Professional Documents

Culture Documents

1in 300 19 73716

1in 300 19 73716

Uploaded by

Mygame 1402Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1in 300 19 73716

1in 300 19 73716

Uploaded by

Mygame 1402Copyright:

Available Formats

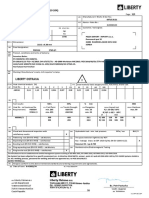

COMPANY WITH

MANAGEMENT SYSTEM

·CERTIFIED BY DNV GL

= ISO 9001 =

0 METALFAR PRODOTTI INDUSTRIALI SPA

23861 CESANA BRIANZA (LC) - ITALY

IIF

VIA G. PARINI, 28

PHONE + 39 031 655441 - FAX +39 031 655149

A01 COMPANY WITH

MANAGEMENT SYSTEM

CERTIFIED BY DNV GL

= ISO 9001 =

= ISO 1400 1 =

= ISO 14001 = �... co� certificate@metalfaritaly.com

INSPECTION CERTIFICATE EN 10204:2004/ 3.1 A02 NrAo3 2021-C_MFF-00205 · Data I Dated 26.01.2021 Z02

PT. PARADISE PERKASA A06 Ordine/ PO 2120100139 A07

JL. PANGERAN JAYAKARTA 66, KOMPLEK PESONA, BLOK B6, Item 007

10730 MANGGA DUA SELATAN, SAWAH BESAR, JAKARTA ... ID DDT I Delivery note 2021-3E301-0000188

Packing List 2021-3E401-0000198

Fattura/ Invoice 2021-3E401-0000198 A06

Ns. rif./ Our ref. 2020-3E201-0002J19-0007

007 B07 808 B01 . (B09 · B11)

Cod. colata Nr. colata Quantita Descrizione

Heat Code Heat Nr Quantity Description

19/73716 416,00 W/N 300 RF 1" STD A105N

Mat. in acc. a/ Mat. in acc. to 802 ASTM A105M - 18 ,ASME SA105M-19 ASME CODE SECT. II, PART A, ED. 201S

NACE MR-0175/2015 ISO 15156-2 :2015

NACE MR-0103/2015 ISO 17945 :2015

Q.A.S.IN ACCORD.WITH PRESS.EQUIPM.DIRECT.2014/68/EU(PED) ANNEX l,PPP,\GRP 'H 4.3

CERT.4687-2014-CE-ITA-DNV GL

Ann. mat. / Mat. remarks B02 FULLY KILLED STEEL AND FINE GRAIN PRACTICED

<c 1 · ce2,

Elementi/ Elements C Si Mn s p Cr Ni Mo Ti Cu V Nb N

LADLE ANALYSIS 0,185 0,240 1,020 0,007 0,007 0,120 0,070 0,020 0,019 0,140 0,002 0,001 0,010

PRODUCT ANALYSIS 0,184 0,232 1,011 0,008 0,009 0,127 0,074 0,015 0,020 0,135 0,001 0,003 0,012

Al B Ca CE LF CE SF F1 F2 PREN

LADLE ANALYSIS 0,032 0,0001 0,001 0,397 0,355 0,352 0,140

PRODUCT ANALYSIS 0,027 0,0000 0,001 0,395 0,353 0,352 0,142

CE LF=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15 CE SF=C+(Mn/6) F1=Cu+Ni+Cr+Mo+V F2=Cr+Mo

Provetta Formac10 °0:03 Snervamento>0,2%c11 Snervamento>1,0% c11 Rottui'a C12 Allungamento c13 Contrazione c1s

Test specimen Shape Yield Strength>0,2% Yield Strength>1,0% Tensile Elongation P�duction of area

Sez/Sect mm2 Gauge L.mm 1=0 - 2=0 MPa MPa MPa % %

126,60 50,80 1 20 338,0 504,0 37,C' 62,0

DUREZZA/ HARDNESsc� RESILIENZA / IMPACT TEST

HBW Tipo/TypeC4° Provetta/ Test Specimen •c co3 1-Joule C42 2-Joule C42 3-Jo1 1 l1:> 2 ;lftedia/Average C43

r_

C,4

146,0; 142,0 KV 10x10mm 20 119 149 1E. 143,7

I Tratt. Term. I Heat treatment c10 1 NORMALIZED AT 920 °C - COOLED IN STILL AIR GA' FURNACE

814 ASME/ANSI B16.5 -2017; ASME/ANSI 836.10M -2018; ASME/ANSI B16.25 -2017

J Dim In acc. a/ Dim. acc. to J

Finitura .1 Roughness

Marcatura in acc.806

I

ASME/ANSI B46.1 -2019

RF FINISHING 125-250 uln AARH

Origine E'UROPE,c\N UNION

I

ANSI/MSS SP-25-2018 Vis. & Dim. SATISFACTORY

Marking in acc. to Origin of Steel

Note/ Notes 100% MANUFACTURED IN ITALY

MATERIAL IN ACCORDANCE WITH ORDER AND SPECIFICATION

UFFICIO CONTROLLO QUALITA' AOS ENTE UFFICIALE DI COLLAUDO Z03 MARCH10 PRODUZIONE A04

QUALITY CONTROL DEPARTMENT INSPECTION AUTHORITY MANUFACTURER'S 3YMBOL

/tMri�

�FE

Page 8- 30

You might also like

- OSE Separator Spare PartsDocument120 pagesOSE Separator Spare PartsNico AgustyoNo ratings yet

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- Assignment #2 CAE Model For A Mechanical Assembly in SolidWorksDocument6 pagesAssignment #2 CAE Model For A Mechanical Assembly in SolidWorksJeevaNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- Combine Sertifikat TapenDocument60 pagesCombine Sertifikat TapenMygame 1402No ratings yet

- MFF Spect. Blind 6 CL 150Document1 pageMFF Spect. Blind 6 CL 150Mohamed RaafatNo ratings yet

- G3dv98ut-Brida BL Ac 300 A105 RF 2 MTFDocument1 pageG3dv98ut-Brida BL Ac 300 A105 RF 2 MTFantonio larottaNo ratings yet

- Snervamento 0,2% Snervamento 1,0% Yield Strength 0,2% Yield Strength 1,0% Sez/Sect mm2 Gauge L.MMDocument1 pageSnervamento 0,2% Snervamento 1,0% Yield Strength 0,2% Yield Strength 1,0% Sez/Sect mm2 Gauge L.MMMygame 1402No ratings yet

- 9q2fh6at-Brida BL Ac 300 A105 RF 2 MTFDocument1 page9q2fh6at-Brida BL Ac 300 A105 RF 2 MTFantonio larotta100% (1)

- ZR300X100X 5 K S355 - 1124241B - 120M - ArvediDocument2 pagesZR300X100X 5 K S355 - 1124241B - 120M - Arvedimcmrr69No ratings yet

- Certificate Material Tubing 3.1-Voorbeeld-CertificaatDocument3 pagesCertificate Material Tubing 3.1-Voorbeeld-Certificaatcahyo wibowoNo ratings yet

- Crne Besavne CeviDocument10 pagesCrne Besavne CeviDragan MarkovicNo ratings yet

- MaterialId 52-9180-597614 DocId 19827860 PDFDocument1 pageMaterialId 52-9180-597614 DocId 19827860 PDFangelokyoNo ratings yet

- Certificado Calidad CodosDocument1 pageCertificado Calidad CodosAndresFelipeCorreaNo ratings yet

- Round Bar Incoloy 825 Dia 40 MM 4 - ApprovedDocument6 pagesRound Bar Incoloy 825 Dia 40 MM 4 - ApprovedBogdan CăpățînăNo ratings yet

- MaterialId 52-9241-600081 DocId 19905690 PDFDocument1 pageMaterialId 52-9241-600081 DocId 19905690 PDFangelokyoNo ratings yet

- Test Certificate-ER347-lot 563092-75344Document1 pageTest Certificate-ER347-lot 563092-75344Mohammad HassanNo ratings yet

- Ssab Emea Ab, Se-781 84 Borlänge, Sweden: Carbon Equivalent Etc C93-C99Document1 pageSsab Emea Ab, Se-781 84 Borlänge, Sweden: Carbon Equivalent Etc C93-C99angelokyoNo ratings yet

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Document2 pagesWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNo ratings yet

- Ssab Emea Ab, Se-781 84 Borlänge, Sweden: Carbon Equivalent Etc C93-C99Document1 pageSsab Emea Ab, Se-781 84 Borlänge, Sweden: Carbon Equivalent Etc C93-C99angelokyoNo ratings yet

- Inspection Certificate 3.1+PED PN-EN 10204Document1 pageInspection Certificate 3.1+PED PN-EN 10204lwwwl2No ratings yet

- Product Chemical CompositionDocument1 pageProduct Chemical CompositionMohammed HamedNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Arcelormittal Galati S.A. - Romania: Inspection Certificate 20564275 According To: en 10204/2004/3.1 Date: 26.11.2018Document1 pageArcelormittal Galati S.A. - Romania: Inspection Certificate 20564275 According To: en 10204/2004/3.1 Date: 26.11.2018Felicia Cioaba100% (2)

- Certificado Supercore 2205P U2FC153058Document1 pageCertificado Supercore 2205P U2FC153058Leonardo CruzNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romero100% (1)

- Certificati LSE03-61172 P. 10-11-17-18Document6 pagesCertificati LSE03-61172 P. 10-11-17-18pippoNo ratings yet

- Yonks Tubing A Inox 3-8Document1 pageYonks Tubing A Inox 3-8Fercomil S.A.SNo ratings yet

- M 001 22Document1 pageM 001 22LUISNo ratings yet

- MS Sheets MTCDocument6 pagesMS Sheets MTCAmit Kumar OjhaNo ratings yet

- Data Sheet For Special Check Valve (Non-Slam) : Dahej Petrochemical ComplexDocument2 pagesData Sheet For Special Check Valve (Non-Slam) : Dahej Petrochemical ComplexSteve WanNo ratings yet

- Ok Aristorod 12.50Document1 pageOk Aristorod 12.50yuraNo ratings yet

- SI Engine CombustionDocument1 pageSI Engine CombustionPerumal GovindanNo ratings yet

- GK 223370 SRTDocument1 pageGK 223370 SRTömer cılızNo ratings yet

- Cofran Mecanep 220 enDocument2 pagesCofran Mecanep 220 enMATHEW JOSENo ratings yet

- Calibration SampleDocument2 pagesCalibration SampleSazzath HossainNo ratings yet

- AcerinoxDocument1 pageAcerinoxOmkar PrindavankarNo ratings yet

- Sample Test Cert. 07.09.2011 - 02Document1 pageSample Test Cert. 07.09.2011 - 02Vipul PanchalNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- Reducciones CopaDocument2 pagesReducciones CopaYazeth MartinezNo ratings yet

- Test Certificate: QR/BTC/01 ISO 9001:2015 CompanyDocument1 pageTest Certificate: QR/BTC/01 ISO 9001:2015 CompanyRai Singh MalhiNo ratings yet

- 7963 Brida Ac WN 6 X 150 SCH STD SWDocument2 pages7963 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- J 46 en 5 SBTRDDocument3 pagesJ 46 en 5 SBTRDMohamed SelimNo ratings yet

- Sarma Tub Inox Certificat PDFDocument1 pageSarma Tub Inox Certificat PDFJacob HarrisNo ratings yet

- Verti-Cor 3XP - 1.2mm - Part 720919 - Lot 2001309066Document1 pageVerti-Cor 3XP - 1.2mm - Part 720919 - Lot 2001309066Brad MannNo ratings yet

- Inspection CertificateDocument1 pageInspection CertificatemohamedNo ratings yet

- Product Certificate Welding Wire-ModelDocument1 pageProduct Certificate Welding Wire-ModelRamona CrangasNo ratings yet

- Bohler E 8010 4,0mm 2142568 PDFDocument1 pageBohler E 8010 4,0mm 2142568 PDFJack KomboyNo ratings yet

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

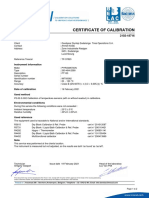

- Certificate of Calibration: Customer InformationDocument2 pagesCertificate of Calibration: Customer InformationSazzath HossainNo ratings yet

- Ducted Split: LG Air ConditionersDocument100 pagesDucted Split: LG Air Conditionersjose antonioNo ratings yet

- Inspection Cert StafDocument1 pageInspection Cert Stafacr84No ratings yet

- Accreditation by PNACDocument8 pagesAccreditation by PNACsujudNo ratings yet

- Metallurgical Test Certificate: Doc. No. R-QC.11 Nov.12Document2 pagesMetallurgical Test Certificate: Doc. No. R-QC.11 Nov.12MacelNo ratings yet

- No. A-14-401751 Rev 00Document3 pagesNo. A-14-401751 Rev 00Adrian CeplinschiNo ratings yet

- Quality Certificate / Material Test Certificate (Certificate Acc To Bs en 10204/3.1)Document1 pageQuality Certificate / Material Test Certificate (Certificate Acc To Bs en 10204/3.1)SarlisNo ratings yet

- 2211J5444 90mm WeldablesDocument1 page2211J5444 90mm WeldablesChethan Nagaraju KumbarNo ratings yet

- E10018d2-Eng LINCOLNDocument1 pageE10018d2-Eng LINCOLNBenfil ViernezNo ratings yet

- 6061 T6 -22.02.2020Document1 page6061 T6 -22.02.2020Danie SwanepoelNo ratings yet

- 6061 T6Document1 page6061 T6Danie SwanepoelNo ratings yet

- Bohler Dcms T-MCDocument1 pageBohler Dcms T-MCFlaviu-Andrei AstalisNo ratings yet

- 6 in 150 08596N Comb I1020411632-01Document2 pages6 in 150 08596N Comb I1020411632-01Mygame 1402No ratings yet

- Valve 2in 150 12063Document1 pageValve 2in 150 12063Mygame 1402No ratings yet

- Gate Valve 3in 150 XMK1020754308-27Document5 pagesGate Valve 3in 150 XMK1020754308-27Mygame 1402No ratings yet

- Elbow 6in 90N SCH 40 63e00m072Document1 pageElbow 6in 90N SCH 40 63e00m072Mygame 1402No ratings yet

- Red Co 8 X 4 40 94760197Document1 pageRed Co 8 X 4 40 94760197Mygame 1402No ratings yet

- Snervamento 0,2% Snervamento 1,0% Yield Strength 0,2% Yield Strength 1,0% Sez/Sect mm2 Gauge L.MMDocument1 pageSnervamento 0,2% Snervamento 1,0% Yield Strength 0,2% Yield Strength 1,0% Sez/Sect mm2 Gauge L.MMMygame 1402No ratings yet

- List Tools CEPUDocument4 pagesList Tools CEPUMygame 1402No ratings yet

- Hse ReportDocument1 pageHse ReportMygame 1402No ratings yet

- PURWANTODocument1 pagePURWANTOMygame 1402No ratings yet

- Astm A490m 1993Document5 pagesAstm A490m 1993Jesse ChenNo ratings yet

- Japanese Industrial StandardsDocument10 pagesJapanese Industrial StandardsKen SelorioNo ratings yet

- BUP 1-2-3 + Coper - CompressedDocument107 pagesBUP 1-2-3 + Coper - Compressedcontact kmcNo ratings yet

- Commercial Experience in The Operation of Ards Units in Kuwait National Petroleum Company at Mina Al-Ahmadi RefineryDocument15 pagesCommercial Experience in The Operation of Ards Units in Kuwait National Petroleum Company at Mina Al-Ahmadi RefineryOwais AhmedNo ratings yet

- WX100Document21 pagesWX100Emir AkçayNo ratings yet

- Use of Uoropolymer Permanent Release Coatings For Molded Polyurethane Foam ProductionDocument9 pagesUse of Uoropolymer Permanent Release Coatings For Molded Polyurethane Foam ProductionkingswordscNo ratings yet

- Laws of Production-Law of Variable ProportionDocument15 pagesLaws of Production-Law of Variable Proportionprabhatrc4235No ratings yet

- 4 Lean ManufacturingDocument2 pages4 Lean ManufacturingCyril Grace Alburo BoocNo ratings yet

- UD20199B A Baseline Video Intercom Main Unit Quick Start Guide V2.2.3Document4 pagesUD20199B A Baseline Video Intercom Main Unit Quick Start Guide V2.2.3avkt2005No ratings yet

- Api 577 Reponse01Document3 pagesApi 577 Reponse01korichiNo ratings yet

- Use and Maintenance of Cleaning Tools, MaterialsDocument22 pagesUse and Maintenance of Cleaning Tools, MaterialsLheiMarShārīGwynNo ratings yet

- Grasa AeroShell 5Document2 pagesGrasa AeroShell 5epesanoNo ratings yet

- Genovesi DKK., 2022Document9 pagesGenovesi DKK., 2022hajaxat617No ratings yet

- Gravitex Plus: Technical Data Sheet & Process GuideDocument3 pagesGravitex Plus: Technical Data Sheet & Process GuideOluwaseun TaiwoNo ratings yet

- BoQ PricedDocument1 pageBoQ PricedNadaNo ratings yet

- QCR W 2014Document3 pagesQCR W 2014Madhan KannanNo ratings yet

- Din 9427 - Metric Socket Button Head Cap ScrewsDocument1 pageDin 9427 - Metric Socket Button Head Cap ScrewsAlexis BarolinNo ratings yet

- Quote of 2-35T Dryer & 2000T Corn SiloDocument12 pagesQuote of 2-35T Dryer & 2000T Corn SiloGESTION COMERCIALNo ratings yet

- Shield-Bright 2209: Gas-Shielded Flux-Cored Wires (Fcaw) Stainless Steel WiresDocument1 pageShield-Bright 2209: Gas-Shielded Flux-Cored Wires (Fcaw) Stainless Steel WiresvallirajuNo ratings yet

- Industrial Training Presentation: (Cold Rolled Coils)Document18 pagesIndustrial Training Presentation: (Cold Rolled Coils)Parvesh GoyalNo ratings yet

- ICT - 9 Summative Test Q3 (Cycle1) TEMPDocument2 pagesICT - 9 Summative Test Q3 (Cycle1) TEMPJerrah AmaranteNo ratings yet

- EUROWATER RO Units LeafletDocument4 pagesEUROWATER RO Units LeafletNoah MusundiNo ratings yet

- Aarna Engineering Pvt. Ltd.Document56 pagesAarna Engineering Pvt. Ltd.THE SoLoWNo ratings yet

- Melag Meladem 65 - Watertreatment - User ManualDocument4 pagesMelag Meladem 65 - Watertreatment - User Manualamanuel waleluNo ratings yet

- Workshop Manual FullDocument64 pagesWorkshop Manual Fullzeusesport124No ratings yet

- Endress-Hauser Flowfit W CPA250 enDocument3 pagesEndress-Hauser Flowfit W CPA250 enSyazaNo ratings yet

- Q3 - Science8 - Week 8 LAS 2Document2 pagesQ3 - Science8 - Week 8 LAS 2Mary Queen TeroNo ratings yet

- MHE Chapter 2Document74 pagesMHE Chapter 2nurhussen nureNo ratings yet