Professional Documents

Culture Documents

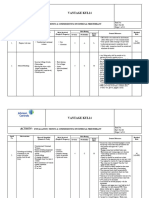

HIRA - Copper Pipe Brazing Work

HIRA - Copper Pipe Brazing Work

Uploaded by

yogeshraut1910Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HIRA - Copper Pipe Brazing Work

HIRA - Copper Pipe Brazing Work

Uploaded by

yogeshraut1910Copyright:

Available Formats

1. Site Safety training will be given and Gate pass will be ensured.

Lack of awarness about

Mobilization of Reasonable 2. HSE induction Training will be given before enter the site.

1 work area/Site leads to *PH = Physical Hazard 2 3 3 No

manpower

Physical injury.

Risk 3. PPE’s (Safety helmet, Reflective jacket, Goggles, Safety shoes) will

be given.

1. Tool Box Talk will be conducted about site area and its clearance.

2. Housekeeping work permit will be obtained before starting of work.

3. Method statement of Housekeeping will be referred.

Existing Combustible

2 4 3 3 Yes Reasonable 4. PPE’s (Safety helmet, Cotton hand gloves, Reflective jacket, Safety

Site Area Clearence materials in work area *F = Fire Hazards

leads to fire

Risk shoes) will be provided.

5. Fire extinguisher and Fire bucket will be provided.

6. All the Dust, Scraps and Combustible materials in work area will be

cleared away from the work area.

1. TBT will be given for Shifting of Brazing Set .

2. PPE's (Safety helmet, Cut resistance hand gloves, Reflective jacket,

3 Shifting of Brazing Personal injury due to 3 3 3 No Reasonable Safety shoes) will be given.

*M = Mechanical Hazard

Set manually contact with sharp edge Risk 3. Gas cylinders vertically sitting on trolley then tighten with chain

4.Equipped with flash back arrester (both oxygen andacetylene

5.Gas cylinder cap available

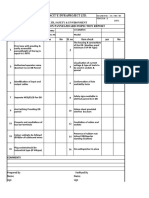

1. Hot job must be barricaded and display safety sign board

2.Trained person in the operation of fire extinguisher and informative in

case of emergency

3. All cylinders shall be placed upright position.

1)fire

4. All cylinder shall be transport thoroughly trolley only. and should be

2) Burn injury locked by chain

3) may be fatal 5. Check the hose pipe before initiation work.

Handling of Gas 3 3 3 No Reasonable

4 Cutting Brazing set

4)Respiratory problem *PH = Physical Hazard

Risk

6. Flash back arrestor should be used for gas cutting set.

5) Heat stress 7. Prior to starting the work, hot work permit will be obtained.

6) Heat & spark 8. Procedures of handling Brazing set will be referred.

7) Explosion

9. Daily inspection checklist ofBrazing set will be maintained.

10.Brazing set will not be allowed for operating in wet areas.

11. Continuous supervision will be deployed.

12. PPE's (Safety helmet, Rubber hand gloves for, Goggles, Reflective

jacket, Safety shoes) will be provided.

1. Equipment condition shall be inspected prior to use.

5 Handling of Gas 3 3 3 No Reasonable 2. Use of appropriate PPE (Hand gloves, safety shoes, helmet, jacket

Explosion *PH = Physical Hazard

Cutting Brazing set Risk etc.)

1. 1. Task specific training and TBT will be conducted.

2. Prior to starting the work, hot work permit will be obtained.

3. Procedures of handling Brazing set will be referred.

Loose lugs of Burn injury

6 Handling of Brazing 5 3 3 Yes Reasonable 4. Daily inspection checklist of Brazing set will be maintained.

can result in sparks which *F = Fire Hazards

set

can leads to fire.

Risk 5.Brazing set will not be allowed for operating in wet areas.

6. Continuous supervision will be deployed.

7. PPE's (Safety helmet, Rubber hand gloves for, Goggles, Reflective

jacket, Safety shoes) will be provided.

1. Task specific training and TBT will be conducted.

2. Prior to starting the work, Hot work permit will be obtained.

3. Handling of Brazing set Procedures will be referred.

4. Weekly inspection checklist of Brazing set will be maintained.

Earth leakage can cause 5. Continuous supervision will be deployed.

Handling of Brazing electric shock to the 3 3 3 No Reasonable

7 set work person handling the

*PH = Physical Hazard

Risk

8. PPE's (Safety helmet, Rubber hand gloves for electrical

Brazing set . maintenance, Leather hand gloves for welding work., welding apron,

goggles, Reflective jacket, Safety shoes) will be provided.

9. All electrical cables are in good condition & joints free.

10. All electrical cables are taken overhead 7 ft. from ground level.

1. Task specific training and TBT will be conducted.

2. Prior to starting the work, Hot work permit will be obtained.

3. Handling of Brazing set Procedures will be referred.

4. Weekly inspection checklist of Brazing set will be maintained.

1. Damaged Brazing Set 5. Continuous supervision will be deployed.

8 Handling of Brazing 4 3 3 Yes Reasonable

set

hose clamp at the *PH = Physical Hazard

Risk

8. PPE's (Safety helmet, Rubber hand gloves for electrical

connecting point available maintenance, Leather hand gloves for welding work., welding apron,

goggles, Reflective jacket, Safety shoes) will be provided.

9. All electrical cables are in good condition & joints free.

10. All electrical cables are taken overhead 7 ft. from ground level.

1. The return holders should be in good condition and shall be

inspected before use.

Copper pipeing brazing 2.Hot job must be barricaded and display safety sign

9 Handling of Brazing sparks will cause fire if any 5 3 3 Yes Reasonable board

*F = Fire Hazards

Set flammable materials Risk 3. Fire extinguishers & Fire buckets to be kept.

nearby 4. Fire watcher should be available.

5. Only authorized electricians will be deployed for connecting cables to

earth return holder with proper insulating.

Brazing Sethandles in 1. Equipment condition shall be inspected prior to use.

Handling of Brazing damaged condition, can 3 3 3 No Reasonable 2. Use of appropriate PPE (Hand gloves, safety shoes, helmet, jacket

10 *M = Mechanical Hazard:

Set lead to body injury during Risk etc.)

operation.

1.The Brazing set hose clamp at the connecting point available

should be in good condition

Makingl 5. All Cylinder Key/Handleare trolley proper current rating double

11 connections 5 3 3 Yes Reasonable insulated & joints free.

Fire Hazard Respiratory *PH = Physical Hazard

/disconnection of Risk 6. PPE's (Safety helmet, rubber hand gloves, safety shoes and

Brazing Set reflective jacket will be provided.

7. Ensure proper job earthing to be connecting before start of the

activity

1. Combustible flammable material removed from Gas Cutting work

area

(Housekeeping)

Fire due to hot material or 2. The Scrap welding electrodes shall be disposed of properly after they

hot welding electrodes cool down.

12 5 3 3 Yes Reasonable

Brazing set work coming in contact with any *F = Fire Hazards

Risk

3. Fire extinguisher and fire bucket will be kept near the work location.

flammable material in the 4. Fire watcher will be deployed for continuous supervision.

work area. 6. Fire Blankets should be use duringBrazing set work.

5. PPE's (Safety helmet, Leather hand gloves for welding work.

Reflective jacket, Safety shoes) will be provided.

1. Authorized persons are allowed for welding operation area.

Burn injury due to contact 2. Hot scrap materials should be staged in identified location

with hot metal. 4 3 3 Yes Reasonable

13 Brazing set work *PH = Physical Hazard

Risk

3. PPE's (Safety helmet, leather hand gloves, welding apron, Aram

sleeves & legs sleeves, safety goggles, Safety shoes) will be provided.

1. Only authorized person/ Brazing are allowed for Brazing set

operation.

2. Brazing set radiation filter glass will be used for Brazing set purpose.

14 4 3 3 Yes Reasonable

Brazing set work Fire Hazard Respiratory *CH = Chemicl Hazard.

Risk

3. Brazing set face shield & mask should be providing to Brazing

setduring Brazing set work.

4. PPE's (Safety helmet, leather hand gloves, Brazing setapron,

Brazing set face shield, safety shoes) will be provided.

1. Persons working at height will be provided with Full Body Safety

Harness and the checklist for FBSH will be maintained.

2. Toe guards are provided at the working platform of the scaffold to

prevent the material/Tools slip from height.

Head, hand and leg injury 3. Fire extinguisher and fire bucket will be kept near the work location.

15 Brazing set work on 3 3 3 No Reasonable

height.

due to fall of person on *PH = Physical Hazard

Risk

4. Fire watcher will be deployed for continuous supervision.

height. 5. The work area will be barricaded to restrict un-authorized access.

6. PPE's (Safety helmet, Leather hand gloves for Brazing set work.

welding apron, Reflective jacket, and Safety shoes) will be provided.

7. Provide continuous site supervision & safety observations.

8. Display safety sign boards at working area.

1. Persons working at height will be provided with Full Body Safety

Harness and the checklist for FBSH will be maintained.

2. Toe guards are provided at the working platform of the scaffold to

prevent the material/Tools slip from height.

3. Fire extinguisher and fire bucket will be kept near the work location.

TheBrazing Set sparks

16 Brazing Set work on 5 3 3 Yes Reasonable 4. Fire watcher will be deployed for continuous supervision.

falling on combustible *F = Fire Hazards

height.

materials leads to fire.

Risk 5. The work area will be barricaded to restrict un-authorized access.

6. PPE's (Safety helmet, Leather hand gloves for welding work. welding

apron, Reflective jacket, and Safety shoes) will be provided.

7. Provide continuous site supervision & safety observations.

8. Display safety sign boards at working area.

1. Hammers will be visually inspected and will be approved if it is free

from any damage in handle and other parts.

2. Hammers and other tools which is safe to work will be allowed to

1. Finger injured in work.

between hammer & metal.

17 3 3 3 No Reasonable 3. Necessary rubber grippes will be given to the hammer handle.

Hammering work *PH = Physical Hazard

2. Damage hammer handle

Risk 4. Fire extinguisher and fire bucket will be kept near the work location.

causes Hand injury 5. Fire watcher will be deployed for continuous supervision.

6. PPE's (Safety helmet, Leather hand gloves for welding work. welding

apron, Reflective jacket, and Safety shoes) will be provided.

7. Deployed only trained person for the job.

1. Task specific training and TBT will be conducted on associated

hazards on scrap materials.

Cut injury due to contact 2. Procedures of Housekeeping will be referred.

18 Shifting the scrap with sharp edges. 3 3 3 No Reasonable 3. Fire watcher & site supervisor will be deployed for continuous

*PH = Physical Hazard

material Risk supervision.

4. PPE's (Safety helmet, Cut resistant hand gloves, Reflective jacket,

Safety shoes) will be provided.

1) Cutting zone should be isolated by G.I. sheet.

2) DCP type fire extinguisher Sand bucket should be installed.

3) Use required PPE such as leather hand gloves, helmet ,Goggles etc

4) Hot job must be barricaded and display safety sign board

5) Trained person in the operation of fire extinguisher and informative in

19 Shifting the scrap Foot injury due to material 4 3 3 Yes Reasonable

material fall on foot Heat & spark.

*PH = Physical Hazard

Risk

case of emergency

6) All cylinders shall be placed upright position.

7) All cylinder shall be transport thoroughly trolley only. and should be

locked by chain

8) Check the hose pipe before initiation work.

1. Task specific training and TBT will be conducted on housekeeping.

2) Housekeeping of gas cutting zone must be fulfilled

i)Raw material

ii) Finished product

Hand/Foot Injury, Cut

20 3 3 3 No Reasonable iii) scrap

Housekeeping injury *PH = Physical Hazard

Risk iv) Isolate from all combustible material like wood, paper etc.

3. Procedures of Housekeeping will be referred.

4. Fire watcher will be deployed for continuous supervision.

5. PPE's (Safety helmet, Cut resistant hand gloves, Leather apron,

Reflective jacket, Safety shoes) will be provided.

You might also like

- 1 - Ford Bantam Workshop ManualDocument1,663 pages1 - Ford Bantam Workshop ManualLouis Lion90% (21)

- Risk Assessment Fire Hydrant Installation Testing CommissioningDocument11 pagesRisk Assessment Fire Hydrant Installation Testing CommissioningAmie GTunedNo ratings yet

- SFFECO Profile - PreQualification - 2019 PDFDocument240 pagesSFFECO Profile - PreQualification - 2019 PDFMohammed SbeitanNo ratings yet

- Post Hole Borer Risk Assessment: September 2015 //1Document2 pagesPost Hole Borer Risk Assessment: September 2015 //1Rajendra0% (1)

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- RA-Suspended Gypsum, Metallic Tiles Celling WorksDocument4 pagesRA-Suspended Gypsum, Metallic Tiles Celling Worksfaizan khanNo ratings yet

- Sealcoating /crack Repair Parking Lots: Job Safety AnalysisDocument3 pagesSealcoating /crack Repair Parking Lots: Job Safety AnalysisRetselisitsoe0% (1)

- 675Document2 pages675Rameese MuhammedNo ratings yet

- Jsa Bitumen Heating, Lying at DahejDocument6 pagesJsa Bitumen Heating, Lying at DahejJayavant LoharNo ratings yet

- Jsa English HindiDocument12 pagesJsa English HindiPradip mallaNo ratings yet

- JSA FabricationDocument3 pagesJSA FabricationSwaroop Cherry100% (1)

- Hira For Pipe Coating Monsher Fire Protectioin System P. L.Document31 pagesHira For Pipe Coating Monsher Fire Protectioin System P. L.Nikhil ManjrekarNo ratings yet

- Jsa - Cable TerminationDocument4 pagesJsa - Cable TerminationD FiransyahNo ratings yet

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Lessons Learnt - Trench CollapseDocument2 pagesLessons Learnt - Trench CollapseEhab SaadNo ratings yet

- Dyer JSA - Brazing CopperDocument2 pagesDyer JSA - Brazing Copperdawn yatesNo ratings yet

- 142 Jsa Modify To 2 Inch MPW-2 To Reactor 2 Piping LineDocument6 pages142 Jsa Modify To 2 Inch MPW-2 To Reactor 2 Piping LineMohd KhaidirNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- ISLA JHA Removal of BarricadeDocument3 pagesISLA JHA Removal of Barricadeaasafety06No ratings yet

- Safety Data Sheet: ARDROX 907PB AerosolDocument11 pagesSafety Data Sheet: ARDROX 907PB Aerosolabdulbaset alselwi100% (1)

- Jsa Ducting Rev 00Document1 pageJsa Ducting Rev 00SRR HSE Department, Sandvik Project,No ratings yet

- Risk Assessment of Manual HandlingDocument2 pagesRisk Assessment of Manual HandlingMAB AliNo ratings yet

- JHA Formation Preparation or Leveling.Document2 pagesJHA Formation Preparation or Leveling.Mark Buendia100% (1)

- JSA-03 Shed DismantlingDocument3 pagesJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- Safe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro ManilaDocument6 pagesSafe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro Manilanani ferrerNo ratings yet

- PCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Document17 pagesPCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Geethika SandaruwanNo ratings yet

- Confined Space PermitDocument1 pageConfined Space PermitNethiyaaRajendranNo ratings yet

- JSA of Materila Handling ApproviedDocument2 pagesJSA of Materila Handling Approviedsakthi venkatNo ratings yet

- Jha Miura Z-Steam Boilers Intallation2Document8 pagesJha Miura Z-Steam Boilers Intallation2perquino oasanNo ratings yet

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- Qcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEDocument75 pagesQcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEbryanpastor106100% (1)

- M/S Gubbi Civil Engineer: Hazard Identification & Risk AnalysisDocument3 pagesM/S Gubbi Civil Engineer: Hazard Identification & Risk AnalysisHARSHADNo ratings yet

- Safety Data Sheet Conbextra Gp2: Revision Date: 01/01/2020 Revision: 0ADocument8 pagesSafety Data Sheet Conbextra Gp2: Revision Date: 01/01/2020 Revision: 0AAnonymous kRIjqBLkNo ratings yet

- JHA For Work PermitDocument1 pageJHA For Work PermitShahid RazaNo ratings yet

- Jsa For Dismantel of StructureDocument2 pagesJsa For Dismantel of StructureBaiju SinghNo ratings yet

- ENGY-EnG3-MOS-20210603-002 - Method of Statement For Concrete Pavement WorksDocument21 pagesENGY-EnG3-MOS-20210603-002 - Method of Statement For Concrete Pavement WorksTemur LomidzeNo ratings yet

- Tank ErectionDocument3 pagesTank ErectionPrasanth BharathNo ratings yet

- Heat Stress Awareness Drill June 2022Document18 pagesHeat Stress Awareness Drill June 2022Subbu AbuNo ratings yet

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- HIRA Reference Bearing & StopprtDocument51 pagesHIRA Reference Bearing & StopprtPlanning C7100% (1)

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- Jsa For Site EstablishmentDocument8 pagesJsa For Site EstablishmentBenasher IbrahimNo ratings yet

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- Hot Work Activities (Cutting)Document9 pagesHot Work Activities (Cutting)Al Mughsar CompanyNo ratings yet

- HEAT Job Safety Analyisis (JSA)Document6 pagesHEAT Job Safety Analyisis (JSA)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- 3 SPS Sop RCC FullDocument14 pages3 SPS Sop RCC FullDwitikrushna RoutNo ratings yet

- 9-1 Moem Hirarc Feb 2017Document1 page9-1 Moem Hirarc Feb 2017PHH9834No ratings yet

- Monthly Store Inspection ReportDocument1 pageMonthly Store Inspection ReportgkNo ratings yet

- JSA - Batching Plant OperationDocument3 pagesJSA - Batching Plant OperationNisith SahooNo ratings yet

- Panipat Refinery & Petrochemical Complex Job Safety AnalysisDocument6 pagesPanipat Refinery & Petrochemical Complex Job Safety AnalysisSaiyad RiyazaliNo ratings yet

- Mie Hse Jha 004 Installation of TransformerDocument5 pagesMie Hse Jha 004 Installation of TransformerMd Gulam SafiNo ratings yet

- Risk Assessment Roller Shutter DoorDocument4 pagesRisk Assessment Roller Shutter DoorphoenixsafetyconsultantNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- TFU-Risk Assessment RA-11 - Use of Grooving & Threading MachinesDocument1 pageTFU-Risk Assessment RA-11 - Use of Grooving & Threading Machinesarshin wildan100% (1)

- Hadeed JSA Shearing Machine InstallationDocument11 pagesHadeed JSA Shearing Machine InstallationDhanu NikkuNo ratings yet

- SDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Risk Assessment For Mechanical: Preparation WorkDocument3 pagesRisk Assessment For Mechanical: Preparation Workahmedalderbi801No ratings yet

- Hira HousekeepingDocument1 pageHira Housekeepingspst03792100% (1)

- 25 JHA On Erection of Cabling, Cable Trays, Cable Supports Inside TunnelsDocument3 pages25 JHA On Erection of Cabling, Cable Trays, Cable Supports Inside TunnelsPiyush SinghNo ratings yet

- Fire AwarenessDocument1 pageFire AwarenessNick LatumboNo ratings yet

- De Thi Hoc Sinh Gioi Cap Huyen Mon Tieng Anh Lop 9 Huyen Bao Thang Nam 2014 2015Document10 pagesDe Thi Hoc Sinh Gioi Cap Huyen Mon Tieng Anh Lop 9 Huyen Bao Thang Nam 2014 2015Nguyen TrienNo ratings yet

- K-22 Magnum Model HL22 (SIN RA1011) Early Suppression Fast Response (ESFR) SprinklerDocument4 pagesK-22 Magnum Model HL22 (SIN RA1011) Early Suppression Fast Response (ESFR) SprinklerFire ChileNo ratings yet

- Types of FiresDocument13 pagesTypes of FiresAlbert FrayNo ratings yet

- ARC-SOR-HSE-000001-00-Arcadis - Al Babtain Projects HSE Site Observation Report 05 OpenDocument11 pagesARC-SOR-HSE-000001-00-Arcadis - Al Babtain Projects HSE Site Observation Report 05 Openابو محمد عليNo ratings yet

- 1G Toucan TLUD For Biochar ProductionDocument7 pages1G Toucan TLUD For Biochar ProductionDavidEJacksonyNo ratings yet

- Kitchen SAfety Power Point ComDocument38 pagesKitchen SAfety Power Point CombibubhaskarNo ratings yet

- LEC 2017 - Post-Test in Fire Technology & Arson InvesDocument8 pagesLEC 2017 - Post-Test in Fire Technology & Arson InvesBokhary Dimasangkay Manok Elias100% (1)

- Praktis Ramalan 2019 SPM Bahasa Inggeris (Paper 1) - Set 1: Section A: Directed WritingDocument7 pagesPraktis Ramalan 2019 SPM Bahasa Inggeris (Paper 1) - Set 1: Section A: Directed WritingFirdaus ZulkifliNo ratings yet

- Section 26: Casing of New MachineryDocument5 pagesSection 26: Casing of New MachineryKANIKA SAININo ratings yet

- Dewatering Works - RADocument4 pagesDewatering Works - RAJames Bonito100% (1)

- Presentation ON Fire InsuranceDocument20 pagesPresentation ON Fire InsuranceS. M. Faysal 172-11-5575No ratings yet

- G4G23 - Climate Change Adaptation Lightning TalksDocument72 pagesG4G23 - Climate Change Adaptation Lightning Talks770923tomasNo ratings yet

- 47 - 02A Panchadasi Text & NotesDocument174 pages47 - 02A Panchadasi Text & NotesVhanie D100% (1)

- Compas Swing FF-02Document1 pageCompas Swing FF-02mohd azizul SabaranNo ratings yet

- Pec Table 9 Chapter 9Document46 pagesPec Table 9 Chapter 9Lester MuscaNo ratings yet

- PBF MSDS AsphaltDocument11 pagesPBF MSDS AsphaltAgustn LopzNo ratings yet

- 4B 6kochi BlogspotDocument71 pages4B 6kochi BlogspotHisham AreekkanNo ratings yet

- LNG FamiliarisationDocument80 pagesLNG FamiliarisationGee Villadarez100% (1)

- Study On Hotel Fire Investigation Based On FDSDocument4 pagesStudy On Hotel Fire Investigation Based On FDSNelso BedinNo ratings yet

- 00 06992Document5 pages00 06992enockprivateNo ratings yet

- 3029 4039, 4045 6059, 6068 Engines (Saran) (-499999CD) : John Deere Usine de Saran CTM3274 (01JUL99)Document10 pages3029 4039, 4045 6059, 6068 Engines (Saran) (-499999CD) : John Deere Usine de Saran CTM3274 (01JUL99)WSMengine WSMengineNo ratings yet

- User's Guide: Agilent 240/280 Series AA (Including Zeeman)Document64 pagesUser's Guide: Agilent 240/280 Series AA (Including Zeeman)Martin GuerreroNo ratings yet

- Arachis OilDocument2 pagesArachis OilAnn CatherynNo ratings yet

- Pending Work List With Budget2Document2 pagesPending Work List With Budget2SofiqNo ratings yet

- Combustion Engineering PDFDocument236 pagesCombustion Engineering PDFChristed Aljo BarrogaNo ratings yet

- Im10568 MANUAL OPERADOR LINCOLN ELECTRIC 600-IDocument60 pagesIm10568 MANUAL OPERADOR LINCOLN ELECTRIC 600-IKevin SaldanaNo ratings yet

- 021 Fire and Life Safety System - V0.1 - Nov-19Document66 pages021 Fire and Life Safety System - V0.1 - Nov-19Đức Huấn Đỗ100% (3)