Professional Documents

Culture Documents

HIRA Ducting Works

HIRA Ducting Works

Uploaded by

yogeshraut1910Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HIRA Ducting Works

HIRA Ducting Works

Uploaded by

yogeshraut1910Copyright:

Available Formats

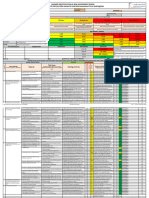

HIRA DOCUMENT

Note: Master document shall be revised in every 6 months based on the analysis of OHSE dashboard analysis & key learnings of various incidents both internal & external issues

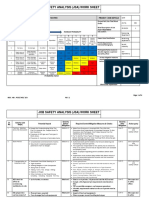

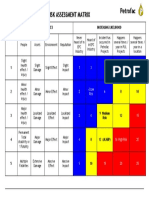

CATEGORY OF

COMPLIANCE WITH

SEVERITY LEVEL EXPOSOURE PROBABLITY

LEGISLATION AND

REGULATIONS

SR NO.

DISCRIPTION (S) FREQUENCY (E) DISCRIPTION (P)

RATING RATING RATING LEGISLATION RATING

All aspects to

No health effect which

1 /injury /No damage. 1 (Very Low) Rarely 1 (Very Low) Never heard in Projects / Office 1 (Very Low) legislation/reg YES - Significance

ulations

First Aid Injury / applies

The existence

Slight health effect / of

little damage to legislation/reg

property ulations has

no influence NO - No

2 2 (Low) Once in month 2 (Low) Heard in Projects / Offices outside 2 (Low)

on Significance

significance

Minor Injury / health 3 (Moderate) Incident happened in Projects of REVISION REGISTER:

3 3 (Moderate) Once in a week 3 (Moderate)

effect / illness our organization / company 2-3

Major injury / health times in a year.

Happened in Projects of our

effect / illness organization / company 5-6 times

4 (fractures, breaking 4 (High) Once/twice a day 4 (High) in a year 4 (High)

of organs, injury to

body parts).

Fatal / Permanent 5 (Very High)

loss of organs / Happened several times in a year

5 functions (eyes, 5 (Very High) Continuous 5 (Very High)

in our Projects / Offices

legs, hands.) /

Dangerous

Risk Evaluation REMARKS:

LOW: MODERATE: HIGH:

IMPACT RISK UPTO 30 IMPACT RISK 31 TO 60 IMPACT RISK 61 & ABOVE

1 In the event Severity is 5 or the legislation is "NO"- irrespective of overall score, Risk is always high.

2. PM's to delete the Note Points from 01 to 06 while sharing with the client & contractor

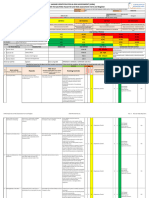

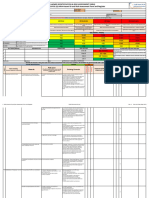

PROJECT SPECIFIC HIRA DOCUMENT FOR REFERENCE

REGION : PUNE

Project Name : BMC Software Ind Pvt Ltd Location: BMC Software , Business Bay ,Tower 2, Tech Park Yerwada, Pune

411006 Prepared & : Name &

Yogesh Raut

Signature

Activity: Duct Erection

Reviewed By

Note: All the activities will be carried out with prevention measures of Covid -19 like Social distancing and related PPE.

SEVERITY S EXPOSOURE PROBABLITY P ACTION MEASURE FOR RISK CONTROL OPERATIONAL CONTROL

(Relates to FREQUENCY E (Relates to DOCUMENTS & Reference no

Associated (Relates to Hazard) Incidents)

ID No. ACTIVITY HAZARDS ASSOCIATED RISK Risk) LEGISLATION L IMPACT RISK RISK LEVEL

1.Before entering plant safety induction training to be

Lack of awarness about

Mobilization of Reasonable conducted & gate pass to be ensured.

1 manpower

work leads to Personnel PH=Physical hazard 1 3 2 No Risk 2.PPE's shall be provided.(Helmet Reflective jacket and safety

injury

shoes,goggle and hand gloves).

1. Daily Tool Box Talk (TBT) shall be conducted.

2. Task specfic training will be conducted.

3. Follow proper work permit system.

4. Provide Proper PPE Helmet Reflective jacket and safety

shoes,goggle and hand gloves.

2 Shifting of Material GI Slip, Trip or Fall hazards 2 3 2 Yes Reasonable

*PH = Physical Hazard 5. Continuous supervision shall be provide.

Sheets due to Personnal Injury Risk

6. Trained labor shall be allowed

for the job.

7. Provide shoulder pad and cut Resistance hand gloves shall

be provided.

1. Ensure no any worker lift weight more than 20 kg.

2. Provide PPE Hand gloves,shoulder pad,Cut Resistance

shifting of Materail GI Ergonomic hazards due to

3 2 3 2 No Reasonable hand gloves shall be provided.

sheetsand Duct excess weight lifting by *E = Ergonomic Hazards

Risk 3. Deployed Only trained person for the activity.

Erection person

4. Warning signages will be depolyed.

5.Ensure one duct lift at one time one worker only by

manual shiftying of duct.

1. Appropriate PPE Should be Provide Helmet Reflective

shifting of Materail Foot injury due to fall of 2 3 2 Yes Reasonable jacket and safety shoes, goggle and hand gloves.

4 Pipes and GI sheets material.

*PH = Physical Hazard

Risk 2. safe access shall be provide

3. Continuous supervision shall be provide.

1. Cut resistance hand gloves shall be provided.

5 shifting of Materail Hand injury due to contact 2 3 2 Yes Reasonable

*PH = Physical Hazard 2. Continuous supervision shall be provide.

GI sheets with sharp object. Risk

3. warning signages shall be display on working area.

1. Working platform should not be overloaded by material.

2. Working platform secured by mid rail and top railing,toe

guard with adequate specification.

3.Ensure no any defects identified in working platform.

4.Provide working

Proper working

Worker fall from height due platform, safe access & use of full body safety harness above

6 platform /scaffolding 3 3 2 Yes Reasonable

to improper working *PH = Physical Hazard 1.2mtr from ground level.

with staging for fix Risk

platform

Ducting & Bolts.

5.Scaffolding check list will be maintained on daily basis.

6.Ensure proper site supports should be provide for

scaffolds.& approved from HSE Dept.

7.Appropriate PPE Should be provide.(Safety Helment ,

Jacket, Safety Shoes,Hand gloves,goggle etc.

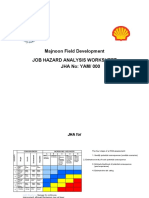

1. Cotton handgloves should be provide.

Erection of Vartical 2. Ensure work permit before start of any work activity.

Cut injury due to contact 3 3 2 No Reasonable

7 Full thred Rod

with sharp edge

*PH = Physical Hazard

Risk

3. Deployed Only trained person for the activity.

Suppert Patti 4. Continuous supervision shall be

provide.

1.Tool box Talk shall be conducted before start work.Ensure

permit before start wok.

8 .Cutting & Duct Fall hazards due to access 3 3 2 Yes Reasonable

*PH = Physical Hazard 2.Scaffold check list will be Maintained on daily basis

Fabrication obstruction. Risk

3. Appropriate PPE Should be provide(FBSH,

helmet,jacket,hand gloves,gogglre etc.)

1.Work permit shall be taken before start the work.

Concreating for the 2. Area shall be barricated.

9 Eye & skin irritation due to 2 3 2 No Reasonable

fixing the Pipes & *PH = Physical Hazard 3. Eye wash bottle shall be provided.

concrete particle flying. Risk

Foundation 4. Appropriate PPE Shall be provide( Hand gloves, Safety

goggle etc.)

1. Tool box Talk shall be conducted.

2. Work permit shall be taken before start the work.

3. Provide proper PPE Helmet Reflective jacket and safety

shoes,goggle and hand gloves.

welding activity for flammable /compositable

5 3 2 Yes Reasonable 4. Continuos supervision shall be provide.

10 the Pipe joints & material leads to fire *F = Fire Hazards

Risk 5. fire extinguisher kept on near working area.

brazings Hazard

6.Flammable or compositable material shall be removed from

working area before start the work.

7. Deployed only trained manpower.

1. Tool box Talk shall be conducted

2. Work permit shall be taken before start the work.

3. Drill machine inspection shall be done before start of the

activity.

4. Ensure25 mA ELCB provide for welding machine & its

Drill machie activity working condition.

11 Electrical Shock due to 4 3 2 Yes Reasonable

for the Suppert *PH = Physical Hazard 5. Ensure all electrical cables should be in good condition &

Personnel Injury Risk

Patti& brazings joints free.

6. Deployed only authorized welder for welding activity.

7.Provide Proper PPE Helmet, Reflective jacket and safety

shoes,goggle andwelding leather hand gloves, welding face

sheild.

8. Continuos supervision shall be provide.

1. Barricade work areas and display warning signage's.

2. Do not use work

platform as material storage.

Full thired Rod

12 Body injury due to fall of 3 3 2 Yes Reasonable 3. Provide Helmet Reflective jacket and safety shoes,goggle

activity for the *PH = Physical Hazard

person on height. Risk and hand gloves.

Suppert Patti

4. Proper Access & Approved scaffold / working platform

should be provide.

5. Full body safety Belt shall be provided

6. Check list will be Maintained on daily basis.

1.Proper PPE Should be Provide safety helmet, safety

shoes,goggles,jacket. Cut Resistance hand gloves.

Cut injury due to contact 2 3 2 No Reasonable

13 Fixing the GI sheet

with sharp edge

*PH = Physical Hazard

Risk

2. Ensure work permit before start of any work activity.

3.Continuos supervision shall be provide.

1. Barricade work areas and display warning signage's.

2.Use tools box , bag for loose

14 Damage hammer handle 2 3 2 Yes Reasonable materials.

Hammering work *PH = Physical Hazard

cause of body injury, Risk Hand Tools check list will be Maintained on daily

basis.audit will be conducted monthly basis.

3.Appropriate PPE shall be use.

1. Use of safety helmet, safety shoes, goggles, Cut

15 Sharp edges leads to cut 3 3 2 Yes Reasonable Resistance hand gloves and Nose Mask)

House Keeping PH=Physical hazard

injury Risk 2. Ensure work permit

before start of any work activity.

You might also like

- Year 9 Assessment Task 1 STELR Depth Study Report PDFDocument5 pagesYear 9 Assessment Task 1 STELR Depth Study Report PDFGremlin ChildNo ratings yet

- ABC - ra.CWSS.19-HIRA-Erection of Precast Columns, BeamsDocument5 pagesABC - ra.CWSS.19-HIRA-Erection of Precast Columns, BeamsShafie ZubierNo ratings yet

- Environmental Impacts and Aspects RegisterDocument9 pagesEnvironmental Impacts and Aspects RegisterSlobodan Jankovic100% (1)

- HIRA - Loading Unloading 0 Material ShiftingDocument1 pageHIRA - Loading Unloading 0 Material Shiftingyogeshraut1910No ratings yet

- HIRA Drilling WorksDocument1 pageHIRA Drilling Worksyogeshraut1910No ratings yet

- 5.1 HIRA For Installation of DUCTDocument3 pages5.1 HIRA For Installation of DUCTRAM KUMAR K RNo ratings yet

- Peb HiraDocument2 pagesPeb HiraRANJEET SINGH100% (1)

- 1 HIRA Site Mobilization Work RBIPL EHS HIRA 02Document3 pages1 HIRA Site Mobilization Work RBIPL EHS HIRA 02SuvarnrajNo ratings yet

- OHSE - Honeywell Project - HIRA Rev 00 (4 Activity)Document1 pageOHSE - Honeywell Project - HIRA Rev 00 (4 Activity)Gnanesh SNo ratings yet

- OHSE Project HIRA - Fencing Work - R 1Document1 pageOHSE Project HIRA - Fencing Work - R 1Pankaj SinghNo ratings yet

- Project Risk Index For Hira: Severity Level ProbablityDocument4 pagesProject Risk Index For Hira: Severity Level ProbablitysayleeNo ratings yet

- OHSE Project HIRA - Fencing Work - R 00Document3 pagesOHSE Project HIRA - Fencing Work - R 00Pankaj SinghNo ratings yet

- OHSE Project HIRA - Fencing Work - R 01Document8 pagesOHSE Project HIRA - Fencing Work - R 01Pankaj SinghNo ratings yet

- HIRA-Shaft Cable Tray N Cable InstallationDocument2 pagesHIRA-Shaft Cable Tray N Cable InstallationDivakar Dhande100% (1)

- OHSE Project HIRA - GI Sheet Removal From Roof To Ground (Manually) - R 00Document2 pagesOHSE Project HIRA - GI Sheet Removal From Roof To Ground (Manually) - R 00Pankaj SinghNo ratings yet

- Project Hira-Razor Pay-EIPL-RPDocument12 pagesProject Hira-Razor Pay-EIPL-RPKamesh A100% (1)

- Oil and Gas 4 PDF FreeDocument4 pagesOil and Gas 4 PDF FreeabdelhalimNo ratings yet

- RAM BrochureDocument5 pagesRAM BrochureAndra SerbanNo ratings yet

- Formation Day 2Document19 pagesFormation Day 2Mokhtar MahboubeNo ratings yet

- Jha - Wheel & Tire Removal and Repair ActivityDocument7 pagesJha - Wheel & Tire Removal and Repair ActivityPradip Kumar ShaNo ratings yet

- Risk Assessment of Fabrication, Welding, Cutting WorkDocument7 pagesRisk Assessment of Fabrication, Welding, Cutting WorkAbdul MujeebNo ratings yet

- Fahm-Electrical JhaDocument6 pagesFahm-Electrical Jhaindiasingapore9No ratings yet

- OHS-PR-09-03-F02 HIRA - 005 Office Rev.2021Document6 pagesOHS-PR-09-03-F02 HIRA - 005 Office Rev.2021sayed fida hussainNo ratings yet

- 000 - JHA TemplateDocument8 pages000 - JHA TemplateMohammed AdnanNo ratings yet

- RA MatrixDocument1 pageRA MatrixAkhdamli ServicesNo ratings yet

- OHS-PR-09-03-F02 HIRA - 002 Route Surveying Tower Spotting Rev. 2021Document18 pagesOHS-PR-09-03-F02 HIRA - 002 Route Surveying Tower Spotting Rev. 2021Jaafar LagayanNo ratings yet

- Risk Assessment Of-Scaffolding Erection, Dismantling WorkDocument8 pagesRisk Assessment Of-Scaffolding Erection, Dismantling WorkAbdul MujeebNo ratings yet

- OHS-PR-09-03-F02 HIRA - 001 Site Survey of Land Rev. 2021Document8 pagesOHS-PR-09-03-F02 HIRA - 001 Site Survey of Land Rev. 2021MuhammadAsimMuneerNo ratings yet

- OHS-PR-09-03-F02 HIRA - 001 Mobilization and Preparation of Site Offices Rev. 2021Document21 pagesOHS-PR-09-03-F02 HIRA - 001 Mobilization and Preparation of Site Offices Rev. 2021Jaafar LagayanNo ratings yet

- Risk Assessment For COVID-19Document3 pagesRisk Assessment For COVID-19Ali KaziNo ratings yet

- Environmental Aspect Impact RegisterDocument17 pagesEnvironmental Aspect Impact Registersyahir et0% (1)

- Ltesp SP01 F02 EaiDocument6 pagesLtesp SP01 F02 EaiGautam PrajapatiNo ratings yet

- LTESP SP01 F02 EAI Rev.01Document6 pagesLTESP SP01 F02 EAI Rev.01Gautam PrajapatiNo ratings yet

- 6 - AI Register PDS 22.05Document13 pages6 - AI Register PDS 22.05Raghwendra RaghavNo ratings yet

- OHS-PR-09-03-F02 HIRA - 005 Access Road and Structure Pad Preparation For Plain AreaDocument10 pagesOHS-PR-09-03-F02 HIRA - 005 Access Road and Structure Pad Preparation For Plain AreaJaafar LagayanNo ratings yet

- OHS-PR-09-03-F02 HIRA - 005 Light Materials and Equipment Loading - Unloading Rev. 2021Document6 pagesOHS-PR-09-03-F02 HIRA - 005 Light Materials and Equipment Loading - Unloading Rev. 2021MuhammadAsimMuneerNo ratings yet

- 7.OHS-PR-09-03-F02 HIRA - 30 Hydro Testing of Gas PipelineDocument5 pages7.OHS-PR-09-03-F02 HIRA - 30 Hydro Testing of Gas PipelineabbasNo ratings yet

- OHS-PR-09-03-F02 HIRA - 004 Mobilization and Preparation of Site Offices Rev. 2021Document6 pagesOHS-PR-09-03-F02 HIRA - 004 Mobilization and Preparation of Site Offices Rev. 2021MuhammadAsimMuneerNo ratings yet

- Job Safety Analysis (Jsa) Work Sheet: Doc NoDocument4 pagesJob Safety Analysis (Jsa) Work Sheet: Doc NoDeka sandraNo ratings yet

- OHS-PR-09-03-F02 HIRA - 002 Marking and Layout of Site Being Surveyed Rev. 2021Document11 pagesOHS-PR-09-03-F02 HIRA - 002 Marking and Layout of Site Being Surveyed Rev. 2021MuhammadAsimMuneerNo ratings yet

- OHS-PR-09-03-F02 HIRA - 003 Soil Investigation For High Terain AreaDocument12 pagesOHS-PR-09-03-F02 HIRA - 003 Soil Investigation For High Terain AreaJaafar LagayanNo ratings yet

- Insignificant (2) Minor (3) Moderate (4) Major (5) CatastrophicDocument6 pagesInsignificant (2) Minor (3) Moderate (4) Major (5) Catastrophicabhinav dj50% (2)

- OHS-PR-09-03-F02 HIRA - 003 Temporary Perimeter Fencing Rev. 2021Document7 pagesOHS-PR-09-03-F02 HIRA - 003 Temporary Perimeter Fencing Rev. 2021MuhammadAsimMuneerNo ratings yet

- OHS-PR-09-03-F02 HIRA - 006 Access Road and Structure Pad Preparation For High Terrain AreaDocument10 pagesOHS-PR-09-03-F02 HIRA - 006 Access Road and Structure Pad Preparation For High Terrain AreaJaafar LagayanNo ratings yet

- Manhole Construction - ExcavationDocument1 pageManhole Construction - Excavationasr.engineering2023No ratings yet

- Aspects Format-01Document6 pagesAspects Format-01Mohamed RizwanNo ratings yet

- Risk Assessment Manhole CleaningDocument9 pagesRisk Assessment Manhole CleaningShah MuzzamilNo ratings yet

- OHS Risk Register - KNPCDocument4 pagesOHS Risk Register - KNPCMohamed RizwanNo ratings yet

- Risk Assessment of WaterproofingDocument7 pagesRisk Assessment of WaterproofingAbdul Mujeeb100% (1)

- 016 Hse Incident Accident Investigation ReportDocument5 pages016 Hse Incident Accident Investigation ReportomarqasimNo ratings yet

- Ra FormDocument5 pagesRa FormEngrHazrat MaazNo ratings yet

- OHS-PR-09-03-F02 HIRA - 020 Lifting of Heavy Equipment Using Crane Rev. 2021Document14 pagesOHS-PR-09-03-F02 HIRA - 020 Lifting of Heavy Equipment Using Crane Rev. 2021bilalgradioshNo ratings yet

- OHS-PR-09-03-F02 HIRA - 004 Soil Investigation For Plain AreaDocument6 pagesOHS-PR-09-03-F02 HIRA - 004 Soil Investigation For Plain AreaJaafar LagayanNo ratings yet

- Template HIRADocument21 pagesTemplate HIRADeptHSE SSSNo ratings yet

- OHS-PR-09-03-F02 HIRA - 053 Installation of Fiber Optic Cable Panel - Rev. 2021Document16 pagesOHS-PR-09-03-F02 HIRA - 053 Installation of Fiber Optic Cable Panel - Rev. 2021Ebrahsm ElshenawyNo ratings yet

- Risk Assessment: Block Works Larsen & Toubro Limited PT&D (I) (Africa)Document4 pagesRisk Assessment: Block Works Larsen & Toubro Limited PT&D (I) (Africa)Naveen GladsonNo ratings yet

- 046 - Delivery and Installation of Cabins at CPPDocument11 pages046 - Delivery and Installation of Cabins at CPPMohammed AdnanNo ratings yet

- 011 - Remedial Works at Yabani BridgeDocument11 pages011 - Remedial Works at Yabani BridgeMohammed Adnan100% (1)

- Risk Assessment: Site Facilities Larsen & Toubro Limited PT&D (I) (Africa)Document4 pagesRisk Assessment: Site Facilities Larsen & Toubro Limited PT&D (I) (Africa)Naveen GladsonNo ratings yet

- Oh&s 401Document1 pageOh&s 401Ranjana SushilkumarNo ratings yet

- Introduction To CRMDocument20 pagesIntroduction To CRMflaviagonNo ratings yet

- General ConclusionDocument2 pagesGeneral ConclusionAdelNo ratings yet

- Water Unit 1-NotesDocument35 pagesWater Unit 1-NotesEng Venance MasanjaNo ratings yet

- The Literary Formofthe QuranDocument10 pagesThe Literary Formofthe QuranTrina CanizoNo ratings yet

- Abb Flyer Diode ThyristorDocument2 pagesAbb Flyer Diode ThyristorHusejin Mehmedović100% (1)

- Solar Generator (LB-P500-A) : Product DetailsDocument2 pagesSolar Generator (LB-P500-A) : Product Detailsbogdan danescuNo ratings yet

- Function 4Document61 pagesFunction 4Jegatheesh EashwaranNo ratings yet

- 364.7T-02 (11) Evaluation and Minimization of Bruising (Microcracking) in Concrete Repair (TechNote)Document3 pages364.7T-02 (11) Evaluation and Minimization of Bruising (Microcracking) in Concrete Repair (TechNote)YaserNo ratings yet

- Hankel TransformDocument30 pagesHankel TransformMuhammad KamranNo ratings yet

- Analysis of Behaviour of Multistorey RCC Structure With Different Types of Bracing System (By Using Software)Document9 pagesAnalysis of Behaviour of Multistorey RCC Structure With Different Types of Bracing System (By Using Software)IJRASETPublicationsNo ratings yet

- NO. WD-37-MISC-2004: Specification Design, Development and Supply Premium Elastomeric Pads Broad Gauge Freight BogiesDocument14 pagesNO. WD-37-MISC-2004: Specification Design, Development and Supply Premium Elastomeric Pads Broad Gauge Freight BogiesOM MishraNo ratings yet

- Expansion Joint - REJECT PDFDocument34 pagesExpansion Joint - REJECT PDFJuan LubonNo ratings yet

- The Best of The KambulowsDocument149 pagesThe Best of The Kambulowswalthope100% (1)

- Difference Between Discrete & Repetitive ManufacturingDocument2 pagesDifference Between Discrete & Repetitive ManufacturingSyed Amir HussainNo ratings yet

- (Technical) Pİ PO K 140-47 Concrete PumpDocument9 pages(Technical) Pİ PO K 140-47 Concrete PumpZeljko DjurdjevicNo ratings yet

- Ehs Hospital List For Both TG & ApDocument43 pagesEhs Hospital List For Both TG & ApAvulaHarikrishnaYadavNo ratings yet

- NO. Diseases Vaccine Type Doses Dosage Site Brand Names: Route Interval Age Given (First Dose)Document3 pagesNO. Diseases Vaccine Type Doses Dosage Site Brand Names: Route Interval Age Given (First Dose)Breezy ReveloNo ratings yet

- Redemption of Umayyad Memory by The AbbāsidsDocument26 pagesRedemption of Umayyad Memory by The AbbāsidsghouseNo ratings yet

- Cox, David SOT Meeting Minutes 01-26-23Document2 pagesCox, David SOT Meeting Minutes 01-26-23David M. Cox ESNo ratings yet

- Activity1 - nickiejaneGE1Document3 pagesActivity1 - nickiejaneGE1nickie jane gardoseNo ratings yet

- Overhead Power Cable by CP41Document1 pageOverhead Power Cable by CP41Ricardo LourençoNo ratings yet

- Blackrock Us Factor Outlook July 2017 en UsDocument6 pagesBlackrock Us Factor Outlook July 2017 en UsAugusto Peña ChavezNo ratings yet

- Form 02 QuestionsDocument7 pagesForm 02 QuestionsMagomed KitaevNo ratings yet

- Amit - CSV Compliance - 2024Document4 pagesAmit - CSV Compliance - 2024eyamit.patilNo ratings yet

- Gertrud Rosshalde Ultima Vara A Lui Klingsor Romanian Edition by Hermann Hesse 6066096141Document5 pagesGertrud Rosshalde Ultima Vara A Lui Klingsor Romanian Edition by Hermann Hesse 6066096141Zaiu DaiuNo ratings yet

- Higher Modern Languages: What Is New?Document28 pagesHigher Modern Languages: What Is New?bleinNo ratings yet

- Classification of Android Apps and Malware Using Deep Neural NetworksDocument8 pagesClassification of Android Apps and Malware Using Deep Neural NetworksAbhishek ChattopadhyayNo ratings yet

- CTEKS 12-14 X 50 HGSDocument2 pagesCTEKS 12-14 X 50 HGSPT SHS Garasi GempolNo ratings yet

- List of Break Dance MovesDocument11 pagesList of Break Dance MovesAkshai KsNo ratings yet