Professional Documents

Culture Documents

What Is PCA PCB

What Is PCA PCB

Uploaded by

jackOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Is PCA PCB

What Is PCA PCB

Uploaded by

jackCopyright:

Available Formats

RAYMING PCB & ASSEMBLY

What is PCA PCB?

PCA and PCB are used interchangeably in the PCB industry. Electronic devices serve multiple functions and

as such, need circuit boards. It is crucial to understand the difference between PCB and PCA. This article

seeks to provide more knowledge about PCA PCB

Table of Contents

What Does PCA Mean?

A PCA refers to printed circuit assembly. Furthermore, a PCA is a printed circuit board populated

with electronic components. What makes up a PCA is the presence of electronic components. Without these

components installed, this board is a mere printed circuit board. PCA PCB is widely used across several

applications.

Generally PCBs offer two functions. The first is to enable the installment of electronic components on

designated locations on the external layers. The second function is to offer reliable electrical connections

between the terminals of the components. PCAs are primarily distinguished by the absence or presence of

attachments on the circuit board.

These components allow your PCB to function well. Also, the assembly of components on your circuit board

is what results in PCA. PCA also refers to printed circuit board assembly (PCBA). Printed circuit

assemblies involve the whole process of passing a bare board through SMT or PTH processes. With these

processes, the electronic components are carefully installed and soldered on the bare circuit board.

Request PCB Manufacturing & Assembly Quote Now

Difference Between a PCA and a PCB

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

PCB is a bare circuit board while PCA is a finished board. PCA comprises several electronic components

like diodes, transistors, capacitors, and more. Also, these components are critical for the functioning of a

circuit board. A PCB is a bare circuit board before electronic components assembly. Once a bare board has

an electronic component soldered on it, it becomes a printed circuit assembly (PCA).

It is crucial to understand that PCB manufacturing is different from printed circuit assembly. While PCB

manufacturing involves various processes like PCB design and PCB prototyping, the PCB assembly

involves installing components on a board.

Once a PCB is fabricated, there is a need for the placement of electronic components. In addition, PCA can

be through hole or surface mount. However, these two processes involve the mounting of electronic

components on the circuit board.

PCBs and PCAs are the outcomes of two various steps of the same process. Also, a printed circuit board

isn’t functional until it features electronic components. The manufacturing of bare circuit is simpler than

producing a PCA.

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

Why you Should Clean a PCA

Electronic assemblies manufacturing involves several series of chemical processes. Also, the steps involved

in these processes can leave toxic materials on the PCA. These toxic materials can compromise the

reliability of the assembly. To remove these harmful residues, cleaning is often required. This helps to

enhance reliability. Also, cleaning aids inspection.

Customers usually request for the cleaning of the PCA to ensure cleanliness and proper

testing. Furthermore, PCBA processes are in two categories. These include those that integrate a cleaning

process and those that don’t integrate a cleaning process.

Cleaning the parts is important after and before soldering. Improper cleanliness can result in solderability

problems. Furthermore, proper cleaning can enhance good adhesions, prevent corrosion, and avoid leakage

paths.

Request PCB Manufacturing & Assembly Quote Now

Applications of a PCA PCB

A PCA PCB is a circuit board that already has electronic components installed on it. Bare PCBs don’t offer

any function in electronic applications. Also, it is the presence of electronic components that make a PCA

PCB functional. PCA PCB comprises electronic components like diodes, resistors, transistors, and more.

Also, a PCA PCB is widely used in several applications like:

Medical

A PCA PCB plays a significant role in the designing and manufacturing of medical devices. These boards

are available in devices like heart monitoring machines, X-ray machines, etc. Also, they are available in

advanced machines used in the medical industry.

Consumer electronics

This is one of the common applications of a PCA PCB. You will find printed circuit assemblies in consumer

electronics like televisions, smartphones, smartwatches, and radios. PCAs serve as the foundation for these

electronic devices.

Automotive

The automotive industry relies on PCA PCB. Some parts of vehicles feature a wide range of electrical

and electronic parts which offer more functionality. Printed circuit assemblies have several uses in this sector.

You will find PCAs in the navigation system and control systems. Some modern cars feature built-in sensors

which help proximity monitors to judge distances and monitor blind spots.

Industrial applications

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

PCAs are widely integrated in manufacturing facilities and production lines. Also, PCAs are available in

assembly machines, power inverters, ramps, and power supplies. The industrial sector require printed circuit

assemblies designed to their needs. Also, high power and durable PCAs are commonly used in this industry.

Request PCB Manufacturing & Assembly Quote Now

Types of PCA Process

The outcome of the assembly process is the printed circuit assemblies. Also, the assembly of electronic

components on a bare circuit board is a process. However, there are different types of assembly process. This

process includes surface mount assembly, through hole assembly, and mixed technology.

Surface mount technology

This assembly process involves mounting surface mount devices directly on the surface of a bare PCB. Also,

surface mount technology involves the use of pick and place machine to mount components on PCB surface.

Also, SMT features an automatic mounting process from solder paste printing to reflow soldering.

Furthermore, SMT is commonly used for modern devices. This is because it helps in designing smaller and

more compact electronic devices.

Through hole technology

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

THT is an assembly process that involves the mounting of components using plated through holes. These

holes are drilled to allow components pass through them. This assembly process existed before the advent of

surface mount technology. Also, THT created strong bonds between the board and THT components.

Therefore, it is an ideal choice for assembling boards that will undergo environmental and mechanical stress.

Mixed technology

Some PCB assemblers integrate both surface mount and through hole technologies. This type of assembly

process combines the strength of both SMT and THT. Therefore, it offers the benefits of both mounting

technologies.

Conclusion

PCA PCBs are widely used across several industries. Also, printed circuit assemblies serve as the building

block of most electronic devices. There is a huge difference between PCA and PCB. Some people use these

terms interchangeably. This article has explained the differences between these two terms.

Related Posts:

1. The Main Features and Properties of the Isola IS415 PCB Material

2. What are the Recommended Process Conditions of the Arlon 37N PCB Material?

3. How to Guarantee SMT Production Quality

4. Panasonic MEGTRON M R-5735 Laminate – A Solution to Signal Integrity Problems in High

Frequency Applications

https://www.raypcb.com/pca-pcb/

PCB Manufacturing & Assembly Services https://www.raypcb.com/

You might also like

- ROE Session UNIT 4Document22 pagesROE Session UNIT 4Amina Abdullahi33% (3)

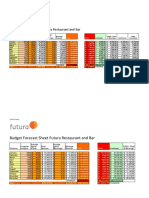

- Budget Forecast Sheet Futura Restaurant and BarDocument4 pagesBudget Forecast Sheet Futura Restaurant and BarRaviNo ratings yet

- What Is CPU PCB Manufacturing and SupplyingDocument4 pagesWhat Is CPU PCB Manufacturing and SupplyingjackNo ratings yet

- What Are The Applications of Suntak PCBDocument7 pagesWhat Are The Applications of Suntak PCBjackNo ratings yet

- Problems Frequently Found in Complex PCB AssemblyDocument8 pagesProblems Frequently Found in Complex PCB AssemblyjackNo ratings yet

- Impact of CPU PCBA in Computing DevicesDocument7 pagesImpact of CPU PCBA in Computing DevicesjackNo ratings yet

- Importance of Circuit Card Manufacturing in Electronics IndustryDocument7 pagesImportance of Circuit Card Manufacturing in Electronics IndustryjackNo ratings yet

- Digital PCB Assembly in The Sphere of ElectronicsDocument11 pagesDigital PCB Assembly in The Sphere of ElectronicsjackNo ratings yet

- An Overview of The Embedded PCBDocument10 pagesAn Overview of The Embedded PCBjackNo ratings yet

- Printed Circuit Boards Assembly (PCBA) Process - PCBCartDocument10 pagesPrinted Circuit Boards Assembly (PCBA) Process - PCBCartlittlekheongNo ratings yet

- Abbreviation of ManufacturingDocument16 pagesAbbreviation of ManufacturingjackNo ratings yet

- What Is Ems PcbaDocument11 pagesWhat Is Ems PcbajackNo ratings yet

- Factors To Consider When Choosing A Volume PCBDocument7 pagesFactors To Consider When Choosing A Volume PCBjackNo ratings yet

- What Are The Trends in Consumer Electronics AssemblyDocument4 pagesWhat Are The Trends in Consumer Electronics AssemblyjackNo ratings yet

- In-Plant Training Report PresentationDocument24 pagesIn-Plant Training Report PresentationPratyush Pandey100% (1)

- Creating The Layout From Your SchematicDocument10 pagesCreating The Layout From Your SchematicjackNo ratings yet

- What Does Electronics Product Assembly EntailDocument7 pagesWhat Does Electronics Product Assembly EntailjackNo ratings yet

- Common Circuit Board Component Abbreviations and PCB TerminologiesDocument8 pagesCommon Circuit Board Component Abbreviations and PCB TerminologiesjackNo ratings yet

- What Is The Purpose and Applications of A PCB MotherboardDocument4 pagesWhat Is The Purpose and Applications of A PCB MotherboardjackNo ratings yet

- Top Techniques, and Guide To Mount PCB in ElectronicsDocument7 pagesTop Techniques, and Guide To Mount PCB in ElectronicsjackNo ratings yet

- What Is The Difference Between PCB and PCBADocument18 pagesWhat Is The Difference Between PCB and PCBAjackNo ratings yet

- What Are PCB Pins and How Do They WorkDocument4 pagesWhat Are PCB Pins and How Do They WorkjackNo ratings yet

- Creating The Layout From Your SchematicDocument13 pagesCreating The Layout From Your SchematicjackNo ratings yet

- The Complete Guide To PCB Design and How It Affects Video Electronics and SystemsDocument12 pagesThe Complete Guide To PCB Design and How It Affects Video Electronics and SystemsjackNo ratings yet

- What Is PCB MillingDocument9 pagesWhat Is PCB MillingjackNo ratings yet

- How To Use Altium Multi Board PCB DesignerDocument5 pagesHow To Use Altium Multi Board PCB DesignerjackNo ratings yet

- SolidWorks PCB Services, What Is It All AboutDocument4 pagesSolidWorks PCB Services, What Is It All AboutjackNo ratings yet

- What Does Assembled PCB SMT MeanDocument6 pagesWhat Does Assembled PCB SMT MeanjackNo ratings yet

- What Is DRC PCBDocument4 pagesWhat Is DRC PCBjackNo ratings yet

- Basic Thing You Should Know About PCB Assembly ProcessDocument29 pagesBasic Thing You Should Know About PCB Assembly ProcessjackNo ratings yet

- Everything You Need To Know About SMT LinesDocument6 pagesEverything You Need To Know About SMT LinesjackNo ratings yet

- Why OEM Circuit Boards Are Ideal For Use in Several ApplicationsDocument6 pagesWhy OEM Circuit Boards Are Ideal For Use in Several ApplicationsjackNo ratings yet

- What Are The Applications and Design Considerations of The Robot PCBDocument9 pagesWhat Are The Applications and Design Considerations of The Robot PCBjackNo ratings yet

- Why Need Tooling Holes On PCBDocument10 pagesWhy Need Tooling Holes On PCBjackNo ratings yet

- PCB Design BasicsDocument8 pagesPCB Design Basicshungdee100% (1)

- PCB Design Hand BookDocument30 pagesPCB Design Hand BookDeepak Srinivasan75% (4)

- Day 4Document17 pagesDay 4j2yshjzzsxNo ratings yet

- PWB Vs PCB Vs PCBAWhat Are Differences and SimilaritiesDocument16 pagesPWB Vs PCB Vs PCBAWhat Are Differences and SimilaritiesjackNo ratings yet

- Printed Circuit Boards: Component Technology and Design Parameters'Document5 pagesPrinted Circuit Boards: Component Technology and Design Parameters'Ann MutisyaNo ratings yet

- How To Design Your Own Custom Microcontroller Unit - MCU PCBDocument10 pagesHow To Design Your Own Custom Microcontroller Unit - MCU PCBjackNo ratings yet

- Top Benefits of Automated PCB Manufacturing and AssemblyDocument5 pagesTop Benefits of Automated PCB Manufacturing and AssemblyjackNo ratings yet

- Why Wireless PCB Assembly Is Crucial in Some Electronic DevicesDocument5 pagesWhy Wireless PCB Assembly Is Crucial in Some Electronic DevicesjackNo ratings yet

- What Are Box Build AssembliesDocument5 pagesWhat Are Box Build AssembliesjackNo ratings yet

- Seminar On Industrial TrainingDocument36 pagesSeminar On Industrial TrainingRahul KumarNo ratings yet

- How To Use and Design Interposer PCB in Chip PackagingDocument11 pagesHow To Use and Design Interposer PCB in Chip PackagingjackNo ratings yet

- Why You Should Opt For PCB Assembly OutsourcingDocument5 pagesWhy You Should Opt For PCB Assembly OutsourcingjackNo ratings yet

- What Is Remote Control Manufacturing and Its BenefitsDocument6 pagesWhat Is Remote Control Manufacturing and Its BenefitsjackNo ratings yet

- What Is The Surface Mount Vs Through Hole DifferenceDocument15 pagesWhat Is The Surface Mount Vs Through Hole DifferencejackNo ratings yet

- The Complete SMT Process and What SMT Process Engineers Do in The ProcessDocument5 pagesThe Complete SMT Process and What SMT Process Engineers Do in The ProcessjackNo ratings yet

- 16 Easy Steps To Start PCB Circuit DesignDocument10 pages16 Easy Steps To Start PCB Circuit DesignjackNo ratings yet

- What Is Automatic Optical InspectionDocument13 pagesWhat Is Automatic Optical InspectionjackNo ratings yet

- Top Companies Offering PCB Assembly in San JoseDocument14 pagesTop Companies Offering PCB Assembly in San JosejackNo ratings yet

- What Are The Requirements For Building A Circuit Board PrototypeDocument5 pagesWhat Are The Requirements For Building A Circuit Board PrototypejackNo ratings yet

- What Do You Need To Know About Trace PCBDocument8 pagesWhat Do You Need To Know About Trace PCBjackNo ratings yet

- A Complete Guide On PCB Quick Turn What You Must KnowDocument6 pagesA Complete Guide On PCB Quick Turn What You Must KnowjackNo ratings yet

- Is The Integrated Circuit Diagram ImportantDocument10 pagesIs The Integrated Circuit Diagram ImportantjackNo ratings yet

- How Main PCB Impacts The Functionality of Electronic DevicesDocument4 pagesHow Main PCB Impacts The Functionality of Electronic DevicesjackNo ratings yet

- How Can A Large PCB Be FabricatedDocument10 pagesHow Can A Large PCB Be FabricatedjackNo ratings yet

- What Is FCT Test Meaning To PCBDocument21 pagesWhat Is FCT Test Meaning To PCBjackNo ratings yet

- PCB Functional Testing vs. PCBA Functional TestDocument11 pagesPCB Functional Testing vs. PCBA Functional TestjackNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- Xilinx XAZU2EG-1SBVA484I Fpga ApplicationDocument5 pagesXilinx XAZU2EG-1SBVA484I Fpga ApplicationjackNo ratings yet

- Why The Arlon 49N PCB Material Is Useful in High Temperature or High Performance ApplicationsDocument4 pagesWhy The Arlon 49N PCB Material Is Useful in High Temperature or High Performance ApplicationsjackNo ratings yet

- Why You Should Choose The Shengyi S7439G PCB MaterialDocument5 pagesWhy You Should Choose The Shengyi S7439G PCB MaterialjackNo ratings yet

- Why Is The Panasonic R-F705S Useful For Mobile and Automotive ProductsDocument4 pagesWhy Is The Panasonic R-F705S Useful For Mobile and Automotive ProductsjackNo ratings yet

- Why A PCB Ground Plane Is Crucial For PCB FunctioningDocument3 pagesWhy A PCB Ground Plane Is Crucial For PCB FunctioningjackNo ratings yet

- Why Is The Home Energy Monitor ImportantDocument7 pagesWhy Is The Home Energy Monitor ImportantjackNo ratings yet

- What Is The Significance of Home Electronics PCBDocument6 pagesWhat Is The Significance of Home Electronics PCBjackNo ratings yet

- Who Are The Leading Electrical Coil ManufacturersDocument5 pagesWho Are The Leading Electrical Coil ManufacturersjackNo ratings yet

- Why Non Recurring Engineering Cost (NRE Charge) Is Important For Your PCBDocument4 pagesWhy Non Recurring Engineering Cost (NRE Charge) Is Important For Your PCBjackNo ratings yet

- Why OEM Circuit Boards Are Ideal For Use in Several ApplicationsDocument6 pagesWhy OEM Circuit Boards Are Ideal For Use in Several ApplicationsjackNo ratings yet

- What Is The Significance of ENIG Plating ThicknessDocument4 pagesWhat Is The Significance of ENIG Plating ThicknessjackNo ratings yet

- Where To Buy Rogers RT Duroid 5880 LaminateDocument5 pagesWhere To Buy Rogers RT Duroid 5880 LaminatejackNo ratings yet

- Where Does The QuickLogic Eclipse FPGA Architecture Family Play A RoleDocument11 pagesWhere Does The QuickLogic Eclipse FPGA Architecture Family Play A RolejackNo ratings yet

- Why 3D Print PCBs Matter in Today's Electronics ProductionDocument4 pagesWhy 3D Print PCBs Matter in Today's Electronics ProductionjackNo ratings yet

- What Is The Melting Point of SolderDocument4 pagesWhat Is The Melting Point of SolderjackNo ratings yet

- What Is Xilinx Virtex-5 FPGADocument8 pagesWhat Is Xilinx Virtex-5 FPGAjackNo ratings yet

- What Is The Purpose and Applications of A PCB MotherboardDocument4 pagesWhat Is The Purpose and Applications of A PCB MotherboardjackNo ratings yet

- What Is Xilinx Spartan-7 Its Datasheet and Reference DesignsDocument20 pagesWhat Is Xilinx Spartan-7 Its Datasheet and Reference DesignsjackNo ratings yet

- What Is The Significance of IOT in AgricultureDocument8 pagesWhat Is The Significance of IOT in AgriculturejackNo ratings yet

- What Is Xilinx XA6SLX75T-2FGG484I ChipDocument5 pagesWhat Is Xilinx XA6SLX75T-2FGG484I ChipjackNo ratings yet

- What Is The Difference Between ARM and FPGA ProcessorsDocument9 pagesWhat Is The Difference Between ARM and FPGA ProcessorsjackNo ratings yet

- What Is Signal Integrity A Comprehensive OverviewDocument9 pagesWhat Is Signal Integrity A Comprehensive OverviewjackNo ratings yet

- What Is The Significance of Azure IoTDocument6 pagesWhat Is The Significance of Azure IoTjackNo ratings yet

- What Is Taconic TSM-DS3b PCBDocument7 pagesWhat Is Taconic TSM-DS3b PCBjackNo ratings yet

- What Is Through Hole PCB AssemblyDocument12 pagesWhat Is Through Hole PCB AssemblyjackNo ratings yet

- What Is Thermal Consideration in PCB DesignDocument6 pagesWhat Is Thermal Consideration in PCB DesignjackNo ratings yet

- What Is SMT Soldering Process Step by StepDocument12 pagesWhat Is SMT Soldering Process Step by StepjackNo ratings yet

- What Is The Difference Between FFC Connector and FPC ConnectorDocument14 pagesWhat Is The Difference Between FFC Connector and FPC ConnectorjackNo ratings yet

- What Is Xilinx Kintex UltraScale UltraScale+Document8 pagesWhat Is Xilinx Kintex UltraScale UltraScale+jackNo ratings yet

- What Is The Difference Between Clean Flux and No Clean Flux Off PCBDocument13 pagesWhat Is The Difference Between Clean Flux and No Clean Flux Off PCBjackNo ratings yet

- AfganistanDocument4 pagesAfganistankoenbrotoNo ratings yet

- Name: - Date - Per - : Series and Parallel Circuits WorksheetDocument4 pagesName: - Date - Per - : Series and Parallel Circuits WorksheetRebecca RodriguezNo ratings yet

- Lycoming DirectDriveOverhaulDocument152 pagesLycoming DirectDriveOverhaulleather_nun100% (1)

- Pump PipingDocument58 pagesPump PipingSoumitra Gupta100% (3)

- Sugarcane Bagasse BricksDocument8 pagesSugarcane Bagasse BricksganeshNo ratings yet

- 30 of BodybuildingDocument10 pages30 of Bodybuildingariven11No ratings yet

- Composites IntroDocument74 pagesComposites IntroFikri SiplhoNo ratings yet

- Ethics-Activity 2 UtilitarianismDocument2 pagesEthics-Activity 2 UtilitarianismAngelou RomancaNo ratings yet

- Course Title: Facilitating Learner Centered Teaching Course Description: This Course Explores The Fundamental PrinciplesDocument2 pagesCourse Title: Facilitating Learner Centered Teaching Course Description: This Course Explores The Fundamental PrinciplesLaurence Bernard Balbin II100% (3)

- Psychotherapy of Depression in Children and AdolescentsDocument58 pagesPsychotherapy of Depression in Children and AdolescentsYamila Borges Rivera100% (1)

- House Bill 3925Document11 pagesHouse Bill 3925Pamela TambaloNo ratings yet

- HVAC Air Distribution SystemsDocument23 pagesHVAC Air Distribution Systemsbernardsilvano100% (1)

- Night-Lite Pro II Parts Manual (2021-110292 Rev E)Document514 pagesNight-Lite Pro II Parts Manual (2021-110292 Rev E)nursultanNo ratings yet

- El ProgramDocument29 pagesEl ProgramSaurav Kishor100% (1)

- Ielts Task 1 (Academic Exam) How To Write at A 9 Level PDFDocument41 pagesIelts Task 1 (Academic Exam) How To Write at A 9 Level PDFmurtada yousifNo ratings yet

- BS en 12373-2-1999Document8 pagesBS en 12373-2-1999Arzu AkarNo ratings yet

- Process Flow Limits Valve Symbology Connections Fluid Codes: IG N E DDocument1 pageProcess Flow Limits Valve Symbology Connections Fluid Codes: IG N E DCabello V. LizandroNo ratings yet

- Paoay Lake National High School: "Road To Exceddence Starts Here"Document3 pagesPaoay Lake National High School: "Road To Exceddence Starts Here"Gio Aldrin ManuelNo ratings yet

- F61TB-9104 - F61 - General Brochure - 08 2014 - ENDocument6 pagesF61TB-9104 - F61 - General Brochure - 08 2014 - ENSaad PathanNo ratings yet

- FIGO Recommendations On Adolescent Preconception and Maternal Nutrition Think Nutrition First 2015 WebDocument43 pagesFIGO Recommendations On Adolescent Preconception and Maternal Nutrition Think Nutrition First 2015 WebAndi Fahira NurNo ratings yet

- Physical Chemistry I (Solid State) : DR Fatah EltaboniDocument20 pagesPhysical Chemistry I (Solid State) : DR Fatah EltaboniDina Garan100% (1)

- CO2 Safety ManualDocument51 pagesCO2 Safety ManualKrishna YadavNo ratings yet

- Wastewater Pumps - Eng'g ManualDocument87 pagesWastewater Pumps - Eng'g ManualIsmael Llamelo PerezNo ratings yet

- Our History: The Beginning and The Journey: The GenesisDocument9 pagesOur History: The Beginning and The Journey: The GenesisAntariksh BhandariNo ratings yet

- Ecological Terms - 1 PDFDocument2 pagesEcological Terms - 1 PDFraviNo ratings yet

- 2016 - Are There Subconcussive Neuropsychological Effects in Youth Sports? An Exploratory Study of High - and Low-Contact SportsDocument8 pages2016 - Are There Subconcussive Neuropsychological Effects in Youth Sports? An Exploratory Study of High - and Low-Contact SportsRaúl VerdugoNo ratings yet

- IAL As Chemistry SN 4Document116 pagesIAL As Chemistry SN 4Michael J George100% (2)

- Mmed Anaes A Exam SyllabusDocument16 pagesMmed Anaes A Exam SyllabusLaserPiratePewPewNo ratings yet