Professional Documents

Culture Documents

8- 中英文 - 推土机服务报告 - 2020-revised

8- 中英文 - 推土机服务报告 - 2020-revised

Uploaded by

Asif JavedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8- 中英文 - 推土机服务报告 - 2020-revised

8- 中英文 - 推土机服务报告 - 2020-revised

Uploaded by

Asif JavedCopyright:

Available Formats

投诉邮箱Complaint Email: earthmoving-service@zoomlion.

com

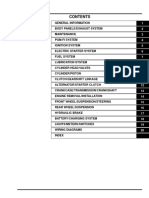

中联重科推土机/履带装载机 服务报告

SERVICE REPORT FOR ZOOMLION BULLDOZER/CRAWLER LOADER

表格编号 设备型号 出厂编号

Report No. Machine Model Manufacturing No.

区域 国家 交机日期

Region Country Delivery Date

用户名称(公司) 产品使用地

Customer Name Location of Machine

服务类型 服务信息

Service Type Service Information

出保前末检 工作

故障报修 第3月例检 第6月例检

Final Inspection at 小时数 检查日期

□ Trouble-

shooting

□ 3rd Month

Inspection

□ 6th Month

Inspection

□ the End of Working Inspection Date

Warranty Period Hours

※ 使用下列对应符号将检查结果标记在右侧的方框内 Mark the corresponding symbols below into the right 'Result' columns according to the inspection results.

√ 正常 Good Condition — 不适用 Not Applicable X 异常 Bad Condition OK 已修复 Correction Made

检测项目 结果 检测项目 结果

Inspection Items Result Inspection Items Result

(1) 驾驶室门锁及窗能自如锁闭、附件齐全良好、无漏水现象、驾驶室外观无明显缺陷

(1) 发动机机油、机油滤芯更换 Inspect whether door locks and windows of the cab can be easily locked and unlocked,

Replace the engine oil and engine oil filter element. whether attachments are complete and in good condition and whether there is water

leakage. Inspect for obvious defects in appearance of the cab.

(2)发动机柴油系统滤芯更换 (2) 座椅能灵活调整,锁止可靠

Replace the filter element in the engine diesel oil system. Inspect whether the operator's seat can be flexibly adjusted and reliably locked.

(3) 发动机冷却系统滤芯更换 (3) 各照明灯具使用正常

Replace the filter element in the engine cooling system. Inspect whether all lightings and illuminations are in normal functions.

(4) 各液压系统部位运行正常,无渗油、漏油

(4) 发动机空气滤芯更换

Inspect whether each location in the hydraulic system is in normal operation and whether oil

Replace the air filter element for engine.

penetrates and leaks from the hydraulic system.

Maintenance

(5) 液压油回油滤芯、吸油滤芯、先导滤芯更换 (5) 空调无渗漏、异响,制冷制热效果正常(如有安装)

Replace the return-line filter element, suction oil filter element and pilot filter element for Inspect whether there are leakage and abnormal sound from the air conditioner and inspect

保养

the hydraulic oil. whether refrigeration and heating effects are normal (if it is installed).

(6) 控制面板 (仪表面板仪,警示灯,指示灯)显示正常及控制开关完好

(6) 发动机冷却液更换

Inspect whether the control panel (instrument panel, warning lights, indicators) has normal

Replace the engine coolant.

display and whether the control switches and buttons are in good condition.

(7) 后桥箱液力传动油更换 (7) 驱动皮带张紧度检查

Replace hydrodynamic drive oil for the steering case. Inspect tension of the drive belt.

(8) 发动机运行正常,无异响,空滤灰尘指示器正常

(8) 终传动齿轮油更换

Inspect whether the engine works normally and without abnormal sound and whether the

Performance of Complete Vehicle

Replace the final drive gear oil.

dust indicator for air filter is normal.

(9) 各工作装置油缸无异响、无卡滞,油缸活塞杆无划痕、碰伤

(9) 液压系统液压油更换 Inspect whether there are abnormal sound and blocking of oil cylinders for each work

整机性能

Replace hydraulic oil in the hydraulic system. equipment. Inspect whether the piston rod for oil cylinder has scratch and bumping

damages.

(10)铲刀或铲斗以及松土器或其他装置运行正常(如有加装)

(1) 外观油漆完好,无裂纹,无生锈,无碰撞损坏

Inspect whether the blade or bucket and ripper or other equipment are in normal operation

Appearance

Inspect painting of vehicle appearance, and inspect for cracks, rust and bumping damages.

(if it is installed).

外观

(2)安全、操作和润滑标志无语言错误,无漏标,无错标

(11) 变速箱及换挡操纵机构使用正常

Inspect whether there are language error, and missing & wrong position of safety,

Inspect whether the transmission and gearshift control mechanism are in normal operation.

operation & lubrication labels.

(1)发动机机油量正常 (12) 各传动机构工作正常

Inspect whether the engine oil level is normal. Inspect whether each drive mechanism works normally.

(2)液压油油量正常 (13) 行走、转向使用正常

Inspect whether the hydraulic oil level is normal. Inspect whether the traveling and steering systems are in normal operation.

(3)后桥箱油量正常 (14) 履带涨紧度正常

Inspect whether the oil level in steering case is normal. Inspect whether track tension is normal.

(15) 主要部位螺丝无松动,如:履带板、驱动轮、刀铲撑杆等

(4)终传动油量正常

Fliuid Levels

Inspect whether screws at the main locations, e.g. track shoe, drive sprocket and blade stay,

油液容量

Inspect whether the final drive oil level is normal.

etc. are loose.

(16) 各大结构件外观无明显缺陷,工作使用正常

(5)各加注润滑脂油部位正常

Inspect whether there are obvious defects at the appearance of each large structural

Inspect whether all lubricant levels are normal.

members and inspect whether they are in normal operation.

(6)水箱冷却液正常 (17) 转向离合器及刹车制动检查和调整

Inspect whether the coolant level in water tank is normal. Inspect and adjust the steering clutch and brake.

(7)支重轮、托轮、引导轮的油量正常

(18) 底盘、铲刀或铲斗刀刃和/或斗齿及松土器的磨损情况检查

Inspect whether oil levels in track roller, carrier roller and idler are normal.

Inspect wear conditions of undercarriage, blade, bucket edge cutting and/or tooth as well as

(8)蓄电池完好

ripper.

Inspect whether the battery is in good condition.

检查结论与建议

Conclusions and Suggestions

客户评论与建议 Customer Comments and Suggestions

有以上未明确情况,请填写。空白视为没有其他问题 Please fill in the column below with matters not covered above. The blank column will be viewed as no other problems.

非常满意 满意 不满意 非常不满意

Very satisfied Satisfied Dissatisfied Very dissatisfied

□ 10' □ 9' □ 8' □ 7' □ 6' □ 5' □ 4' □ 3' □ 2' □ 1'

客户签字

Signature of Customer

客户联系邮箱/电话

Customer Email/Phone No.

服务工程师签字

Signature of Service Engineer 仅限中联重科使用

服务商(签章) For Zoomlion Use Only

Signature/Seal of After Service Provider

(白联:公司联 红联:客户联 黄联: 服务商联)

(White Copy for Zoomlion, Red Copy for Customer, Yellow Copy for After Service Provider) PSRE09V1-2020

You might also like

- Service Manual: GK21, GK25 EngineDocument153 pagesService Manual: GK21, GK25 EngineAsif Javed100% (5)

- Honda Grom Service Manual 150117060710 Conversion Gate01 PDFDocument266 pagesHonda Grom Service Manual 150117060710 Conversion Gate01 PDFLê Thành Nam75% (4)

- 4M Change Management FormatDocument1 page4M Change Management FormatSUBODHH100% (2)

- Ac DC Servo DriveDocument306 pagesAc DC Servo DrivePaun Al100% (2)

- Pas Reform: Smartpro™ Combi IncubatorDocument2 pagesPas Reform: Smartpro™ Combi IncubatorAndre FahmiNo ratings yet

- Hollow State in A Solid State WorldDocument1 pageHollow State in A Solid State Worldapi-3701386No ratings yet

- Delivery Service report-2021版Document1 pageDelivery Service report-2021版Irul UmamNo ratings yet

- Formulir Premob Inspection LoaderDocument3 pagesFormulir Premob Inspection LoaderElni Gita Girsang100% (1)

- Formulir Premob Inspection LVDocument2 pagesFormulir Premob Inspection LVElni Gita GirsangNo ratings yet

- 003 Light Vehicle Stattion Wagon, Minibus Pick UpDocument3 pages003 Light Vehicle Stattion Wagon, Minibus Pick UpFuad Ahmad NafisNo ratings yet

- Formulir Premob Inspection ExcavatorDocument3 pagesFormulir Premob Inspection ExcavatorElni Gita GirsangNo ratings yet

- 4M Inspection ReportDocument4 pages4M Inspection ReportKaran Malhi100% (1)

- Telescopic Boom Pre-Mob Inspection Report: Description To Be CheckedDocument28 pagesTelescopic Boom Pre-Mob Inspection Report: Description To Be CheckedyogiNo ratings yet

- Inspection Sheet GensetDocument2 pagesInspection Sheet GensetDwiNo ratings yet

- Check List Grue A Tour Tower CraneDocument3 pagesCheck List Grue A Tour Tower Cranemed sarhanNo ratings yet

- 02 - MaintInspecForm - Booms HartDocument5 pages02 - MaintInspecForm - Booms HartOtto PlataformasNo ratings yet

- Double Punch 63241: Quality Problem Note (Supplier/In House/SYIPL Dock/Customer)Document1 pageDouble Punch 63241: Quality Problem Note (Supplier/In House/SYIPL Dock/Customer)ladkasaurabhNo ratings yet

- 004 BusDocument2 pages004 BusFuad Ahmad NafisNo ratings yet

- 006 Dozer Track LoaderDocument3 pages006 Dozer Track LoaderFuad Ahmad NafisNo ratings yet

- Mini Bus C 001 RW 12 Rev.1Document2 pagesMini Bus C 001 RW 12 Rev.1slamet4riadi100% (1)

- Formulir Premob Inspection LVDocument2 pagesFormulir Premob Inspection LVElni Gita GirsangNo ratings yet

- Roller Plate Compactor Inspection ChecklistDocument1 pageRoller Plate Compactor Inspection Checklistarunjith rNo ratings yet

- C 035 RW Vibrator12 Rev.1Document1 pageC 035 RW Vibrator12 Rev.1slamet4riadiNo ratings yet

- Pre-Mobilization Re-Inspection: Description To Be CheckedDocument5 pagesPre-Mobilization Re-Inspection: Description To Be CheckedRonny DoankNo ratings yet

- ITP AND Reports Only ApprovedDocument18 pagesITP AND Reports Only Approvedb.l.narayana0307No ratings yet

- ITR For Electrical Instrument PDFDocument4 pagesITR For Electrical Instrument PDFCokro YudhaNo ratings yet

- Ducati ServiceDocument1 pageDucati ServiceamaleenarhmnNo ratings yet

- BPAC-FR-OHSE-028 Commissioning MAN HAULDocument3 pagesBPAC-FR-OHSE-028 Commissioning MAN HAULFahmi Noviandri100% (1)

- Excavator TrackDocument3 pagesExcavator TrackRonny DoankNo ratings yet

- Mẫu báo cáo nghiệm thu khởi động máyDocument13 pagesMẫu báo cáo nghiệm thu khởi động máyduccanh98.hustNo ratings yet

- 02 MaintInspecForm BoomsDocument5 pages02 MaintInspecForm BoomsmicandechilesheNo ratings yet

- 02 MaintInspecForm BoomsDocument5 pages02 MaintInspecForm BoomsImam AffandyNo ratings yet

- 02 MaintInspecForm ScissorsDocument4 pages02 MaintInspecForm ScissorsWilliam RodriguezNo ratings yet

- Annexure A - PDI Check SheetDocument1 pageAnnexure A - PDI Check SheetGyan Swaroop Tripathi100% (1)

- Compactor Inspection Form 2024Document2 pagesCompactor Inspection Form 2024Ryan TanjungNo ratings yet

- Form-I-044 Excavator FormDocument1 pageForm-I-044 Excavator FormSigit PurwandiNo ratings yet

- 149735 مخطط تدقيقDocument3 pages149735 مخطط تدقيقAlQasemNo ratings yet

- Check Sheet Improved MT Inspection Procedure Report For C-0662Document3 pagesCheck Sheet Improved MT Inspection Procedure Report For C-0662Himanyu RafiqNo ratings yet

- DemacrationReport 2072022000889780Document1 pageDemacrationReport 2072022000889780عبدالرحمن كرديNo ratings yet

- Nouveau Document Microsoft WordDocument1 pageNouveau Document Microsoft WordKingKongzNo ratings yet

- 005 ForkliftDocument3 pages005 ForkliftFuad Ahmad NafisNo ratings yet

- Shipbuilding Project Management WorkProc PDFDocument1 pageShipbuilding Project Management WorkProc PDFStathis MoumousisNo ratings yet

- Discrepancy Report Spare Parts Form-English Version (New)Document8 pagesDiscrepancy Report Spare Parts Form-English Version (New)Joe SatriajiNo ratings yet

- Roller Plate Compactor Inspection ChecklistDocument1 pageRoller Plate Compactor Inspection Checklistarunjith rNo ratings yet

- QMLSF-4!7!2020-016 螺杆空压机开关机点检表 Daily Check List for Screw Air Compressor SwitchingDocument1 pageQMLSF-4!7!2020-016 螺杆空压机开关机点检表 Daily Check List for Screw Air Compressor SwitchingJeevan RajNo ratings yet

- 01 PreDeliveryPreparationReport PDFDocument1 page01 PreDeliveryPreparationReport PDFLeobardo Genaro Roque NájeraNo ratings yet

- Service A Service B: AP00.20-P-1228CA OVERVIEW For Service Sheet 19.05.2022 Model 205 (Countries With High Dust Levels)Document6 pagesService A Service B: AP00.20-P-1228CA OVERVIEW For Service Sheet 19.05.2022 Model 205 (Countries With High Dust Levels)mthobisithwala10No ratings yet

- Construction Vehicle Inspection Register NEW LOGO A8 PIPELINE WESTCLIFFDocument2 pagesConstruction Vehicle Inspection Register NEW LOGO A8 PIPELINE WESTCLIFFTshireletso MphaneNo ratings yet

- Formato - Service Report - Excavator - KLTDDocument1 pageFormato - Service Report - Excavator - KLTDWILDERNo ratings yet

- NDT-PT Report For C-0821Document21 pagesNDT-PT Report For C-0821Himanyu RafiqNo ratings yet

- Daily Preventive Maintenance Check List - TURNINGDocument1 pageDaily Preventive Maintenance Check List - TURNINGAnkurNo ratings yet

- JAPL-F-HE-019 Scraper CheckDocument1 pageJAPL-F-HE-019 Scraper CheckAli HassanNo ratings yet

- Roller Plate Compactor Inspection ChecklistDocument1 pageRoller Plate Compactor Inspection Checklistarunjith rNo ratings yet

- RIR & SIR - 6 Monthly Safety Inspection - TCMSDocument4 pagesRIR & SIR - 6 Monthly Safety Inspection - TCMSRonny DoankNo ratings yet

- VMC1000 Sno X2023050318Document2 pagesVMC1000 Sno X2023050318Manoj V MNo ratings yet

- PCP Chassis Frame 2801000 BU04Document8 pagesPCP Chassis Frame 2801000 BU04Võ Trung HiếuNo ratings yet

- 707C IndDocument2 pages707C Indmark.wilsonNo ratings yet

- Berau Coal Green Mining System: Switchgear and Switchboard Commissioning FormDocument1 pageBerau Coal Green Mining System: Switchgear and Switchboard Commissioning FormBarlian Caxica PristyNo ratings yet

- PMV Org Chart Mobile Workshop Etc - CompressedDocument5 pagesPMV Org Chart Mobile Workshop Etc - CompressedPoojaNo ratings yet

- Purpose:: Monthly Theme Based ActivityDocument6 pagesPurpose:: Monthly Theme Based Activitybabuhsr5096100% (2)

- Control Plan: Process / Operation DescriptionDocument3 pagesControl Plan: Process / Operation DescriptionsharanNo ratings yet

- 91-Ac-Rfa-Stp-Me-002 Equipment List Rockwell NaraDocument44 pages91-Ac-Rfa-Stp-Me-002 Equipment List Rockwell NaraJovenal TuplanoNo ratings yet

- LNV Technology (P) LTD ACC LTD, Tikaria Expansion Project: Daily Crane Inspection Checklist - Format / CraneDocument1 pageLNV Technology (P) LTD ACC LTD, Tikaria Expansion Project: Daily Crane Inspection Checklist - Format / CraneRajuNo ratings yet

- Preventive Maintenance - Schedule A: A Engine Compartment RemarksDocument1 pagePreventive Maintenance - Schedule A: A Engine Compartment RemarksPearly RederaNo ratings yet

- Cartridge Filter Dust Collector InstructionDocument8 pagesCartridge Filter Dust Collector InstructionAsif JavedNo ratings yet

- Sectional Door Installation ManualDocument92 pagesSectional Door Installation ManualAsif JavedNo ratings yet

- 2024YS0122WDocument1 page2024YS0122WAsif JavedNo ratings yet

- Hydraulic Control Valve SupplyDocument3 pagesHydraulic Control Valve SupplyAsif JavedNo ratings yet

- FL936H折页Document2 pagesFL936H折页Asif JavedNo ratings yet

- APRILPARTS横版Document24 pagesAPRILPARTS横版Asif JavedNo ratings yet

- Electronic DiagramDocument1 pageElectronic DiagramAsif JavedNo ratings yet

- 7 Page Folding FlyerDocument2 pages7 Page Folding FlyerAsif JavedNo ratings yet

- Instrument Specification-2018.8.2Document12 pagesInstrument Specification-2018.8.2Asif JavedNo ratings yet

- Onyx ProfileDocument4 pagesOnyx ProfileAsif JavedNo ratings yet

- Four Guide Rails Cargo Lift: (HS Code: 8428909090)Document9 pagesFour Guide Rails Cargo Lift: (HS Code: 8428909090)Asif JavedNo ratings yet

- 步行式宽支腿堆高车Document7 pages步行式宽支腿堆高车Asif JavedNo ratings yet

- Report 3Document1 pageReport 3Asif JavedNo ratings yet

- 8FBET16 - Rear Wheel TextDocument1 page8FBET16 - Rear Wheel TextAsif JavedNo ratings yet

- Airfreight Proforma Invoice - ITQ2022HK052801Document1 pageAirfreight Proforma Invoice - ITQ2022HK052801Asif Javed100% (1)

- New Doc 03-03-2022 11.05 - 2 - Report 1Document1 pageNew Doc 03-03-2022 11.05 - 2 - Report 1Asif JavedNo ratings yet

- 337-02 LDC - GB - XXXXDocument93 pages337-02 LDC - GB - XXXXAsif Javed100% (1)

- UntitledDocument32 pagesUntitledAsif JavedNo ratings yet

- GD Manual Pallet StackersDocument1 pageGD Manual Pallet StackersAsif JavedNo ratings yet

- Shaukat Khanum Memorial Cancer Hospital & Research Centre Annual Tender For Engineering & Maintenance Supplies For The Year 2022-23Document7 pagesShaukat Khanum Memorial Cancer Hospital & Research Centre Annual Tender For Engineering & Maintenance Supplies For The Year 2022-23Asif JavedNo ratings yet

- Jme 9Document5 pagesJme 9Asif JavedNo ratings yet

- Stockage Proposal Truck Type 1276-01 LXDocument9 pagesStockage Proposal Truck Type 1276-01 LXAsif JavedNo ratings yet

- E25s 2Document1 pageE25s 2Asif JavedNo ratings yet

- Report 6Document1 pageReport 6Asif JavedNo ratings yet

- E25s 1Document1 pageE25s 1Asif JavedNo ratings yet

- Service PlanDocument2 pagesService PlanAsif JavedNo ratings yet

- Report 2Document1 pageReport 2Asif JavedNo ratings yet

- SIG Metal SakurduDocument3 pagesSIG Metal SakurduAsif JavedNo ratings yet

- Jme 5Document5 pagesJme 5Asif JavedNo ratings yet

- Bravo 2&3 Pir - Manual Instalare PDFDocument1 pageBravo 2&3 Pir - Manual Instalare PDFDarie SilviuNo ratings yet

- 1 Awt2290 PDFDocument14 pages1 Awt2290 PDFDejan Đuričić ĐuraNo ratings yet

- 24 LC 2561Document12 pages24 LC 2561ricardo_MassisNo ratings yet

- Artemide Orbiter Ceiling 3474054 enDocument1 pageArtemide Orbiter Ceiling 3474054 enAngelica A. PereiraNo ratings yet

- Hl-3040cn, Hl-3070cw Parts ListDocument38 pagesHl-3040cn, Hl-3070cw Parts ListlftrevNo ratings yet

- Qubepower Parts Manual V10Document35 pagesQubepower Parts Manual V10Sandeep Singh ChaudharyNo ratings yet

- Type MRTP Supervision For AC Pilot CircuitsDocument8 pagesType MRTP Supervision For AC Pilot CircuitsNguyễn Huy HoàngNo ratings yet

- Work Breakdown StructureDocument1 pageWork Breakdown Structurekillnine100% (10)

- I20036 - Mn02x4w1-33m149-3tl21a0a10-SDocument3 pagesI20036 - Mn02x4w1-33m149-3tl21a0a10-SYibrail Veliz PluaNo ratings yet

- Adjustment Instructions: RobotDocument21 pagesAdjustment Instructions: RobotNicolas MolinaNo ratings yet

- NC3 Service ManualDocument50 pagesNC3 Service ManualDEPARTAMENTO TECNICONo ratings yet

- CSS G10 Act 2Document5 pagesCSS G10 Act 2Hueay Condes (Qtt)No ratings yet

- R 2000ic Operators PDFDocument222 pagesR 2000ic Operators PDFAdam ZiobrowskiNo ratings yet

- Unlock-B31.3 Process Piping Course - 11 Designing With Expansion JointsDocument15 pagesUnlock-B31.3 Process Piping Course - 11 Designing With Expansion JointsProkopNo ratings yet

- CIR-e: Portable Power AnalyzerDocument2 pagesCIR-e: Portable Power AnalyzerDakshitha KarunaratneNo ratings yet

- Data TeknisDocument12 pagesData TeknisJeff KlotsNo ratings yet

- 104 en - Multifunction Power Supply, Large - PRA-MPS3Document23 pages104 en - Multifunction Power Supply, Large - PRA-MPS3Wilmer MojicaNo ratings yet

- Drills TheoryDocument56 pagesDrills TheoryrohanNo ratings yet

- Steering Housing and Control UnitDocument30 pagesSteering Housing and Control UnitChristian Bedoya0% (1)

- Guide For VFDDocument22 pagesGuide For VFDRatilal M JadavNo ratings yet

- Fonestar 4x40w Ver Dap AudioDocument14 pagesFonestar 4x40w Ver Dap AudioAntonio LopezNo ratings yet

- Installation Clean Agent SystemsDocument14 pagesInstallation Clean Agent Systems721917114 47No ratings yet

- KX-MB2025 2030FX SMDocument313 pagesKX-MB2025 2030FX SMkacperorNo ratings yet

- DAC, ADC, Sensor, Interfacing DevicesDocument36 pagesDAC, ADC, Sensor, Interfacing DevicesSimranSiMmy100% (1)

- AH5As - Speaker PAGA SystemDocument2 pagesAH5As - Speaker PAGA SystemRidho Saputro HutomoNo ratings yet

- Cable SizingDocument10 pagesCable SizingAhmed MagdyNo ratings yet