Professional Documents

Culture Documents

Pilot Pressure System Operation

Pilot Pressure System Operation

Uploaded by

a.ilchuk39Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pilot Pressure System Operation

Pilot Pressure System Operation

Uploaded by

a.ilchuk39Copyright:

Available Formats

Pilot pressure system operation

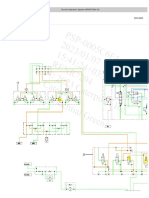

GUID-A2939B99-42F8-4B25-9932-4B15A52A6230

1 Feed from pump

2 Return line to tank

3 Feed to spreader damping cylinders

4 Pilot feed to proportional valves

5 Feed to accumulator

6 Train to tank

7 Pilot pressure relief valve

8 Oil filter

9 Check valve

10 WDO (watchdog) valve

11 Pressure sensor

The pilot system is supplied with oil by the right side 19 cc pump mounted in front of the main Linde

pump. The main components and operation of the system are as follows.

Oil is supplied through line (1) (P-port) passing through filter (8) and check valve (9) and out through line

(5) (SP-port) to charge the accumulator. Oil also supplied out through line (3) (M-port) directly to the

spreader damping cylinders.

As soon as the operator moves the joystick for any boom functions (lift, lower, extend or retract), WDO

valve (10) will be energized by the IQAN system and oil will pass through WDO valve (10) out of line (4)

(B-port) to the proportional valve block.

Should the pressure rise to 30 bar relief valve (7) will dump the remaining oil through line (2) (T-port)

back to tank. The check valve (9) ensures that the accumulator pressure is available to the pilot circuit

for brief emergency operation of the boom functions (only retract and lower) in the event of an engine

or pump failure.

The WDO valve (10) is under control of the IQAN system. The WDO valve will only be energised if the

joystick is moved to operate lift, lower, extend or retract functions. As soon as the IQAN system detects a

problem the WDO valve as well as the Joystick will be switched off and an alarm message is

generated on the MDL.

You might also like

- SM VOLVO L90C WHEEL LOADER Service Repair ManualDocument16 pagesSM VOLVO L90C WHEEL LOADER Service Repair ManualMarco Yarasca Romero100% (2)

- Instruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionDocument42 pagesInstruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionVladimirNo ratings yet

- Hydraulic System: Systems OperationDocument28 pagesHydraulic System: Systems OperationRoberto BaierNo ratings yet

- Att System OperationDocument41 pagesAtt System OperationchanlinNo ratings yet

- General Information: Systems OperationDocument52 pagesGeneral Information: Systems OperationFernando QSNo ratings yet

- Valvula Selectora Trans.Document4 pagesValvula Selectora Trans.enriqueNo ratings yet

- Stick Hydraulic System: Systems OperationDocument11 pagesStick Hydraulic System: Systems OperationKusharyantoNo ratings yet

- Bucket Hydraulic SystemDocument4 pagesBucket Hydraulic SystemNay SoeNo ratings yet

- Stick Hydraulic SystemDocument11 pagesStick Hydraulic SystemAllan LariosaNo ratings yet

- Bucket Hydraulic System: Operación de SistemasDocument4 pagesBucket Hydraulic System: Operación de SistemasvidalNo ratings yet

- Bucket Hydraulic SystemDocument3 pagesBucket Hydraulic Systemjuan david loyola100% (1)

- Section 5 Steering SystemDocument13 pagesSection 5 Steering SystemPriscila RodriguesNo ratings yet

- Negative Flow Control SystemDocument6 pagesNegative Flow Control SystemAva Rhan ThauNo ratings yet

- Valvula de Control DireccionDocument5 pagesValvula de Control DireccionRafael RodriguezNo ratings yet

- Transmission Control Valve: Shutdown SIS Previous ScreenDocument13 pagesTransmission Control Valve: Shutdown SIS Previous ScreenYudi setiawanNo ratings yet

- Control Valve Straight TravelDocument5 pagesControl Valve Straight TravelSteven Y.MNo ratings yet

- 2.main Hydraulic SystemDocument10 pages2.main Hydraulic Systemhendra hardyNo ratings yet

- Excavator Hydraulic System-Bucket SystemDocument3 pagesExcavator Hydraulic System-Bucket Systemjohn ayengahNo ratings yet

- Control Valve (Straight Travel)Document5 pagesControl Valve (Straight Travel)Steven ManuputtyNo ratings yet

- Steering System: Systems OperationDocument12 pagesSteering System: Systems Operationhidekel crafort vinicioNo ratings yet

- Funcionamiento - Valvula Control de Transmision 160 HDocument14 pagesFuncionamiento - Valvula Control de Transmision 160 Hfelipe cortesNo ratings yet

- AndresitoDocument25 pagesAndresitoJoan VasquezNo ratings yet

- 1 Main Hydraulic SystemDocument6 pages1 Main Hydraulic SystemZawminhtunNo ratings yet

- Main Control Valve 966Document22 pagesMain Control Valve 966Ahmed RezkNo ratings yet

- Boom Drift ReductionDocument4 pagesBoom Drift Reductionchanlin100% (1)

- E200b Sistema HidraulicoDocument149 pagesE200b Sistema HidraulicoLuis Carlos RamosNo ratings yet

- Sistema PilotoDocument24 pagesSistema Pilotomrcruzito_2099No ratings yet

- Negative Flow Control System: Systems OperationDocument9 pagesNegative Flow Control System: Systems OperationYudi setiawanNo ratings yet

- Boom Drift Reduction ValveDocument4 pagesBoom Drift Reduction ValveJuan Daniel Martinez MontoyaNo ratings yet

- 446D Valvula de Prioridad. Operacion de SistemaDocument8 pages446D Valvula de Prioridad. Operacion de SistemaCarlos IrabedraNo ratings yet

- Main Hydo Pump 320DDocument9 pagesMain Hydo Pump 320DSteven Y.MNo ratings yet

- Steering System: Operación de SistemasDocument11 pagesSteering System: Operación de SistemasMikeNo ratings yet

- 938F Wheel Loader 7SN00001-UP (MACHINE) POWERED BY 3116 Engine (SEBP2374 - 53) - Sistemas y ComponentesDocument15 pages938F Wheel Loader 7SN00001-UP (MACHINE) POWERED BY 3116 Engine (SEBP2374 - 53) - Sistemas y ComponentesCarlos Andres Campos TorresNo ratings yet

- 950G Hydraulic SystemDocument8 pages950G Hydraulic SystemMed EkahNo ratings yet

- Funcionamiento Valvula de ControlDocument8 pagesFuncionamiento Valvula de Controlseba6487No ratings yet

- Sis 2.2Document7 pagesSis 2.2Mohamed OmarNo ratings yet

- Transmission: Hydraulic ControlDocument4 pagesTransmission: Hydraulic Controlardan fadilah100% (1)

- Fuel Oil Forwarding System Training MaterialDocument11 pagesFuel Oil Forwarding System Training MaterialMohammed Ibrahim AsifNo ratings yet

- 312C EXCAVADORA CAT Operación de Sistemas Main Hydraulic SystemDocument5 pages312C EXCAVADORA CAT Operación de Sistemas Main Hydraulic SystemBASILIO JARA HUERTANo ratings yet

- Steering Control Valve - HMU Steering 950G 2002Document15 pagesSteering Control Valve - HMU Steering 950G 2002ssinokrotNo ratings yet

- 980 K BrakeDocument42 pages980 K BrakeMohamed W. KandilNo ratings yet

- Relief Valve CrossoverDocument5 pagesRelief Valve CrossoverSherlock HolmesNo ratings yet

- 320dl Bucket Hydraulic SystemDocument3 pages320dl Bucket Hydraulic SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- Secondary Steering System (HMU Steering) 966Document9 pagesSecondary Steering System (HMU Steering) 966Ahmed RezkNo ratings yet

- Stik in SlowDocument12 pagesStik in SlowSofiane SophianeNo ratings yet

- 32odl Swing Oil Makeup SystemDocument4 pages32odl Swing Oil Makeup SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- Section 6 Work EquipmentDocument37 pagesSection 6 Work EquipmentPriscila RodriguesNo ratings yet

- Boom HoldDocument4 pagesBoom HoldSherlock HolmesNo ratings yet

- 325 L XIME Governor ADJUST LIMITDocument16 pages325 L XIME Governor ADJUST LIMITDaniel TekleNo ratings yet

- Steering Control ValveDocument12 pagesSteering Control Valvehidekel crafort vinicioNo ratings yet

- ArtesDocument28 pagesArtesarturo laosNo ratings yet

- Swing Hydraulic System: Systems OperationDocument12 pagesSwing Hydraulic System: Systems OperationRainer Lopez ENo ratings yet

- 320dl Stick SystemDocument8 pages320dl Stick SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- 11 Main Hydraulic PumpDocument4 pages11 Main Hydraulic PumpZawminhtun100% (1)

- EH750-3 Rigid Hauler Hydraulic Training 3 RD PartDocument15 pagesEH750-3 Rigid Hauler Hydraulic Training 3 RD Partthan zaw win100% (1)

- 325C DEGU Pilot Hydraulic SystemDocument11 pages325C DEGU Pilot Hydraulic SystemDaniel TekleNo ratings yet

- 320dl Swing SystemDocument10 pages320dl Swing SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- Parking Brake SysOpDocument11 pagesParking Brake SysOpDikeledi MolotoNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet