Professional Documents

Culture Documents

Shopfloor Check Points

Shopfloor Check Points

Uploaded by

rohit.sharma4030 ratings0% found this document useful (0 votes)

4 views4 pagesCopyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

4 views4 pagesShopfloor Check Points

Shopfloor Check Points

Uploaded by

rohit.sharma403Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 4

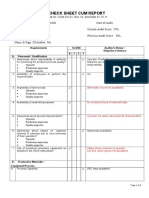

Shop floor Self Assessment Check Sheet

DATE Auditor NAME-

Supplier Name

Location

Time

Audit Team

Tier-2

Tier-2

Tier-2

Tier-2

Tier-2

Tier-1

SR.N CLAUSE VSA-19 Requirements Observation on Shop Floor Action Plan Target Date Responsibility

O. NAME

1 4m change Status Board On machine

2 4m Change Display Board on Shopfloor (Section Wise)

3 4m Change Management WI/SOP/Annexure Display on Shop

floor in Local Language

4 4M change Material Identifiacation Tag

5 4m Change Hold Area

Shop

Floor

6 Initial Part Tag

7 Initial Part separate Lock & Key Area (IPP Summary log bok

/Display Board/Authorize person etc)

8 Display of Skill Matrix(Helper/Operator/Inspector) and

Competency Matrix(Staff) On shopfloor

9 Display of Abnormal Situation on Shop floor in Local Language

10 Awareness of abnormal Situation & 4m Change Managemenent

Red Bin Meeting Area (Red Bin/Red Bin attandence

11 Record/Display Board/Inhouse Rejection Trend/Criteria/Scrap

note/CFT Team)

Display of Inhouse Rejection Trend(Pareto Chart) and Customer

12 Complaint on Shop floor(Specially In the Final inspection &

Packing Area)

13 Material To be Kept in Covered Area away from Dust, Rust,

Scratches(Raw material/WIP/FG/Packed Material )

14 Designated Area for RM/BOP/Hold,

Suspected/WIP/Rework/Scrap/FG/Packed Material/IPP

15 Workshop Enviorement Lux level & Noise Level in Shop floor as

per Indian Standard

16 Inspection Should be on Working Table Only (Not on Ground

Floor)

17 General Condition on Machine & Shop floor :- 5S should be

maintained

18 i. No Loose or open Wiring

19 ii. No Oil Lekage on Machine or Shop floor

Shop

Floor

20 Stogare of Inspection Instrument in Boxes (When not in Use)

21 Display/Awareness/Checking/Verification of Daily Machine check

sheet

22 Display/Awareness/Checking/Verification of Poka yoka on

Shopfloor

23 Calibration Plan Display

24 Limit Sample Availablility (Approved form Customer & should be

displayed in front of Operator & Inspector)

25 Visual Display of Ok & NG sample at WIP/FG area

Visualizer (Tower Light) and Alarm System(Hooter) at critical

26 Operation for confirming the competion of work and Machine

Status (Implement Tower Light for all Machine)

Display of all process WI/SOP/OCS/Process parameter/product

27 Parameter/Inspection statndard in local language on Each

Machine

Judgement Criteria(Upper/Lower tolerance) & final judgement

28 for the part or Product should be available in all inspection shet

(Ensure this point for all inspection reports-RI/Inprocess/Final

Inspection)

29 FIFO(First In First out) at all stage of production should be

followed (RI/WIP/FG/Packed material)

30 Identification Tag with following Details Route card/Heat No./Lot

No./Production date & shift

Separate ID tag should be avaialble for

31 IPP/IPC/RM/WIP/Hold/Suspected/4M change/Ok/Scrap/Similar

Part/rework etc.

32 Display of Similar parts samples & list in WIP/FG/Packed material

storage area (Different Tag/Bin/Packaging)

33 Bin Should be Defined for Storing

OK/Suspected/WIP/Reject/Rework/IPP/IPC/Similar material

Rework Register For Traceability of Person doing Rework and

34 person approving parts after Rework-RECORD SHOULD BE

AVAIALBLE

35 Shop Rework Area should be defined

Floor

Display & awareness of Rework Matrix/Rework WI, List of

36 Authorized Person for Rework their Skil Matrix (Availablility of

Rework Record & Training Record)

37 Display & Awareness of Customer Approved Packing Standard in

Packing & Dispatch Area

38 Condition of Bin & trolley should be Proper (No

damage/Uncleaned Bin or Trolley)

39 Identified area for Bin/Troller Cleaning/Maintenance/repair and

storage

40 Display of Bin/Trolley Cleaning,Maintenance,repair WI &

Authorize Person list

41 Record of Bin/Trolley Cleaning,Maintenance,repair

42 List of Inspection Instrument & Testing Equipement

43 Calibration Record of All Inspection Instrument & Testing

Equipement

44 List of Authorize persons and Training record of the person

operating Inspection Instrument & Testing Equipment

45 Display of Metrology/Metallurgy lab person Competency Matrix

and availiability of their Training Record

46 Display of Organization Chart /Plant Layout along with the Escape

Route

47 Awareness of Safety PPE's & PPE Matrix

48 Availability of Safety PPE's to all shopfloor persons & safety

Guard on all Machines

49 Safety Display Board in Shop floor for monitoring Major/Minor

accident and Near Miss

50 Shop Fire Extinguisher & fire Fighteners availablity

Floor

51 Fire & safety Training Record Availablity

52 First Aid Kit Availablity & trained Person (Training Record)

53 Green Status in Fire & Safety Audit through MSIL approved third

Party.

54 Availability & Awareness of Different type of waste storage bin in

shop floor

55 Availability of Waste Disposition Record

You might also like

- Line Clearance ProcedureDocument3 pagesLine Clearance ProcedurePrince Moni80% (5)

- Heavy Equipment Inspection ChecklistDocument18 pagesHeavy Equipment Inspection ChecklistJuned Hamid Khan89% (9)

- SQ Mark & 100ppm ChecklistDocument14 pagesSQ Mark & 100ppm Checklistkarpags100% (2)

- Mewp Inspection ChecklistDocument4 pagesMewp Inspection ChecklistBiswajit BiswasNo ratings yet

- IQ, OQ, PQ For FBDDocument31 pagesIQ, OQ, PQ For FBDBayyapureddy Rakesh89% (46)

- Validation & Qualification of Dry Powder Mixers, Fluid Bed Dryer, Tray DryerDocument32 pagesValidation & Qualification of Dry Powder Mixers, Fluid Bed Dryer, Tray DryerPatricia Joyce Malabanan SunglaoNo ratings yet

- Risk Assessment For Waste Management: SL No Potential Hazard Risk Persons at Risk Control Measures Risk RatingDocument3 pagesRisk Assessment For Waste Management: SL No Potential Hazard Risk Persons at Risk Control Measures Risk Ratingطارق رضوان100% (1)

- Fill in The Blanks With One Word or Phrase From The ListDocument6 pagesFill in The Blanks With One Word or Phrase From The Listivanov ioana100% (1)

- Gujarat Factory Rules 1963Document108 pagesGujarat Factory Rules 1963aadham100% (1)

- Method Statement For Earthing and Lightning ProtectionDocument12 pagesMethod Statement For Earthing and Lightning ProtectionAnandu Ashokan100% (1)

- Process Audit - Sheet New ......Document1 pageProcess Audit - Sheet New ......MUKESH KUMAR100% (1)

- Instruction Value: Electric Air Compressor - Low PressureDocument3 pagesInstruction Value: Electric Air Compressor - Low Pressuredima65No ratings yet

- Process Audit Check SheetDocument2 pagesProcess Audit Check Sheetsohaghmd111No ratings yet

- Process+Audit+Check+Sheet V0Document2 pagesProcess+Audit+Check+Sheet V0subhajitp139No ratings yet

- Shriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)Document5 pagesShriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)deepak sharma100% (1)

- FBD Tray Dryer Validation MalibaDocument46 pagesFBD Tray Dryer Validation MalibaApoloTrevinoNo ratings yet

- FBD Tray Dryer Validation MalibaDocument46 pagesFBD Tray Dryer Validation MalibaSandip Najan100% (1)

- Mewp Inspection ChecklistDocument4 pagesMewp Inspection ChecklistBiswajit BiswasNo ratings yet

- Ppap 02080 - A01Document66 pagesPpap 02080 - A01shiromaxs100% (1)

- SATR-J-6913 Rev 0 PDFDocument6 pagesSATR-J-6913 Rev 0 PDFAdel KlkNo ratings yet

- Process Audit Check Sheet Cum ReportDocument4 pagesProcess Audit Check Sheet Cum ReportLakshmanan Venkatesan100% (3)

- CL GL Hal Ni 208Document4 pagesCL GL Hal Ni 208LismiantoNo ratings yet

- Venkateswaraa Insulation Achieve 100Ppm / SQ Mark - Check ListDocument14 pagesVenkateswaraa Insulation Achieve 100Ppm / SQ Mark - Check ListdysonNo ratings yet

- 19-F13 Vehicle Mounted Crane Inspection ChecklistDocument2 pages19-F13 Vehicle Mounted Crane Inspection ChecklistSn Ahsan100% (1)

- Ppap 01157 - F03Document72 pagesPpap 01157 - F03shiromaxsNo ratings yet

- B737-300F Aircraft Daily CheckDocument10 pagesB737-300F Aircraft Daily CheckUmer JavedNo ratings yet

- Bharat Heavy Electricals Limited Inspection of Batching PlantDocument2 pagesBharat Heavy Electricals Limited Inspection of Batching PlantRanjan SahooNo ratings yet

- Ohs-Pr-09-19-F05 (A) Forklift Daily InspectionDocument2 pagesOhs-Pr-09-19-F05 (A) Forklift Daily InspectionShafie ZubierNo ratings yet

- LOADER ChecklistsDocument1 pageLOADER ChecklistsSalvacion Jaro100% (1)

- Equipment QualificationDocument23 pagesEquipment QualificationDrSyeda Rima100% (4)

- Note:-: Mro Data Downloading Facility For HhmpiDocument2 pagesNote:-: Mro Data Downloading Facility For HhmpiNiraj YogiNo ratings yet

- Manlift Inspection ReviewDocument3 pagesManlift Inspection Reviewjose corrosionNo ratings yet

- Chemical Plant Audit Datalist 2022Document40 pagesChemical Plant Audit Datalist 2022Govind ChaudharyNo ratings yet

- CSI Daily Diary - 1Document1 pageCSI Daily Diary - 1Site.ProjectE and INo ratings yet

- SATR-J-6501 - Rev 0 PDFDocument5 pagesSATR-J-6501 - Rev 0 PDFAdel KlkNo ratings yet

- Boq Fire Fighting SystemDocument15 pagesBoq Fire Fighting SystemAnonymous VpG5VhEgGNo ratings yet

- Layered Process Audit ChecklistDocument1 pageLayered Process Audit ChecklistMuniyappan TNo ratings yet

- Pressure Safety Valves SDRL Rev 1Document3 pagesPressure Safety Valves SDRL Rev 1salesNo ratings yet

- Saic LPT 2006Document12 pagesSaic LPT 2006jerinNo ratings yet

- 19-F12 Mobile Crane Daily Inspection ChecklistDocument2 pages19-F12 Mobile Crane Daily Inspection ChecklistSn AhsanNo ratings yet

- Checklist of DU250 & DU400Document9 pagesChecklist of DU250 & DU400MadanBhadoriyaNo ratings yet

- Saudi Aramco Test Report: Vaccum Box Leak Test Report 15-Dec-09 MECH-NDEDocument2 pagesSaudi Aramco Test Report: Vaccum Box Leak Test Report 15-Dec-09 MECH-NDEWaleed MedhatNo ratings yet

- Celebrity Biopharma LimitedDocument10 pagesCelebrity Biopharma LimitedchalicevitalchemNo ratings yet

- Instruction Value: Generator SkidDocument4 pagesInstruction Value: Generator Skiddima65No ratings yet

- BOEMRE - MSS Inspection HandbookDocument66 pagesBOEMRE - MSS Inspection Handbookbrianpham007No ratings yet

- Technical Evaluation For The Provision of Physical Security Service at ERIDocument10 pagesTechnical Evaluation For The Provision of Physical Security Service at ERITrading AccountNo ratings yet

- Vendors Certification AnnexuresDocument16 pagesVendors Certification Annexuresisrael afolayan mayomiNo ratings yet

- SAIC-N-2042 Rev 0Document2 pagesSAIC-N-2042 Rev 0philipyapNo ratings yet

- AHU Block-V Rev 00 - 2023Document36 pagesAHU Block-V Rev 00 - 2023Chirag S. PatelNo ratings yet

- PHMSA Form 10 Standard Breakout Tank Insp 2008Document21 pagesPHMSA Form 10 Standard Breakout Tank Insp 2008Irvansyah RazadinNo ratings yet

- NCR ProcedureDocument10 pagesNCR ProcedureLilian RobertsonNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportSino hydroNo ratings yet

- V P 205 1341 0011 M 0002 - Factory - Acceptance - Test - ProcedureDocument7 pagesV P 205 1341 0011 M 0002 - Factory - Acceptance - Test - ProceduredodonggNo ratings yet

- Lifting Equipment Controller NotesDocument5 pagesLifting Equipment Controller NotesHitesh GuptaNo ratings yet

- SOP For Line Clearance of Production AreaDocument2 pagesSOP For Line Clearance of Production Areabashar jordanNo ratings yet

- SAMPLED-Example of Audit SheetDocument9 pagesSAMPLED-Example of Audit Sheetchristina sitorusNo ratings yet

- BSEE Production Inspection HandbookDocument71 pagesBSEE Production Inspection HandbookStephanie Burns AyersNo ratings yet

- REPORTING VALUATION Points To Be Observed in Reporting: Sl. No. Description RemarksDocument4 pagesREPORTING VALUATION Points To Be Observed in Reporting: Sl. No. Description RemarksVishwanath MurthyNo ratings yet

- FMEA PDocument6 pagesFMEA Pparu1982No ratings yet

- API System Inspection ChecklistDocument2 pagesAPI System Inspection ChecklistYasir ArafatNo ratings yet

- Nitp 9 Vehicle TanksDocument18 pagesNitp 9 Vehicle Tanksakhil rameshNo ratings yet

- Check List HVAC FORMSDocument20 pagesCheck List HVAC FORMStraadel_320610041No ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Food Traceability GuidanceFrom EverandFood Traceability GuidanceNo ratings yet

- Catalogo Bollitori Inglese 2017 - 2018 PDFDocument331 pagesCatalogo Bollitori Inglese 2017 - 2018 PDFFlorian AngererNo ratings yet

- Child Labor LessonDocument2 pagesChild Labor Lessonsimon_williams_57No ratings yet

- Water Pollution: Everything You Need To KnowDocument7 pagesWater Pollution: Everything You Need To KnowManu Jacob Steaphen 19MST0050No ratings yet

- Stockosorb 660 msds2Document6 pagesStockosorb 660 msds2fluffybaer2259No ratings yet

- Wastage Operational SummaryDocument5 pagesWastage Operational SummaryWXYZ-TV Channel 7 DetroitNo ratings yet

- A Study On Swachh Bharat Abhiyan and Management LessonsDocument2 pagesA Study On Swachh Bharat Abhiyan and Management LessonsarcherselevatorsNo ratings yet

- Eng W4-DraftDocument5 pagesEng W4-DraftRhamona BacoNo ratings yet

- Global Synthetics Secutex Brochure PDFDocument11 pagesGlobal Synthetics Secutex Brochure PDFyuNo ratings yet

- IWA SG Global TrendsDocument113 pagesIWA SG Global Trendsandik_yNo ratings yet

- Recovery of Active Cathode Materials From Lithium-Ion Batteries UsingDocument9 pagesRecovery of Active Cathode Materials From Lithium-Ion Batteries UsingEnzo BelliniNo ratings yet

- Actionplan - SAHANPUR BijnorDocument43 pagesActionplan - SAHANPUR BijnorLimra TravelsNo ratings yet

- SLS134 EngDocument77 pagesSLS134 Engapi-3769211100% (1)

- Housekeeping NC2Document11 pagesHousekeeping NC2Paola QuintosNo ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance/mixture and of The Company/undertakingDocument5 pagesSafety Data Sheet: Section 1: Identification of The Substance/mixture and of The Company/undertakingalimoya13No ratings yet

- Spesifikasi IPAL 10 m3Document2 pagesSpesifikasi IPAL 10 m3RIONo ratings yet

- Considerations On The Use of Air - Lift Pumps in The Sewage Treatment PlantsDocument7 pagesConsiderations On The Use of Air - Lift Pumps in The Sewage Treatment PlantsvladmmuresanNo ratings yet

- Water Carriage SystemDocument9 pagesWater Carriage Systemsanshlesh kumarNo ratings yet

- Introduction To Dual Fuel InjectionDocument8 pagesIntroduction To Dual Fuel InjectionAbhiNo ratings yet

- Air Blowing of Piping (PTJ-Lub-Growth II-COM-008) Rev.01Document9 pagesAir Blowing of Piping (PTJ-Lub-Growth II-COM-008) Rev.01Ahmed Al SharabasyNo ratings yet

- Penguard HB - Comp ADocument5 pagesPenguard HB - Comp ABalasubramanian AnanthNo ratings yet

- Paes (Agricultural Structures)Document299 pagesPaes (Agricultural Structures)Billy AgustinNo ratings yet

- Wil Ar 2015-16Document212 pagesWil Ar 2015-16Kishore JohnNo ratings yet

- Design For EnvironmentDocument19 pagesDesign For EnvironmentAkshAy ShAhNo ratings yet

- Linear Heat Sensor CableDocument40 pagesLinear Heat Sensor CableMuhammad Fadhil Budiman100% (1)

- MSDS EnglishDocument7 pagesMSDS EnglishdimasfebriantoNo ratings yet

- Sustainable Use of Industrial-Waste As Partial Replacement of Fine Aggregate For Preparation of Concrete - A ReviewDocument33 pagesSustainable Use of Industrial-Waste As Partial Replacement of Fine Aggregate For Preparation of Concrete - A ReviewMarina Munaretto CopettiNo ratings yet