Professional Documents

Culture Documents

Audit Prioritization Number

Audit Prioritization Number

Uploaded by

Brahmananda ChakrabortyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Audit Prioritization Number

Audit Prioritization Number

Uploaded by

Brahmananda ChakrabortyCopyright:

Available Formats

Document: Document #: Revision: 1.

0

Audit Prioritization Number (APN)

Calculation EMEAI-PUR-WI-0008

1. Purpose

This document describes responsibilities and step by step process of Audit Prioritization

Number (APN) calculation and supplier evaluations.

2. Scope

EMEAI Beckman Coulter Commercial Operations suppliers with quality impact used by

Beckman Coulter Dx & LS associates.

3. Definitions

Terms Definition

APN Audit Prioritization Number

Business impact is based upon the BEC revenue impact that the

Business impact supplier would create in case of a supply disruption and inability

to deliver products

Europe, METAM, India

EMEAI

METAM: Turkey, Russia, South Africa, Saudi Arabia

Availability and restrictions of the product / service from suppliers

Source restriction:

like sole, single and multi-sourced

Sole source of product(s) are not available by other approved

Sole

supplier (Intellectual Property, design, or other limitations)

Single source of products are those items which are only source

Single from one approved supplier, but we can sourced from another

supplier, which has not been qualified yet

Multi-sourced products are and can be source from other

Multi-sourced

suppliers in approved supply base

4. Roles and Responsibilities

Role Responsibility

Kick off APN Calculation process, preparation of the supplier list,

providing required data to Local Quality

Complete APN Calculation templates (GLB-QS-TMP-0148 and

GLB-QS-TMP-0049)

Support Local Quality team for APN Calculation process

Prepare of Annual Supplier Audit Schedule

EMEAI Supplier Share the audit / assessment schedule with the Global Supplier

Quality Quality team to adjust the local and European audits with global

actions

Ensure timely completion of APN Calculation process and actions

in the annual audit schedule

Act as a Local Quality if supplier is approved for multiple countries

Review the data in APN Calculation Templates, collect required

Local Quality data and complete APN Calculation process for suppliers

approved for countries under their responsibilities

Provide input to Local Quality for business impact analysis in APN

Procurement

Calculation

Page 1 of 13

Company Confidential, not for external distribution

Confidential - Company Proprietary

Document: Document #: Revision: 1.0

Audit Prioritization Number (APN)

Calculation EMEAI-PUR-WI-0008

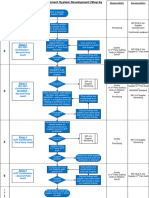

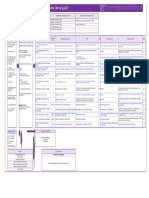

5. APN Calculation Steps

APN Calculation process starts at the beginning of Q2 and finish by end of Q4 each year. As

a result of APN Calculation, annual audit schedule is prepared. Annual audit schedule can

contain remediation activities.

Year N Q2-Q3 Year N Q4 Year N+1 Q1-Q3

Supplier lists APN APN

cleaning Calculation calculation

actions: audits

schedules,

remédiations

activities,...

5.1 Cleaning of Supplier List (1st step: Q2 & Q3 of the year N)

a. EMEAI QA Supplier Management team

- Run OBI report (Purchasing – Supplier Yearly Overview) to identify suppliers with no

active business in the last 2 years.

- Extract the list of conditionally approved suppliers (last 1 year) from the Supplier

Management SharePoint / ASL / ASPL.

- Combine these two files to prepare the list with suppliers suggested for inactivation.

- Share the list with suggested suppliers with local QA representatives.

b. Local QA representatives

- Provide feedback about inactivation decision.

- Complete the form EMEAI-PUR-TMP-0003 and send to the mailbox

eusupplierqa@beckman.com within one month.

c. EMEAI QA Supplier Management team

- Inactivate the designed suppliers following the section 5.3 of EMEAI-PUR-PCD-0001.

- Inactivation should be done by the end of Q3. Suppliers not inactivated by end of Q3, will

be included in APN Calculation Process.

5.2 APN Calculation (2nd step: Q4 of the year N)

5.2.1 Preparation of Supplier List with Required Information

a. EMEAI QA Supplier Management team:

- Prepare one list of service providers for the APN calculation assessment using GLB-QS-

TMP-0148 Service Provider Re-Evaluation Tool.

- Prepare one list of material providers for APN calculation assessment using GLB-QS-

TMP-0049.

- The list contains Supplier Oracle number, supplier legal name, location, category,

supplier last audit date / self-assessment date, number of SCARs, supplier status.

Page 2 of 13

Company Confidential, not for external distribution

Confidential - Company Proprietary

Document: Document #: Revision: 1.0

Audit Prioritization Number (APN)

Calculation EMEAI-PUR-WI-0008

- For extracting the complete list of suppliers from the SP, use ExportPart1 (first 5000

suppliers) and ExportPart2 (newly created suppliers):

NOTE: Follow the supplier category & periodicity of assessment as described in the

EMEAI-PUR-PCD-0001.

- Organize yearly Kick-off meeting and training session with local QA representatives

providing the information about the category selection and the timelines.

5.2.2 Supplier Information Review

a. Local QA representatives

- Verify the accuracy of information prepared by EMEAI supplier quality team in GLB-QS-

TMP-0148 and GLB-QS-TMP-0049.

- If any of the information is not correct, provide the right information in the comment

section & do the remediation.

- In case the Oracle data is incorrect, like legal supplier name, several Oracle numbers for

the same suppliers, duplications, etc.:

o Update the APN file with correct information in the Comment section

o Continue with the APN Calculation

- In case the category is incorrect

o Update the APN file with correct category in the Comment section

In case the correct category is in scope of the APN calculation continue with the

APN Calculation

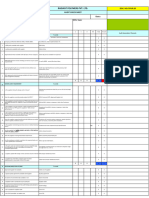

5.2.3 APN Calculation / Re-evaluation Templates

a. Local QA representatives

Material supplier (GLB-QS-TMP-0049) Service provider (GLB-QS-TMP-0148)

5.2.3.1 Calculate the Beckman Product risk

Material Supplier Enter the

category following number

CAT 1 3 Not applicable for service providers

CAT 2 2

CAT 3, 4 & 5 1

Page 3 of 13

Company Confidential, not for external distribution

Confidential - Company Proprietary

Document: Document #: Revision: 1.0

Audit Prioritization Number (APN)

Calculation EMEAI-PUR-WI-0008

Material supplier (GLB-QS-TMP-0049) Service provider (GLB-QS-TMP-0148)

5.2.3.2 Evaluation of Business risk

Local Quality contacts with the local The local QA representative contacts with

procurement, strategic procurement or finance the local procurement, applicable

team to have the information for the Business stakeholders to:

risk assessment. o evaluate if the supplier is the sole/single

or multisource supplier.

Additional methods to determine business risk is o if an agreement is signed with the

available in Annex- 1 supplier.

o if the supplier is used locally or by

Business Unit, or globally.

For SP-APN Calculation For SP-APN Calculation

Business Risk ≤ 2.0 use 1-LOW Business Risk ≤ 2.0 use 1-LOW

Business Risk = 2.1-4.0 use 2-MEDIUM Business Risk = 2.1-4.0 use 2-MEDIUM

Business Risk = 4.1-6.0 use 3-HIGH Business Risk = 4.1-6.0 use 3-HIGH

SOURCE SOURCE

BUSINESS IMPACT D & B SCORE BUSINESS IMPACT Service Agreement

RESTRICTION RESTRICTION

Option Score Option Score Option Score Option Score Option Score Option Score

MULTI No Service

< 10% 1 1 1-3 1 MULTI

SOURCED < 10% 1 1 Agreement 1

SOURCED

10 - 30% 3 SINGLE 3 4-6 3 required

> 30% 6 SOLE 6 7-9 6 Active

10 - 30% 3 SINGLE 3 Service 3

Agreement

Expired

> 30% 6 SOLE 6 Service 6

Agreement

ASSESSMENT SCORING

WEIGHTING ASSESSMENT SCORING

CRITERIA 1 3 6 WEIGHTING

CRITERIA 1 3 6

BUSINESS

< 10% 10 - 30% > 30% 30% BUSINESS Business

IMPACT Local Global 30%

SOURCE MULTI IMPACT Unit

SINGLE SOLE 30% SOURCE MULTI

RESTRICTION SOURCED SINGLE SOLE 30%

D & B SCORE 1-3 4-6 7-9 40% RESTRICTION SOURCED

No

Active

Service Expired

SERVICE Service

Agreeme Service 40%

AGREEMENT Agreeme

nt Agreement

nt

required

5.2.3.3 Evaluation of Quality risk

Quality Risk is calculated based on three inputs: For service Supplier, the status of the

Supplier Status, FA Number and SCAR supplier conditional approved or approved

Number. is verified by Local QA representatives.

Complete the calculations as described below for

the Supplier Status, FA Number and SCAR

number, and select the highest received score

(number) to calculate the Quality Risk.

The status of the supplier conditional approved or

approved on the Supplier Share point or

ASL/ASPL is verified by Local Quality

Page 4 of 13

Company Confidential, not for external distribution

Confidential - Company Proprietary

Document: Document #: Revision: 1.0

Audit Prioritization Number (APN)

Calculation EMEAI-PUR-WI-0008

Material supplier (GLB-QS-TMP-0049) Service provider (GLB-QS-TMP-0148)

Service Performance: Acceptable or

Material Supplier Enter the following Unacceptable

status number - Acceptable Performance if ≤ 1 SCARs and

0 Field Action / Quality Stop Ship

Conditionally - Unacceptable Performance if ≥ 2 SCARs,

3

approved or ≥ 1 Field Action / Quality Stop Ship, or

per discretion/documentation of originator

Approved 1

o Field actions can be obtained with reports from

BEC FA share point (and selection of for BU:

Pass-through) (Annex 2: How to Extract Field

Action Report from BEC FA Application) and / or

from Field Action Coordinator

Note: The field action related manufacturer out

of EMEAI should not be considered. The field

action related Manufacturer of EMEAI &

Distributors should be incorporated to the

calculation.

Material

Enter the following

Supplier FA

number

Number

≥5 3

3 to 4 2

≤2 1

o # of SCARs and score provided by EMEAI

o # of SCARs and score provided by EMEAI

Supplier Quality is verified by Local Quality

Supplier Quality is verified by Local Quality

Material

Supplier SCAR Enter the following number Service

Enter the following

Number Supplier SCAR

number

Number

≥2 3

Unacceptable

≥1 2 ≥2

performance

0 1 ≤1 Acceptable performance

The highest score from Status, # of FA and #

SCARs is used for APN calculation (e.g. the number

from status is 1, from FA also 1 and from SCAR is 3,

put 3 in APN calculation sheet).

Page 5 of 13

Company Confidential, not for external distribution

Confidential - Company Proprietary

Document: Document #: Revision: 1.0

Audit Prioritization Number (APN)

Calculation EMEAI-PUR-WI-0008

Material supplier (GLB-QS-TMP-0049) Service provider (GLB-QS-TMP-0148)

5.2.3.4 Supplier audit information

Last audit /assessment date is verified by Local Quality.

Date of the last audit /assessment available on the Supplier Management SharePoint / ASL / ASPL

Material/Service Supplier last

Enter the following number

audit timeline

>5 3

Between 3 to 5 years 2

<3 years 1

- Complete the Excel file for APN calculation provided by the EMEAI Supplier QA team on the

Supplier Management SharePoint and send it to eusupplierqa@beckman.com.

5.2.4 Consolidation of the APN Calculation / Re-evaluation

a) EMEAI QA Supplier Management team:

- Consolidate all the APN Calculation inputs from Local Quality, Procurement and finalize

APN Calculation Process.

- Confirm the Evaluation Score based on the supplier APN calculation.

- Record the action to be performed in the APN Calculation tab, including justifications if

actions differ from the recommendations.

- Route final evaluation for approval to management of Supplier Quality and Procurement

5.3 Preparation of Annual Audit / Assessment Schedule

a) EMEAI QA Supplier Management team:

- Prepare the audit / assessment schedule upon APN Calculation analysis. On site audits,

self-assessments are added to the audit schedule. Even if there is no recommended

action, if supplier category is not correct or remediation is needed due to missing

document etc. , remediation actions are also added to the supplier audit schedule.

NOTE: To be inactivated material and service providers should not be included in the audit

schedule.

- Share the audit / assessment schedule with the Global Supplier Quality team to adjust

the local and European audits with global actions planned. (objective do not perform

audit locally if it’s planned globally)

- If the assessment score is “on site audit” for the distributor of the manufacturer due to

number of Field Actions, manufacturer can be added to the audit plan and action is

cancelled for supplier.

- Share the final schedule with local QA Representatives

Page 6 of 13

Company Confidential, not for external distribution

Confidential - Company Proprietary

Document: Document #: Revision: 1.0

Audit Prioritization Number (APN)

Calculation EMEAI-PUR-WI-0008

b. Local QA representative & EMEAI QA Supplier Management team:

- Define scheduled date of the audit / assessment including Lead Auditor within max 1

month.

5.4 Performing APN Calculation Actions 3rd step: Q1 of the year N+1

a. Local QA representative & EMEAI QA Supplier Management team:

- Proceed with the activities: Audit / assessment and remediations.

- Update the Supplier Management SharePoint and ASL/ASPL with the date of the last

audit / assessment and add the documents to the supplier folder in the share point: audit

reports/assessments to have the traceability.

Concept of Practice

If supplier sends a copy of their 3rd party (Accredited Certified Body) audit report completed

in last 6 months, onsite audit action can be closed. There is no need for Beckman to conduct

an onsite audit of the supplier at this time.

In case supplier refuses to share the 3rd party audit report then proceed with onsite audit

plan.

On site/ virtual audits and self-assessments are conducted per GLB-QS-PCD-0008 Supplier

Quality Audit Method

6 Records and Retention

Documents have to be kept according to corporate procedure Quality Records

Management GLB-QS-PCD-0060.

7 References

6.1 External References

GLB-QRA-REF-0002 External References

6.2 Parent Document

EMEAI-PUR-PCD-0001 EMEAI Supplier Quality Management for Commercial

Operations

6.3 Internal References

GLB-QS-TMP-0148 (Service provider)

GLB-QS-TMP-0049 (Material supplier)

GLB-QS-PCD-0008 Supplier Quality Audit Method

6.4 Tools

Supplier Management Sharepoint

Danaherprocurement.com

ASL & ASPL

BEC FA - PowerApps

Page 7 of 13

Company Confidential, not for external distribution

Confidential - Company Proprietary

Document: Document #: Revision: 1.0

Audit Prioritization Number (APN)

Calculation EMEAI-PUR-WI-0008

8 Appendix

Annex 1 : Additional methods to determine business risk

Annex 2: How to Extract Field Action Report from BEC FA Application

Page 8 of 13

Company Confidential, not for external distribution

Confidential - Company Proprietary

Document: Document #: Revision: 1.0

Audit Prioritization Number (APN)

Calculation EMEAI-PUR-WI-0008

ANNEX 1 - Additional Methods To Determine Business Risk

Information is found on Danaherprocurement.com. If the supplier is not found on

Danaherprocurement.com, consider it as number 1

1. Log onto www.danaherprocurement.com and extract supplier data per Workday training titled

"Supply Chain Risk Management – Digital”

2. Locate supplier on extracted spreadsheet by finding supplier's name per global approved

supplier list. If supplier cannot be located, review for alternative supplier names and

spellings.

3. Identify and document each supplier's business risk score. No additional calculation required

because Danaher business risk score is the same formula as Beckman APN definition.

4. If supplier cannot be located on the extracted dataset from www.danaherprocurement.com,

then the supplier is considered to have had no purchasing activity in last 24 months.

5. For suppliers that have not been used in last 24 months, the business risk may be

documented as a score of 1 since the supplier had no impact to Beckman Coulter revenue

or business continuity

ANNEX 2: How to Extract Field Action Report from BEC FA Application

1. Open the FA Application BEC FA - PowerApps

2. Open the Reports: Click on the button on left corner, then click on the “Reports”

Page 9 of 13

Company Confidential, not for external distribution

Confidential - Company Proprietary

Document: Document #: Revision: 1.0

Audit Prioritization Number (APN)

Calculation EMEAI-PUR-WI-0008

3. Sign in Power BI

4. Filter Pass Through Field Actions in “General” Tab. And extract the report by following 3

steps shown in the figure below

Page 10 of 13

Company Confidential, not for external distribution

Confidential - Company Proprietary

Document: Document #: Revision: 1.0

Audit Prioritization Number (APN)

Calculation EMEAI-PUR-WI-0008

a. In General tab; impacted cluster, manufacturer name, Part number & description,

lot number, FA Coordinator name, whether the issue is known or suspected to be

Supplier related information is available

b. Filter Country Cluster “EU, METAM, ROSA, EAO”

c. Requested Review Date and FA SC Decision Date should be checked before

filter per APN Calculation evaluation period

5. Go to Country List to see impacted countries in the cluster.

Page 11 of 13

Company Confidential, not for external distribution

Confidential - Company Proprietary

Document: Document #: Revision: 1.0

Audit Prioritization Number (APN)

Calculation EMEAI-PUR-WI-0008

6. Identify suppliers impacted in ASL & ASPL and Supplier Management Sharepoint

a. Part number

b. Manufacturer name

c. Impacted Countries

d. Confirm the reason of the FA. Check Issue/ Event Brief Description of Issue

Page 12 of 13

Company Confidential, not for external distribution

Confidential - Company Proprietary

Document: Document #: Revision: 1.0

Audit Prioritization Number (APN)

Calculation EMEAI-PUR-WI-0008

7 Change Control

SUMMARY OF CHANGE:

Initial release.

SECTION # REASON FOR CHANGE / OBSOLESCENCE

Throughout Initial release.

TRAINING REQUIREMENT

✘ Training is required for this revision.

✘ Initial release

Remediation training

Change affects process

Training is not required for this revision.

Change does not affect process

Obsolescence

Training is not required for this document type.

IMPACT ASSESSMENT

Evaluate any IMPLEMENTATION PROCESS IMPACT

interrelated QMS and/or Update EMEAI-PUR-PCD-0001 EMEAI Supplier Quality Management for

Business processes to Commercial Operations

determine if changes

are required. If yes, list IMPLEMENTATION PLAN

affected documents. If Update EMEAI-PUR-PCD-0001 EMEAI Supplier Quality Management for

no, indicate no impact. Commercial Operations

Page 13 of 13

Company Confidential, not for external distribution

Confidential - Company Proprietary

You might also like

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionFrom EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionRating: 4.5 out of 5 stars4.5/5 (10)

- Turgeon - Hematology Study QuestionsDocument65 pagesTurgeon - Hematology Study QuestionsGertrudeshane IletoNo ratings yet

- APQP ProcedureDocument9 pagesAPQP ProcedurePk Nimiwal100% (5)

- Fs - Evilla, E. (Vertam Farms Opc) 2020Document44 pagesFs - Evilla, E. (Vertam Farms Opc) 2020Ma Teresa B. Cerezo100% (2)

- 29.00.00004 28-JUN-2019 21-JAN-2021 Open A318, A319, A320, A321 29-00 UpdateDocument26 pages29.00.00004 28-JUN-2019 21-JAN-2021 Open A318, A319, A320, A321 29-00 Updatesaid PalaoNo ratings yet

- 0703 Vendor Selection & ControlDocument13 pages0703 Vendor Selection & ControlSundara Rajan RamakrishnanNo ratings yet

- Supplier Quality DMR and PPM ProcedureDocument5 pagesSupplier Quality DMR and PPM ProcedureYoohyun LeeNo ratings yet

- 19 Purchasing ProcedureDocument7 pages19 Purchasing ProcedureSasi KssNo ratings yet

- QMS-4 Api Q2 For The Petroleum Natural Gas Industry - Bryan Wollam PDFDocument35 pagesQMS-4 Api Q2 For The Petroleum Natural Gas Industry - Bryan Wollam PDFIan Kevin100% (1)

- P-01 Quality Assurance ProcedureDocument26 pagesP-01 Quality Assurance Proceduresharif1974No ratings yet

- New Supplier Survey FormDocument14 pagesNew Supplier Survey Formsutharitessh100% (1)

- QM 8 - Section 8.Document31 pagesQM 8 - Section 8.cghodake1No ratings yet

- Supplier Quality System Audit Report: Quanta Computer IncDocument78 pagesSupplier Quality System Audit Report: Quanta Computer IncVanessa MansurNo ratings yet

- F19 FSMS 2018 Stage 1Document6 pagesF19 FSMS 2018 Stage 1ISO board QS GroupNo ratings yet

- Supplier Evaluation For It SMSDocument4 pagesSupplier Evaluation For It SMSAnkurNo ratings yet

- 11) External Provided Processes - Purchasing Process-6Document7 pages11) External Provided Processes - Purchasing Process-6Sagar DaundNo ratings yet

- Form 1315 Preliminary EvaluationDocument27 pagesForm 1315 Preliminary EvaluationMakeshNo ratings yet

- As Is Vendor TPMDocument3 pagesAs Is Vendor TPMabhijitgharatNo ratings yet

- Cara ReportDocument25 pagesCara ReportSurendharNo ratings yet

- Malpani Alloy & Extrusions PVT LTD QSP - 02: 1.0 PurposeDocument4 pagesMalpani Alloy & Extrusions PVT LTD QSP - 02: 1.0 PurposeANBUNo ratings yet

- Waterville TG Inc.: Purchasing GroupDocument35 pagesWaterville TG Inc.: Purchasing GroupShahnawaz PathanNo ratings yet

- Supplier Manual TribarDocument17 pagesSupplier Manual TribarAvyan Kelan100% (1)

- 13.1 PURCHASE PROCEDURE - Updated 07.01.2021Document7 pages13.1 PURCHASE PROCEDURE - Updated 07.01.2021cghodake1No ratings yet

- 11) QAP - External Provided Processes - Purchasing ProcessDocument7 pages11) QAP - External Provided Processes - Purchasing ProcessSagar DaundNo ratings yet

- Working STNDDocument4 pagesWorking STNDvekas bhatiaNo ratings yet

- CBC-TM-PM-02 - Corrective Action ProcedureDocument3 pagesCBC-TM-PM-02 - Corrective Action ProcedureJonnel CatadmanNo ratings yet

- Bureau Veritas Certification Management System Certification Audit Report For The Initial Audit of RENA Technical Services Co. Agency :689Document8 pagesBureau Veritas Certification Management System Certification Audit Report For The Initial Audit of RENA Technical Services Co. Agency :689SAEEDNo ratings yet

- Steel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Internal Quality AuditDocument2 pagesSteel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Internal Quality AuditmahendraNo ratings yet

- Rediant-Supplier Audit Check Sheet RevisedDocument8 pagesRediant-Supplier Audit Check Sheet RevisedRohit TripathiNo ratings yet

- Activating Source Inspection For Externally Procured PartsDocument16 pagesActivating Source Inspection For Externally Procured PartsAnonymous MeeBXp4fINo ratings yet

- QSP 05 Internal AuditsDocument7 pagesQSP 05 Internal Auditskmvimal36No ratings yet

- Vendor Assessment - Self AssessmentDocument10 pagesVendor Assessment - Self Assessmentjennice18No ratings yet

- APPENDIX C PEAR - Purchasing ExampleDocument2 pagesAPPENDIX C PEAR - Purchasing Examplefelicita16No ratings yet

- QSP 07 CAPA Rev 1Document4 pagesQSP 07 CAPA Rev 1kmvimal36No ratings yet

- GR Power Switchgear Limited: Quality System Management ISO 9001:2015Document5 pagesGR Power Switchgear Limited: Quality System Management ISO 9001:2015G RajasekharNo ratings yet

- QSP 05 Internal Audits REV 1Document7 pagesQSP 05 Internal Audits REV 1kmvimal36No ratings yet

- FM 198 Q1 ISO 9001 Audit Report Form Revision 7 20210803Document17 pagesFM 198 Q1 ISO 9001 Audit Report Form Revision 7 20210803Supriya GothwalNo ratings yet

- Procedure (English)Document13 pagesProcedure (English)Phu ThanhNo ratings yet

- 08.03.07 - Internal Quality Audit-R1Document5 pages08.03.07 - Internal Quality Audit-R1tanmayascribdNo ratings yet

- Customer-Specific Requirements: For Use With ISO/TS 16949 Second Edition March 2012Document4 pagesCustomer-Specific Requirements: For Use With ISO/TS 16949 Second Edition March 2012befoaNo ratings yet

- Audit Report FormDocument18 pagesAudit Report Formmngmnt.repNo ratings yet

- 1+checklistDocument193 pages1+checklistbennacer.mansourNo ratings yet

- 2018HB74037 - QMS - Assignment 1 PDFDocument7 pages2018HB74037 - QMS - Assignment 1 PDFBhagyashree ChouhanNo ratings yet

- AUDIT Year Wise RTP Compilation 2015 Dec To 2021 DecDocument330 pagesAUDIT Year Wise RTP Compilation 2015 Dec To 2021 Decmeme.arena786No ratings yet

- 32) Sap MM SopDocument38 pages32) Sap MM SopSagar DaundNo ratings yet

- CQI 19 Supplier Assessment - GF SPR 21.7Document9 pagesCQI 19 Supplier Assessment - GF SPR 21.7nitinNo ratings yet

- Vendor RegistrationDocument31 pagesVendor RegistrationShailesh kumarNo ratings yet

- WP PUR PRO 003 Supplier QMS DevelopmentDocument1 pageWP PUR PRO 003 Supplier QMS DevelopmentdhuntNo ratings yet

- SOP 2 (Supplier Approval)Document18 pagesSOP 2 (Supplier Approval)Prince MoniNo ratings yet

- Audit Reprot - MK Lide - 2019Document9 pagesAudit Reprot - MK Lide - 2019Abhishek Sharma100% (1)

- Vendor Registration Sop Ver 2.2Document33 pagesVendor Registration Sop Ver 2.2Ayaskant KanungoNo ratings yet

- IT Audit CH 3Document5 pagesIT Audit CH 3JC MoralesNo ratings yet

- QMS 04 A Interested Parties FreeDocument5 pagesQMS 04 A Interested Parties FreeLisardo ConstelaNo ratings yet

- Ac7108 Rev e NadcapDocument73 pagesAc7108 Rev e NadcapJose LuisNo ratings yet

- Supplier Quality Assurance Manual: Special Devices, Incorporated Daicel Safety Systems America Arizona, IncDocument14 pagesSupplier Quality Assurance Manual: Special Devices, Incorporated Daicel Safety Systems America Arizona, IncJeelanNo ratings yet

- Department: Auditor: Auditee:: Date: Shift &time: Sr. No Audit Point Yes / No Evidence Sighted StatusDocument2 pagesDepartment: Auditor: Auditee:: Date: Shift &time: Sr. No Audit Point Yes / No Evidence Sighted StatusAnkit SainiNo ratings yet

- Title: Halliburton Management System FO-GL-HAL-SCQ-703A-3 Area: Function/PSL: Owner: Approved By: Job Revision By: Rev NoDocument6 pagesTitle: Halliburton Management System FO-GL-HAL-SCQ-703A-3 Area: Function/PSL: Owner: Approved By: Job Revision By: Rev NoJuan G Cleves ANo ratings yet

- Audit & Assurance: Suggested AnswersDocument9 pagesAudit & Assurance: Suggested AnswersMuhammad HussainNo ratings yet

- PSIPL-PUR-06Supplier Evaluation - FormatDocument6 pagesPSIPL-PUR-06Supplier Evaluation - Formatcghodake1No ratings yet

- Training Manual Materials Management TMM - 12 - Vendor EvaluationDocument11 pagesTraining Manual Materials Management TMM - 12 - Vendor Evaluationganesha.trengginas GENESISNo ratings yet

- FRM-0005-R5 2017 01 18Document36 pagesFRM-0005-R5 2017 01 18dyolotzinNo ratings yet

- Needs and Expectations, Turtle ChartDocument1 pageNeeds and Expectations, Turtle ChartCHANDRUNo ratings yet

- Wiley CMAexcel Learning System Exam Review 2017: Part 1, Financial Reporting, Planning, Performance, and Control (1-year access)From EverandWiley CMAexcel Learning System Exam Review 2017: Part 1, Financial Reporting, Planning, Performance, and Control (1-year access)No ratings yet

- Laptop VerDocument1 pageLaptop VerBrahmananda ChakrabortyNo ratings yet

- MS4 Error MessagesDocument5 pagesMS4 Error MessagesBrahmananda ChakrabortyNo ratings yet

- Case 5 Workbook and DiscussionDocument14 pagesCase 5 Workbook and DiscussionBrahmananda ChakrabortyNo ratings yet

- Printer InfoDocument1 pagePrinter InfoBrahmananda ChakrabortyNo ratings yet

- MS4 Certification - Verification ProcedureDocument4 pagesMS4 Certification - Verification ProcedureBrahmananda ChakrabortyNo ratings yet

- MS3-MS4 Small and Large Aperture Additional TechniquesDocument5 pagesMS3-MS4 Small and Large Aperture Additional TechniquesBrahmananda ChakrabortyNo ratings yet

- B23942ab Ms4e V-Check Review OnlyDocument78 pagesB23942ab Ms4e V-Check Review OnlyBrahmananda ChakrabortyNo ratings yet

- Digha Is The Most Popular Sea Beach in West BengalDocument2 pagesDigha Is The Most Popular Sea Beach in West BengalBrahmananda ChakrabortyNo ratings yet

- QC InstallDocument2 pagesQC InstallBrahmananda ChakrabortyNo ratings yet

- Panel Rule Presentation and QCDocument11 pagesPanel Rule Presentation and QCBrahmananda ChakrabortyNo ratings yet

- Craig Chronic Lymphoid Disorders Useful Information CCEN India 2018 FinalDocument9 pagesCraig Chronic Lymphoid Disorders Useful Information CCEN India 2018 FinalBrahmananda ChakrabortyNo ratings yet

- Reticulocyte Platlett j.1939-165X.2008.00086Document9 pagesReticulocyte Platlett j.1939-165X.2008.00086Brahmananda ChakrabortyNo ratings yet

- 5 Challenge Case Workbook and DiscussionDocument17 pages5 Challenge Case Workbook and DiscussionBrahmananda ChakrabortyNo ratings yet

- CLPD SopDocument9 pagesCLPD SopBrahmananda ChakrabortyNo ratings yet

- Craig Mature B-Cell Neoplasms CCEN India 2018 FinalDocument24 pagesCraig Mature B-Cell Neoplasms CCEN India 2018 FinalBrahmananda ChakrabortyNo ratings yet

- Navios Start UpDocument4 pagesNavios Start UpBrahmananda ChakrabortyNo ratings yet

- QC Data GB 500 180722Document1 pageQC Data GB 500 180722Brahmananda ChakrabortyNo ratings yet

- Leukemia SOPDocument8 pagesLeukemia SOPBrahmananda ChakrabortyNo ratings yet

- Trip Information - Reference Number: TRS0350B6OWDocument1 pageTrip Information - Reference Number: TRS0350B6OWBrahmananda ChakrabortyNo ratings yet

- PM Report 180722Document1 pagePM Report 180722Brahmananda ChakrabortyNo ratings yet

- Avanti JE Service Codes Pocket CardDocument1 pageAvanti JE Service Codes Pocket CardBrahmananda ChakrabortyNo ratings yet

- Powerbank 600 BrochureDocument8 pagesPowerbank 600 BrochureBrahmananda ChakrabortyNo ratings yet

- Blessed Anne Marie Javouhey Quiz MaterialDocument37 pagesBlessed Anne Marie Javouhey Quiz MaterialBrahmananda ChakrabortyNo ratings yet

- LAZUDAN ZEKRELLAH I. BSMT 2 BD WATCH 1 Semi Final Exam 1Document8 pagesLAZUDAN ZEKRELLAH I. BSMT 2 BD WATCH 1 Semi Final Exam 1Macxie Baldonado QuibuyenNo ratings yet

- Final Report.Document48 pagesFinal Report.Arjun Singh ANo ratings yet

- Canadian Preferred Shares Yield TablesDocument29 pagesCanadian Preferred Shares Yield TablesrblaisNo ratings yet

- OBIEE Technical Check-ListDocument6 pagesOBIEE Technical Check-ListKrista SmithNo ratings yet

- CAPM in Capital BudgetingDocument2 pagesCAPM in Capital BudgetingNaga PraveenNo ratings yet

- FSC International StandardDocument15 pagesFSC International StandardEMINANo ratings yet

- DD RhinosinusitisDocument9 pagesDD RhinosinusitisZuhal Darwis100% (1)

- Nvidia - LeetCodeDocument2 pagesNvidia - LeetCodePeeyushNo ratings yet

- Maintenance of PSC GirdersDocument10 pagesMaintenance of PSC GirdersradhakrishnangNo ratings yet

- New ThummaDocument5 pagesNew ThummaSabharish KoruturuNo ratings yet

- Charts of Male, Female Vote Percentage & Number of Electors, PC For General Elections (1951 To 2004)Document1 pageCharts of Male, Female Vote Percentage & Number of Electors, PC For General Elections (1951 To 2004)dagotrasuraj888No ratings yet

- Sustainability AccountingDocument14 pagesSustainability AccountingAbba ShallomNo ratings yet

- Labour Law - GuidelinesDocument21 pagesLabour Law - GuidelinesJames AdesinaNo ratings yet

- Procedures For Reimbursement of Expenses Relating To Official TravelsDocument14 pagesProcedures For Reimbursement of Expenses Relating To Official TravelsNeringa Gudelevičiūtė - PolitienėNo ratings yet

- Level Control Trainer FinalDocument6 pagesLevel Control Trainer FinalSiddhartha SharmaNo ratings yet

- Cisco Cloud DefinitionDocument72 pagesCisco Cloud DefinitionmienmobkNo ratings yet

- Chapter7 Approximate Analysis of Stitically Deteminate StructureDocument42 pagesChapter7 Approximate Analysis of Stitically Deteminate StructureChime MornNo ratings yet

- Eviction Information Requirements Rev0819 en FilDocument2 pagesEviction Information Requirements Rev0819 en FilLittle TownNo ratings yet

- Workbook Answer Key Unit 8 AcbeuDocument1 pageWorkbook Answer Key Unit 8 AcbeuLuisa Mari AlvamoreNo ratings yet

- About JK TyreDocument10 pagesAbout JK TyreAshish Adholiya0% (1)

- Cheatsheet Gimp-Letter PDFDocument1 pageCheatsheet Gimp-Letter PDFRox DiazNo ratings yet

- South Bend SB1002 Lathe Owners ManualDocument84 pagesSouth Bend SB1002 Lathe Owners ManualRendab100% (2)

- Timothy StainbrookDocument1 pageTimothy Stainbrookapi-548131304No ratings yet

- Shreya Dikshit ISSNDocument16 pagesShreya Dikshit ISSNPratikNo ratings yet

- Embedded System DesignDocument22 pagesEmbedded System Designtrail meNo ratings yet

- Good Homes - June 2015 IN PDFDocument90 pagesGood Homes - June 2015 IN PDFElena ElenaNo ratings yet

- Torque Spiral Wound GSKT TableDocument2 pagesTorque Spiral Wound GSKT TableCarlos Roberto Tamariz100% (1)