalNo ratings yet

- Radiography Part 2 - TWIDocument8 pagesRadiography Part 2 - TWIKolusu Sivakumar100% (1)

- Handout Ultrasonic Testing Level II - Rev. 1 - 12 May 2010Document185 pagesHandout Ultrasonic Testing Level II - Rev. 1 - 12 May 2010deari nur azisNo ratings yet

- Welds Written ReportDocument4 pagesWelds Written ReportChris Paulo100% (1)

- 4845 PDFDocument1 page4845 PDFRavi patelNo ratings yet

- Digital Ultrasonic Flaw Detectors For Curved SurfaceDocument11 pagesDigital Ultrasonic Flaw Detectors For Curved Surfaceiprao0% (1)

- (Ultrasonic Thickness Gauging) : ProcedureDocument8 pages(Ultrasonic Thickness Gauging) : ProcedureARUNNo ratings yet

- MT Procedure Rkl-Pro-08-ThocDocument26 pagesMT Procedure Rkl-Pro-08-ThocEmmad JriNo ratings yet

- Nasa STD 5006aDocument33 pagesNasa STD 5006atoadstooll100% (1)

- Specifications For Plates: Chemical Composition Mechanical PropertiesDocument7 pagesSpecifications For Plates: Chemical Composition Mechanical Propertiesprajakt_pieNo ratings yet

- M 2 SAW D1.1 2015 Form PDFDocument1 pageM 2 SAW D1.1 2015 Form PDFyounessNo ratings yet

- UT of Immersion Test of ExtrusionDocument7 pagesUT of Immersion Test of ExtrusionSiggy LaiNo ratings yet

- Codes and Standards Level 2Document31 pagesCodes and Standards Level 2Vimukthi KumaraNo ratings yet

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 pagesUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mNo ratings yet

- Radiography TestingDocument1 pageRadiography TestingGulfnde Industrial ServicesNo ratings yet

- UT Outline Training LV IIIDocument4 pagesUT Outline Training LV IIITrung Tinh HoNo ratings yet

- UT3Document115 pagesUT3Nikhil KashyapNo ratings yet

- Complete Short Circuit CycleDocument8 pagesComplete Short Circuit CycleWilly UioNo ratings yet

- AsuuuuuuuuuuuuDocument22 pagesAsuuuuuuuuuuuuyusuf akbar100% (1)

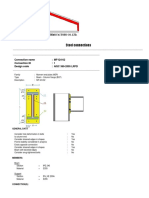

- Steel Connections: Connection Name: MF-I24-02 Connection ID: 1 Design Code: AISC 360-2005 LRFDDocument12 pagesSteel Connections: Connection Name: MF-I24-02 Connection ID: 1 Design Code: AISC 360-2005 LRFDmalikasalNo ratings yet

- 0455e - Welding Inspector Visual Acuity Record PDFDocument1 page0455e - Welding Inspector Visual Acuity Record PDFAbu HanifaNo ratings yet

- EuroIncon Master Ut NotesDocument95 pagesEuroIncon Master Ut NotesmohamedNo ratings yet

- C36. SMEP-2900-QA-6180-0023 - UT Procedure As Per AWS D1.1 Steel Structure (Cristar) - Rev 01C - ApprovedDocument45 pagesC36. SMEP-2900-QA-6180-0023 - UT Procedure As Per AWS D1.1 Steel Structure (Cristar) - Rev 01C - Approvedfikril shaharudinNo ratings yet

- SAIW Course Prospectus 2017Document76 pagesSAIW Course Prospectus 2017Caleb ConradNo ratings yet

- Porosity in WeldingDocument13 pagesPorosity in Weldingbn pandeyNo ratings yet

- Codes and Standards: Specific ObjectivesDocument14 pagesCodes and Standards: Specific ObjectivesJahan ZebNo ratings yet

- Welder Qualification ReportDocument2 pagesWelder Qualification ReportSyed Mahmud Habibur RahmanNo ratings yet

- ppt1 PDFDocument48 pagesppt1 PDFOmar SalihNo ratings yet

- Radioactive Decay Measurement:: T o (Time/HL)Document2 pagesRadioactive Decay Measurement:: T o (Time/HL)DeepakRajurkarNo ratings yet

- G S Earth WireDocument10 pagesG S Earth WiresaratNo ratings yet

- b954 SBDH Appendix3Document177 pagesb954 SBDH Appendix3qgfytzvqabzqrxyilmNo ratings yet

- Nondestructive Examination (NDE) Technology and Codes Student Manual Introduction To Ultrasonic ExaminationDocument78 pagesNondestructive Examination (NDE) Technology and Codes Student Manual Introduction To Ultrasonic ExaminationRaj KumarNo ratings yet

- NDT-Basic-FormulaeDocument3 pagesNDT-Basic-FormulaeJayeshNo ratings yet

- Duplex IQI 67 - 113Document2 pagesDuplex IQI 67 - 113Esin DenizNo ratings yet

- DD 4a NORMALDocument2 pagesDD 4a NORMALilham machmudNo ratings yet

- E0274-AD-105-C-330314 - Rev 4 - CRSDocument3 pagesE0274-AD-105-C-330314 - Rev 4 - CRSdeivam04No ratings yet

- 202 Substructure Cracks AnalysisDocument1 page202 Substructure Cracks AnalysisAngel PerdomoNo ratings yet

- Jack203 Damaged BHADocument2 pagesJack203 Damaged BHAAngel PerdomoNo ratings yet

- Red ZoneDocument1 pageRed ZoneAngel PerdomoNo ratings yet

- 757 - Belt Tong 220479-8-1Document3 pages757 - Belt Tong 220479-8-1Angel PerdomoNo ratings yet

- 201 - CAT3 ABCO - Hook Block (24-Jul-2023)Document17 pages201 - CAT3 ABCO - Hook Block (24-Jul-2023)Angel PerdomoNo ratings yet

- E-2200 Pg.2 (6-15-66)Document1 pageE-2200 Pg.2 (6-15-66)Angel PerdomoNo ratings yet

- Calibration Certificates List - CompressedDocument7 pagesCalibration Certificates List - CompressedAngel PerdomoNo ratings yet

- Oilwell HD1400&1700 C&oDocument102 pagesOilwell HD1400&1700 C&oAngel PerdomoNo ratings yet

- SS - 01 - Rev - 2Document26 pagesSS - 01 - Rev - 2Angel PerdomoNo ratings yet

- 203 WheelLoader (25-Mar-23)Document3 pages203 WheelLoader (25-Mar-23)Angel PerdomoNo ratings yet

- Oliwell HD1400PT PartslistDocument18 pagesOliwell HD1400PT PartslistAngel PerdomoNo ratings yet

- 177 - Crystin Safety Valve 67449Document4 pages177 - Crystin Safety Valve 67449Angel PerdomoNo ratings yet

- Oilwell A1700PT DATA SHEETDocument4 pagesOilwell A1700PT DATA SHEETAngel PerdomoNo ratings yet

- Unit1 Three Phase Induction MotorDocument36 pagesUnit1 Three Phase Induction MotorPalak JioNo ratings yet

- S10FE IIa B 47 Electromagnetic SpectrumDocument6 pagesS10FE IIa B 47 Electromagnetic SpectrumMICHAEL-JEFF GAGABENo ratings yet

- EdcDocument252 pagesEdcMy WritingsNo ratings yet

- ECE 332 Study Guide Module 4Document10 pagesECE 332 Study Guide Module 4dummyNo ratings yet

- Modern Physics: Substructure of The NucleusDocument7 pagesModern Physics: Substructure of The NucleusMa. Gienica AnonuevoNo ratings yet

- Representation of Power Systems: 1.1 One Line DiagramDocument17 pagesRepresentation of Power Systems: 1.1 One Line DiagramDr. Gollapalli Naresh100% (1)

- Physics Deleted and Added Portion - 231009 - 143759Document2 pagesPhysics Deleted and Added Portion - 231009 - 143759ABCD Play schoolNo ratings yet

- The Electric Properties of Molecules: ExercisesDocument16 pagesThe Electric Properties of Molecules: ExercisesSergio Magalhaes FerreiraNo ratings yet

- Adil - MWD REPORTDocument39 pagesAdil - MWD REPORTHamid MasoodNo ratings yet

- PARTS LITS Air Cooled Packaged Water ChillersDocument11 pagesPARTS LITS Air Cooled Packaged Water ChillersOng MatNo ratings yet

- Science 7 Third Quarter Learners MaterialDocument38 pagesScience 7 Third Quarter Learners MaterialMILAGROS GUARINONo ratings yet

- PI044F - Winding 05: Technical Data SheetDocument9 pagesPI044F - Winding 05: Technical Data SheetmunhNo ratings yet

- 2CDS213001R0324Document2 pages2CDS213001R0324Julio César Elías RiveraNo ratings yet

- Info Iec62271-200 (Ed1.0) en D PDFDocument11 pagesInfo Iec62271-200 (Ed1.0) en D PDFVivekKajlaNo ratings yet

- Laser Diode: Product Specification Sheet L658P040Document1 pageLaser Diode: Product Specification Sheet L658P040Jorge GuerreroNo ratings yet

- 2020-21 Series Test 1 QPDocument1 page2020-21 Series Test 1 QPred18ggmuNo ratings yet

- Fdocuments - in - 11 Tmss 02 r0Document34 pagesFdocuments - in - 11 Tmss 02 r0Sukant BhattacharyaNo ratings yet

- Gyrator - Wikipedia PDFDocument44 pagesGyrator - Wikipedia PDFRishabh MishraNo ratings yet

- DC GeneratorsDocument29 pagesDC Generatorsmario286950% (2)

- Rish 12S 16S Multi - . .: User ManualDocument16 pagesRish 12S 16S Multi - . .: User ManualSandeep SNo ratings yet

- 6 D O9 Pgoqgi PJK X1 IfssxDocument24 pages6 D O9 Pgoqgi PJK X1 IfssxYeri KhaNo ratings yet

- Presentation of XPSDocument12 pagesPresentation of XPSyasir jamilNo ratings yet

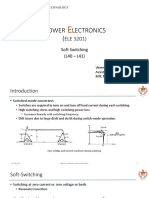

- Ower Lectronics (: Soft Switching (L40 - L41)Document7 pagesOwer Lectronics (: Soft Switching (L40 - L41)Mayank KashyapNo ratings yet

- Science: Quarter 1 - Module 5 Colors of LightDocument27 pagesScience: Quarter 1 - Module 5 Colors of LightMarie Diana B. DagadagNo ratings yet

- PacificWireless PAWDCA-24Document2 pagesPacificWireless PAWDCA-24Alfred ScholldorfNo ratings yet

- Disconnect Switch - 02Document4 pagesDisconnect Switch - 02Mudabbir HussainNo ratings yet

- HPH103 - Waves and Optics 1 - Lecture # 3Document22 pagesHPH103 - Waves and Optics 1 - Lecture # 3Praise NehumambiNo ratings yet

- Brown and Orange 4 Panel Comic StripDocument1 pageBrown and Orange 4 Panel Comic StripChan8O1 (channi)No ratings yet

- Alcon CapaciterDocument8 pagesAlcon CapaciterAnmohieyNo ratings yet

- Synchronous Motor PROJECTDocument9 pagesSynchronous Motor PROJECTMd Samee MNo ratings yet