Professional Documents

Culture Documents

HDTL 025

HDTL 025

Uploaded by

Angga 99Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HDTL 025

HDTL 025

Uploaded by

Angga 99Copyright:

Available Formats

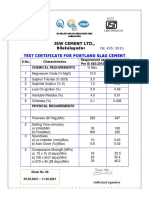

PT.

Tekenomiks Indonesia

Office : Jl. Jend Sudirman No. 58 RT 29 Balikpapan, 76114 Indonesia

PROBLEM

TECHNICAL ADVANCE FOR ECONOMIC GAIN

Wear Metal Report: 02127770

Client: PT. PANA OIL INDONESIA

Attention: PT. AWDU SITE ANGGANA

Address OFFICE JL. PLUIT SEL. RAYA BLOK Q JAKARTA UTARA 14450 N

Machine: TONLY TL875KR ID No: HDTL-025

Oil Name: PANAOIL CRUISER ADV PLUS 15W40

Visc@40°C: - Visc@100°C: 15.38 TBN: 11.24

Compartm't: ENGINE S/N: -

Sample Date: 03/10/2022 21/10/2022 09/12/2022 26/12/2022 14/01/2023 29/01/2024

Received Date 03/11/2022 17/11/2022 17/01/2023 19/01/2023 24/01/2023 22/02/2024

Analysis Date: 03/11/2022 17/11/2022 17/01/2023 19/01/2023 24/01/2023 22/02/2024

Reported Date 05/11/2022 22/11/2022 19/01/2023 24/01/2023 26/01/2023 23/02/2024

Sample no: 01867344 01874884 01905447 01906875 01909513 02127770

SMU:(hrs) 1745 2002 2491 2737 3032 6699

Oil Hrs: 220 998 205 246 295 429

Oil Changed: No Yes Yes No Yes Yes

Component Hours - - - - - -

Wear Metal Rate 0.07 0.02 0.36 0.09 0.21 1.91

Wear Metals METHOD RESULT Caut High Comments on elevated results

lead (Pb)(mg/kg) ASTM D6595 3.5 0.6 0.1 0.1 0.8 5.2 25 50 POI-EXT/II/2024/8779. Viskositas oli

iron (Fe)(mg/kg) ASTM D6595

normal. PQ Fe Al Cr Si di level tinggi dan Cu

7.4 16.3 64.2 18.5 49.6 670.6 75 150

Na medium. Kemungkinan dari wear

aluminium (Al)(mg/kg) ASTM D6595 2.6 3.0 3.0 1.2 3.9 80.7 15 30 Cylinder liner piston ring piston valve train

copper (Cu)(mg/kg) ASTM D6595 1.1 1.0 2.1 0.5 1.7 33.4 23 45 bearing thrust washer Seals/gasket leak

kontaminasi coolant. Oli sudah diganti.

chromium (Cr)(mg/kg) ASTM D6595 1.0 1.0 3.2 0.9 4.0 31.4 8 15 Inspeksi engine overheating. Cek engine

tin (Sn)(mg/kg) ASTM D6595 0.1 1.0 0.1 0.1 0.1 0.1 10 20 noise. Cek filter cut. Cek mechanism valve.

nickel (Ni)(mg/kg) ASTM D6595 0.1 1.1 0.1 0.1 1.8 0.1 5 10 Cek injector timing. Inspeksi air induction

system dari kebocoran. Cek kontaminasi

Contaminants debu masuk. Cek dust indikator. Cek kondisi

silicon (Si)(mg/kg) ASTM D6595 0.2 6.2 7.7 5.3 10.0 91.4 23 45 turbocharger dan temperatur. Cek

sodium (Na)(mg/kg) ASTM D6595

keseluruahn engine dari adanya kebocoran.

2.5 3.0 3.4 2.4 4.3 30.7 25 50

Cek internal Cooling system dari kebocoran.

Oil Additives Tes performa engine. Lakukan pemeriksaan

magnesium (Mg)(mg/kg) ASTM D6595 13 15 18 14 23 79 0 0 segera. Cek compartment life. by(Supian)

Warning limits (caution/high) refer to OEM

zinc (Zn)(mg/kg) ASTM D6595 790 1133 1068 1056 1090 600 0 0 Manufacture.

molybdenum (Mo)(mg/kg) ASTM D6595 19 34 30 32 59 21 0 0

calcium (Ca)(mg/kg) ASTM D6595 3659 3751 4808 4885 4715 4369 0 0

phosphorous (P)(mg/kg) ASTM D6595 673 974 954 989 955 537 0 0

boron (B)(mg/kg) ASTM D6595 29 265 270 252 389 103 0 0

Infra Red

TBN(mgKOH/g) ASTM D4739 9.28 8.97 9.20 9.26 8.98 8.91 4 0

TAN(mgKOH/g) ASTM D974 n/a n/a n/a n/a n/a n/a 0 0

soot(Abs/cm) ASTM E2412 6 16 16 18 25 41 50 100 Approved by : Ita Saronika ( Manager Lab )

glycol(% vol) ASTM E2412 0 0 0 0 0 0 2 3

oxidation((x.100)abs/0.1mm) ASTM E2412 5 5 10 6 12 8 40 80

nitration((x.100)abs/0.1mm) ASTM E2412 3 3 3 2 4 11 40 80

sulphation((x.100)abs/0.1mm) ASTM E2412 4 3 10 9 10 0 40 80

Physical Tests Particle Cleanliness Analysis

water(ppm) ASTM D6304 n/a n/a n/a n/a n/a n/a 0 0 ISO 4406 - 04 | -

fuel dilution(% vol) In-house 0.00 0.00 0.00 0.00 0.00 0.00 2 3 ISO 4406 - 06 | -

water(%) ASTM E2412 0.00 0.00 0.00 0.00 0.00 0.00 0.2 0.2 ISO 4406 - 14 | -

F.debris(mg Fe/L) ASTM D8120 3 4 7 6 4 309 10 20 Count 1ml | -

visc @ 100oC(mm2/s) ASTM D445 13.14 13.08 12.59 13.62 12.93 11.94 11.54/1 10.77/1

9.23 9.99

visc @ 40oC(mm2/s) ASTM D445 101.2 94.92 88.72 96.49 94.23 86.35 0 0

Iso Code (Part/mL)() ISO 4406 -/-/- -/-/- -/-/- -/-/- -/-/- -/-/- 0 0

Element Trends Graph

For enquiries: Tekenomiks Balikpapan, email : Labbpn@techenomics.com, phone : 0542-762226 fax : 0542-762256 mobile : 0542-764681

This wear analysis and oil condition report should be used in conjunction with normal maintenance and evaluated from sample to sample. Every care will be taken in processing samples but no express or implied guarantee is furnished in

regard to the continuing operation or condition of this machinery or any part thereof.

The Result of Analysis is only related to the sample analyzed.

You might also like

- Ford Transit 2006.5 04.2006 Workshop Manual ( (04.2006-) )Document834 pagesFord Transit 2006.5 04.2006 Workshop Manual ( (04.2006-) )slawek100% (2)

- Ex409 MmeDocument3 pagesEx409 MmeHERY HAKAT CHANELNo ratings yet

- DT041Document5 pagesDT041HERY HAKAT CHANELNo ratings yet

- DT1342 EngineDocument1 pageDT1342 EnginedayatNo ratings yet

- t345 Engine UpdateDocument1 paget345 Engine Updatearif adi saputraNo ratings yet

- Oil Sample S315Document1 pageOil Sample S315yudhaperkasa92No ratings yet

- DT2407 DifferentialDocument1 pageDT2407 DifferentialdayatNo ratings yet

- Olc Document1706595038Document1 pageOlc Document1706595038arief fardy yuskaNo ratings yet

- DT2872 Final Drive Center RHDocument1 pageDT2872 Final Drive Center RHdayatNo ratings yet

- Batch 124232 Pt. Kerta Bumi Teknindo - PLTD TinaboganDocument5 pagesBatch 124232 Pt. Kerta Bumi Teknindo - PLTD Tinaboganamin ghozaliNo ratings yet

- Pap GS010Document1 pagePap GS010Johan NicholasNo ratings yet

- Pap S315 11may21Document1 pagePap S315 11may21yudhaperkasa92No ratings yet

- HGR3098 Engine 23augDocument1 pageHGR3098 Engine 23augIndo BemlNo ratings yet

- DTHW 005Document1 pageDTHW 005Angga 99No ratings yet

- HGR3100 Engine 23augDocument1 pageHGR3100 Engine 23augIndo BemlNo ratings yet

- TM GDR-413Document2 pagesTM GDR-413Ahmat RamadaniNo ratings yet

- Pdf24 MergedDocument9 pagesPdf24 MergedauliaadyaksaNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- DiagnosisDocument3 pagesDiagnosispalashNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- California Bearing Ratio (CBR) Test Report: Hyundai Engineering & Const. Co., Ltd. Indonesia Sarulla GPP ProjectDocument7 pagesCalifornia Bearing Ratio (CBR) Test Report: Hyundai Engineering & Const. Co., Ltd. Indonesia Sarulla GPP ProjectRango Santoso100% (1)

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Old Certificate TC-2796-Cerachem - CONVOLUTED MOD - 128D - TOCO-55RI-21.01.22Document2 pagesOld Certificate TC-2796-Cerachem - CONVOLUTED MOD - 128D - TOCO-55RI-21.01.22NabielNo ratings yet

- Mix Design Bosowa PDFDocument11 pagesMix Design Bosowa PDFEriPrawitoNo ratings yet

- FOB Extra Duty Gear Oil TDSW 815913 - 815914Document3 pagesFOB Extra Duty Gear Oil TDSW 815913 - 815914Elwin arifinNo ratings yet

- Q8 Goya DDocument3 pagesQ8 Goya DMoutaz IsmailNo ratings yet

- WCC.10002MG (Tanjung Bin)Document10 pagesWCC.10002MG (Tanjung Bin)keymal9195No ratings yet

- Test Report For Gabion Wire: Parameters ResultDocument1 pageTest Report For Gabion Wire: Parameters ResultmirwaisNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- TRDR 300204825BDocument2 pagesTRDR 300204825BVidya SheeshNo ratings yet

- PT Petrolab Services: Test DetailDocument1 pagePT Petrolab Services: Test DetailDiat NorNo ratings yet

- G4Si1 - Lot 19032064 (20200131)Document1 pageG4Si1 - Lot 19032064 (20200131)Peter TvardzíkNo ratings yet

- 06 Week OPC53 TEST CERTIFICATE (PI)Document1 page06 Week OPC53 TEST CERTIFICATE (PI)Kamal NathNo ratings yet

- Tube 20 January 2023Document1 pageTube 20 January 2023पवन द्विवेदीNo ratings yet

- Load-Penetration Curve: Control NoDocument1 pageLoad-Penetration Curve: Control NoGerryBoD.BagtasJr.No ratings yet

- Lembar Kerja Sand Condition Analysis: Sample IdentificationDocument1 pageLembar Kerja Sand Condition Analysis: Sample IdentificationJoel Alfonso ManurungNo ratings yet

- Test Certificate of 53 Grade Ordinary Portland Cement: Shree Digvijay Cement Co. LTD., DigvijaygramDocument232 pagesTest Certificate of 53 Grade Ordinary Portland Cement: Shree Digvijay Cement Co. LTD., DigvijaygramKuldeep ChakerwartiNo ratings yet

- Condensate Specs and TBP 1Document1 pageCondensate Specs and TBP 1asad razaNo ratings yet

- Mycom #1Document1 pageMycom #1Rifky Windya NNo ratings yet

- GM 10 20072020Document2 pagesGM 10 20072020Enrique CallesNo ratings yet

- Dewpoint Copper DPC-0521-DDocument4 pagesDewpoint Copper DPC-0521-DTengku MunzirNo ratings yet

- Report On Compressive Strength of Concrete CylinderDocument2 pagesReport On Compressive Strength of Concrete CylinderRyan condeNo ratings yet

- 06 Week PSC TEST CERTIFICATEDocument1 page06 Week PSC TEST CERTIFICATEKamal NathNo ratings yet

- 2019 Report WeekDocument145 pages2019 Report WeekLabeed ShamilNo ratings yet

- CBR ReportDocument5 pagesCBR ReportPhanindra NathNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Engine Experiment FormatDocument1 pageEngine Experiment FormatMD Ashfakul Karim KausikNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- ŠAVNE CEVI 2 Cola - pdf-2021-6mDocument1 pageŠAVNE CEVI 2 Cola - pdf-2021-6mdario_791473996No ratings yet

- 30 MM Gi Threaded Rod GR 8.8 - Tbi PDFDocument1 page30 MM Gi Threaded Rod GR 8.8 - Tbi PDFm.aliNo ratings yet

- Deg 3 80%Document5 pagesDeg 3 80%bellaNo ratings yet

- G4Si1 - Lot 19042054 (20200204)Document1 pageG4Si1 - Lot 19042054 (20200204)Peter TvardzíkNo ratings yet

- Sau - MTC 0001-002163 - Acc.aºcºDocument24 pagesSau - MTC 0001-002163 - Acc.aºcºrosa aurora montesano somarribaNo ratings yet

- Demes - C2 Spec Data SheetsDocument4 pagesDemes - C2 Spec Data Sheetsbaurzhan.kunkuzhayevNo ratings yet

- Truvu 360 Report Sh002 Eng-L23-6Document8 pagesTruvu 360 Report Sh002 Eng-L23-6AbdoNo ratings yet

- BF20112602 English MTC PDFDocument2 pagesBF20112602 English MTC PDFSvetlana VujovićNo ratings yet

- Certificate of Quality: MOGAS-95Document1 pageCertificate of Quality: MOGAS-95Basant Kumar SaxenaNo ratings yet

- Novel Laparoscopic Training System With Continuously PerfusedDocument8 pagesNovel Laparoscopic Training System With Continuously Perfusedmauricio ricardoNo ratings yet

- The History of Moral and Social Philosophy A Professional Perspective - 2Document24 pagesThe History of Moral and Social Philosophy A Professional Perspective - 2rmm0415No ratings yet

- Mpman High-Tech Mini Electric Scooter User Manual Model: TR800Document18 pagesMpman High-Tech Mini Electric Scooter User Manual Model: TR800ChrisNo ratings yet

- Decommissioning Cost Estimate Study: Duke Energy ProgressDocument73 pagesDecommissioning Cost Estimate Study: Duke Energy ProgressBhartendu goyalNo ratings yet

- Live Lesson 14 Funk Drumming PDFDocument10 pagesLive Lesson 14 Funk Drumming PDFAndrews Rocha100% (3)

- Mysterypowderse 2Document5 pagesMysterypowderse 2api-2125257840% (2)

- One Dimensional Heat EquationDocument30 pagesOne Dimensional Heat Equation20-317 RithvikNo ratings yet

- AR12BVFAAWK2AZDocument4 pagesAR12BVFAAWK2AZFilipe Dias0% (1)

- HVAC Designing Drafting Estimation & InstallationDocument3 pagesHVAC Designing Drafting Estimation & Installationnoha azamali50% (2)

- Mikhaylo Semenko - 6 PoemsDocument3 pagesMikhaylo Semenko - 6 PoemsandreusDADANo ratings yet

- HarvestlandDocument687 pagesHarvestlandJanetNo ratings yet

- CapacitanceDocument36 pagesCapacitanceRpPaNo ratings yet

- Revised Holiday HomeDocument4 pagesRevised Holiday HomerashmichemistryNo ratings yet

- Ground Floor Plan: Nitin SidhpuraDocument14 pagesGround Floor Plan: Nitin SidhpuraRam PatelNo ratings yet

- Plum Concrete WallsDocument4 pagesPlum Concrete WallsnileshNo ratings yet

- Gv300 ManualDocument22 pagesGv300 ManualCarmelo HoyosNo ratings yet

- Cognitive Approaches To TranslationDocument10 pagesCognitive Approaches To TranslationKhali74No ratings yet

- Diagnostic Testing Strategies To Manage COVID-19 Pandemic: Position PaperDocument4 pagesDiagnostic Testing Strategies To Manage COVID-19 Pandemic: Position PaperMia FernandezNo ratings yet

- Experiment#3 - Specific Gravity of Coarse AggregatesDocument4 pagesExperiment#3 - Specific Gravity of Coarse AggregatesRiceth Honeylet CancinoNo ratings yet

- HP ExpertOne Certification PathsDocument34 pagesHP ExpertOne Certification PathsSaurabh0% (1)

- VIBu Introduction Bio Counter 06 - 2012Document11 pagesVIBu Introduction Bio Counter 06 - 2012Asuka Q. QinNo ratings yet

- DSE890 891 Data Sheet PDFDocument2 pagesDSE890 891 Data Sheet PDFYasser JaviNo ratings yet

- Foxboro Evo™ Process Automation System: Product SpecificationsDocument12 pagesFoxboro Evo™ Process Automation System: Product SpecificationsSukdeb MaityNo ratings yet

- Business InfographicDocument1 pageBusiness InfographicCarla Sofía López MorenoNo ratings yet

- GRI 180-12-B-W1K Data SheetDocument3 pagesGRI 180-12-B-W1K Data SheetJMAC SupplyNo ratings yet

- Survey On Physical Layer Security For 5G Wireless NetworksDocument20 pagesSurvey On Physical Layer Security For 5G Wireless NetworksjavaNo ratings yet

- Floor Plan SymbolsDocument34 pagesFloor Plan SymbolsMatthew DavidNo ratings yet

- Quick Installaton Guide-MI-250 Daisy Chain VersionDocument2 pagesQuick Installaton Guide-MI-250 Daisy Chain VersionSunil SinghNo ratings yet