Professional Documents

Culture Documents

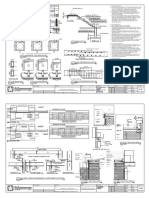

Proposed Office Building: General Notes

Proposed Office Building: General Notes

Uploaded by

Jhon SabinoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Proposed Office Building: General Notes

Proposed Office Building: General Notes

Uploaded by

Jhon SabinoCopyright:

Available Formats

REPUBLIC OF THE PHILIPPINES

GENERAL NOTES: 3.3 WIND LOAD 10. MASONRY & CONCRETE BLOCKS DEPARTMENT OF PUBLIC WORKS

P = qGCp - qh(GCpi) 10.1. ALL NON-LOAD BEARING TYPE CONCRETE BLOCKS SHALL HAVE A UNIT WEIGHT AND HIGHWAYS

1. GENERAL WHERE: P = DESIGN PRESSURE IN KPA NOT TO EXCEED 80 PCF. FOR LOAD BEARING TYPE CONCRETE BLOCKS, A

q = VELOCITY PRESSURE IN KPA

OFFICE OF THE BUILDING OFFICIAL

1.1 REFERENCE TO OTHER DRAWINGS MINIMUM COMPRESSIVE STRENGTH OF 4.80 MPA. SHALL BE DEVELOPED. CITY/MUNICIPALITY

G = GUST EFFECT FACTOR

SEE ARCHITECTURAL DRAWINGS AND OTHER RELEVANT DRAWING FOR KINDS 10.2. PROVIDE 1- Ø 16 VERTICAL BARS AT CORNERS, INTERSECTIONS, END OF 13.0 STRUCTURAL STEEL:

Cp = EXTERNAL PRESSURE COEFFICIENT RECOMMENDING ISSUANCE

OF FLOOR FINISHES, IN WALLS AND SLABS, INTERIOR PARTITIONS, LOCATION WALLS & EACH SIDE OF OPENINGS.

qh = VELOCITY PREESURE EVALUATED AT HEIGHT, Z = h 13.1 ALL MATERIALS AND WORKMANSHIP SHALL CONFORM WITH THE

OF CHB WALLS, ETC.

GCpi = INTERNAL PRESSURE COEFFICIENT AND GUST FACTOR EFFECT, 10.3. LINTEL BEAMS SHALL BEAR AT LEAST 8 INCHES (200 MM.) ON EACH SIDE OF NINTH EDITION OF THE AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1.2 DIMENSIONS TABLE 204-4 MASONRY WALL OPENING. HEAD STRUCTURAL DATE

(AISC) MANUAL UNLESS OTHERWISE SHOWN OR NOTED.

- DIMENSIONS SHOWN ARE IN MILLIMETERS UNLESS OTHERWISE NOTED 3.4 SEISMIC LOAD SECTION

10.4. WALL REINFORCEMENTS (UNLESS INDICATED) SHALL BE AS FOLLOWS: 13.2 CONTRACTOR SHALL FURNISH ALL PLATES, CLIP ANGLES,

- IN THE INTERPRETATION OF THESE DRAWINGS, INDICATED DIMENSIONS 3.4.1 ZONE...........................................................................................0.4

SHALL GOVERN AND DISTANCES OR SIZE SHALL NOT BE SCALED FOR WALL THICKNESS VERTICAL REINFORCEMENT HORIZONTAL REINFORCEMENT CONNECTORS, ETC. REQUIRED FOR COMPLETION OF THE

3.4.2 IMPORTANCE FACTOR.................................................................1.0 STRUCTURE EVEN IF EVERY SUCH ITEM IS NOT SHOWN ON THE

CONSTRUCTION PURPOSES. 3.4.3 Rw...............................................................................................8.5 8 IN. (200 MM.) Ø 12 @ 400 MM. Ø 10 @ 600 MM.

CONTRACT DRAWINGS.

1.3 DISCREPANCIES 3.4.4 SOIL PROFILE...............................................................................SC and SD 6 IN. (150 MM.) Ø 10 @ 400 MM. Ø 10 @ 600 MM.

3.4.5 Cv.................................................................................................0.0.44Nv 4 IN. (100 MM.) Ø 10 @ 400 MM. Ø 10 @ 600 MM. 13.3 WELDING SHALL BE IN ACCORDANCE WITH THE AMERICAN WELDING

- THE CONTRACTOR SHALL COMPARE THE STRUCTURAL DRAWINGS TO THE

ARCHITECTURAL DRAWINGS IN REFERENCE TO THE LAYOUT. DIMENSIONS 3.4.6 Ca.................................................................................................0.56Na 10.5. REINFORCING BARS SHALL BE LAPPED A MINIMUM OF 30 BAR DIAMETERS SOCIETY CODE AWS D 1.1 UNLESS INDICATED OTHERWISE.

Na..........................................................................................................1.00 WHERE SPLICED, HORIZONTAL/VERTICAL DOWELS FROM FOOTINGS, COLUMNS/WALLS OR WELDING ELECTRODES SHALL BE E70XX. ISSUED:

AND ELEVATION SHALL BE CONSULTED TO THE DESIGN ENGINEER IN CASE OF

DISCREPANCIES IN THE ISSUED DRAWINGS. Nv..........................................................................................................1.00 SLABS SHALL EXTEND INTO THE BLOCK WALL A MINIMUM OF 30 BAR DIAMETERS OR A

MINIMUM OF 400 mm. WHICHEVER IS LONGER AND DOWELS TO MATCH VERTICAL 13.4 ALL BOLTS AND THREADED FASTENERS SHALL BE ASTM A 307 BUILDING OFFICIAL DATE

1.4 CONSTRUCTIONS DRAWINGS 4. CONCRETE AND REINFORCEMENT STEEL

REINFORCEMENTS OF WALL. A325, A490 UNLESS INDICATED OTHERWISE.

4.1 ALL MATERIALS & WORKMANSHIP SHALL CONFORM WITH THE LATEST

- ALL DIMENSION SHALL TAKE PRECEDENCE OVER SCALE ON PLANS, SECTION 10.6. ALL CELLS CONTAINING REINFORCING BARS OR INSERTS SHALL BE SOLIDLY

BUILDING CODE OF AMERICAN CONCRETE INSTITUTE (ACI-318) 13.5 ALL STRUCTURE STEEL SHALL BE ASTM A36 WITH

OR DETAILS. NOTES AND DETAILS ON DRAWINGS SHALL TAKE PRECEDENCE FILLED WITH CONCRETE GROUT. (REFER TO SPECIFICATIONS)

4.2 ALL CONCRETE SHALL DEVELOP A MINIMUM COMPRESSIVE STRENGTH AT Fy = 248 MPa Fu = 400 MPa

OVER GENERAL NOTES AND TYPICAL DETAILS.

THE END OF TWENTY EIGHT (28) DAYS WITH CORRESPONDING MAXIMUM SIZE 11. CAMBER REQUIREMENTS

- TYPICAL DETAILS AND GENERAL NOTES ON S-1 APPLY TO ALL PARTS OF THE 1. UNLESS OTHERWISE NOTED ON THE PLANS OR SPECIFICATIONS CAMBER ALL RC BEAMS AT LEAST 10MM.

JOB UNLESS OTHERWISE SHOWN ON THE DRAWINGS. AGGREGATES & SLUMP AS FOLLOWS: FOR EVERY 4000mm. OF CLEAR SPAN EXCEPT CANTILEVERS WHICH SHALL BE 50MM. FOR EVERY 3000MM

LOCATION 28 DAY STRENGTH MAX. SIZE AGGREGATE MAX. SLUMP OF CLEAR SPAN.

- THE CONTRACT STRUCTURAL DRAWING AND SPECIFICATIONS REPRESENT CURBS & SLAB 3000 PSI 3

IN. (19MM) 6 IN. (150MM)

4 2. UNLESS OTHERWISE NOTED IN PLANS OR SPECIFICATIONS, CAMBER ALL SLABS 10MM PER 3000MM OF SHORTER SPAN

THE FINISHED STRUCTURES. THEY DO NOT INDICATE THE METHOD OF ON GRADE AND 20mm. FOR EVERY 2000mm OF SLABS CANTILEVER SPAN 14.0 FABRICATION

CONSTRUCTION UNLESS SO STATED. THE CONTRACTOR SHALL PROVIDE ALL 3

RETAINING WALL 3000 PSI 4 IN. (19MM) 6 IN. (150MM) 12.0 FOUNDATION 14.1 WELDS

NECESSARY MEASURES TO PROTECT THE PERSONS DURING ALL PHASES OF 3

CONSTRUCTION. THE CONTRACTOR SHALL IMMEDIATELY NOTIFY THE OWNER FOUNDATION 5000 PSI 4 IN. (19MM) 6 IN. (150MM) 12.1. FOOTING FOR CHB WALLS AND OTHER MINOR STRUCTURE SHALL BE EMBEDDED AT LEAST -ALL WELDED CONNECTIONS SHALL DEVELOP THE FULL

AND/OR THE ENGINEER OF ANY CONDITION WITCH IN HIS OPINION MIGHT INCLUDING BEAMS 600 MM FROM THE FINISH GRADE LINE UNLESS NOTED OTHERWISE. STRENGTH OF THE MEMBERS CONNECTED.

3

DISTRESS THE STRUCTURE. SUSPENDED SLABS 5000 PSI 4 IN. (19MM) 6 IN. (150MM) 12.2. FOOTING SHALL BE DESIGNED USING THE ASSUMED SOIL BEARING CAPACITY OF 150 KPa

3

a. LENGTH OF WELDS:

COLUMNS, SHEAR WALLS 5000 PSI 4 IN. (19MM) 6 IN. (150MM) TIE BEAM WERE DESIGNED USING THE ASSUMED 25MM DIFFERENTIAL SETTLEMENT BETWEEN TWO ADJACENT

OTHERS -THE MINIMUM LENGTH OF FILLET SHALL NOT BE LESS THAN 4 TIMES

3 FOOTINGS.

ELEVATOR WALLS 500 PSI 4 IN. (19MM) 6 IN. (150MM) THE NOMINAL SIZE WHERE INTERMITTENT WELDS MAY BE USED THE

- CONSTRUCTION MATERIALS SHALL NOT BE STORED ON POURED FLOORS. IT 3 12.3. CONTRACTOR SHALL VERIFY ALL DIMENSIONS AND CONDITIONS AT JOB PRIOR TO POURING OF

IS THE GENERAL CONTRACTOR'S RESPONSIBILITY TO ENSURE THAT THE STAIR AND RAMPS 500 PSI 4 IN. (19MM) 6 IN. (150MM) LENGTH OF SEGMENT SHALL NOT BE LESS THAN 4 TIMES THE WELD

CONCRETE AND PROCEEDING OF WORK. SIZE WITH A MIN. OF 40MM.

SUB-CONTRACTORS ARE INFORMED AND DO NOT VIOLATE THE IMPORTANT 4.3. ALL REINFORCING BARS SHALL CONFORM TO ASTM A615 GRADE 40 FOR DIA.10mm 12.4. COMPACT SOIL OF MAT FOUNDATION. AFTER MAT FOUNDATION, BACKFILL WITH ENGINEERED

REQUIREMENT. & SMALLER BARS & GRADE 60 FOR DIA. 12 & LARGER BARS. COLUMN FILL WITH PLASTICITY INDEX OF 8 TO 15. FIELD DENSITY TESTS SHALL BE UNDERTAKEN AND b. END RETURN OF FILLET WELDS

HOOPS ARE ALL GRADE 40 BARS. APPROVED BY OWNER REPRESENTATIVE ENGINEER. -SIDE OR END FILLET WELDS TERMINATING AST END OR SIDES SHALL BE

- IT IS THE CONTRACTOR'S RESPONSIBILITY TO PROVIDE TEMPORARY

ERECTION BRACING AND SHORING FOR ALL THE STRUCTURAL MEMBERS AS 4.4. IN GENERAL, THE LATEST EDITION OF ACI-315, MANUAL OF STANDARD PRACTICE 12.5. THE CONTRACTOR SHALL NOTIFY THE ENGINEER AFTER FOOTING EXCAVATION HAVE BEEN COMPLETED RETURNED CONTINUOUSLY FOR A DISTANCE NOT LESS THAN TWICE THE

REQUIRED FOR STABILITY DURING ALL PHASES OF THE CONSTRUCTION. DETAILING REINFORCED CONCRETE STRUCTURES SHALL BE ADHERED TO UNLESS AND PRIOR TO CONCRETING TO CONFIRM THE DESIGN SOIL BEARING CAPACITY NOMINAL SIZE OF THE WELD.

OTHERWISE SHOWN OR NOTED.

2. STRUCTURAL DESIGN CRITERIA PARAMETERS c. USE ELECTRODE E70XX COMPLETE JOINT PENETRATION

4.5. MAINTAIN MINIMUM CONCRETE COVER FOR REINFORCING STEEL AS FOLLOWS:

MATERIAL psi MPa NSCP 2010SE. 412 d. SEE SPECIFICATIONS FOR NDT TEST REQUIREMENTS

2.0 CODES AND STANDARDS SUSPENDED SLABS ................................................. 3/4 IN. (19MM.)

f'c 3000 21.00 DEV'T & SPLICE LENGTH e. ALL WELDERS SHALL BE CERTIFIED WITH CURRENT CERTIFICATION CARRIED IN PERSON

2.1 GOVERNING CODES SLAB ON GRADE ......................................................1 1/2 IN. (38MM.)

fy 60000 413.79 12MM & HIGHER

2.1.1 NATIONAL STRUCTURAL CODE OF THE PHILIPPINES - NSCP 2010 WALLS ABOVE GRADE .............................................1 IN. (25MM.)

fyh 40000 275.86 12MM & SMALLER 15.0 BOLTS

2.1.2 AMERICAN CONCRETE INSTITURE - ACI 318 - 08 BEAM STIRRUPS & COLUMN TIES ............................1 1/2 IN. (38MM.)

WHERE CONCRETE IS EXPOSED TO EARTH tie Ø 10 stirrup Ø 12 a. MINIMUM EDGE DISTANCE:

2.2 GOVERNING STANDARDS

BUT POURED AGAINST FORMS .................................2 IN. (50MM.) fyt 33,000 fyt 275.86 -THE MINIMUM EDGE DISTANCE OF BOLTS SHALL CONFORM TO THE

ASTM A615 SPECIFICATION FOR DEFORMED AND PLAIN REQUIREMENTS OF AISC STEEL MANUAL 8TH EDITION.

WHERE CONCRETE IS DEPOSITED

BILLET-STEEL BARS FOR CONCRETE REINFORCEMENT. STANDARD HOOK (mm) TENSION LAP SPLICE (mm) -THE EDGE DISTANCE FROM BOLT CENTER SHALL BE 12 TIMES THICKNESS OF

DIRECTLY AGAINST EARTH .......................................3 IN. (75MM.)

PNS 49 STEEL BARS FOR CONCRETE REINFORCEMENT BARØ ANCHORAGE BEAM COMP. THE PLATE BUT NOT EXCEED 150MM.

4.6. SPLICES SHALL BE SECURELY WIRED TOGETHER & SHALL LAP OR EXTEND IN Ldh(mm) UNIT WT.

SPECIFICATION (mm) LENGTH (mm) SPLICE (mm) BEAM COLUMN

ACCORDANCE WITH TABLE OF LAP SPLICE & ANCHORAGE LENGTH 90° 180° 135°-90° LAP CLASS (kg/m) b. MINIMUM PITCH:

ASTM C33/ STANDARD SPECIFICATION FOR CONCRETE TOP BAR BOTTOM BAR TIED SPIRAL

UNLESS OTHERWISE SHOWN ON DRAWINGS, SPLICES SHALL BE STAGGERED -ON CENTER SPACING OF BOLTS SHALL NO BE LESS THAN 3 TIMES THE

AGGREGATES A 300 300

PNS 18 WHENEVER POSSIBLE. NORMAL DIAMETER

10 300 130 160 130 180~120 300 300 300 0.616

ASTM C39 STANDARD METHOD FOR COMPRESSIVE STRENGTH OF 5. ALL ANCHOR BOLTS, DOWELS, & OTHER INSERTS, SHALL BE PROPERLY B 390 390

16.0 TOLERANCES

CYLINDRICAL CONCRETE SPECIMEN. POSITIONED & SECURED IN PLACE PRIOR TO PLACING OF CONCRETE. A 300 300

12 300 160 200 160 220~140 360 360 360 0.888 -SOME VARIATIONS EXPECTED IN THE FINISH OVERALL DIMENSIONS OF

ASTM C94/ STANDARD SPECIFICATION FOR READY MIXED 6. CONTRACTOR SHALL NOTE & PROVIDE ALL MISCELLANEOUS CURBS, SILLS, B 390 390 FRAMES SHALL NOT EXCEED THE ROLLING TOLERANCE FOR

CONCRETE STOOLS, EQUIPMENT, & MECHANICAL BASES THAT ARE REQUIRED BY THE

ARCHITECTURAL, ELECTRICAL, & MECHANICAL DRAWINGS. A 300 240 CROSS-SECTIONAL DIMENSION, CAMBER AND SWEEP PERMITTED UNDER

PNS 46 16 300 210 260 210 290~190 480 480 480 1.579 ASTM SPECIFICATION A36.

ASTM C150 STANDARD SPECIFICATION FOR PORTLAND CEMENT 7. ALL CONCRETE SHALL BE KEPT MOIST FOR A MINIMUM OF SEVEN (7) B 390 312

CONSECUTIVE DAYS IMMEDIATELY AFTER POURING BY THE USE OF WET BURLAP, 17.0 ERECTION

PNS 16 PHILIPPINE NATIONAL STANDARD FOR CONCRETE A 600 480

FOG SPRAYING, CURING COMPOUNDS OR OTHER APPROVED METHODS. 20 600 260 330 260 360~320 590 590 590 2.466 17.1 BRACING:

HOLLOW BLOCKS B 780 624

SG 671 SPECIFICATION FOR THE DESIGN OF COLD-FORMED 8. STRIPPING OF FORMS & SHORES: -THE FRAME OF STEEL STRUCTURE SKELETON SHALL BE CARRIED UP TRUE

A 800 640

STEEL STRUCTURAL MENBERS BY THE AMERICAN FOUNDATION .................................................................. 24 HRS. 25 800 320 410 330 450~400 740 740 740 3.854 AND PLUMB. WITHIN THE LIMITS DEFINED IN SECTION 7(h) OF THE ANSC CODE

IRON AND STEEL INSTITUTE (AISSI). SUSPENDED SLAB EXCEPT WHEN B 1040 832 OF STANDARD PRACTICE. TEMPORARY BRACING SHALL BE PROVIDED TO

ADDITIONAL LOADS ARE IMPOSED................................. 8 DAYS A 900 720 RESIST ALL LOADS INCLUDING ERECTION EQUIPMENT.

3. LOADING CRITERIA WALLS ........................................................................... 18 HRS. 28 900 360 510 460 500~0 830 830 830 4.833

CENTERING UNDER BEAMS ........................................... 14 DAYS B 1170 936 17.2 ALIGNMENT :

3.0 LOADING CRITERIA

3.1 DEAD LOAD COLUMNS, SIDES OF BEAMS AND GIRDERS .................. 3-10 DAYS A 1100 880 -NO RIVETING, PERMANENT BOLTING OR WELDING SHALL BE DONE UNTIL

32 1100 410 580 530 570~0 950 950 950 6.313

CONCRETE...............................................................................................24.00 KN/M³ 9. REINFORCING BARS SHALL BE FREE OF RUST, GREASE OR OTHER MATERIALS LIKELY TO B 1430 1144 STRUCTURE HAS BEEN PROPERLY ALIGNED.

STEEL......................................................................................................76.91 KN/M³ IMPAIR BOND.

A 1500 1200 17.3 ALIGNMENT :

SOIL.........................................................................................................18.00 KN/M³ 9.1 ALL REINFORCING BARS SHALL BE ACCURATELY AND SECURELY PLACED BEFORE 36 1500 460 650 590 650~0 1060 1060 1060 7.991

CONCRETE PARTITIONS...........................................................................2.00 KPA POURING OF CONCRETE OR APPLYING MORTAR OR GROUT. B 1950 1560 -SAG RODS AND CROSS BRACING SHALL BE INSTALLED AND TIGHTENED

FLOOR TILES............................................................................................0.50 KPA NOTES: BEFORE INSTALLATION OF ROOFING OR WALL CLADDING.

9.2 BAR SPLICES SHALL BE SECURELY WIRED TOGETHER. SPLICES IN REINFORCED CONCRETE

CEILING....................................................................................................0.38 KPA BEAMS, COLUMNS, AND WALLS SHALL BE AS SHOWN IN THE DETAILS. FOR NON STRUCTURAL DEVELOPMENT LENGTH OF INDIVIDUAL BARS WITHIN A BUNDLE, IN TENSION OR COMPRESSION, SHALL BE THAT FOR INDIVIDUAL BARS,

18.0 PAINTING AND SURFACE PREPARATION

WALLS, MASONRY WALLS, AND SLABS, SPLICES SHALL LAP A MINIMUM OF 40 BAR DIAMETERS INCREASED 20% FOR THREE-BUNDLED AND 33% FOR FOUR-BUNDLED BARS.

3.2 LIVE LOAD AND SHALL BE STAGGERED WHENEVER POSSIBLE. FOR COLUMNS AT ANY LEVEL, NO MORE THAN ALTERNATE BARS SHOULD BE SPLICED, NOTMORE THAN 33% OF THE BARS SHALL BE 18.1 STEEL TO BE USED FOR ERECTION OF THIS STRUCTURE SHALL BE

RESIDENTIAL AREA..................................................................................1.90 KPA 9.3 SPLICES REQUIRED IN THE REINFORCEMENT OF BEAMS/GIRDERS FRAMING INTO COLUMNS SPLICED WITHIN THE REQUIRED LAP LENGTH, MINIMUM DISTANCE BETWEEN TWO ADJACENT SPLICED SHALL BE 600mm. PAINTED AND ITS SURFACE PREPARED IN COMPLIANCE WITH THE

CORRIDORLHALLWAY..............................................................................4.80 KPA SHALL NOT BE LOCATED WITHIN THE COLUMN NOR WITHIN A DISTANCE OF TWICE THE BEAM/ SPECIFICATIONS.

TOP BARS ARE HORIZONTAL BARS WITH MORE THAN 300mm DEPTH OF CONCRETE CAST BELOW REINFORCEMENT.

STAIRS.....................................................................................................4.80 KPA GIRDER DEPTH FROM THE FACE OF THE COLUMN. AT LEAST TWO CLOSED STIRRUP TIES SHALL

HEAVY STORAGE......................................................................................12.00 KPA BE PROVIDED AT ALL SPLICES. LAP SPLICE SHALL BE "CLASS B" TENSION LAP SPLICE IF MORE THAN ONE HALF OF THE BARS WERE SPLICED AT ANY SECTION, WHILE 18.2 CONTRACTOR TO VERIFY WITH REPRESENTATIVES - PAINTING AND SURFACE

OFFICE SPACE...........................................................................................2.40 KPA "CLASS A" TENSION LAP SPLICE IF HALF OR FEWER THAN HALF OF BARS WERE SPLICED. PREPARATION SPECIFICATION BEFORE PROCEEDING WITH WORK.

9.4 LAP SPLICES SHALL BE PROVIDED WITHIN THE CENTER HALF OF COLUMN HEIGHT AND THE SPLICE

LENGTH SHALL NOT BE LESS THAN SPECIFIED IN THE COLUMN SPLICE DETAIL. TOP BARS SPLICE FOR BEAMS, SHOULD BE "BEAM COMPRESSIVE SPLICE x1.3"

PREPARED BY: CHECKED BY: PRC NO. SEAL: PROJECT TITLE: CONFORMED : SHEET CONTENTS: SET NO. SHEET NO.

DATE:

PTR: PROPOSED OFFICE BUILDING GENERAL NOTES S1 1

RUFO AGA-ON AYAG DATE: THAHZ BUHISAN DAPOGRACION

CIVIL ENGINEER CIVIL ENGINEER TIN: LOCATION: BRGY. TIMOLAN, TIGBAO ZAMBOANGA DEL SUR OWNER 1-8 -

You might also like

- (Approved) 2 Storey ResidentialDocument10 pages(Approved) 2 Storey ResidentialJOSHUA MEDRANO88% (51)

- Sample Drainage Plan PDFDocument1 pageSample Drainage Plan PDFAredal Semreh100% (1)

- 001 TXP Siemens 2007 EnglishDocument49 pages001 TXP Siemens 2007 Englishwalterbishop100% (1)

- General Construction Notes: Drawing IndexDocument1 pageGeneral Construction Notes: Drawing IndexEdzon Lacay0% (1)

- Drawing KibahaDocument1 pageDrawing KibahaAqurate BuildersNo ratings yet

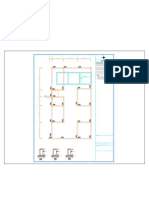

- Lighting Lay-Out Power Lay-Out: LegendDocument1 pageLighting Lay-Out Power Lay-Out: LegendMark Nico Meneses GallogoNo ratings yet

- Pdf-Caissonxlsx CompressDocument2 pagesPdf-Caissonxlsx CompressrvmerchanNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesCarlo M. FloresNo ratings yet

- ST 01Document1 pageST 01Jaspergroup 15No ratings yet

- 32 Oakleigh Way - Drainage - Assessment-X9Document1 page32 Oakleigh Way - Drainage - Assessment-X9Juan Carlos Gaxiola ReinholdNo ratings yet

- MT - Office Structural CA SetDocument55 pagesMT - Office Structural CA SetAzeemuddin Gulam MohammedNo ratings yet

- QP10 Q 1589 TypicalPipeLayingAdjacentToExistingRRWTSPipelinesDocument1 pageQP10 Q 1589 TypicalPipeLayingAdjacentToExistingRRWTSPipelinesMohammad HegazyNo ratings yet

- Pl-Herbert Yu-P-1 PDFDocument1 pagePl-Herbert Yu-P-1 PDFSoy DesignoNo ratings yet

- Mansilingan Structural PDFDocument6 pagesMansilingan Structural PDFSyre Yan Moscoso Tubale100% (1)

- Cs AnchalDocument16 pagesCs AnchalsarunsurendranNo ratings yet

- Lowell Esposo - PlansDocument14 pagesLowell Esposo - PlansEna GonzalesNo ratings yet

- Plan For Cost Estimation-6Document1 pagePlan For Cost Estimation-6Khazran RazaNo ratings yet

- A B C D E F B C D: Lighting Layout PlanDocument1 pageA B C D E F B C D: Lighting Layout PlanAljames TanginamoNo ratings yet

- Revised Structural PlansDocument46 pagesRevised Structural Plansangelandlucifergabriel009No ratings yet

- De02 Struc 2024-03-13 - Wip 1Document59 pagesDe02 Struc 2024-03-13 - Wip 1AnandPrabuNo ratings yet

- Legend & Symbol: Joint DetailDocument5 pagesLegend & Symbol: Joint DetailMike Advincula100% (1)

- LayoutDocument1 pageLayoutjenil satikuvarNo ratings yet

- Proposed Office Building: Thahz Buhisan Dapogracion Rufo Aga-On AyagDocument1 pageProposed Office Building: Thahz Buhisan Dapogracion Rufo Aga-On AyagJhon SabinoNo ratings yet

- QP10-Q-611 Rev0 Typical Cross Section For Roads and TrafficDocument1 pageQP10-Q-611 Rev0 Typical Cross Section For Roads and TrafficnawajhaNo ratings yet

- Test 1Document1 pageTest 1Levinson RubioNo ratings yet

- General Notes: Concrete Notes: Abbreviations: Reinforcement Clearance DetailDocument53 pagesGeneral Notes: Concrete Notes: Abbreviations: Reinforcement Clearance DetailbetojulioNo ratings yet

- SWB2 To VICP Electrical Tie-In Project: Emerg. Ps Es Ps JB PsDocument1 pageSWB2 To VICP Electrical Tie-In Project: Emerg. Ps Es Ps JB PsYogesh MittalNo ratings yet

- St-01a - 14', 18', 21' Compound Wall Section Details - 28-12-20Document1 pageSt-01a - 14', 18', 21' Compound Wall Section Details - 28-12-20tarang patelNo ratings yet

- Unit 11 Lighting LayoutDocument1 pageUnit 11 Lighting Layoutnikkoelbao96No ratings yet

- Typical Detail of Pre-Cast Boundary Wall Section A-A Section A-ADocument1 pageTypical Detail of Pre-Cast Boundary Wall Section A-A Section A-AManupriya KapleshNo ratings yet

- General Notes and Specification: Computation of LoadsDocument1 pageGeneral Notes and Specification: Computation of LoadskyomsfafaNo ratings yet

- Design of PT Slabs On Expansive Soil Ground Based On PTI DC10.5-12 & PTI 3rd EditionDocument5 pagesDesign of PT Slabs On Expansive Soil Ground Based On PTI DC10.5-12 & PTI 3rd Editionridho ziskaNo ratings yet

- G Sheet 2Document1 pageG Sheet 2Earl Jenn AbellaNo ratings yet

- Typical Structural Abbreviations Typical Symbols Legend Typical Plan NotesDocument33 pagesTypical Structural Abbreviations Typical Symbols Legend Typical Plan NotesINNOBUNo7No ratings yet

- MasonryBearingWall IBCDocument9 pagesMasonryBearingWall IBCjorge01No ratings yet

- Design Criteria: Reinforcing SteelDocument12 pagesDesign Criteria: Reinforcing SteelALL-ROUNDER CIVIL ENGINEERS ENGLISHNo ratings yet

- ST 04Document1 pageST 04Jaspergroup 15No ratings yet

- Legend & Symbols:: Lighting Layout Power LayoutDocument1 pageLegend & Symbols:: Lighting Layout Power LayoutAngelo R. AmarNo ratings yet

- Electrical Plan Power HouseDocument1 pageElectrical Plan Power HouseROLAND BENTAZALNo ratings yet

- Borehole (Serenia Bh-27)Document52 pagesBorehole (Serenia Bh-27)azwanNo ratings yet

- General Notes:: Isometric PlanDocument1 pageGeneral Notes:: Isometric PlanAeron Acio0% (1)

- BeamDocument1 pageBeamAnkura bsNo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- 22.130 A220 Proposed Floor PlanDocument1 page22.130 A220 Proposed Floor PlanprlicinesNo ratings yet

- DDHA021065001P00Document1 pageDDHA021065001P00Foumil Albatin IndusNo ratings yet

- General Notes:: Fillet Weld TableDocument1 pageGeneral Notes:: Fillet Weld Tablefrancis sebastian lagamayoNo ratings yet

- Combined 2 PDFDocument33 pagesCombined 2 PDFHassan AlaskaNo ratings yet

- Unit 18 Lighting LayoutDocument1 pageUnit 18 Lighting Layoutnikkoelbao96No ratings yet

- Basis of DesignDocument1 pageBasis of DesignRajaImranNo ratings yet

- ELECTRICALalLDocument1 pageELECTRICALalLleiruzcaneroNo ratings yet

- PHSN-GSA32-FCD-Electrical Plans-E4.00Document1 pagePHSN-GSA32-FCD-Electrical Plans-E4.00daveglai24No ratings yet

- Department of Public Works and Highways: Region VDocument11 pagesDepartment of Public Works and Highways: Region VMarianne Jocel CostacioNo ratings yet

- CW4 00Document1 pageCW4 00daveglai24No ratings yet

- 1SV90904 904D11 Sie 00 ZZ DWG ST 00003Document1 page1SV90904 904D11 Sie 00 ZZ DWG ST 00003ghadeer mattarNo ratings yet

- S3-0-0 - Typical Slab On Grade Details PDFDocument1 pageS3-0-0 - Typical Slab On Grade Details PDFVictor Miranda AcuñaNo ratings yet

- Legend: P 1 4 A Proposed Two-Storey Commercial Building Sps. John and Geesnell YapDocument1 pageLegend: P 1 4 A Proposed Two-Storey Commercial Building Sps. John and Geesnell YapMelvan Paul BarimbaoNo ratings yet

- Row House Plan ElectricalDocument1 pageRow House Plan ElectricalDJ100% (2)

- Ground Floor Plan: Bureau of DesignDocument1 pageGround Floor Plan: Bureau of DesignLowie Torres TonioNo ratings yet

- Friction Pressure Management in Hydraulic Fracturing OperationDocument2 pagesFriction Pressure Management in Hydraulic Fracturing OperationKamal HamzahNo ratings yet

- General Notes: Site PlanDocument1 pageGeneral Notes: Site PlanVicente Adolfo Alegria RostranNo ratings yet

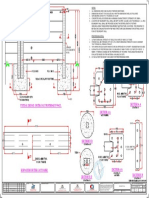

- 2Nd Floor Schedule of Beams: Proposed Office BuildingDocument1 page2Nd Floor Schedule of Beams: Proposed Office BuildingJhon SabinoNo ratings yet

- SC2 SC2 SC1 SC1 F6 F6: Proposed Office BuildingDocument1 pageSC2 SC2 SC1 SC1 F6 F6: Proposed Office BuildingJhon SabinoNo ratings yet

- T2 Truss Detail 14Document1 pageT2 Truss Detail 14Jhon SabinoNo ratings yet

- Location Plan: Office of The Building OfficialDocument1 pageLocation Plan: Office of The Building OfficialJhon SabinoNo ratings yet

- Door Installation Details: Proposed Office BuildingDocument1 pageDoor Installation Details: Proposed Office BuildingJhon SabinoNo ratings yet

- Typical Gravity Reinforced Concrete Beam Detail: Schedule of ColumnDocument1 pageTypical Gravity Reinforced Concrete Beam Detail: Schedule of ColumnJhon SabinoNo ratings yet

- Proposed Office Building: Ground Floor Plan 1 Second Floor Plan 2 Roof Plan 3Document1 pageProposed Office Building: Ground Floor Plan 1 Second Floor Plan 2 Roof Plan 3Jhon SabinoNo ratings yet

- Stair Plan 1 Toilet & Bowl Cut - Section '' '' 1: CR-F CR-MDocument1 pageStair Plan 1 Toilet & Bowl Cut - Section '' '' 1: CR-F CR-MJhon SabinoNo ratings yet

- Proposed Office Building: Thahz Buhisan Dapogracion Rufo Aga-On AyagDocument1 pageProposed Office Building: Thahz Buhisan Dapogracion Rufo Aga-On AyagJhon SabinoNo ratings yet

- Book 1Document2 pagesBook 1Jhon SabinoNo ratings yet

- Section "A": Beam Connection Joint 9Document1 pageSection "A": Beam Connection Joint 9Jhon SabinoNo ratings yet

- Section Detail 19: Stair Footing 17Document1 pageSection Detail 19: Stair Footing 17Jhon SabinoNo ratings yet

- Right View: Proposed Office BuildingDocument1 pageRight View: Proposed Office BuildingJhon SabinoNo ratings yet

- Request Letter For City Engineeing Office 1Document1 pageRequest Letter For City Engineeing Office 1Jhon SabinoNo ratings yet

- SYMTRIK RF Time Solutions: SYM-RFT-XX ModulesDocument3 pagesSYMTRIK RF Time Solutions: SYM-RFT-XX ModuleslupifieriNo ratings yet

- Refresher - Elex 3 (April, 2007)Document11 pagesRefresher - Elex 3 (April, 2007)von kervy onradeNo ratings yet

- Ahmed Ali 2020Document5 pagesAhmed Ali 2020Hazem MohamedNo ratings yet

- Gujarat Technological University: B.E Semester: 4 Electronics & Telecommunication EngineeringDocument2 pagesGujarat Technological University: B.E Semester: 4 Electronics & Telecommunication EngineeringChirag PatilNo ratings yet

- Basic StyrofoamDocument3 pagesBasic StyrofoamIdeabase TechnologiesNo ratings yet

- Lab4 1Document5 pagesLab4 1Troy SharpNo ratings yet

- (123doc) 30 Bai Tap Kiem Tra Dong Tu Khuyet Thieu File Word Co Loi Giai Chi TietDocument8 pages(123doc) 30 Bai Tap Kiem Tra Dong Tu Khuyet Thieu File Word Co Loi Giai Chi TietThảo PhươngNo ratings yet

- IDD-II Series Specs Rev01 enDocument2 pagesIDD-II Series Specs Rev01 entranphuongxd369No ratings yet

- AS5048A/AS5048B: Magnetic Rotary Encoder (14-Bit Angular Position Sensor)Document41 pagesAS5048A/AS5048B: Magnetic Rotary Encoder (14-Bit Angular Position Sensor)alfredhimmokNo ratings yet

- Dgca M-4 Mcqs Part-1Document20 pagesDgca M-4 Mcqs Part-1Abhishek SoniNo ratings yet

- Datasheet: TV10S 335-11Z-M20Document6 pagesDatasheet: TV10S 335-11Z-M20Dayglis CostaNo ratings yet

- 2. Rewinding of single-phase induction motors (1)Document9 pages2. Rewinding of single-phase induction motors (1)JayaprasadGollaNo ratings yet

- Lca Lab ReportDocument9 pagesLca Lab ReportSardar Rehan AhmedNo ratings yet

- LTL089CL02 W SamsungDocument31 pagesLTL089CL02 W SamsungIvan SavićNo ratings yet

- Switching Characteristics of Diode and TransistorDocument17 pagesSwitching Characteristics of Diode and TransistorRipan SahaNo ratings yet

- Elenco TransistorDocument9 pagesElenco TransistorAniello IaccarinoNo ratings yet

- T7S 1250 PR231/P LS/I in 1250A 3p F FDocument3 pagesT7S 1250 PR231/P LS/I in 1250A 3p F FAldair PeraltaNo ratings yet

- Nonsinusoidal Exciting Current: Power TransformersDocument9 pagesNonsinusoidal Exciting Current: Power Transformersali99956No ratings yet

- Electrical Apparatus and DevicesDocument3 pagesElectrical Apparatus and DevicesPel Martine AilesNo ratings yet

- EATON - Heavy Duty Safety SwitchDocument93 pagesEATON - Heavy Duty Safety SwitchomarlgonzNo ratings yet

- Touchless SolutionsDocument60 pagesTouchless Solutionsender40No ratings yet

- Ac Final Exam QuestionnaireDocument4 pagesAc Final Exam QuestionnaireKate Rose SantosNo ratings yet

- Lab 4Document6 pagesLab 4Abdul Moiz QarniNo ratings yet

- Indus Lecture 2 PartialDocument69 pagesIndus Lecture 2 PartialIris Jean Mosquera100% (1)

- EL220 Signals and Systems: Experiment # 12Document6 pagesEL220 Signals and Systems: Experiment # 12Choudhary Abdul AqeelNo ratings yet

- Especificaciones Omega Bos200Document3 pagesEspecificaciones Omega Bos200Uriel San JuanNo ratings yet

- k4td AccDocument14 pagesk4td AccAhmos Y MohamedNo ratings yet

- Date: 08/02/2021 Aim:: Experiment-5Document6 pagesDate: 08/02/2021 Aim:: Experiment-5Vishal ManwaniNo ratings yet

- A4447 High Voltage Step Down Regulator: Features and Benefits DescriptionDocument12 pagesA4447 High Voltage Step Down Regulator: Features and Benefits DescriptionCiprian UngureanuNo ratings yet