Professional Documents

Culture Documents

Datasheet For Ball Valve

Datasheet For Ball Valve

Uploaded by

valveOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet For Ball Valve

Datasheet For Ball Valve

Uploaded by

valveCopyright:

Available Formats

GENERAL ENGINEERING SERVICES

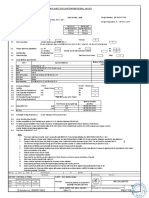

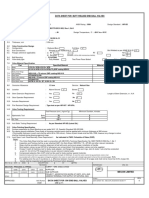

BALL VALVE DATA SHEET PIPE CLASS D1A / D6B PAGE 1 OF 1

DESCRIPTION SPECIFICATION VENDOR'S COMMENTS / DEVIATION

A TAG NO BA-34 VENDOR -

SIZE / QUANTITY 4"-24" (FOR D1B) & 4" -6" (FOR D6B) / AS PER MTO MODEL NO. -

B DESIGN

1 DESIGN SPEC API SPEC 6D / ISO 14313

2 DESIGN SPEC, END FLANGES ASME B16.5 CLASS 600

3 FLANGE FACING AND FINISH RAISED FACE , SMOOTH FINISH,3.2 TO 6.3 MICRON

4 DESIGN SPEC,FACE TO FACE DIM. API SPEC 6D / ASME B16.10 / ISO 14313

5 BODY RATING 600 # ASME B16.34

6 DESIGN CONDITION 1480 Psig @ 100°F, -20°F & 1288 Psig @ 350°F

7 CONSTRUCTION, BODY TWO PIECE/THREE PIECE

8 CONSTRUCTION, MOUNTING OF BALL TRUNNION SUPPORTED BALL BI-DIRECTIONAL

9 TYPE OF BORE REDUCED BORE

10 TYPE OF PATTERN ASME B16.10 LONG

11 GEAR / LEVER OPERATION GEAR OPN. (SEE NOTE-7,8)

12 FIRE SAFE DESIGN REQUIRED (SEE NOTE-8)

13 BLOW OUT PROOF STEM DESIGN REQUIRED (SEE NOTE-8)

REQUIRED ENSURING ELECTRICAL CONTINUITY

14 ANTISTATIC FEATURE

BETWEEN BALL, STEM AND BODY. (SEE NOTE-8)

15 STEM LUBRICATION PROVISION REQUIRED (SEE NOTE-8)

16 VENT AND DRAIN PROVISION REQUIRED (SEE NOTE-8)

17 BODY CAVITY RELIEF REQUIRED (SEE NOTE-6)

16 VENT AND DRAIN PROVISION

1 BODY / BONNET ASTM A 105N / A 216 Gr. WCB

2 TRIM AISI 316

3 STEM ASTM A182 Gr. F316 (NO-CASTING)

4 BALL ONE-PIECE SOLID BALL, ASTM A182 Gr. F316

5 SEAT RINGS ASTM A182 Gr. F316 (SEE NOTE-2,3)

6 SEALS / INSERTS AND RINGS RPTFE / PEEK (SEE NOTE-2)

7 GASKET SS 316 SPIRAL WOUND WITH GRAPHITE FILLER

8 BOLTS & NUTS ASTM A320-L7 / ASTM A194-4

9 SECONDARY SEALS GRAPHITE

10 SPRINGS UNS N07718

INSPECTION & TESTING

D AS PER API 6D /ISO 5208

REQUIREMENTS

TEST DURATIONS API 598 / BS6755 (NOTE -11)

MATERIAL CERTIFICATES AS PER BS EN 10204 - 3.1

TEST CERTIFICATES REQUIRED

FIRE SAFE TEST CERTIFICATION AS PER API 607

E NOTES

VENDOR SHALL FURNISH CROSS SECT. DRAWING SHOWING THE MATERIAL OF CONSTRUCTION FOR EACH

1

COMPONENT OF THE VALVE, AS A PART OF THEIR OFFER.

VENDOR TO CONFIRM SUITABILITY OF MATERIAL FOR PRESSURE-TEMPERATURE RATING FOR HYDROCARBON

2

SERVICE.

ALL MATERIAL USED SHALL BE OF ASTM GRADE ONLY. VENDOR SHALL INDICATE MATERIAL SPECIFICATION AND

3

GRADE IN THE OFFER.

THIS DATA SHEET SHALL BE READ IN CONJUCTION WITH THE REQUIREMENTS STIPULATED

4

5 LO/ LC/ CSO/ CSC REQUIREMENTS SHALL BE AS SPECIFIED IN THE VALVE MTO. (SEE NOTE-9).

FOR TRUNNION MOUNTED BALL VALVES PRESSURE RELIEF FOR BODY CAVITY IS REQUIRED AND SHALL BE IN-

6

BUILT IN THE DESIGN OF SEAT TO RELIEVE TO UPSTREAM SIDE. (SEE NOTE-9).

GEAR BOX OPERATOR SHALL BE SIZED TO PROVIDE AN OUTPUT TORQUE OF AT LEAST 150% OF MAXIMUM

7

REQUIRED VALVE OPERATING TORQUE

8 MAX OPERATING FORCE REQUIRED SHALL NOT EXCEED 350N.

9 VENDOR SHALL PROVIDE REQUIRED COMPLETE DETAILS IN THE OFFER.

VENDOR SHALL CONFIRM COMPLIANCE WITH THE REQUIREMENTS SPECIFIED/ INDICATE SPECIFIC DEVIATIONS IF

10 ANY. THE DATASHEET SHALL BE SIGNED BY THE VENDOR AND HIS SEAL AFFIXED AND SUBMITTED ALONG WITH

THE OFFER.

11 SHELL TEST DURATION SHALL BE MINIMUM 30 MINUTES FOR SIZE 2" AND ABOVE.

12 VALVE MOC TO CONFIRM TO REQUIREMENTS OF NACE MR 01-75/ISO15156

13 TRUNION MOUNTED BALL VALVES TO BE PROVIDED WITH SEALANT INJECTION CONNECTION

F ATTACHMENTS

B 08/07/2021 SSP HAO HAO Final Issue

A 23/02/2016 HAO SSP SSP Final Issue

REV.

DATE PREP. BY CHKD. BY APPD. BY DESCRIPTION

NO.

You might also like

- Geriatric Consideration in NursingDocument31 pagesGeriatric Consideration in NursingBabita Dhruw100% (5)

- AAG Fire Water Cum Foam Monitor 100mmDocument2 pagesAAG Fire Water Cum Foam Monitor 100mmMitul Patel100% (1)

- Ecoline Est 150-600Document21 pagesEcoline Est 150-600Yosses Sang NahkodaNo ratings yet

- Datasheet For Ball Valve123Document1 pageDatasheet For Ball Valve123valveNo ratings yet

- VMS PDFDocument1 pageVMS PDFritoh8657No ratings yet

- Strainer PDFDocument7 pagesStrainer PDFvinoj chandranNo ratings yet

- Valve DatasheetDocument9 pagesValve DatasheetArunkumarNo ratings yet

- VMS - 3Document1 pageVMS - 3ritoh8657No ratings yet

- Ds-pp-0107 - Mechanical Data Sheet For Swivel Joints (Rev.b)Document3 pagesDs-pp-0107 - Mechanical Data Sheet For Swivel Joints (Rev.b)Panisa BanimaNo ratings yet

- Valve Qap - IoclDocument96 pagesValve Qap - Ioclalokgoel_2006No ratings yet

- Tdi 50000 Tpy, GNFCDocument6 pagesTdi 50000 Tpy, GNFCkrunal panchalNo ratings yet

- Tstb-Ifp-40-004-A4 - 0 Ifp For Globe Valve Rev. 0Document8 pagesTstb-Ifp-40-004-A4 - 0 Ifp For Globe Valve Rev. 0agus supriadiNo ratings yet

- IFRVT1Document2 pagesIFRVT1Shilpa SinghNo ratings yet

- Data Sheet 2 Less 800# PV - SW - LT-76Document1 pageData Sheet 2 Less 800# PV - SW - LT-76Sachin KumarNo ratings yet

- Data Sheet For Ball ValveDocument6 pagesData Sheet For Ball ValveTauqueerAhmadNo ratings yet

- VMS - 2Document1 pageVMS - 2ritoh8657No ratings yet

- 19 - PPAG-100-HD-C-001 - s019-0 PDFDocument1 page19 - PPAG-100-HD-C-001 - s019-0 PDFSantiago GarciaNo ratings yet

- Globe Rev. A SHT 1Document1 pageGlobe Rev. A SHT 1Agus SupriadiNo ratings yet

- D 1 1Document956 pagesD 1 1karthi82887100% (1)

- Sample DSDocument1 pageSample DSSachin KumarNo ratings yet

- 13 - PPAG-100-HD-C-001 - s013 (VBA01S020) - 0 PDFDocument1 page13 - PPAG-100-HD-C-001 - s013 (VBA01S020) - 0 PDFSantiago GarciaNo ratings yet

- Specification For Fire Pump - Part 9Document5 pagesSpecification For Fire Pump - Part 9Melisa MackNo ratings yet

- SA 980 P 11430 CS FGD Ball Valve Rev T02Document3 pagesSA 980 P 11430 CS FGD Ball Valve Rev T02altipatlarNo ratings yet

- Data Sheet 2 Less 800# PV - SW - NT-77Document1 pageData Sheet 2 Less 800# PV - SW - NT-77Sachin KumarNo ratings yet

- 12 Valves SpecificationsDocument19 pages12 Valves Specificationsshaliq28100% (1)

- Tstb-Ifp-40-003-A4_0 Ifp for Check Valve Rev. 0Document9 pagesTstb-Ifp-40-003-A4_0 Ifp for Check Valve Rev. 0agus supriadiNo ratings yet

- CORROSION COUPON AT AR 701 Project Description ADocument2 pagesCORROSION COUPON AT AR 701 Project Description AKian GancangNo ratings yet

- Data Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFDocument1 pageData Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFSachin KumarNo ratings yet

- Cs Ball Valve 600#Document4 pagesCs Ball Valve 600#Vijay GaikwadNo ratings yet

- EHK-IKPP-IS-DTS-005 Datasheet For Pressure Safety Valve Rev 2Document7 pagesEHK-IKPP-IS-DTS-005 Datasheet For Pressure Safety Valve Rev 2nathaNo ratings yet

- A. BALL - FloatingDocument3 pagesA. BALL - FloatingSaputraNo ratings yet

- Globe Rev. A SHT 2Document1 pageGlobe Rev. A SHT 2Agus SupriadiNo ratings yet

- VB71 ValveDocument1 pageVB71 Valvescribd_thakurNo ratings yet

- Pwcc-372-Ri-C-1006-A 28Document1 pagePwcc-372-Ri-C-1006-A 28Manolo MontalvanNo ratings yet

- Datasheet Valve ПДНГ 0440 22Document3 pagesDatasheet Valve ПДНГ 0440 22Ngoc Huyen NguyenNo ratings yet

- PCSE 100 HD C 001 - 0 - s001Document1 pagePCSE 100 HD C 001 - 0 - s001tedaguacalidadNo ratings yet

- VMS - 5Document1 pageVMS - 5ritoh8657No ratings yet

- DataSheet 2 More 300# BV - FB - BW - NT-77 PDFDocument1 pageDataSheet 2 More 300# BV - FB - BW - NT-77 PDFSachin KumarNo ratings yet

- Gate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDocument1 pageGate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDIPANKAR LALANo ratings yet

- Valve Data SheetsDocument17 pagesValve Data Sheetszaldy1985No ratings yet

- Technical Notes and Specifications Part CDocument29 pagesTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- 72400726-DS-002 Rev 0Document8 pages72400726-DS-002 Rev 0prabakaran365No ratings yet

- API 6D Wafer Style Dual Plate Check Valves: Fig No: MV-1220Document15 pagesAPI 6D Wafer Style Dual Plate Check Valves: Fig No: MV-1220VIVEK TIWARINo ratings yet

- 12 - PPAG-100-HD-C-001 - s012 (VBA01S019) - 0 PDFDocument1 page12 - PPAG-100-HD-C-001 - s012 (VBA01S019) - 0 PDFSantiago GarciaNo ratings yet

- DATA SHEET MTO # 1 (ITEM # 13) Data Sheet-8 Inch To 24 Inch Size-Reduced Port-Double Block Bleed-Gear OperatedDocument1 pageDATA SHEET MTO # 1 (ITEM # 13) Data Sheet-8 Inch To 24 Inch Size-Reduced Port-Double Block Bleed-Gear OperatedQualival EgyptNo ratings yet

- 18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFDocument1 page18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFSantiago GarciaNo ratings yet

- Data Sheet UbsvDocument6 pagesData Sheet UbsvMeet JaniNo ratings yet

- Globe Valve Specification Manuf'S OfferDocument1 pageGlobe Valve Specification Manuf'S OfferAakash KumarNo ratings yet

- Check ValveDocument1 pageCheck ValveRoshanKuckianNo ratings yet

- 1664189682389-2ba010110 Cced25030Document1 page1664189682389-2ba010110 Cced25030ylc956867No ratings yet

- Valve Data Sheet - Gate Valve: Colves Fluid Control S.R.LDocument1 pageValve Data Sheet - Gate Valve: Colves Fluid Control S.R.LMohamed gaballa SaidNo ratings yet

- Datasheet CHK VLV (14in #150)Document1 pageDatasheet CHK VLV (14in #150)chintanNo ratings yet

- 150# Cs Ball Valve Datasheet: GeneralDocument3 pages150# Cs Ball Valve Datasheet: GeneralVijay GaikwadNo ratings yet

- Gate Valve SpecsDocument2 pagesGate Valve SpecsTauqueerAhmadNo ratings yet

- WAGP-1-PAR-9A-M-SAS-99-0013 Hydrocarbs 2500 ANSI F1Document5 pagesWAGP-1-PAR-9A-M-SAS-99-0013 Hydrocarbs 2500 ANSI F1tope odumboniNo ratings yet

- 25 7731564081 PDFDocument2 pages25 7731564081 PDFbsnegi111No ratings yet

- FU01-S01-02-005-01 Pipe Spec CS22Document8 pagesFU01-S01-02-005-01 Pipe Spec CS22Javed NasirNo ratings yet

- OB32LN-15 Part List PDFDocument16 pagesOB32LN-15 Part List PDFpurchase sigmaairsourceNo ratings yet

- Sample DS-1Document1 pageSample DS-1Sachin KumarNo ratings yet

- Ss Globe Valve 150# - 1Document1 pageSs Globe Valve 150# - 1Vijay GaikwadNo ratings yet

- combinepdf (9)Document3 pagescombinepdf (9)valveNo ratings yet

- C 60 s33Document1 pageC 60 s33valveNo ratings yet

- Specification Main PartsDocument8 pagesSpecification Main PartsvalveNo ratings yet

- Datasheet For Ball Valve123Document1 pageDatasheet For Ball Valve123valveNo ratings yet

- MTR DDD230043635 62 107 01 CF8MDocument1 pageMTR DDD230043635 62 107 01 CF8MvalveNo ratings yet

- The Holy Spirit: A New LifeDocument2 pagesThe Holy Spirit: A New LifeKatu2010No ratings yet

- Offer For C Check On NT-495-MG Harbour Generator Engine Against Customer Job No. E20006Document1 pageOffer For C Check On NT-495-MG Harbour Generator Engine Against Customer Job No. E20006bkrNo ratings yet

- Informe Sobre El Manejo de CostasDocument88 pagesInforme Sobre El Manejo de CostasMetro Puerto RicoNo ratings yet

- Roadmgraybox Ds Oc AeDocument6 pagesRoadmgraybox Ds Oc Aemcclaink06No ratings yet

- Alarm Security Pic - Google ShoppingDocument1 pageAlarm Security Pic - Google Shoppingleeleeleebc123No ratings yet

- Cara Instal SeadasDocument7 pagesCara Instal SeadasIndah KurniawatiNo ratings yet

- A Study On Financial Performance of Selected Public and Private Sector Banks - A Comparative AnalysisDocument3 pagesA Study On Financial Performance of Selected Public and Private Sector Banks - A Comparative AnalysisVarun NagarNo ratings yet

- Software Engineering. Specification, Implementation, VerificationDocument186 pagesSoftware Engineering. Specification, Implementation, Verificationazariel.rodrigo100% (1)

- Essay Wise ChildrenDocument2 pagesEssay Wise ChildrenCarolina MariangelesNo ratings yet

- A 182Document20 pagesA 182Thomas100% (1)

- MC&OB Unit 4Document17 pagesMC&OB Unit 4Tanya MalviyaNo ratings yet

- Eastron Electronic Co., LTDDocument2 pagesEastron Electronic Co., LTDasd qweNo ratings yet

- GDPR ReportDocument84 pagesGDPR ReportKingPlaysNo ratings yet

- HSC 11 Scalars and Vectors Ch2Document5 pagesHSC 11 Scalars and Vectors Ch2Snehal PanchalNo ratings yet

- Teaching Language-Learning StrategiesDocument6 pagesTeaching Language-Learning StrategiesviviNo ratings yet

- GenMath Module 5 Week 5Document15 pagesGenMath Module 5 Week 5Immanuel CañecaNo ratings yet

- Bydf3 ElectricDocument61 pagesBydf3 ElectricIvan Avila100% (1)

- Dbms Lab Dbms Lab: 23 March 202Document12 pagesDbms Lab Dbms Lab: 23 March 202LOVISH bansalNo ratings yet

- Inactive Volcanoes in The Philippine SDocument6 pagesInactive Volcanoes in The Philippine SChristian ParadoNo ratings yet

- Ascariasis Ada GambarDocument4 pagesAscariasis Ada GambarninaNo ratings yet

- Teachers' Interview PDFDocument38 pagesTeachers' Interview PDFlalitNo ratings yet

- Jadwal Pertandingan Liga Inggris 2009-2010Document11 pagesJadwal Pertandingan Liga Inggris 2009-2010Adjie SatryoNo ratings yet

- US Gasification DatabaseDocument9 pagesUS Gasification DatabaseAhmad DaoodNo ratings yet

- Sustainable Consumption Production in India - AnalysisDocument8 pagesSustainable Consumption Production in India - Analysisanon_794541559No ratings yet

- Laboratory For Energy and The Environment: HighlightsDocument14 pagesLaboratory For Energy and The Environment: HighlightsZewdu TsegayeNo ratings yet

- BlueStack Platform Marketing PlanDocument10 pagesBlueStack Platform Marketing PlanFıratcan KütükNo ratings yet

- Naamlp 2002 ProceedDocument578 pagesNaamlp 2002 ProceedRussell HartillNo ratings yet

- Arlegui Seminar RoomDocument1 pageArlegui Seminar RoomGEMMA PEPITONo ratings yet

- The Price of SilenceDocument9 pagesThe Price of Silencewamu885100% (1)